Two-component spraying system

A two-component, conveying system technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems that are difficult to solve two-component coatings with different proportions, cannot meet quality requirements, cannot be continuously produced, etc., to achieve good use and Promote the value, improve the spraying quality and spraying efficiency, and the effect of a wide range of ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

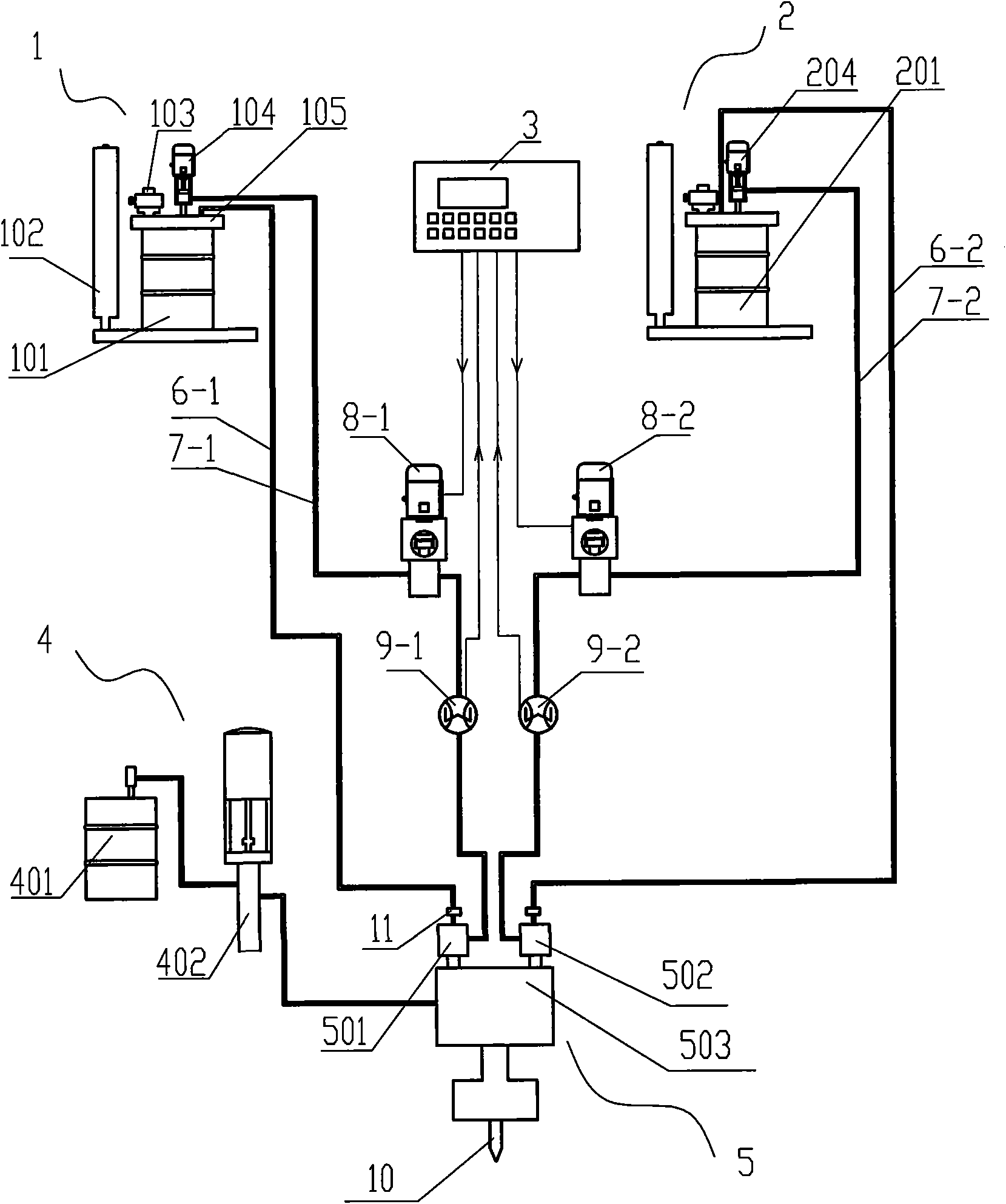

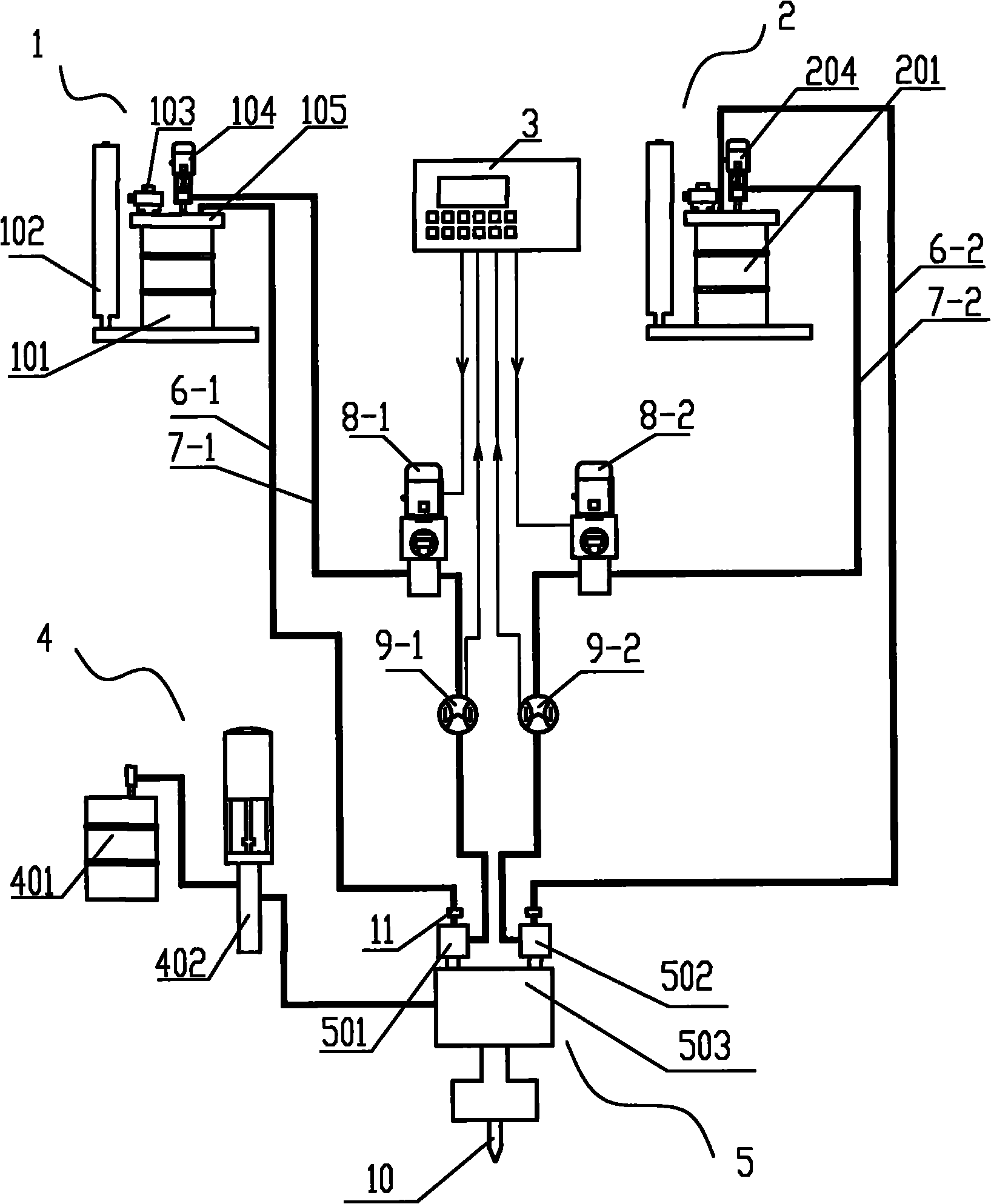

[0014] see figure 1 , the present invention includes a first material delivery system 1, a second material delivery system 2 and a spray gun 10, and the first material delivery system 1 and the second material delivery system 2 include a first material delivery pump 104 and a second material delivery pump respectively 204, also includes a first gear pump 8-1, a second gear pump 8-2, a first flow meter 9-1, a second flow meter 9-2, a mixing device 5 and a PLC control device 3; the first material The outlet of the first delivery pump 104 of the delivery system 1 communicates with the mixing device 5 through the first delivery pipe 7-1, and the first gear pump 8-1 is sequentially installed on the first delivery pipe 7-1 And the first flow meter 9-1, the second feed pump 204 outlet of the second material delivery system 2 communicates with the mixing device 5 through the second feed pipe 7-2, the second feed pipe 7 A second gear pump 8-2 and a second flow meter 9-2 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com