Anti-impact modified polycarbonate plastics for automotive interior parts and preparation method thereof

A polycarbonate plastic and impact-resistant modification technology, which is applied in the field of impact-resistant modified polycarbonate plastic for automotive interior parts and its preparation, and can solve the problems of limiting the application of PC plastics and poor impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Each raw material was weighed according to the data corresponding to Example 1 in Table 1. Mix the components uniformly in a high-speed mixer, control the speed at 300-400 rpm, mix for 5-10 minutes, then melt and knead in a twin-screw extruder, extrude and granulate, and the extruded polycarbonate The ester material is cooled and molded in cold water at 10-40° C. to obtain the impact-resistant modified polycarbonate plastic for automotive interior parts.

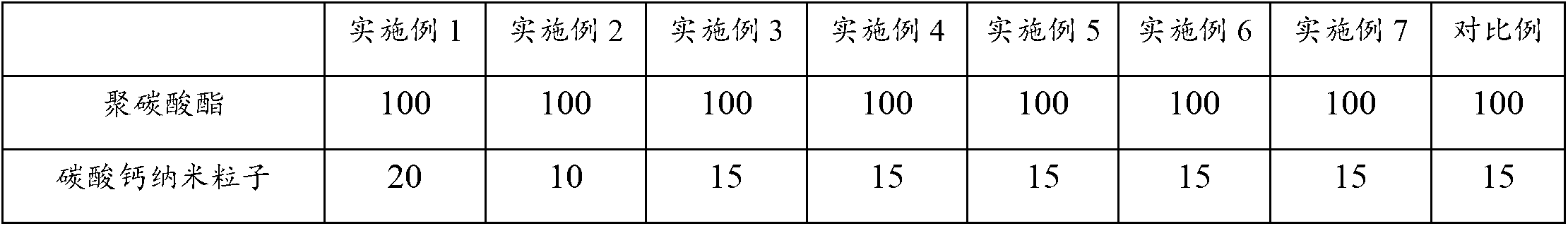

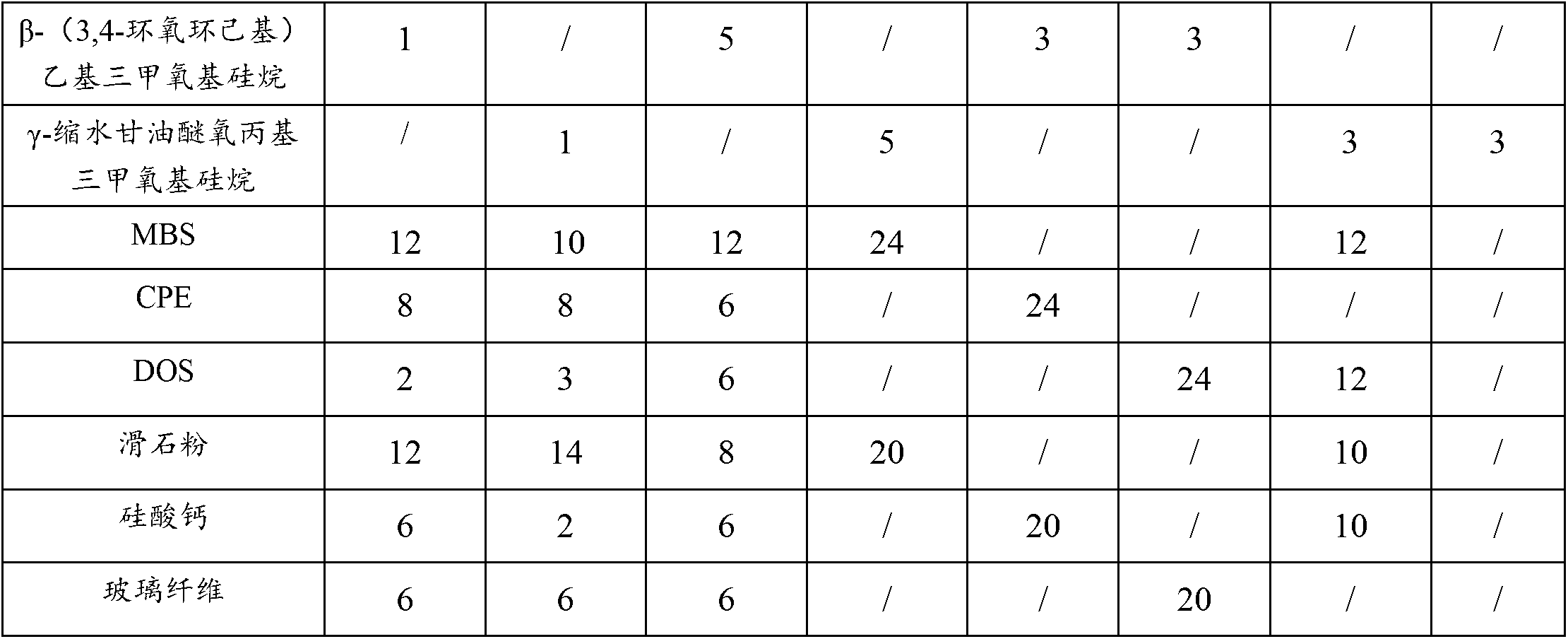

[0051] Table 1: Formulation table of impact-modified polycarbonate plastics for automotive interior parts Unit: kg

[0052]

[0053]

Embodiment 2

[0055] Each raw material was weighed according to the data corresponding to Example 2 in Table 1. The method described in Example 1 was used to prepare the impact-modified polycarbonate plastic for automotive interior parts.

Embodiment 3

[0057] Each raw material was weighed according to the data corresponding to Example 3 in Table 1. The method described in Example 1 was used to prepare the impact-modified polycarbonate plastic for automotive interior parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com