UV-light curing coating

A technology of curing coatings and ultraviolet light, which is applied in coatings and other directions, can solve the problems of poor boiling resistance and achieve good boiling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] According to a preferred embodiment of the present invention, the preparation method is carried out as follows:

[0029] (1) Take the main resin, diluted monomer and organic solvent according to the mass required by the formula, and stir at a low speed (600-800r / min) under a high-speed disperser for 10-100min;

[0030] (2) Add the photoinitiator and auxiliary agent that have been weighed, and continue to stir (600-800r / min) under the high-speed disperser for 5-50min;

[0031] (3) stop stirring, stand defoaming, obtain slurry;

[0032] (4) Viscosity test: Viscosity test was carried out on the slurry obtained in the above step (3) at 25° C. using Iwata No. 2 cup. The viscosity of the slurry obtained according to the preferred ranges of the components provided above in the present invention is generally 13-15s. When spraying, the slurry can be further mixed with an organic solvent, adjusted to a viscosity between 7.5-8.2s, and then sprayed. Generally, it can be formulat...

Embodiment 1-3

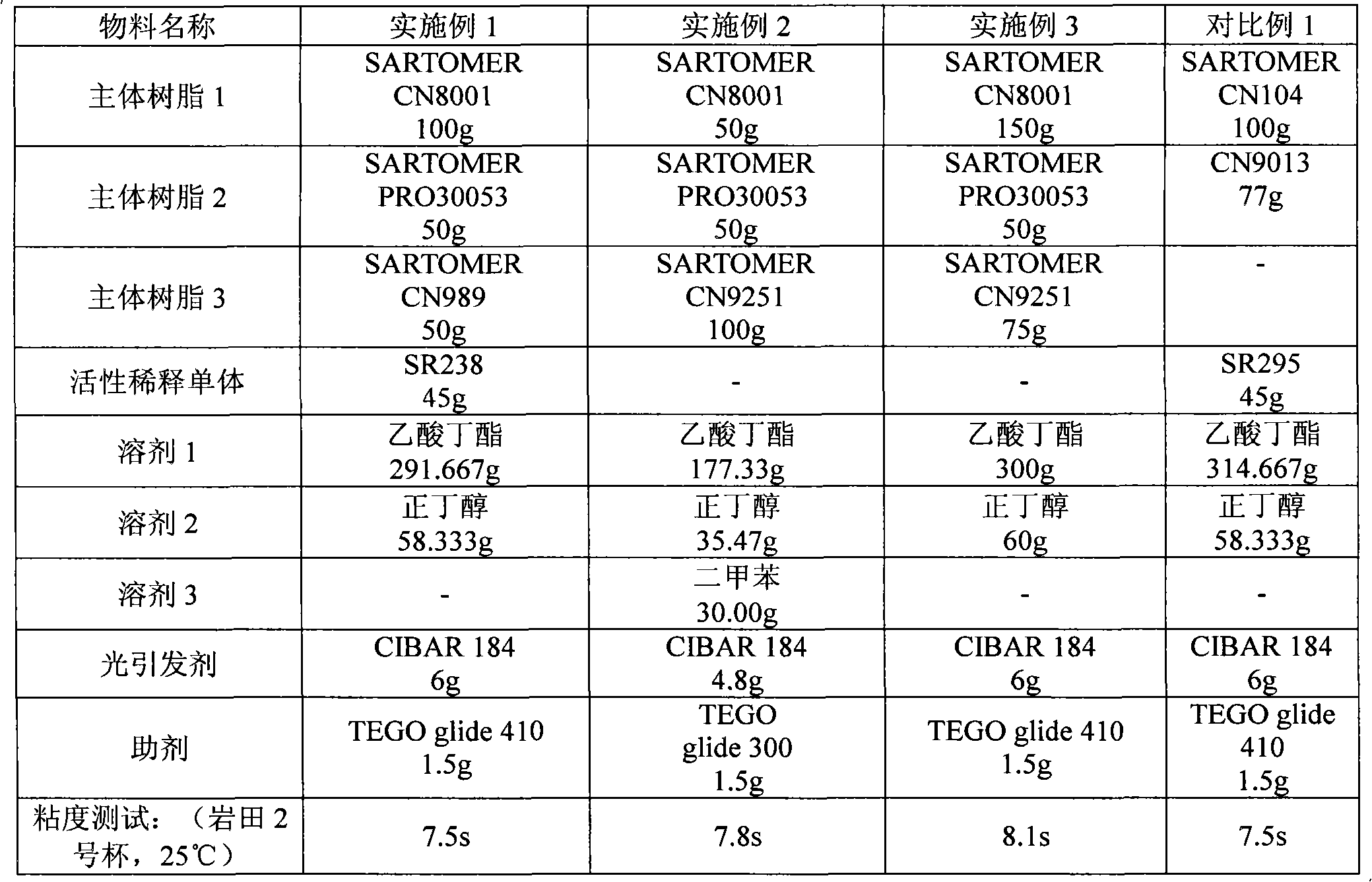

[0036] Use raw materials as shown in Table 1, prepare boiling-resistant coating according to the following method:

[0037] (1) Weigh the required main resin, reactive diluent monomer, and solvent (see Table 1 for the type and amount of substances) as required, and stir for 15 minutes in a high-speed disperser at 600 r / min;

[0038] (2) Add the weighed auxiliary agent and photoinitiator in turn (see Table 1 for the type and amount of the substance) and continue to stir for 5 minutes under the high-speed disperser at 900r / min;

[0039] (3) Take out the uniformly stirred paint and let it stand for defoaming for 20 minutes;

[0040] (4) Use a 350-mesh filter cloth to filter out impurities and dirt to obtain a coating, and mix the gained coating with the same organic solvent used in the preparation process to obtain a corresponding viscosity coating (as shown in Table 1) and then implement spraying according to the following method , and carried out various performance tests, the...

Embodiment 4-7

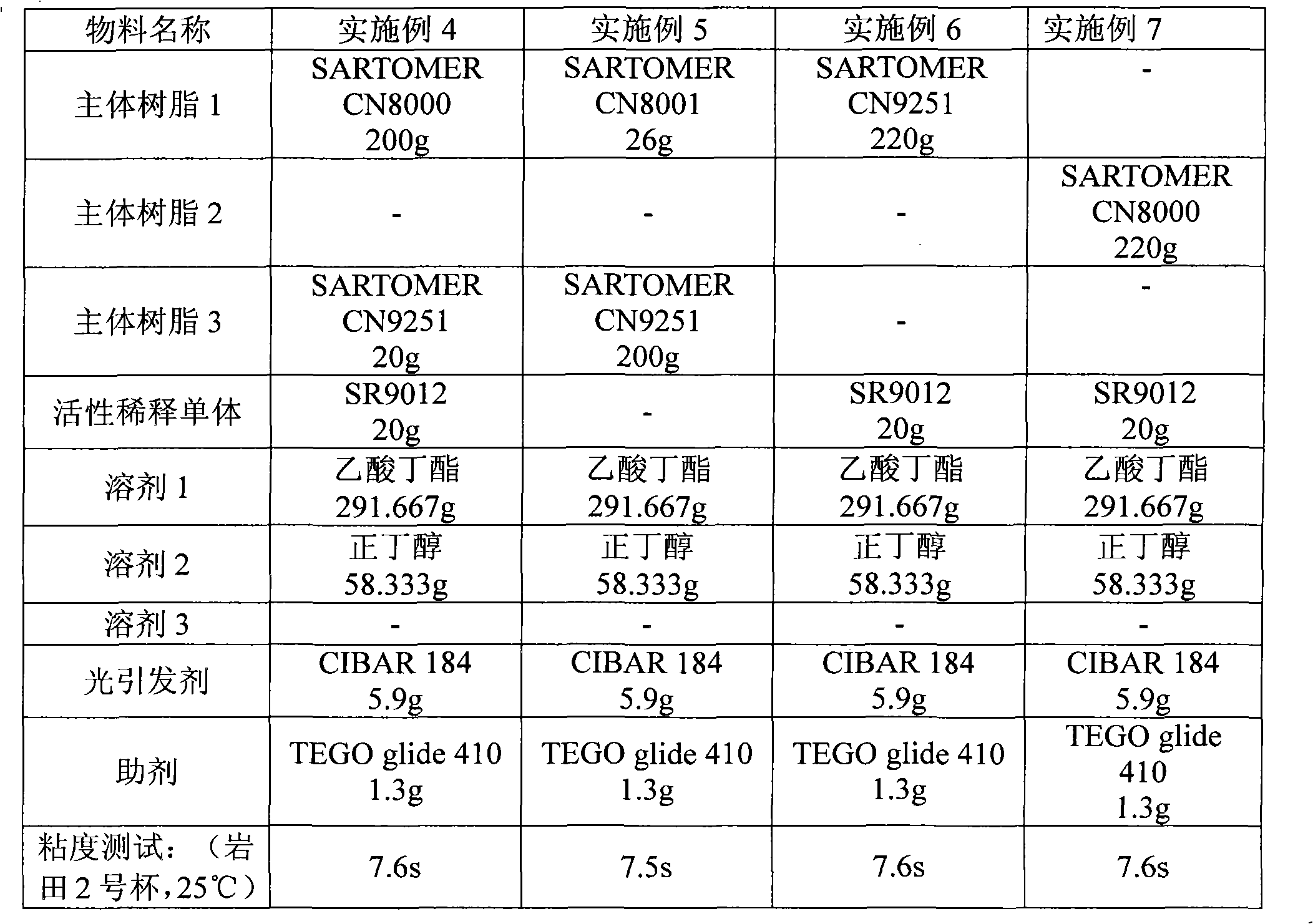

[0045] The preparation method is the same as that of Example 1, except that the types and / or amounts of substances are different, see Table 2 for details. The resulting coating (viscosity as shown in Table 2) was sprayed, the spraying method was consistent with Example 1, and various performance tests were carried out, the results are shown in Table 5.

[0046] Performance Testing:

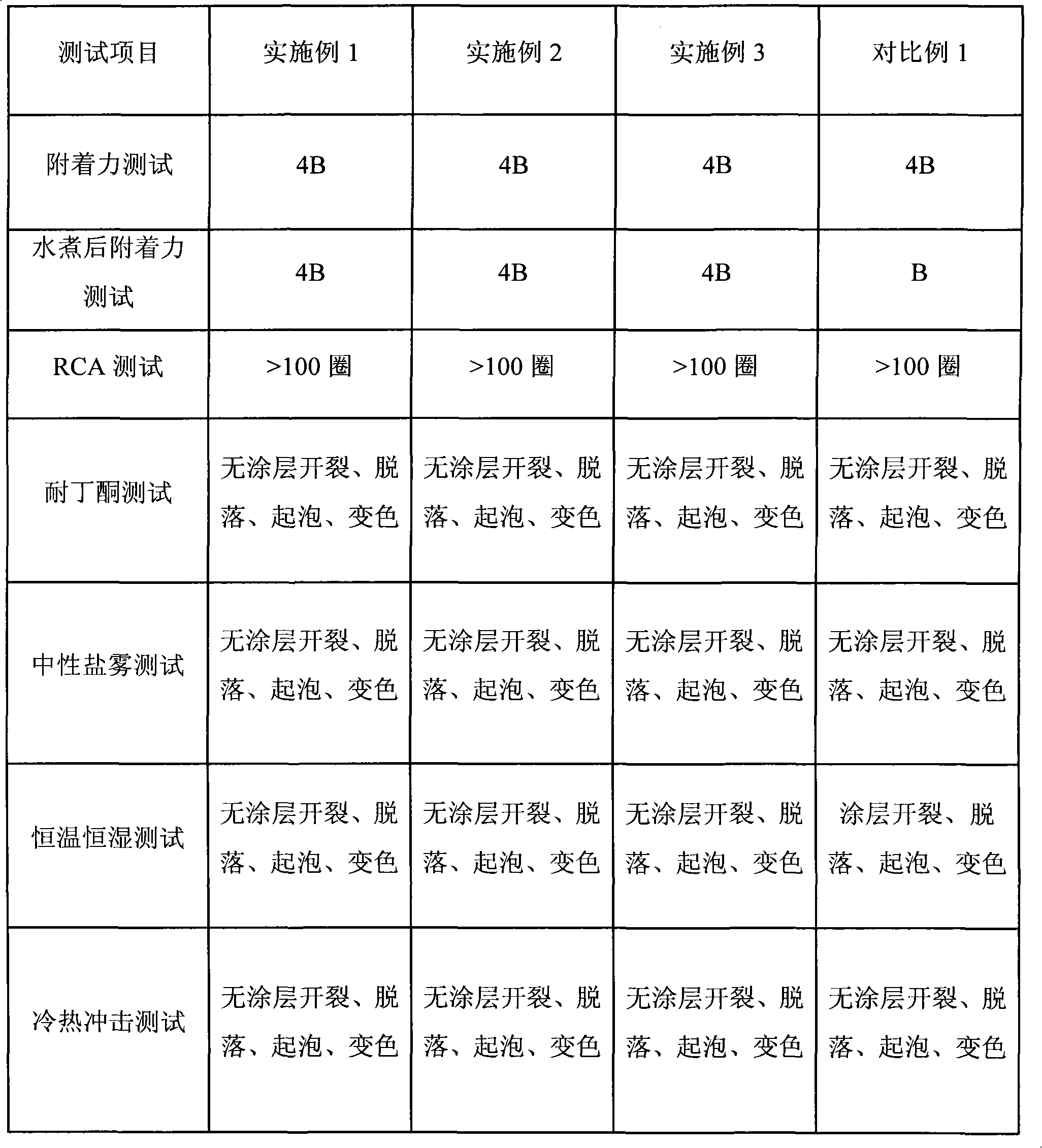

[0047] 1. Adhesion test

[0048] Test standard: ISO 2409

[0049] Test method: After the sprayed parts have been boiled in water for 8 hours, use the back of a surgical scalpel to draw 12 scratches on the coating, at least two of which are at an angle of 90° to other scratches to form on the surface A grid with a side length of 1 mm. Make sure that every scratch cuts to the base material. Use the brush 5 times in both directions of the scratch. Stick 3M tape (Dongguan Omico Company, tape model 3M600) on the surface, rub the tape tightly with your fingertips to ensure good contact with the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com