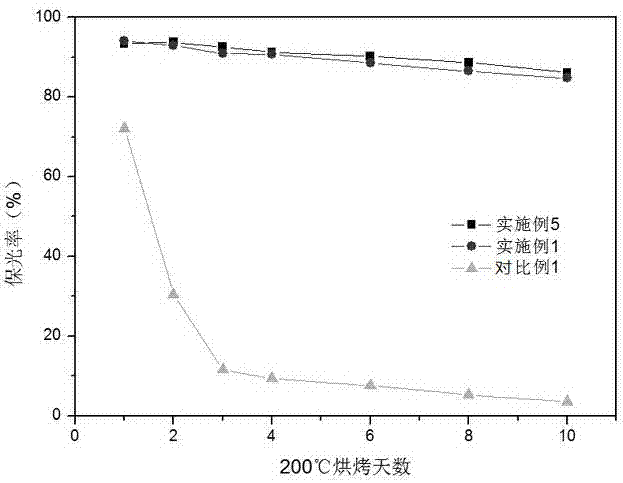

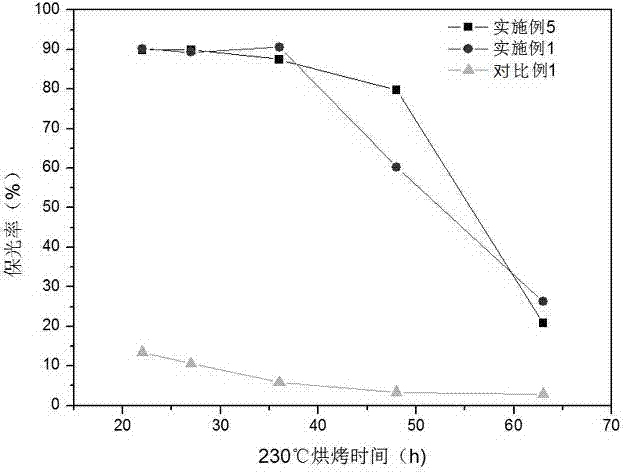

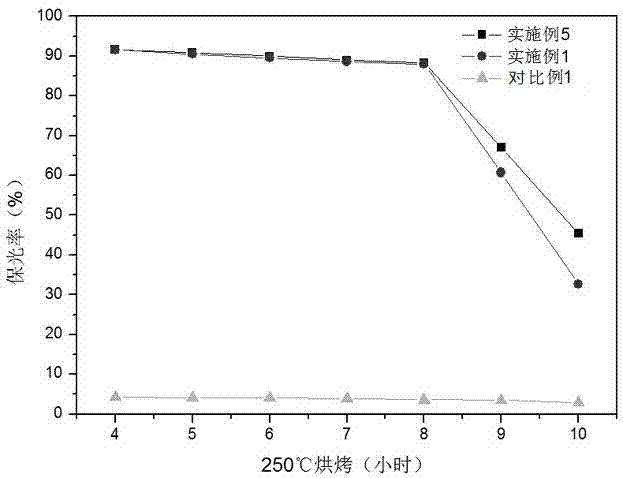

Pure polyester resin for TGIC cured high temperature resistant powder coatings, and preparation method thereof

A technology of polyester resin and powder coating, applied in the field of polyester resin, can solve the problems of reduced flexibility, decreased adhesion, loss of coating, etc., and achieve high gloss retention, excellent heat resistance and mechanical properties, good The effect of boiling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Some specific examples are enumerated below to illustrate the present invention, and Table 1 shows the examples and comparative examples of polyester resins. In the reactor, add neopentyl glycol, trimethylolpropane, trimethylolethane, tris (2-hydroxyethyl) isocyanurate in the ratio listed in Table 1, and heat up to the Melt; then add terephthalic acid and butyl tin oxide, and continue to heat up the reaction with nitrogen gas. Esterified water begins to form and distill at about 185°C, then gradually heat up to 240°C, and react for 10 to 13 hours to reach 95% esterified water After discharge, the acid value reaches 15-18mgKOH / g, add the acidolysis agent isophthalic acid, react for 2.5-4 hours, the acid value reaches 44-47mgKOH / g, vacuumize and polycondense for about 2.5-4 hours, the acid value reaches 30-35mgKOH / g to stop the reaction.

[0022] Acid value: 30~35mgKOH / g; glass transition temperature: 70~75℃; softening point: 112~118℃; melt viscosity at 200℃ (ICI cone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com