UV (ultraviolet)-curing glass coating paint

A coating and glass technology, applied in the field of UV curing glass coating coating, can solve the problems of poor alcohol resistance, poor adhesion, poor water boiling resistance, etc., achieve good adhesion, improve water boiling resistance, and high coating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

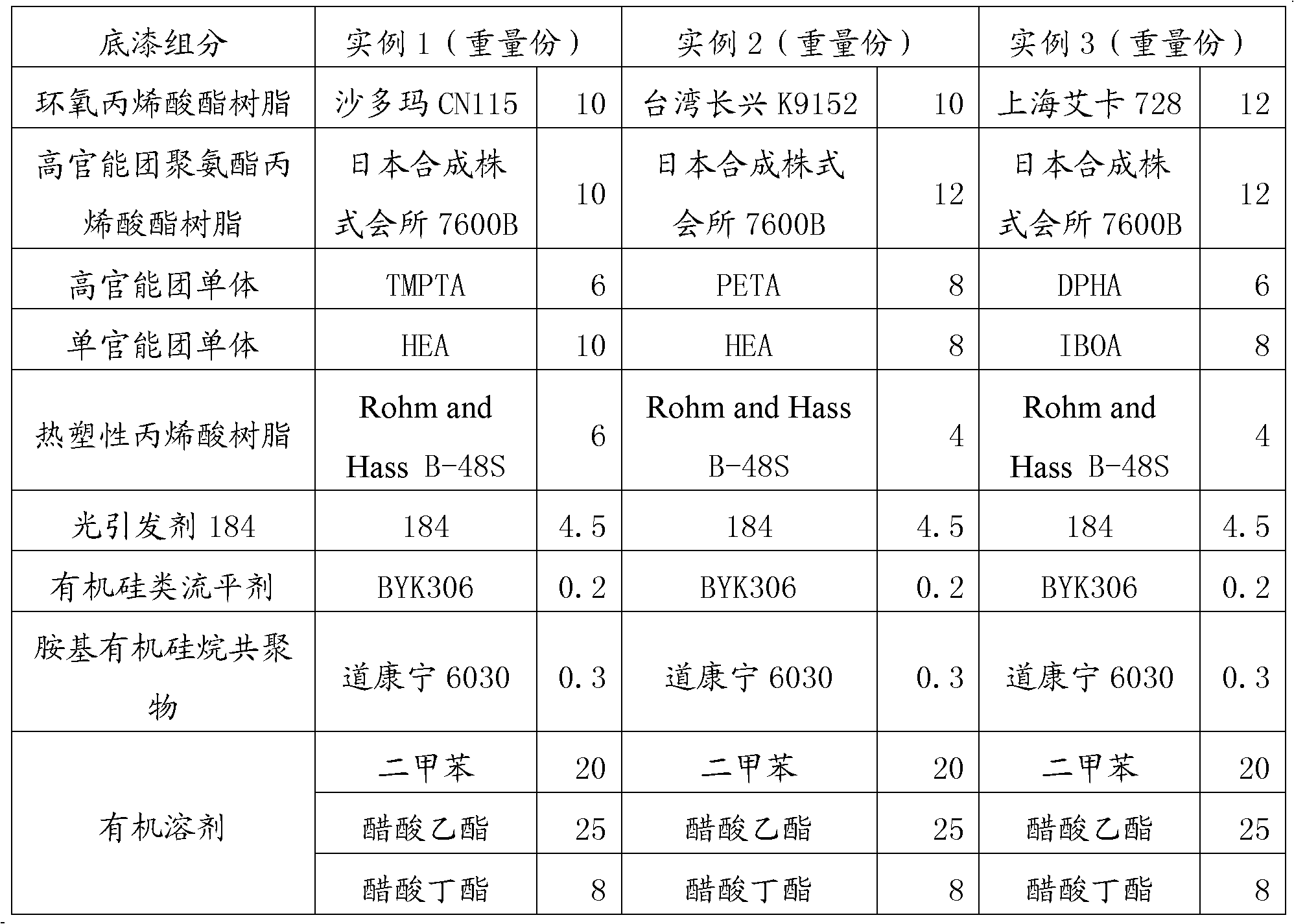

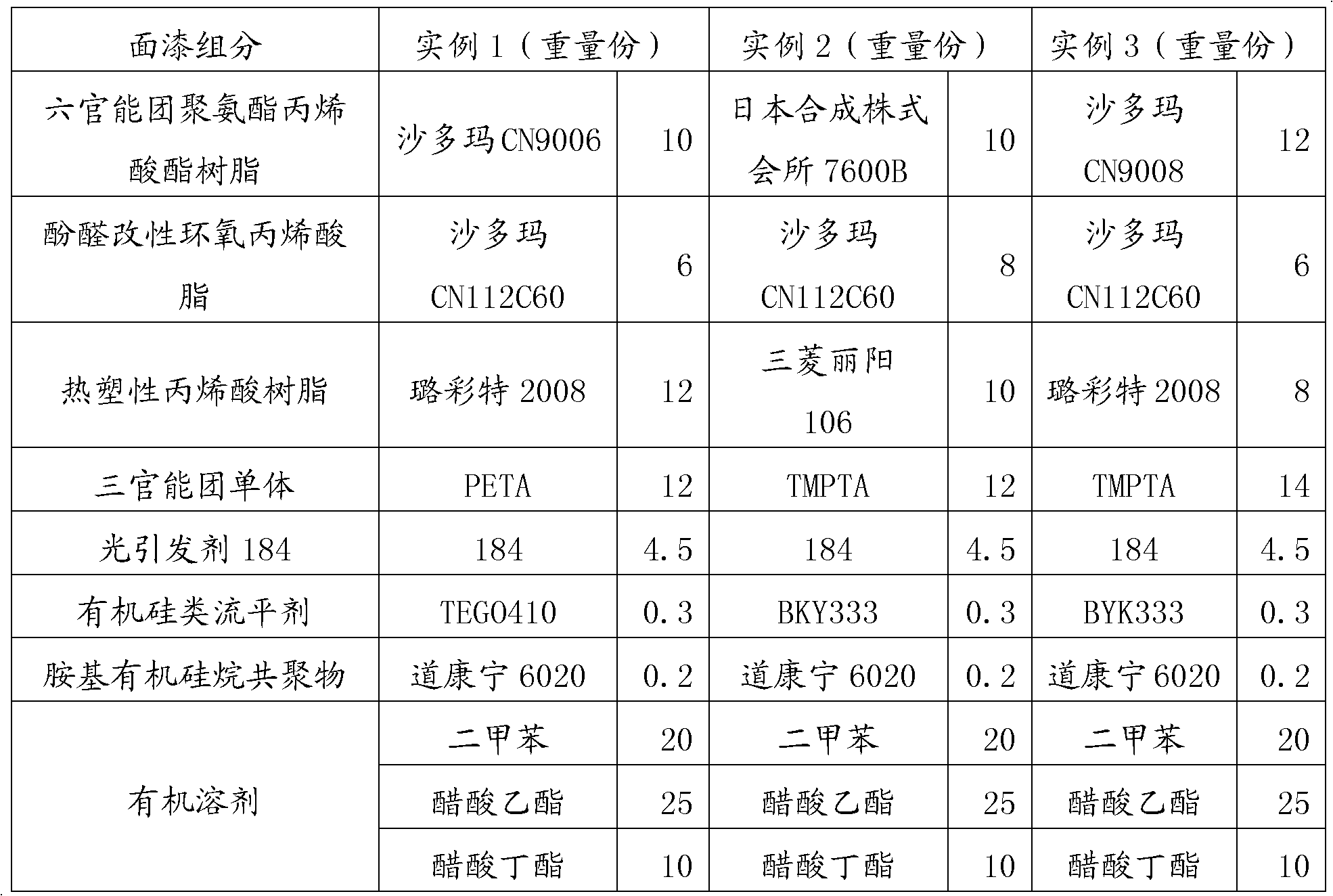

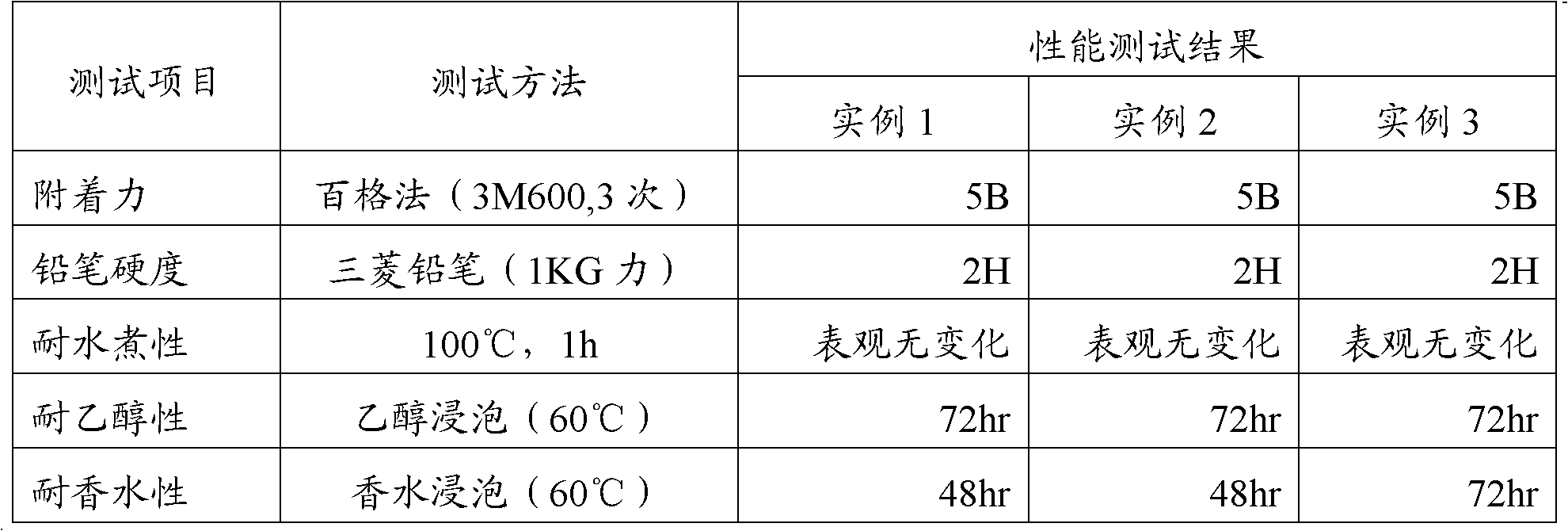

[0040] The following table shows the weight ratio of the three kinds of UV curable glass coating coatings. The configuration process is as follows: First, the thermoplastic acrylate in the primer and top coat needs to be pre-dissolved with solvents, and then accurately according to the formula in the table below. Weigh each component, add uniformly dispersed thermoplastic acrylate into the formula, and finally stir evenly in the dark to make a UV glass true coating. The paint needs to be filtered before packaging, and the filtering accuracy is 1um. Paint should be protected from light, heat and collision during packaging and storage.

[0041]

[0042]

[0043] Apply the above coating on the glass bottle base material, the construction method is as follows:

[0044] 1. Preparation of the substrate: The substrate of the glass bottle needs to be wiped with ethanol first to remove oil.

[0045] 2. Coating and curing: After the glass bottle base material is wiped - electros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com