Scraper blade and method of manufacturing the same

A technology of scraper blades and scrapers, which is applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of weakened scrapers, blunt tips, etc., and achieve the effect of prolonging life and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

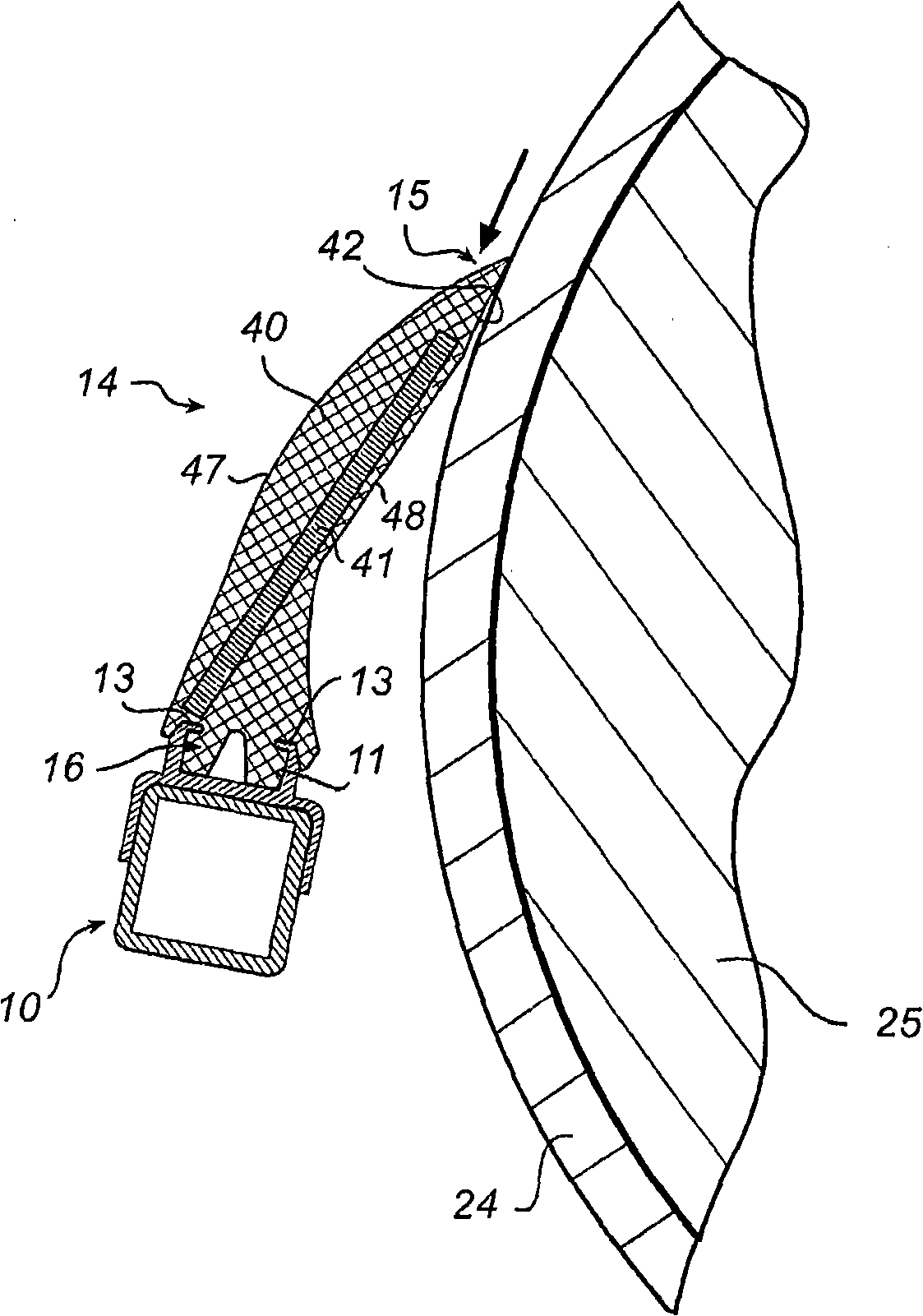

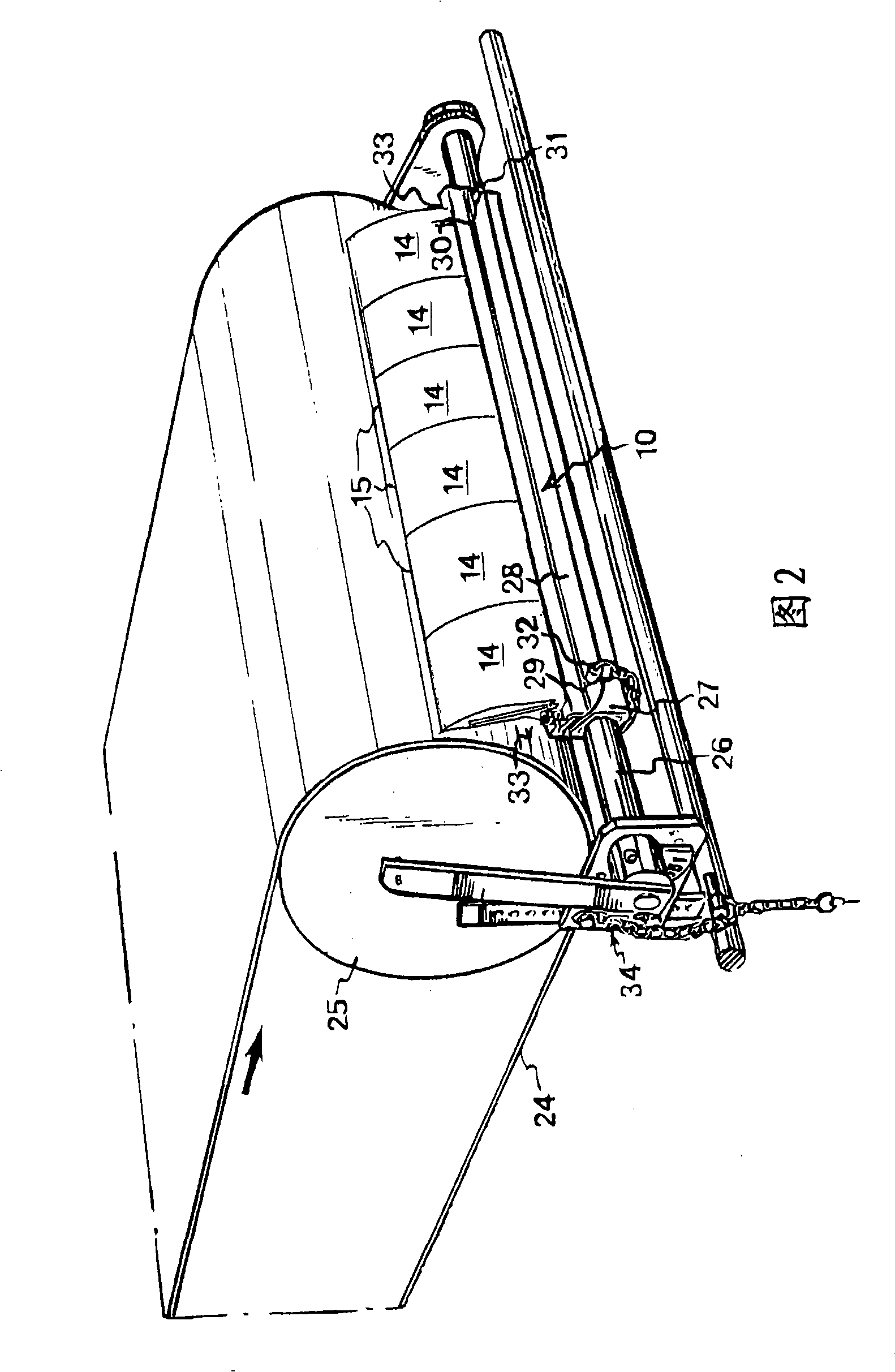

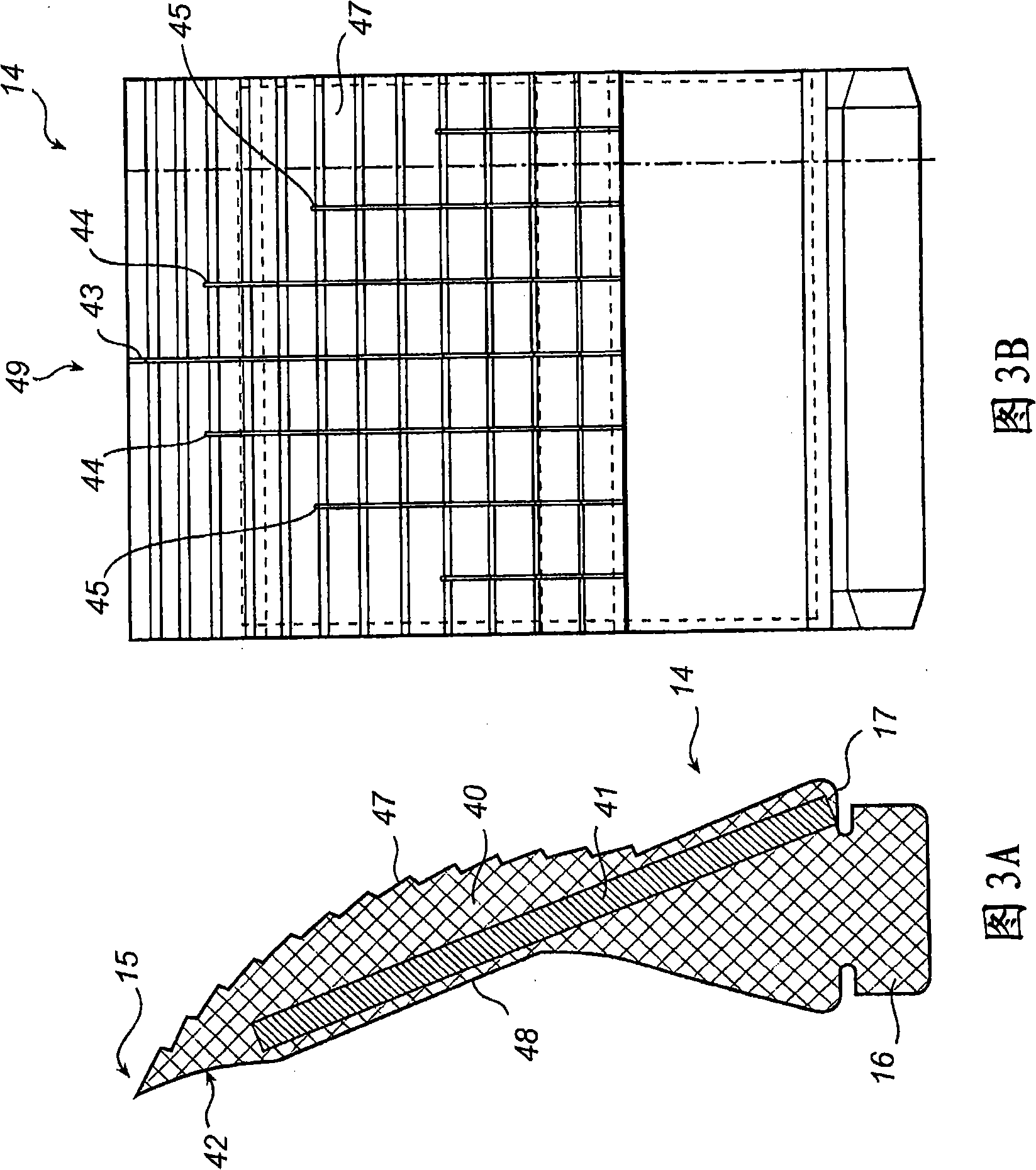

[0035] figure 1 All design points of the belt scraper shown in and 2 have been disclosed by SE-B-468390 and its counterpart US-A-5197587, both of which are hereby incorporated by reference. For the sake of simplicity, identical reference numerals are used for identical elements. However, the doctor blades of the present invention are used instead of the doctor blades disclosed in these documents.

[0036] From figure 1 It is clearly seen in that the belt scraper device is installed so that when the conveyor belt 24 goes around about figure 1 The scraper tip 15 is pressed against the conveyor belt 24 during the operation of the counterclockwise rotating belt drum 25 . available by using the figure 1 The devices shown in detail in to press the belt scraper on the conveyor belt in a conventional manner, these devices make the belt scraper yieldably press on the conveyor belt, and strive to make the scraper tip 15 to figure 1 to move to the right. These devices, not shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com