Fused-bonded epoxy powder paint with high resistance to cathodic disbonding

A fusion-bonded epoxy powder and cathodic stripping technology, which is applied in powder coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of destroying the anti-corrosion effect of the coating, corrosion of the anti-corrosion coating, and coating blistering, etc., to achieve improved Anti-cathode disbondment performance, increase toughness, reduce internal stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

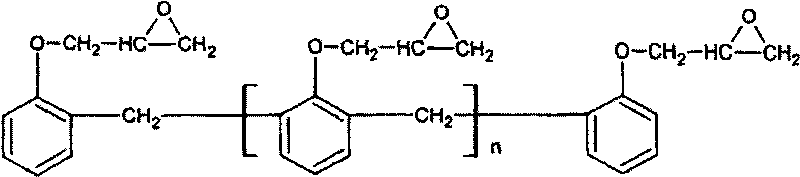

Method used

Image

Examples

Embodiment 1

[0022] This embodiment demonstrates the preparation method of the fusion-bonded epoxy powder coating with high cathodic disbonding resistance performance of the present invention. First, configure the raw materials with the following proportioning:

[0023] Hengyuan 605 phenolic epoxy resin

[0024] Hengyuan 605 phenolic epoxy resin

[0025] After the batching is completed, add the above raw materials into the high-speed mixer, mix at high speed for 8 minutes, then put the premixed material into the extruder for melt extrusion, the temperature of the feeding section is 25°C, the temperature of the melting section is 90°C, and the temperature of the meshing section is 100°C. The section temperature is 95°C, and the residence time is 45s; the molten material is pressed by a tablet machine, and the thickness is controlled at 2mm, and then sent to a mill for crushing and grading, and the superfine powder is separated by a cyclone separator and the product is sepa...

Embodiment 2

[0027] A formulation of high resistance to cathodic disbonding performance fusion-bonded epoxy powder coating is as follows:

[0028] Hongchang 904H epoxy resin

[0029] Manufacturing method is the same as embodiment 1.

Embodiment 3

[0031] A formulation of high resistance to cathodic disbonding performance fusion-bonded epoxy powder coating is as follows:

[0032] 1004 epoxy resin

50.00kg

Phenolic hydroxyl resin

11kg

[0033] 1004 epoxy resin

50.00kg

Titanium dioxide

8.00kg

Silica powder

10.00kg

10.00kg

Phthalo blue

0.15kg

Iron oxide yellow

0.70kg

0.50kg

3048 leveling agent

1.00kg

RK84L

2.80kg

[0034] Manufacturing method is the same as embodiment 1.

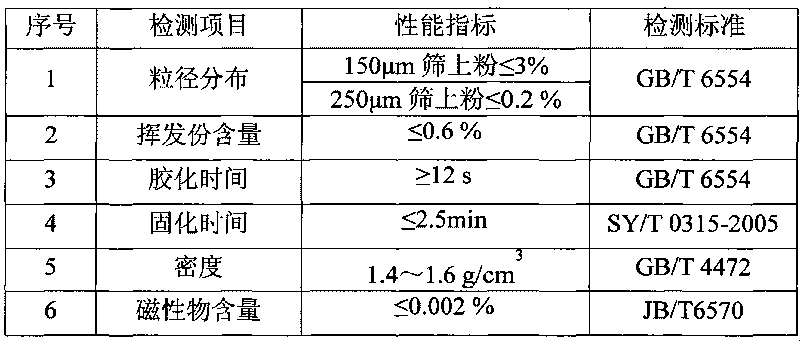

[0035] The high resistance to cathodic disbonding performance fusion-bonded epoxy powder coating obtained by foregoing embodiment can reach following technical index:

[0036] Table 1 Performance indicators of fusion bonded epoxy powder coatings

[0037]

[0038] The performance indicators of the fusion-bonded epoxy powder coating formed by the high resistance to cathodic disbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com