Photo-setting adhesive

An adhesive, light-curing technology, applied in the direction of adhesives, adhesive types, non-polymer organic compound adhesives, etc., can solve the problems of accelerated oxidation cracking of compounds, inability to ensure high bonding strength, and attenuation of bonding strength. , to achieve the effect of excellent adhesive ability, high adhesive strength and improved adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

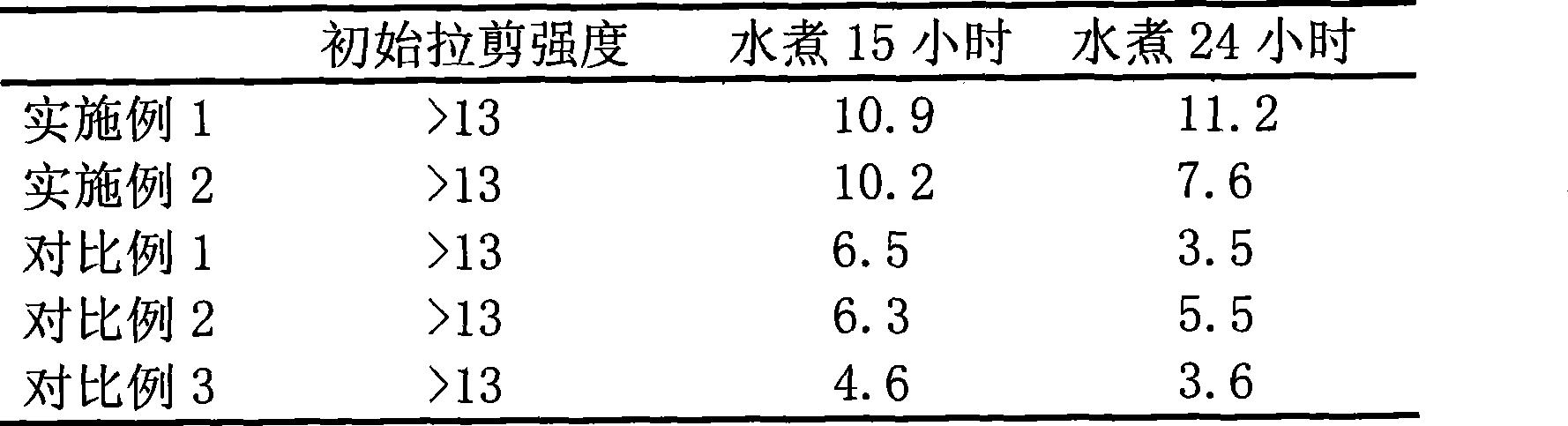

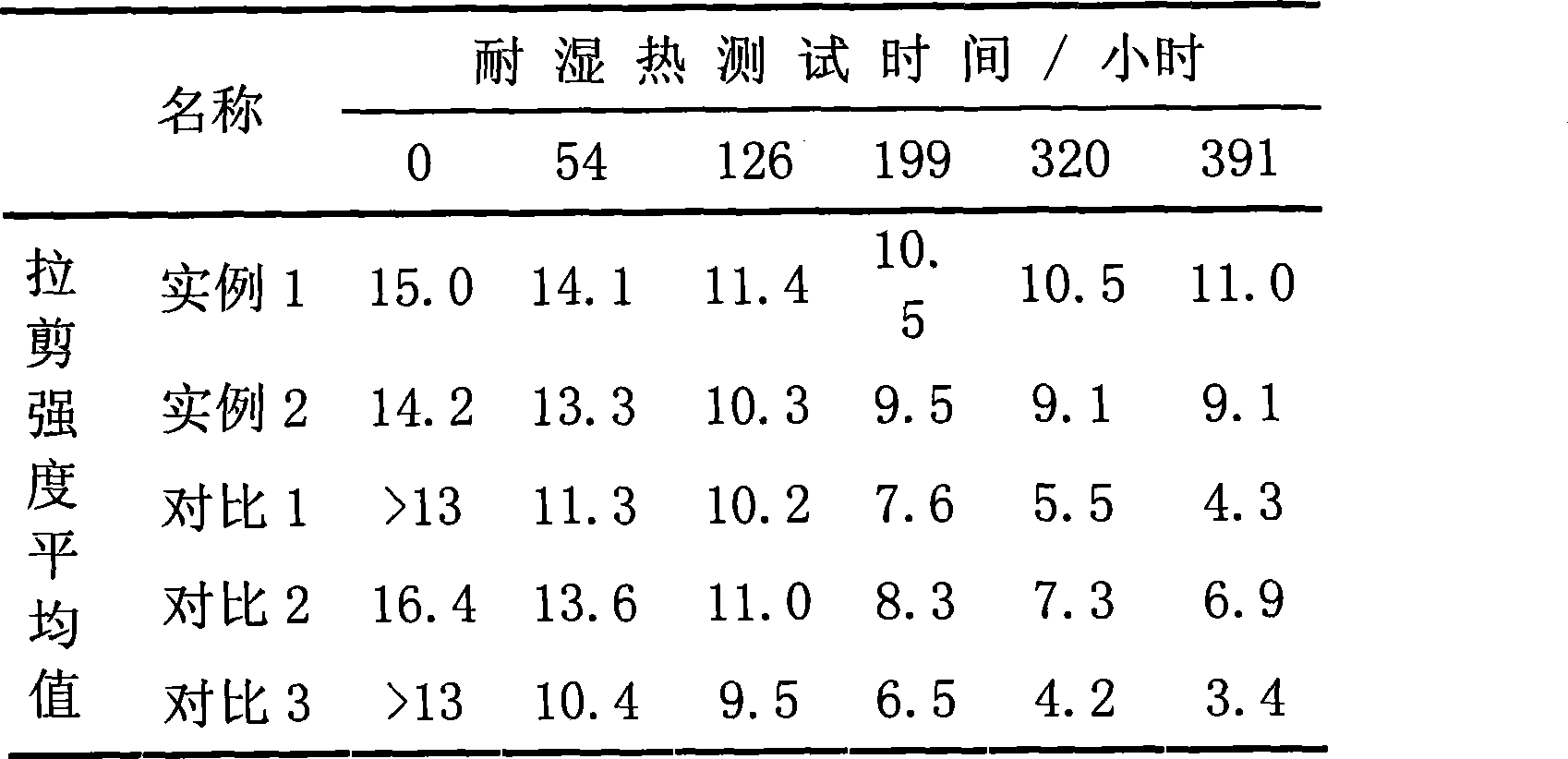

Examples

Embodiment 1

[0027] 1. Take 30g polyether-based polyurethane acrylate (produced by Guangdong Evergrande New Material Technology Co., Ltd., No. PR5002), 20g polybutadiene acrylate (Nippon Soda Co., Ltd., TE-2000), 10g epoxy acrylate ( Sartomer, CN151), 18g SR531 (Sartomer), 15g hydroxypropyl methacrylate HPMA, 3g acrylic acid AA, 4g photoinitiator I-184 (Ciba Specialty Chemicals), stirred and mixed evenly.

Embodiment 2

[0029] 40g polyether-based urethane acrylate (produced by Guangdong Hengda New Material Technology Co., Ltd., No. PR5002), 20g polyester-based urethane acrylate (Sartomer, CN981), 18g SR531 (Sartomer), 15g hydroxypropyl methacrylate HPMA, 3g of acrylic acid AA, 4g of photoinitiator I-184 (Ciba Specialty Chemicals), stirred and mixed evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com