Chlorinated polypropylene-modified acrylic resin having excellent interlayer adhesion force and preparation method thereof

A chlorinated polypropylene and interlayer adhesion technology, applied in the field of polymers, can solve the problems of reduced water boiling resistance, easy drop in the adhesion between primer and topcoat layers, etc., to improve surface tension and improve interlayer Adhesion, the effect of less chain transfer reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

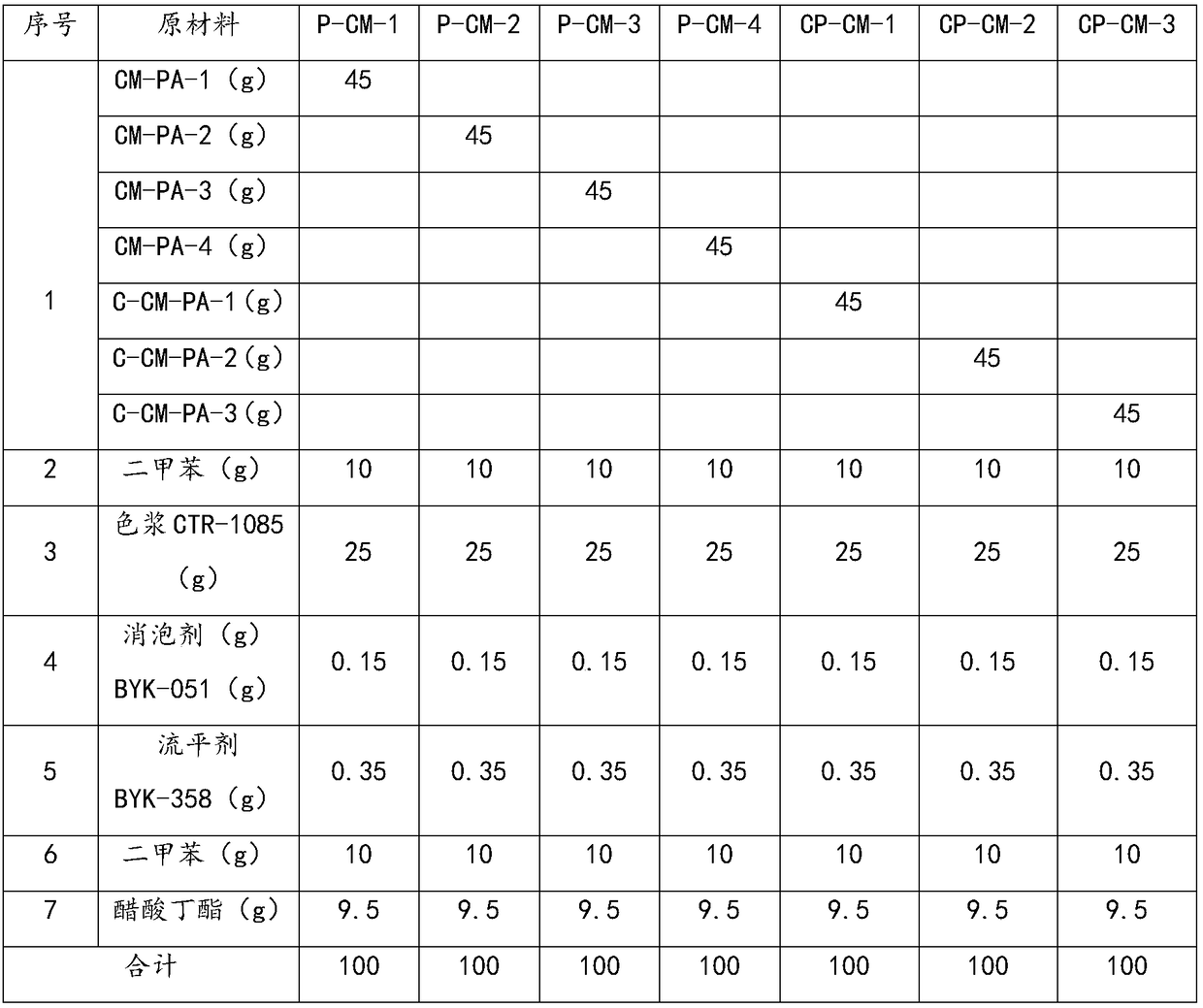

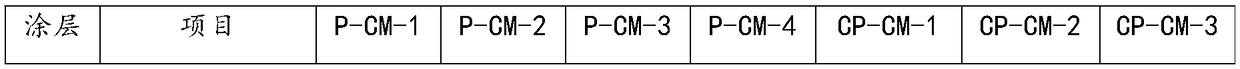

Examples

Embodiment 1

[0039] The chlorinated polypropylene modified acrylic resin with excellent interlayer adhesion in this embodiment is made from the following raw materials:

[0040] 7.5g hydroxypropyl acrylate, 9.5g 4-tert-butylcyclohexyl acrylate, 0.25g azobisisobutyronitrile, 0.25g dibenzoyl peroxide, 20g methyl methacrylate, 12.5g butyl acrylate, 30g xylene , 10g butyl acetate, 10g chlorinated polypropylene resin 16-LP.

[0041] The preparation method of the chlorinated polypropylene modified acrylic resin with excellent interlayer adhesion in this embodiment comprises the following steps:

[0042] 1) Stir and mix 7.5g hydroxypropyl acrylate, 9.5g 4-tert-butylcyclohexyl acrylate and 0.25g azobisisobutyronitrile to obtain mixed monomer A; mix 20g methyl methacrylate, 12.5g butyl acrylate Ester and 0.25g dibenzoyl peroxide were stirred and mixed evenly to obtain mixed monomer B;

[0043] 2) In a flask equipped with a dropping funnel, a thermometer, a condenser and a stirring device, add 30g...

Embodiment 2

[0045] The chlorinated polypropylene modified acrylic resin with excellent interlayer adhesion in this embodiment is made from the following raw materials:

[0046]4.9g hydroxypropyl acrylate, 20g 4-tert-butylcyclohexyl methacrylate, 0.05g azobisisobutyronitrile, 0.05g di-tert-butyl peroxide, 10g methyl methacrylate, 5g butyl acrylate, 30g di Toluene, 20g butyl acetate, 10g chlorinated polypropylene resin PP 803MWS.

[0047] The present embodiment has the preparation method of the chlorinated polypropylene modified acrylic resin of excellent interlayer adhesion, comprises the following steps:

[0048] 1) Stir and mix 4.9g hydroxypropyl acrylate, 20g 4-tert-butylcyclohexyl methacrylate, and 0.05g azobisisobutyronitrile to obtain mixed monomer A; mix 10g methyl methacrylate, 5g butyl acrylate, 0.05g di-tert-butyl peroxide was stirred and mixed uniformly to obtain mixed monomer B;

[0049] 2) In the flask equipped with dropping funnel, thermometer, condenser and stirring device...

Embodiment 3

[0051] The chlorinated polypropylene modified acrylic resin with excellent interlayer adhesion in this embodiment is made from the following raw materials:

[0052] 3g hydroxypropyl acrylate, 2g hydroxyethyl methacrylate, 16g isobornyl methacrylate, 1g azobisisoheptanonitrile, 3g dibenzoyl peroxide, 25g methyl methacrylate, 25g butyl acrylate, 20g xylene, 5g chlorinated polypropylene resin 16-LP.

[0053] The preparation method of the chlorinated polypropylene modified acrylic resin with excellent interlayer adhesion in this embodiment comprises the following steps:

[0054] 1) Stir and mix 3g hydroxypropyl acrylate, 2g hydroxyethyl methacrylate, 16g isobornyl methacrylate and 1g azobisisoheptanonitrile to obtain mixed monomer A; mix 25g methyl methacrylate, 25g of butyl acrylate and 3g of dibenzoyl peroxide were stirred and mixed uniformly to obtain the mixed monomer B;

[0055] 2) In a flask equipped with a dropping funnel, a thermometer, a condenser and a stirring device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com