Patents

Literature

38results about How to "Increase the oxidizing atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass raw material composition, inorganic glass powder, crystalline silicon solar battery aluminum conductive paste and preparation method of the crystalline silicon solar battery aluminum conductive paste

ActiveCN103130413AIncrease the oxidizing atmospherePrevent high temperature reductionNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteNitrate

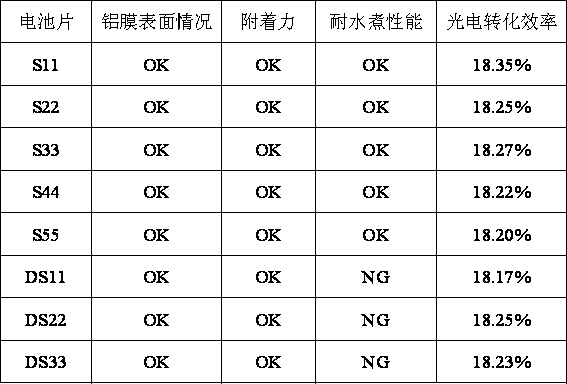

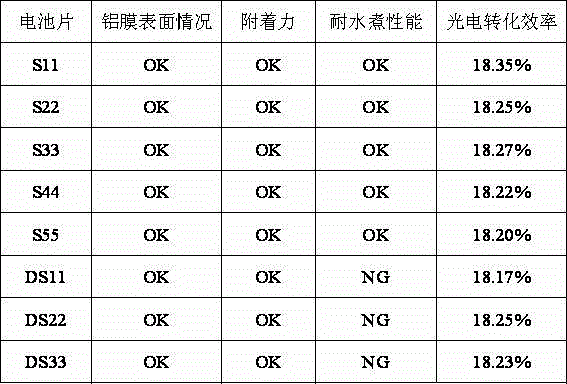

The invention provides a glass raw material composition. The glass raw material composition comprises, by weight, 35 to 60 parts of Bi2O3, 10 to 30 parts of B2O3, 10 to 20 parts of SiO2, 1 to 5 parts of CaO, 0.5 to 5 parts of MgO, 0 to 5 parts of Al2O3, 3 to 8 parts of Sb2O3 and Sb2O5, and a nitrate of which the content is 0.5 to 1.5 times the content of Sb2O3, wherein the nitrate is magnesium nitrate or calcium nitrate. The invention also provides inorganic glass powder prepared from the glass raw material composition, crystalline silicon solar battery aluminum conductive paste prepared from the inorganic glass powder, and a preparation method of the crystalline silicon solar battery aluminum conductive paste. The clear inorganic glass powder can be prepared from the glass raw material composition and thus a battery piece prepared from the crystalline silicon solar battery aluminum conductive paste containing the inorganic glass powder has high photoelectric conversion efficiency and high water boiling resistance.

Owner:BYD CO LTD

Method for preparing chromium salt

The invention discloses a method for preparing chromium salt. The method is characterized by comprising the following steps: sufficiently and uniformly mixing a raw material containing chromium oxide (chrome ore or chromium slag) with sodium carbonate, carrying out oxidizing roasting at the roasting temperature of 900-1100 DEG C for 0.5-2.5 hours in an atmosphere with the oxygen content of higher than 20% by using microwaves as a heat source, leaching the roasted product with water, and preparing chromium salt from the leach solution. The chemical analysis on the clinker and leaching slag indicates that the insoluble waste slag contains less than 5% of chromium (on the basis of chromic oxide). The method reduces the chromium content in the discharged chromium slag, enhances the chromium utilization ratio in the chromium salt production process, effectively saves the chrome ore resources, and has obvious advantages of resource saving and environmental protection by using the microwaves as the heat source instead of the traditional coal and natural gas heating.

Owner:LIAONING SING HORN GROUP CO LTD

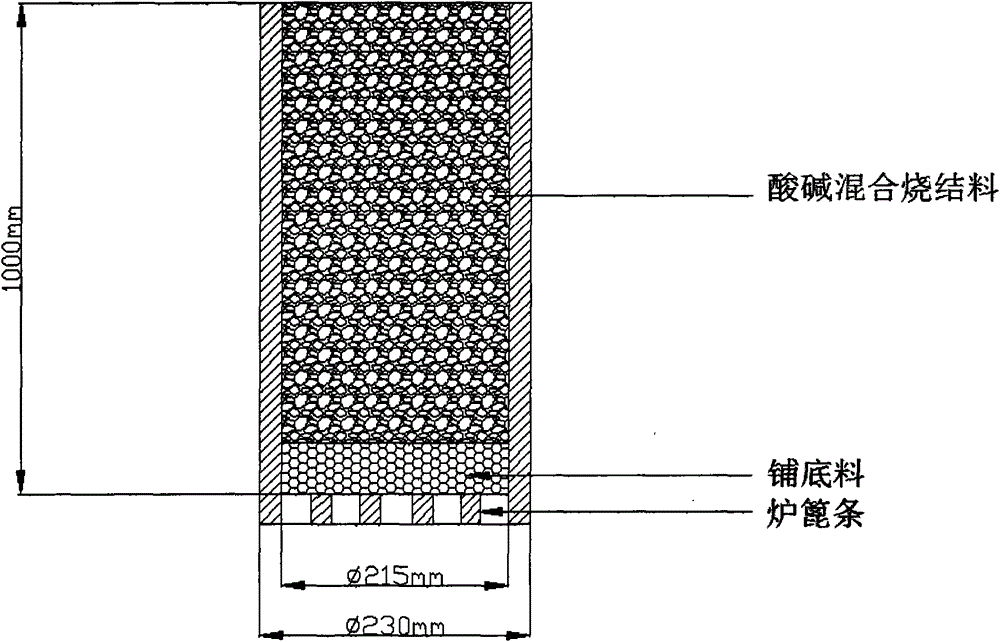

Sintering technology for acidic pellet ore and alkaline material mixed ultra-thick material layer

The invention provides a novel sintering technology for an acidic pellet and alkaline material mixed ultra-thick material layer. The sintering technology contains the following components: 3%-8% of an acidic pellet ore (green ball) with the particle size of 5-8 mm, 10%-15% of an acidic pellet ore (green ball) with the particle size of 8-10 mm, 15%-25% of an acidic pellet ore (green ball) with the particle size of 10-12.5 mm, 2%-5% of an acidic pellet ore (green ball) with the particle size of greater than 12.5 mm, and 50%-70% of an alkaline material (according to the weight percentage). On one hand, the air permeability of a sintered material layer can be improved, the oxidizing atmosphere is strengthened, the thickness of the sintered material layer is increased, and the purposes of improving production and quality and saving energy are achieved; and on the other hand, heat in the sintering process can be fully utilized, a sintered ore with suitable basicity is produced, the production process is shortened, and the production economic benefit is increased. Therefore, the novel acid and alkali mixed ultra-thick material layer sintering technology can be speculated to be capable of improving the air permeability of the material layer, thickening the sintered material layer, strengthening the oxidizing atmosphere and effectively improving the utilization coefficient of a sintering machine, so as to allow sintering production to achieve the purposes of saving energy consumption and improving the sintering quality.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Vanadium-titanium concentrate powder thick material layer sintering technology

The invention discloses a vanadium-titanium concentrate powder thick material layer sintering technology. The vanadium-titanium concentrate powder thick material layer sintering technology comprises the following steps that sintering raw materials are mixed to be uniform, and the sintering raw materials comprise, by weight, 50-60 parts of vanadium-titanium concentrate powder, 5-8 parts of iron oreconcentrate powder, 10-20 parts of a fluxing agent and 3-5 parts of fuel; the sintering raw materials are crushed; the powder is infiltrated with water and then prepared into pellets; the pellets aredistributed on sintering equipment, and the distributing thickness is 720-740 mm; the pellets are sintered into pellet ore; and the pellet ore is cooled. By changing the component proportion of the sintering raw materials and adding the fluxing agent to improve the air flow fluidity, therefore, the large sintering material distributing thickness is achieved, and the sintered ore quality is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Dephosphorization control method for unequal samples at converter smelting end points of DC04 steel

ActiveCN113736948AReduce the temperatureReduce consumptionIncreasing energy efficiencyManufacturing convertersSteelmakingMolten steel

The invention discloses a dephosphorization control method for unequal samples at converter smelting end point of DC04 steel, and belongs to the technical field of converter steelmaking. The method comprises the following steps that on the basis of the optimal slag remaining amount and the slag alkalinity, the molten steel temperature obtained through sublance TSC measurement is t DEG C, the carbon content in molten steel is c%, when t + c * 100-1650 is smaller than or equal to 0, sintering ore is not added in the follow-up auxiliary blowing process, and when t + c * 100-1650 is larger than 0, a certain amount of sintering ore is added in the follow-up auxiliary blowing process; and during sublance TSO measurement, the measured molten steel temperature meets the tapping requirement, and when the measured end point oxygen content of molten steel is larger than or equal to X / 0.0315-55, unequal samples are obtained, wherein X is the average carbon oxygen deposit of first 3 furnaces. When X is smaller than 13, X is 13, when X is larger than 16, X is 16, and when X is larger than or equal to 13 and smaller than or equal to 16, X is the original value. In order to solve the problems in the prior art, it is necessary to research the dephosphorization control method for unequal samples at the converter smelting end point of the DC04 steel, the phosphorus content at the end point of molten steel can be effectively controlled, the qualification rate of the phosphorus content of the molten steel is guaranteed, and tapping can be achieved through unequal samples.

Owner:MAANSHAN IRON & STEEL CO LTD

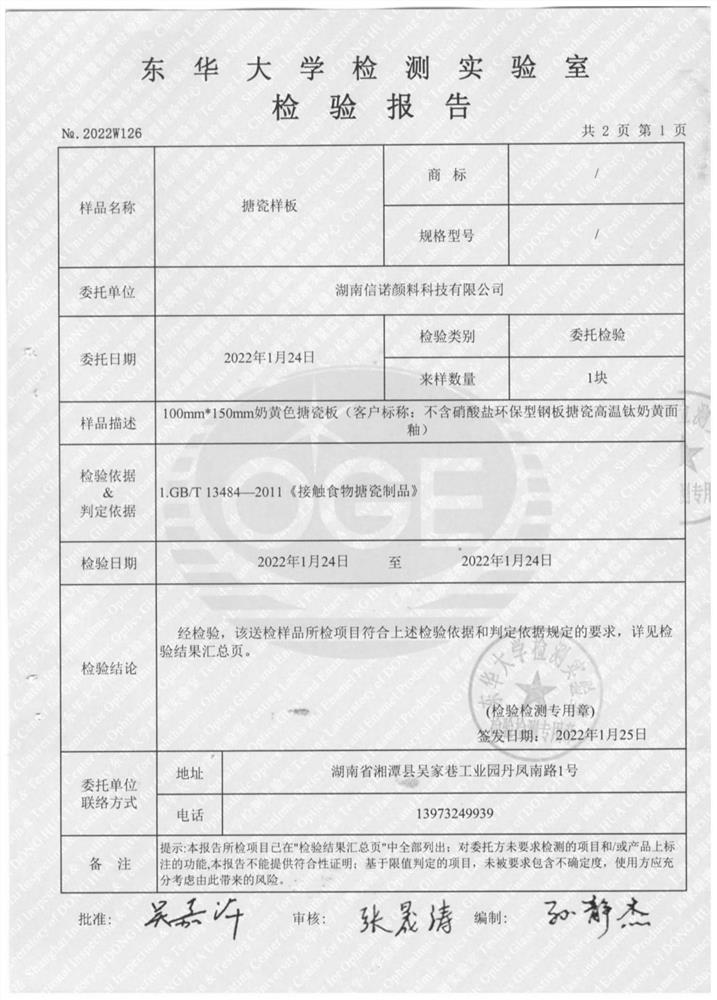

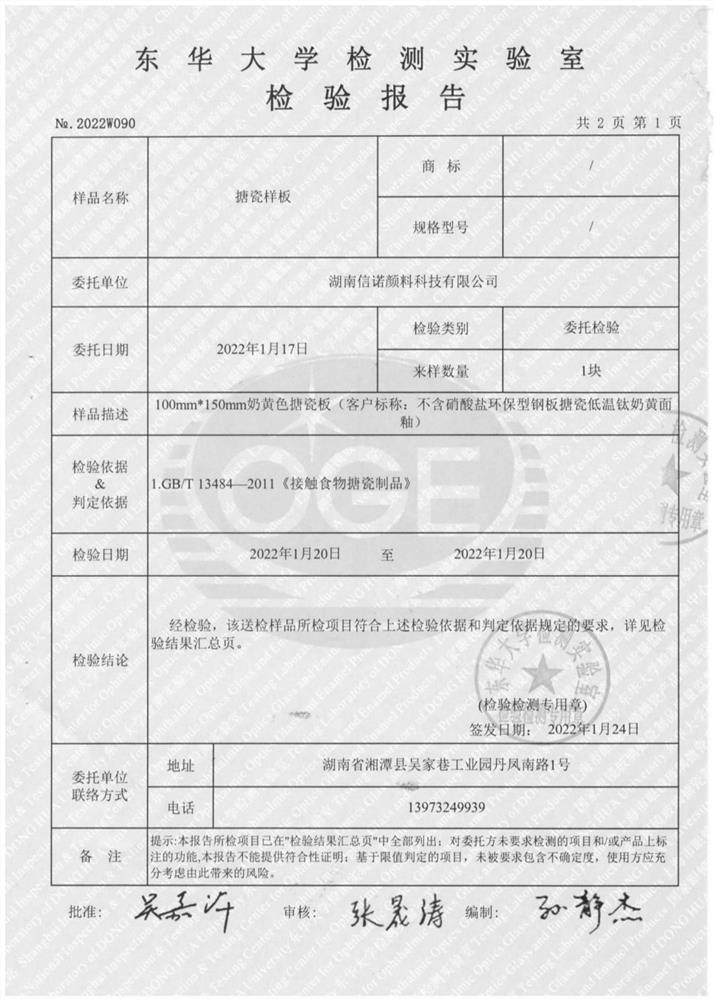

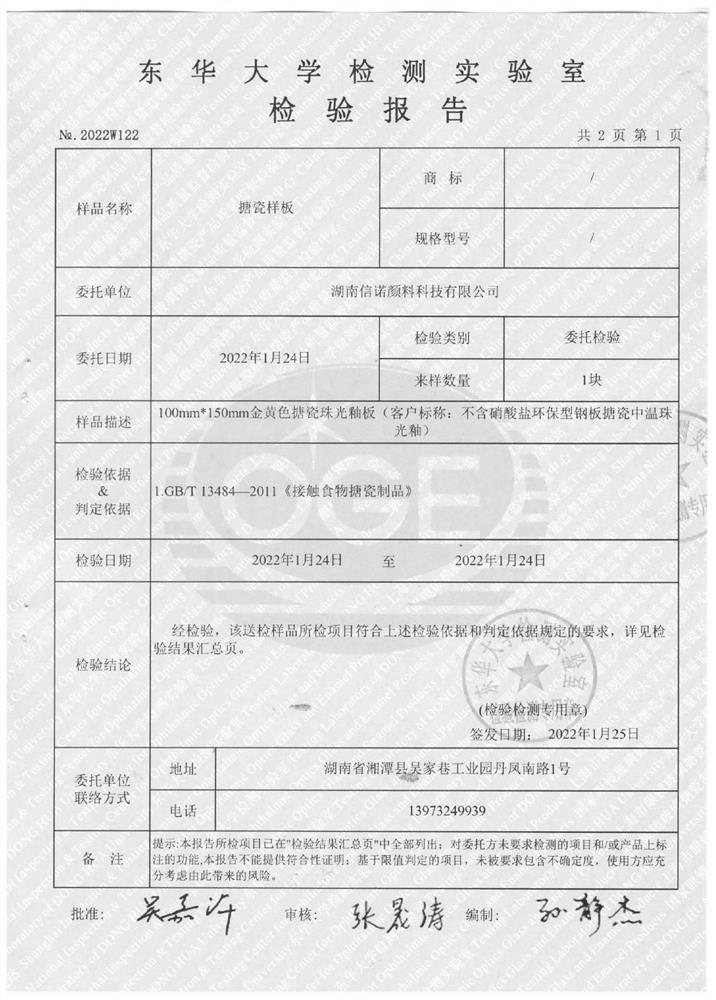

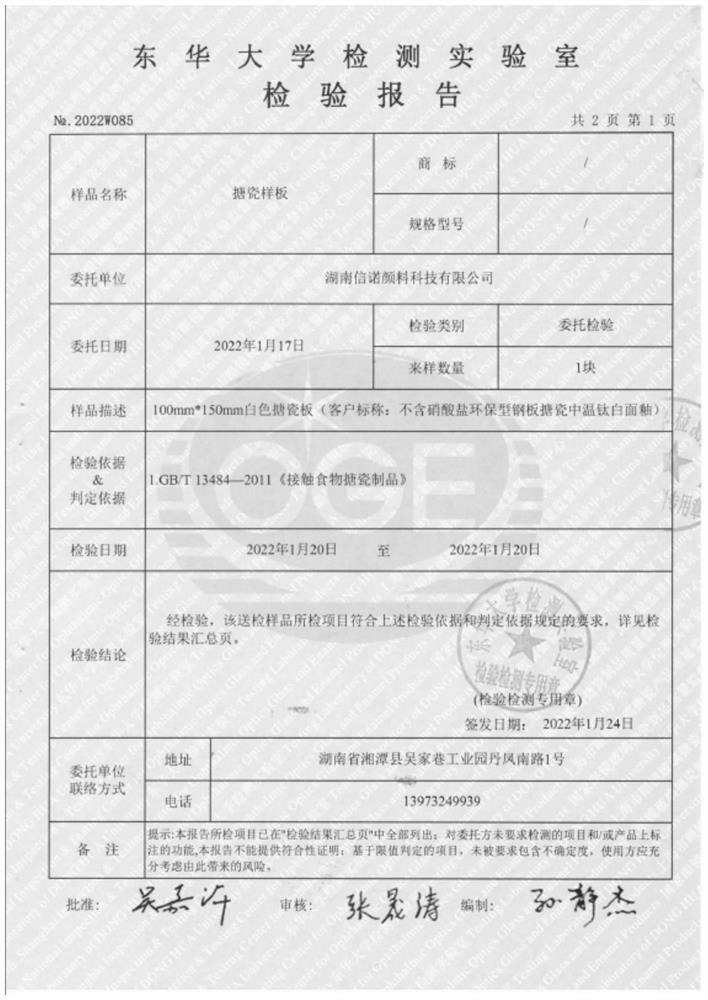

Nitrate-free environment-friendly steel plate enamel medium-temperature titanium creamy yellow cover glaze and preparation method thereof

PendingCN114409257AIncrease the oxidizing atmosphereSolve the pollution of the environmentPotassium feldsparSodium silicate

The invention discloses nitrate-free environment-friendly steel plate enamel medium-temperature titanium creamy yellow cover glaze and a preparation method thereof, and the nitrate-free environment-friendly steel plate enamel medium-temperature titanium creamy yellow cover glaze comprises the following components in parts by mass: 27-29 parts of quartz, 20-22 parts of anhydrous borax, 15-17 parts of rutile, 11-14 parts of potassium feldspar, 2-4 parts of magnesium carbonate, 2-4 parts of potassium carbonate and 9-11 parts of sodium fluosilicate. According to the invention, 1-2 parts by mass of calcium carbonate and 0.02-0.05 part by mass of potassium dichromate are melted at 1260 + / -10 DEG C under the condition of pure oxygen, and the firing temperature of the finished product is 800-830 DEG C. The medium-temperature titanium creamy glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel medium-temperature titanium creamy glaze, nitrogen oxide gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:湖南信诺技术股份有限公司

Sintering process of iron ore powder pellets

ActiveCN114540615AHigh strengthIncrease capillary forceProcess efficiency improvementMaterial distributionUltimate tensile strength

The invention discloses a sintering process of iron ore powder pellets, which fully utilizes the heat storage effect of a material layer and the characteristics that the upper temperature of the material layer is low and the lower temperature of the material layer is high in the sintering process, and adopts a three-layer material distribution mode to ensure the uniformity of the temperature of the material layer, so that the fuel at the lower part of the material layer is less, the fuel at the middle part is higher and the fuel at the upper part is more; the temperature of the whole material layer is uniform. Through layered material distribution, material layer fuel is regulated and controlled to be matched with the temperature, so that the consolidation effect of sintered ore is improved, and solid energy consumption is reduced. The hydrophilic performance of the raw materials is improved through a raw material pretreatment process, and then the air permeability of the raw materials is improved through a pelletizing process; and in the sintering link, the moisture of the sintered material is reduced through the drying process, the phenomenon that the moisture is too high in the sintering process is avoided, and the thermal-state air permeability in the sintering process is improved. The dynamic conditions of mass transfer and heat transfer in the sintering process are improved, the oxidizing atmosphere in the sintering process is improved, reasonable blending of solid-phase consolidation and liquid-phase consolidation of pellet sintering is promoted, and the strength of sintered ore is improved.

Owner:CENT SOUTH UNIV

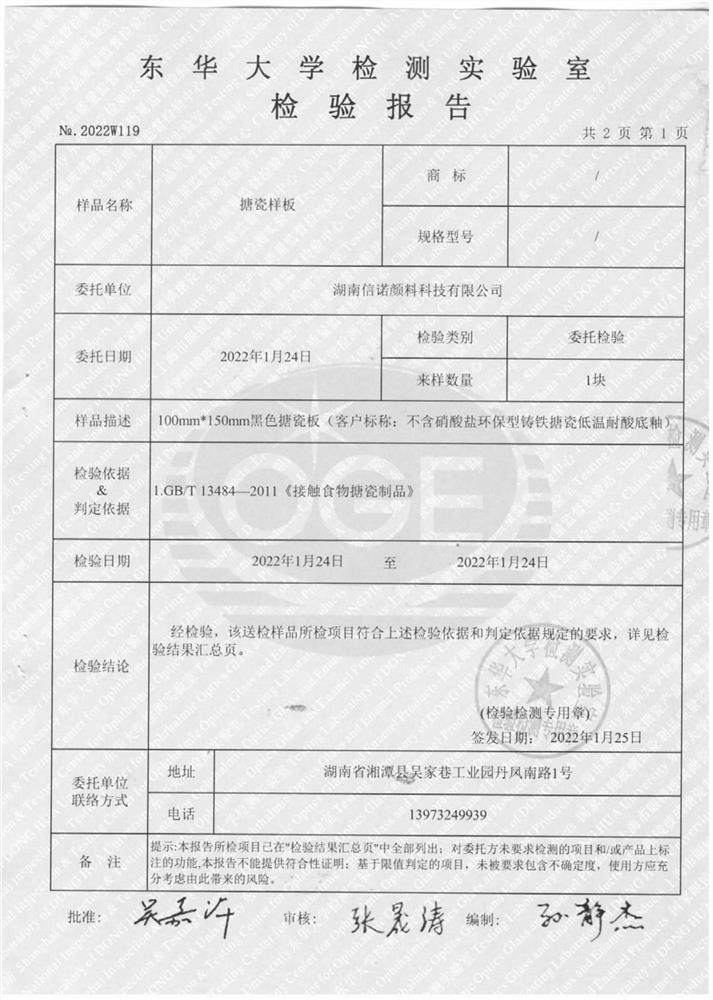

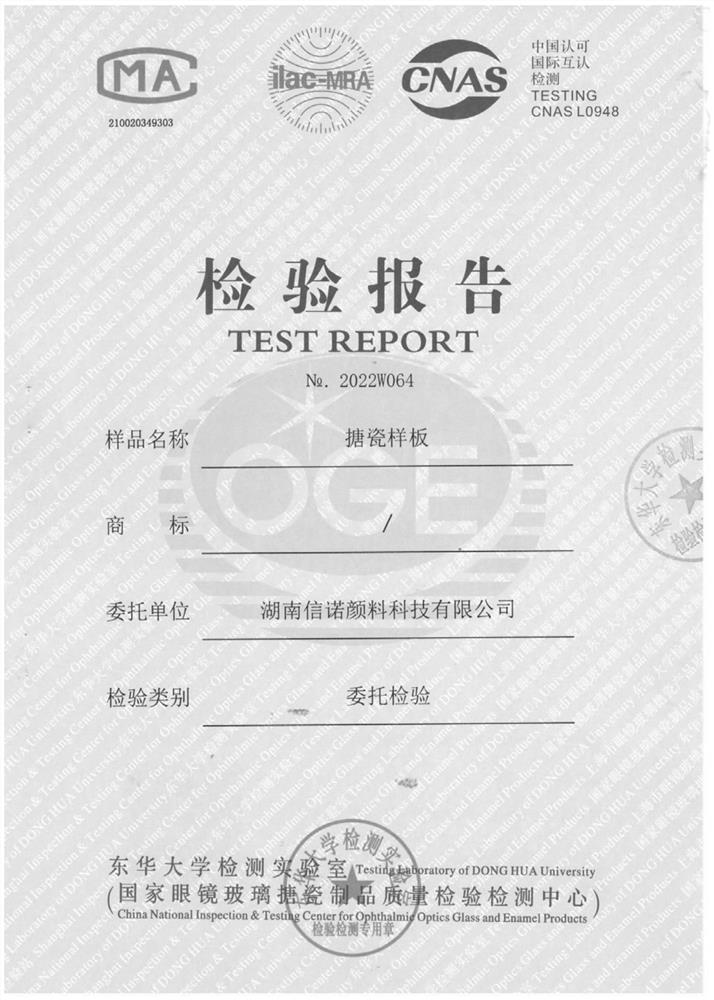

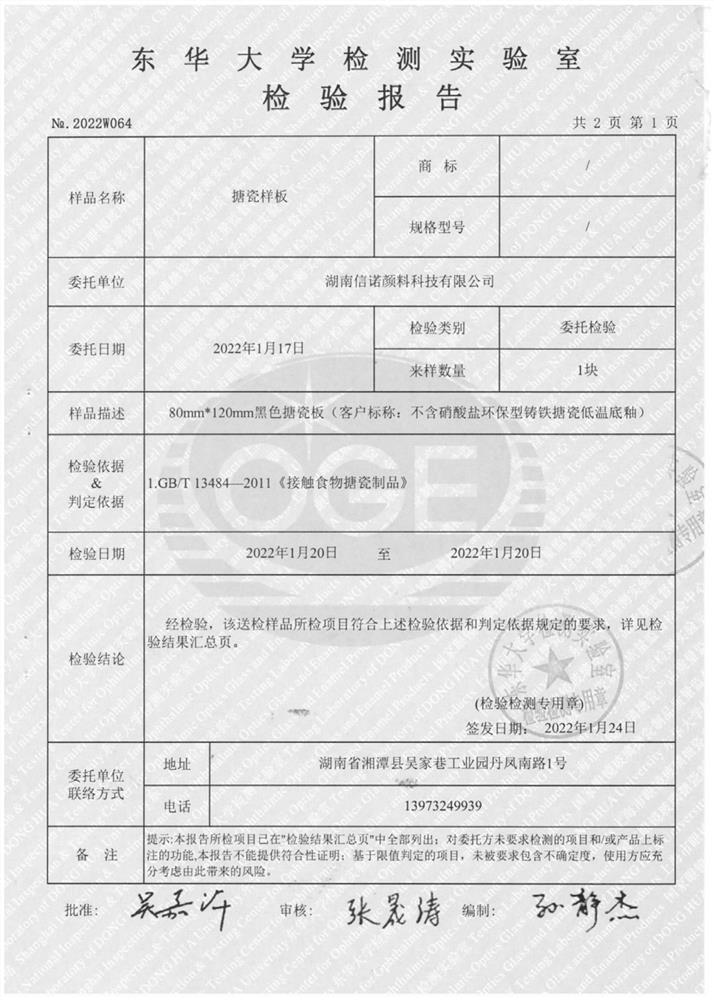

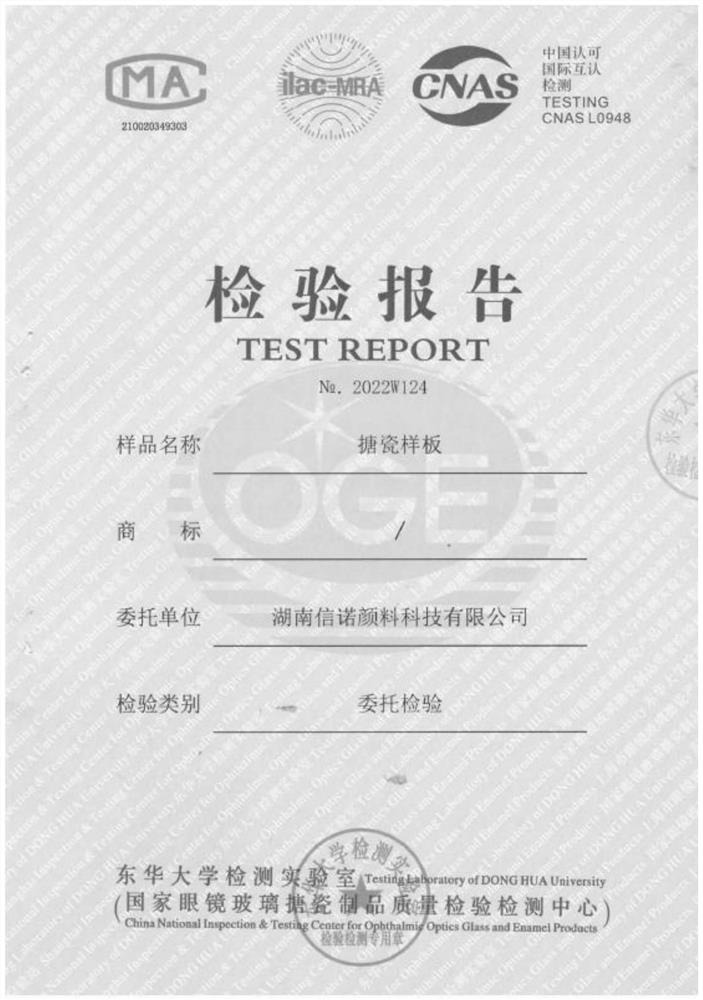

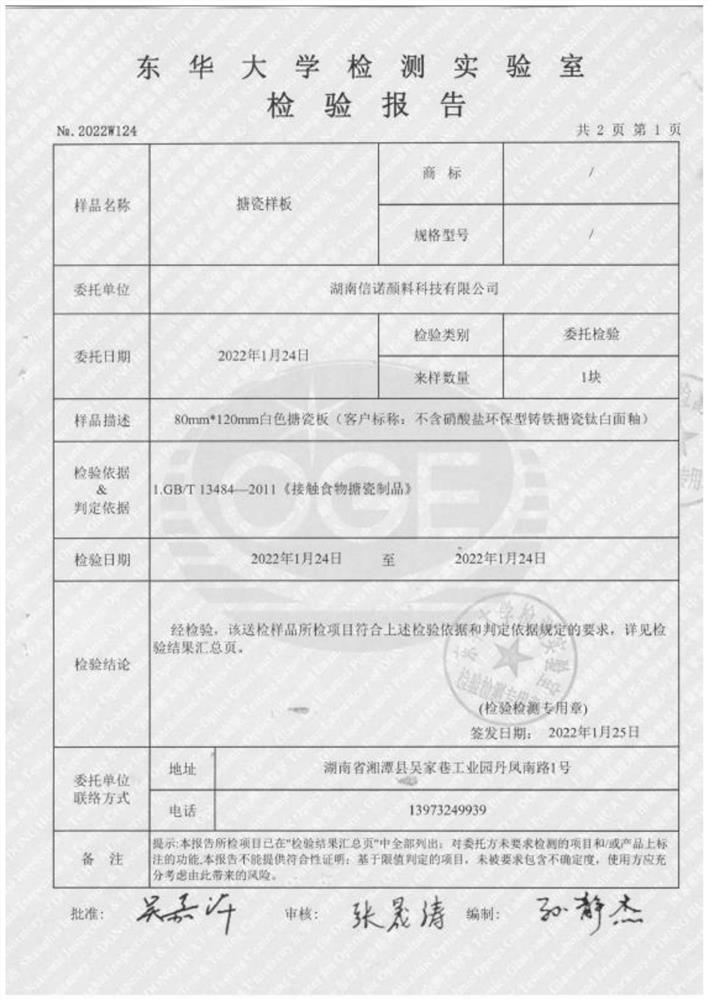

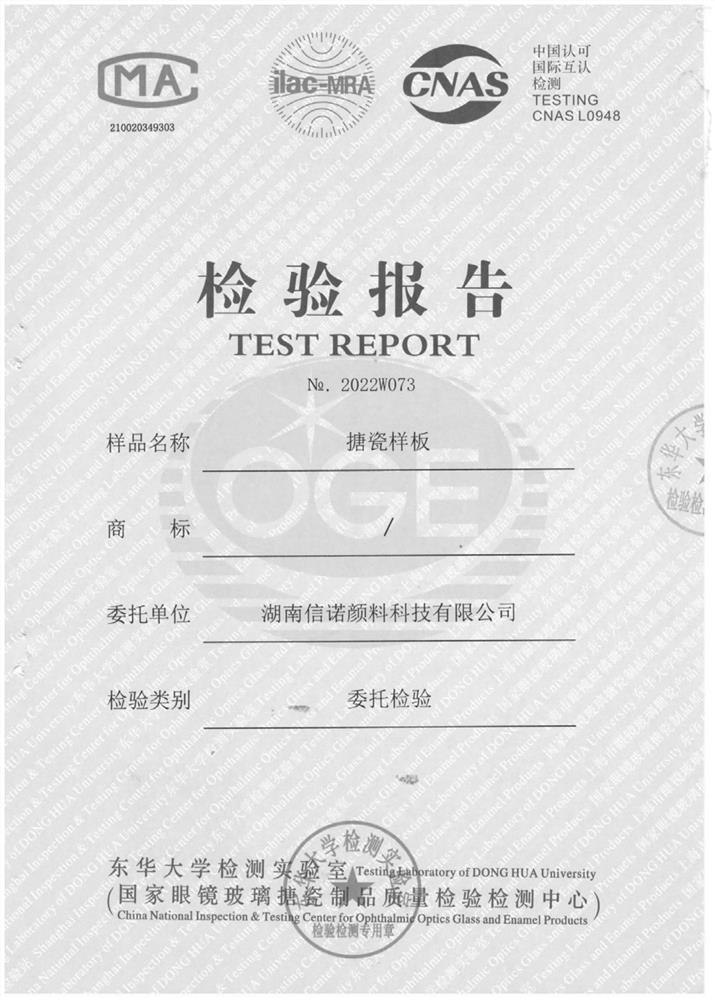

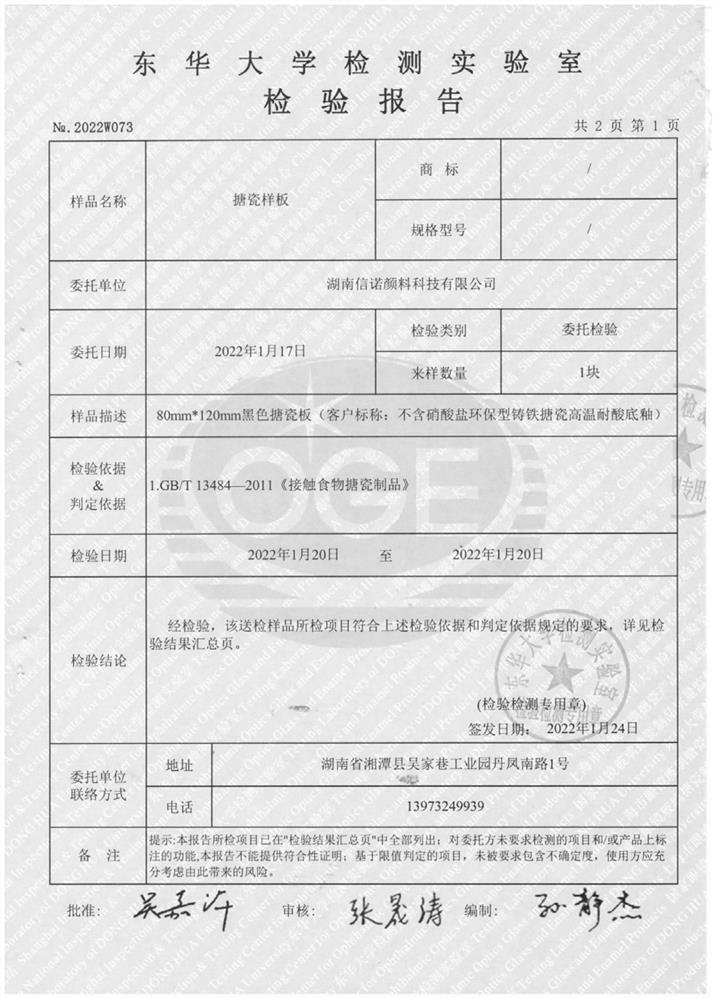

Nitrate-free environment-friendly cast iron enamel low-temperature acid-resistant ground coat and preparation method thereof

The invention discloses a nitrate-free environment-friendly cast iron enamel low-temperature acid-resistant ground coat and a preparation method thereof, and belongs to the technical field of enamel, the formula comprises the following components by mass: 46-50 parts of quartz, 24-27 parts of borax anhydrous, 5-7 parts of sodium carbonate, 1.2-1.4 parts of manganese oxide, 0.6-0.8 part of cobalt oxide, 4.5-5.5 parts of calcium carbonate, 3.5-4.5 parts of sodium fluosilicate, 3.0-4.0 parts of titanium dioxide, and 2.0-3.5 parts of potassium feldspar. And 3.5 to 4.5 parts of lithium carbonate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 740-760 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing cast iron enamel low-temperature acid-resistant ground coat, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

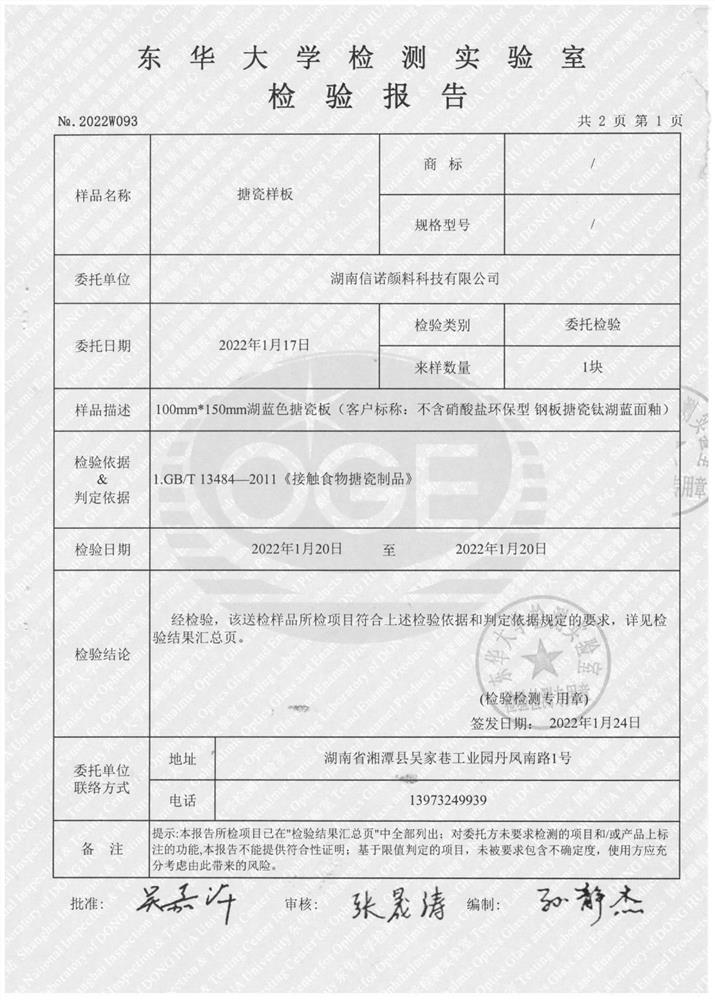

Nitrate-free environment-friendly steel plate enamel titanium lake blue cover glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel titanium lake blue cover glaze and a preparation method thereof, and the nitrate-free environment-friendly steel plate enamel titanium lake blue cover glaze comprises the following components in parts by mass: 22-25 parts of quartz, 28-30 parts of borax anhydrous, 11-14 parts of titanium dioxide, 9-11 parts of potassium feldspar, 0.7-1 part of magnesium carbonate, 1-2 parts of sodium carbonate, 7-9 parts of sodium fluosilicate and 1-2 parts of calcium carbonate. And 1.5-2.5 parts by mass of copper oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-830 DEG C. The titanium lake blue cover glaze does not contain nitrate, and the major technical problem that the environment is polluted due to emission of nitric oxide gas generated in the production process of existing steel plate enamel titanium lake blue cover glaze is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

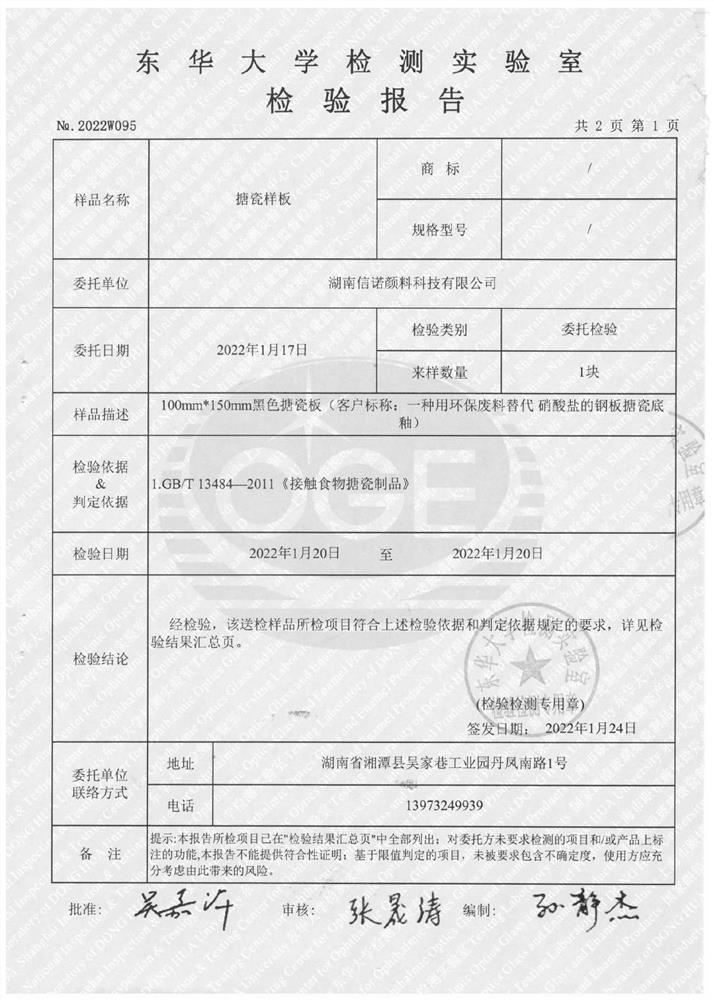

Steel plate enamel ground coat using environment-friendly waste material to replace nitrate and preparation method of steel plate enamel ground coat

PendingCN114315152AIncrease the oxidizing atmosphereFluxing GuaranteeAluminium hydroxideCopper oxide

The invention discloses a steel plate enamel ground coat using environment-friendly waste to replace nitrate and a preparation method thereof. The formula of the ground glaze comprises the following components in parts by mass: 8-10 parts of environment-friendly waste, 17-20 parts of quartz, 13-16 parts of anhydrous borax, 20-22 parts of sodium carbonate, 12-13 parts of potassium feldspar, 7-8 parts of calcium carbonate, 4-5 parts of barium carbonate, 0.4-0.6 part of magnesium carbonate, 2-2.5 parts of aluminum hydroxide, 3-4 parts of ferric oxide, 0.8-1.0 part of manganese oxide, 0.2-0.4 part of copper oxide, 0.8-1.0 part of nickel oxide and 4.5-5 parts of fluorite powder. The raw materials are uniformly mixed according to the proportion and are melted at 1250 + / -10 DEG C under the condition of pure oxygen, and the firing temperature of the finished product is 800-860 DEG C. The formula does not contain nitrate, and the major technical problem that nitrogen oxide (NOx) gas generated in the production process of the existing steel plate enamel ground glaze is discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

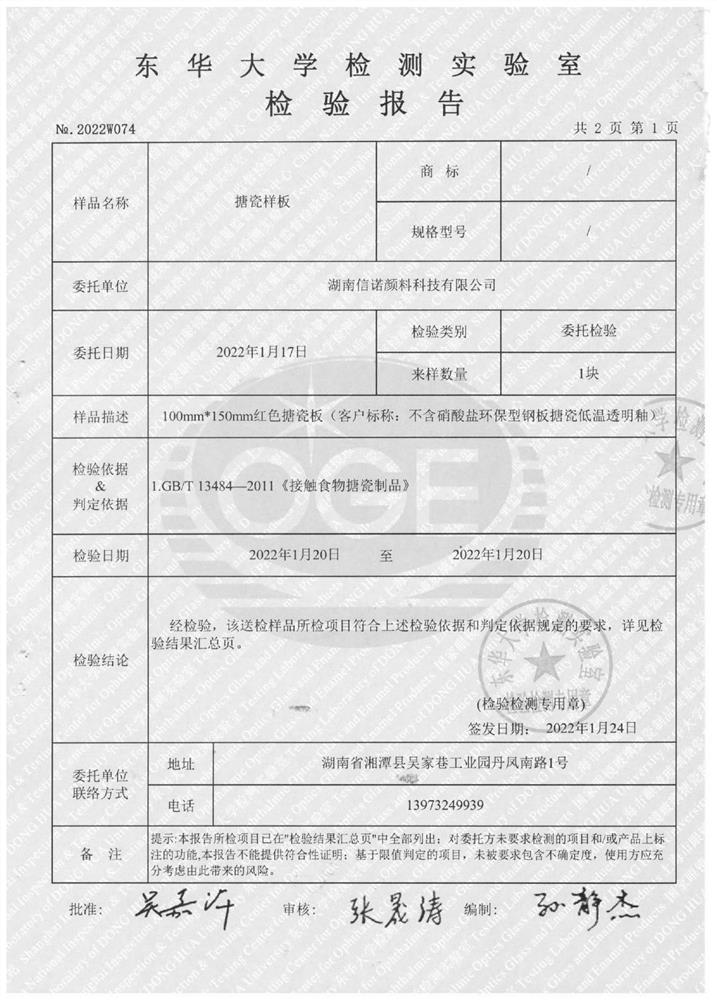

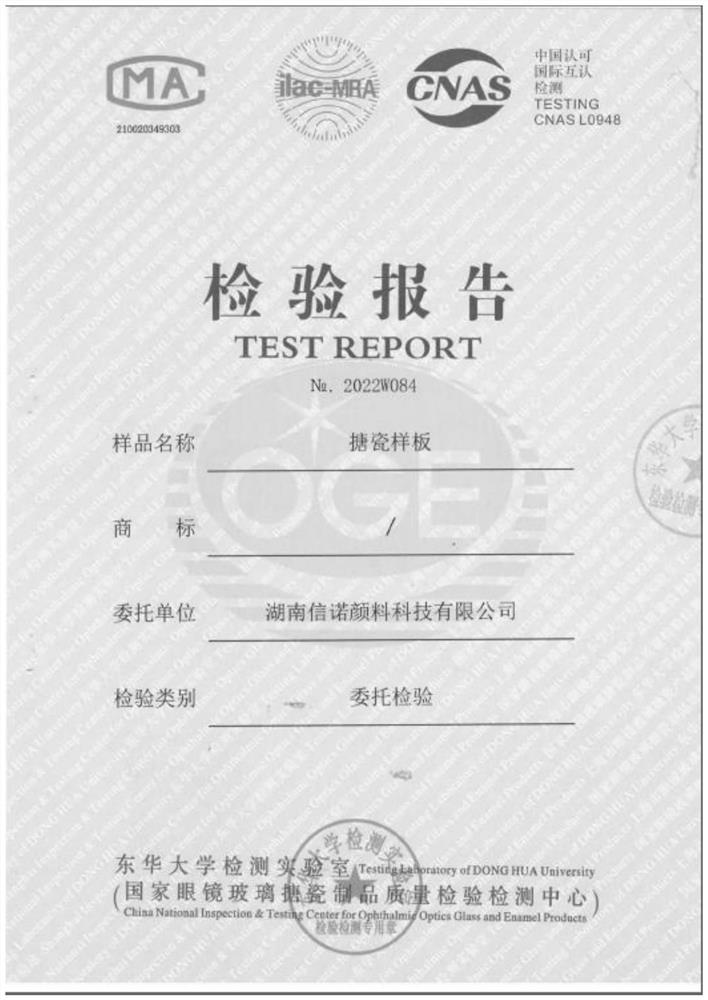

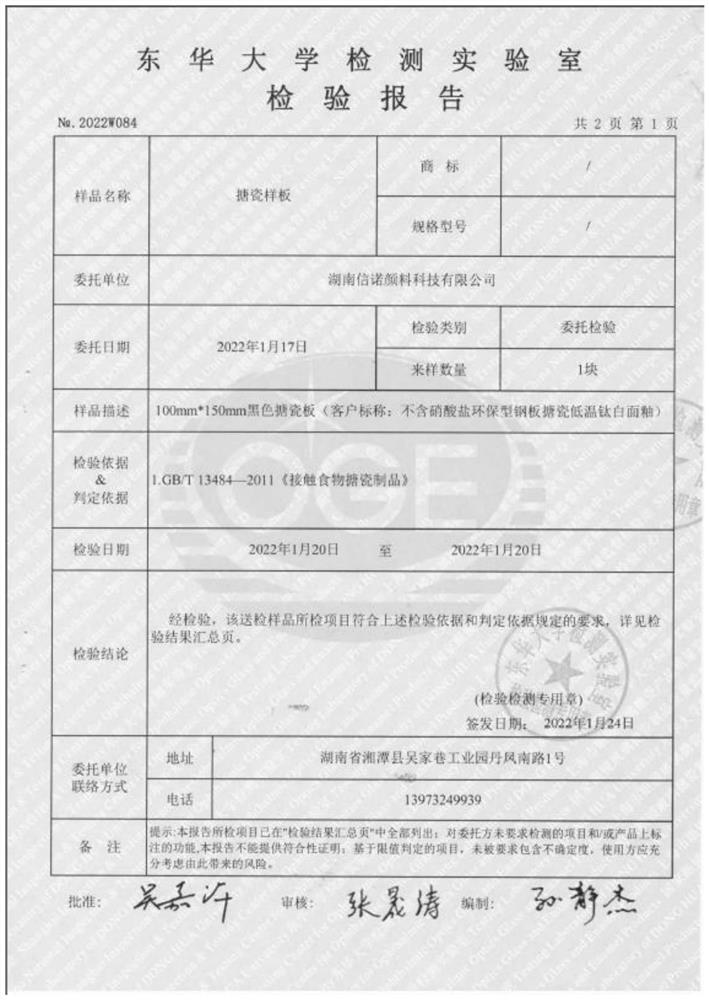

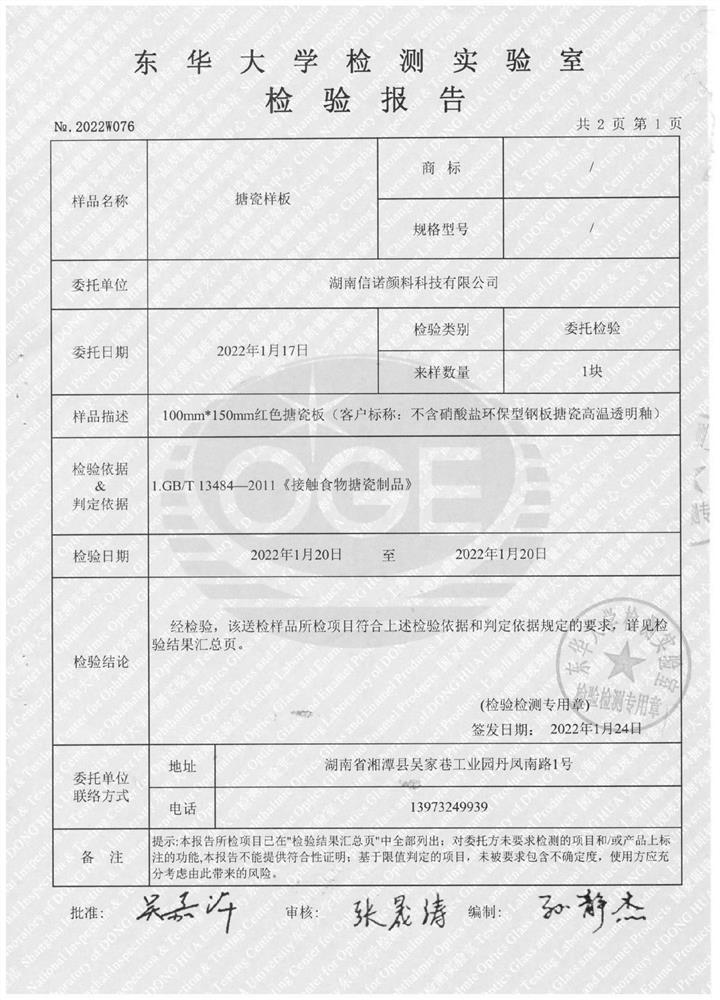

Nitrate-free environment-friendly steel plate enamel low-temperature transparent glaze and preparation method thereof

PendingCN114213016ASolve the pollution of the environmentIncrease the oxidizing atmospherePotassium feldsparSodium silicate

The invention discloses nitrate-free environment-friendly steel plate enamel low-temperature transparent glaze and a preparation method thereof, and belongs to the technical field of enamel, and the formula comprises the following components in parts by mass: 19-22 parts of borax anhydrous, 26-28 parts of potassium feldspar, 24-26 parts of quartz, 9-12 parts of sodium carbonate, 6-8 parts of sodium fluosilicate, 2-4 parts of titanium dioxide and 4-6 parts of fluorite. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 760-790 DEG C. The formula does not contain nitrate, and the major technical problem that the environment is polluted due to emission of nitrogen oxide (NOx) gas generated in the production process of the existing low-temperature transparent glaze for steel plate enamel is fundamentally solved.

Owner:湖南信诺技术股份有限公司

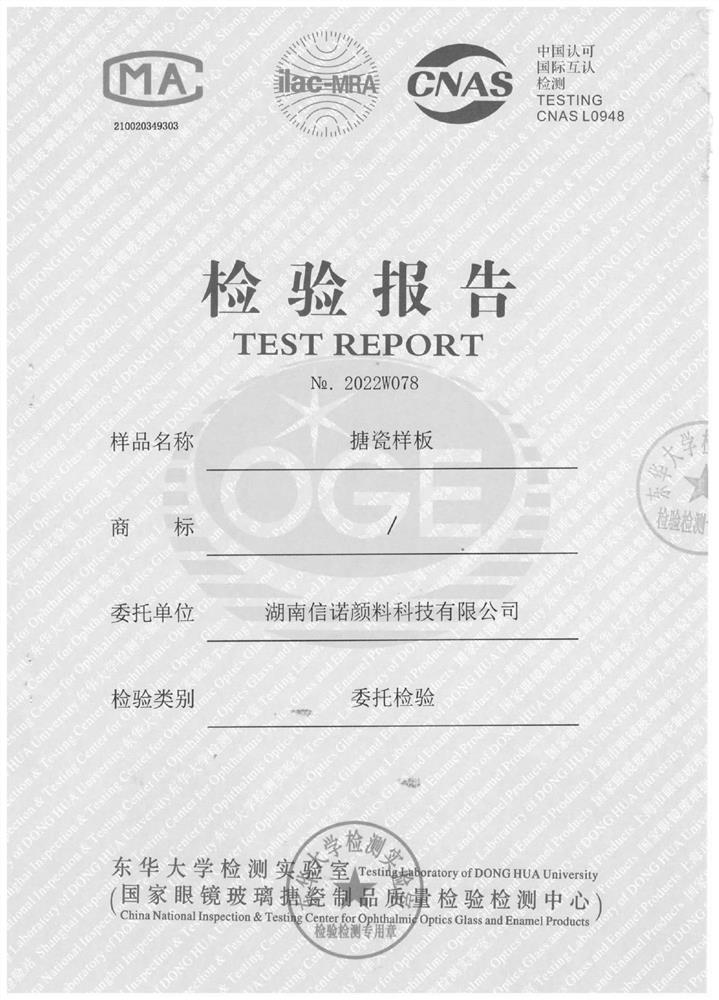

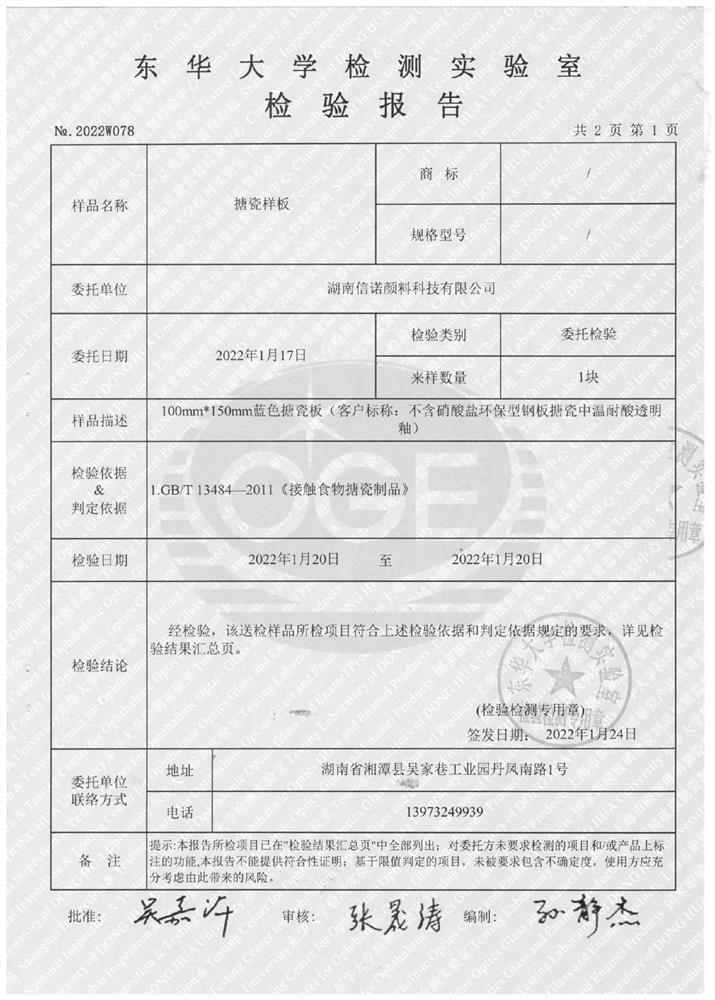

Nitrate-free environment-friendly steel plate enamel medium-temperature acid-resistant transparent glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel medium-temperature acid-resistant transparent glaze and a preparation method thereof, and belongs to the technical field of enamel, and the formula comprises the following components in parts by mass: 23-26 parts of borax anhydrous, 39-41 parts of quartz, 10-13 parts of sodium carbonate, 4-6 parts of titanium dioxide, 6-8 parts of aluminum oxide, 5-7 parts of fluorite and 3-5 parts of barium carbonate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-840 DEG C. The formula does not contain nitrate, and the major technical problem that nitrogen oxide (NOx) gas generated in the production process of the existing steel plate enamel medium-temperature acid-resistant transparent glaze is discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel low-temperature titanium dioxide cover glaze and preparation method thereof

The invention discloses a nitrate-free environment-friendly steel plate enamel low-temperature titanium dioxide cover glaze and a preparation method thereof. The invention belongs to the technical field of enamel. The formula comprises the following components in parts by mass: 38-40 parts of quartz, 33-35 parts of borax anhydrous, 0.01-0.02 part of cobalt oxide, 14-16 parts of titanium dioxide, 1.8-2.5 parts of magnesium carbonate, 2-4 parts of sodium tripolyphosphate, 6-8 parts of sodium fluosilicate, 4-6 parts of potassium carbonate and 1.5-2 parts of aluminum oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 760-790 DEG C. The formula of the low-temperature titanium white cover glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel low-temperature titanium white cover glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

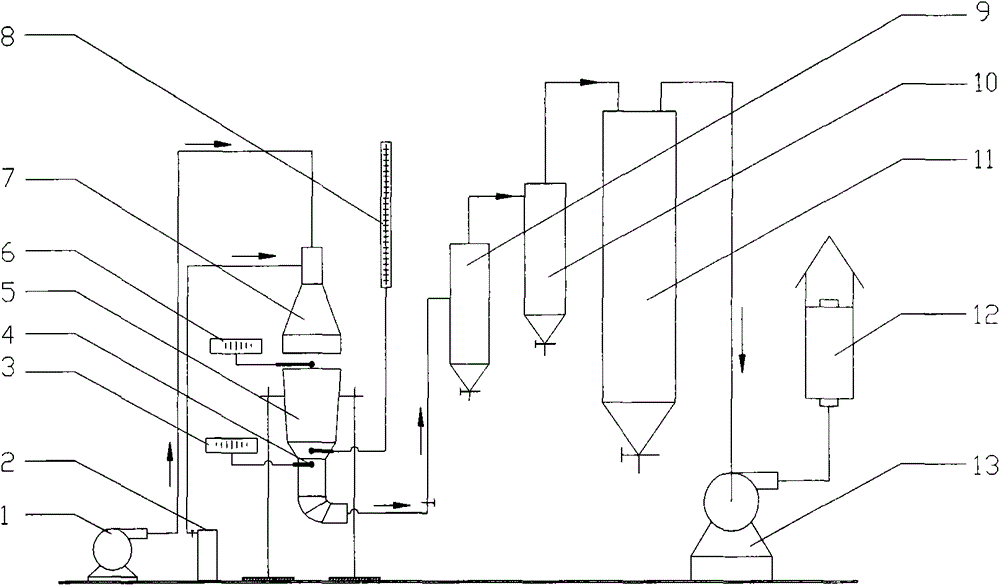

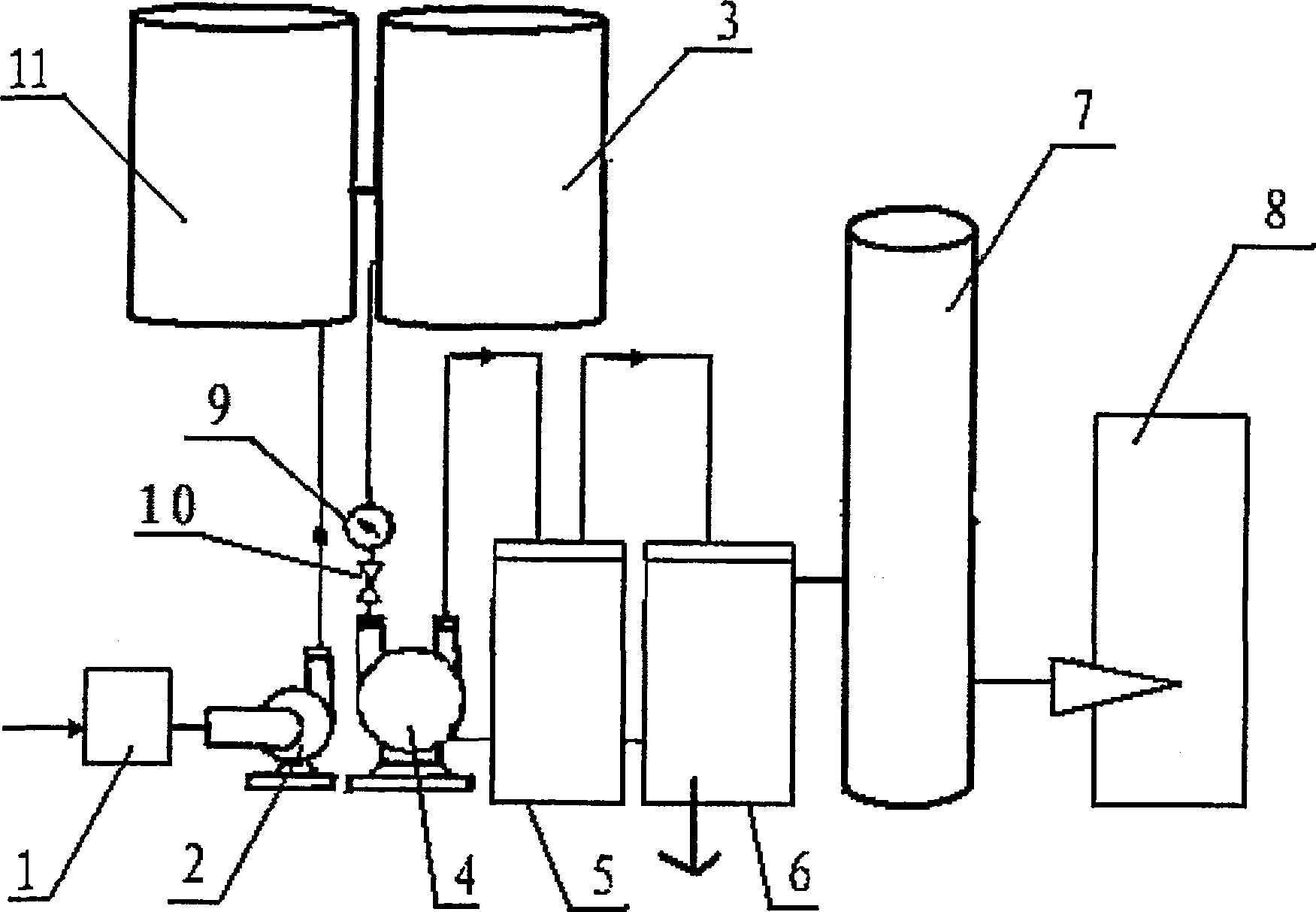

System for cooling vertical furnace and utilizing residual heat

InactiveCN101738083AReduce the temperatureIncrease temperatureVertical furnacesWaste heat treatmentCombustorEngineering

The invention discloses a system for cooling a vertical furnace and utilizing residual heat, and belongs to the technical field of pellet sintering. The problems of low residual heat utilization rate and high pellet-out temperature are universal in the conventional sintering technology. The outside air enters a cooling zone of the vertical furnace under the suction of a combustion fan. The temperature is raised while the temperature of pellets is reduced. Then, the air enters a combustor through the combustion fan. The system for cooling the vertical furnace and utilizing the residual heat improves the temperature of the combustion air, increases a ratio of the combustion air to the fuel, obtains more high-temperature gas by using less fuel, reduces the energy consumption, simultaneously improves the oxidizing atmosphere, contributes to pellet consolidation, reduces the pellet-out temperature, and provides convenience for integral control of the hot air.

Owner:崔成群

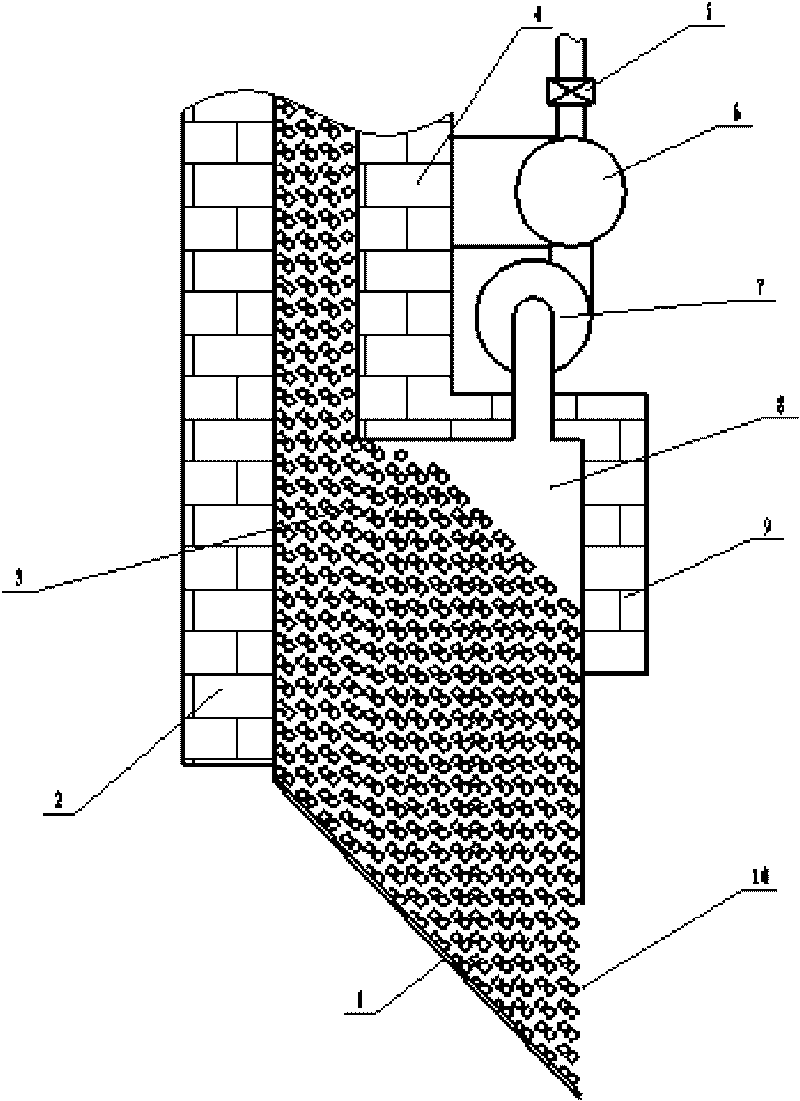

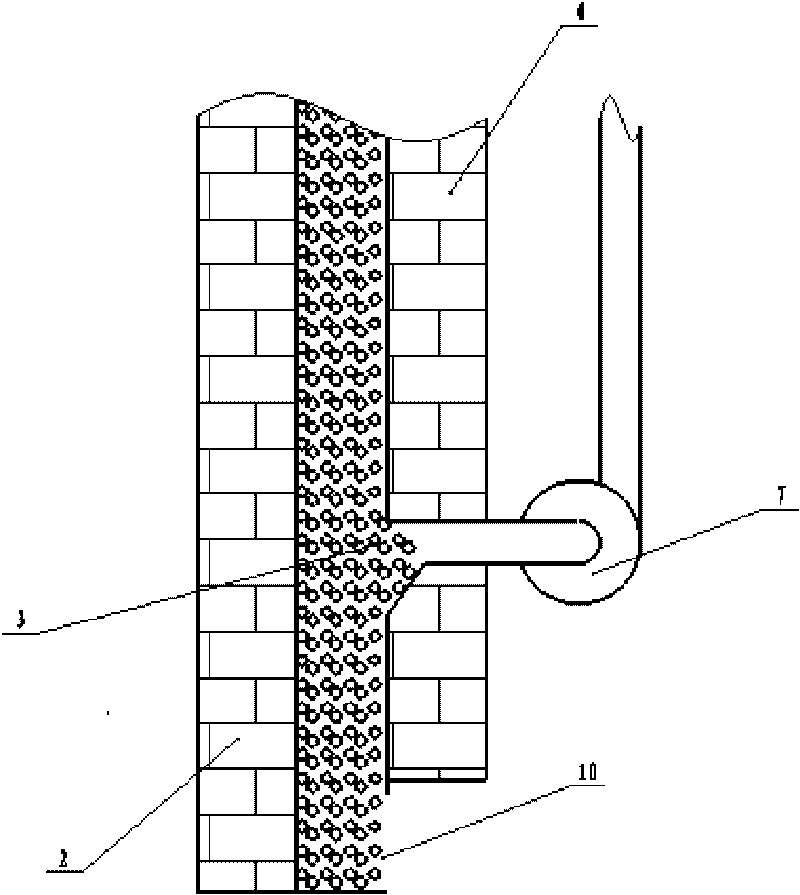

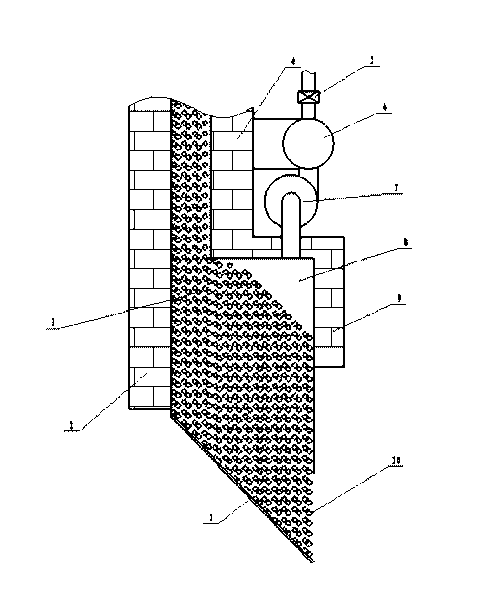

Hot wind oxygen-enriched sintering equipment and method thereof

InactiveCN100513961CIncrease the oxidizing atmosphereQuality improvementMaintainance of heating chambersFlue gasBuffer tank

Owner:KUNMING IRON & STEEL

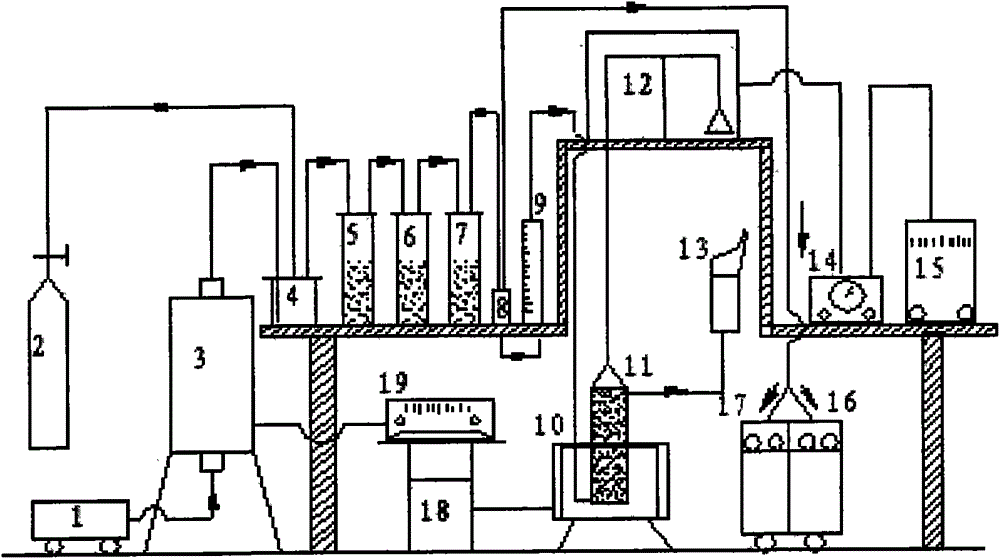

Roasting method for refining vanadium pentoxide

InactiveCN102586588BEasy temperature controlIncrease conversion rateProcess efficiency improvementSlagCoal

The invention discloses a roasting method for refining vanadium pentoxide, which comprises the steps, performing heating roasting to a mixture of raw ore of stone coal navajoite and decarburization slag of the stone coal navajoite, or the raw ore of the stone coal navajoite, or the decarburization slag of the stone coal navajoite, or a vanadium-containing material containing tiny combustible components, or a vanadium-containing material containing no combustible component which serves as a raw material; enabling the raw material to enter into a roasting chamber at an ignition point lower than that of contained carbon or in a normal-temperature state so as to be roasted; enabling a roasting heat source in the roasting chamber to be high-temperature gas directly sprayed into each part of raw material through at least one group of pipelines arranged in the roasting chamber and / or a combustible material evenly sprayed in the raw material through at least one group of pipelines arranged in the roasting chamber, and performing ignition; and being capable of performing crushing, grinding, pelletizing, addition of an additive and the like before the raw material enters into the roasting chamber. The roasting method has the advantages of being scientific and reasonable, low in energy consumption and oxygen consumption, high in vanadium conversion rate and yield and low in pollution.

Owner:彭武星

Glass raw material composition, inorganic glass powder, crystalline silicon solar battery aluminum conductive paste and preparation method of the crystalline silicon solar battery aluminum conductive paste

ActiveCN103130413BIncrease the oxidizing atmospherePrevent high temperature reductionNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteNitrate

The invention provides a glass raw material composition. The glass raw material composition comprises, by weight, 35 to 60 parts of Bi2O3, 10 to 30 parts of B2O3, 10 to 20 parts of SiO2, 1 to 5 parts of CaO, 0.5 to 5 parts of MgO, 0 to 5 parts of Al2O3, 3 to 8 parts of Sb2O3 and Sb2O5, and a nitrate of which the content is 0.5 to 1.5 times the content of Sb2O3, wherein the nitrate is magnesium nitrate or calcium nitrate. The invention also provides inorganic glass powder prepared from the glass raw material composition, crystalline silicon solar battery aluminum conductive paste prepared from the inorganic glass powder, and a preparation method of the crystalline silicon solar battery aluminum conductive paste. The clear inorganic glass powder can be prepared from the glass raw material composition and thus a battery piece prepared from the crystalline silicon solar battery aluminum conductive paste containing the inorganic glass powder has high photoelectric conversion efficiency and high water boiling resistance.

Owner:BYD CO LTD

Composite Na-based bentonite and preparation method thereof

The invention relates to composite Na-based bentonite and a preparation method thereof. The composite Na-based bentonite is prepared by the following steps of material selecting, drying, chemosynthesiThe invention relates to composite Na-based bentonite and a preparation method thereof. The composite Na-based bentonite is prepared by the following steps of material selecting, drying, chemosynthesis, crushing, re-synthesis and post-processing. The composite Na-based bentonitic clay prepared according to the method solves the problem that is required to be solved but can not be solved in iron ins, crushing, re-synthesis and post-processing. The composite Na-based bentonitic clay prepared according to the method solves the problem that is required to be solved but can not be solved in iron industry for many years, greatly reduces the soil quantity during the production, and simultaneously realizes multiple comprehensive economic benefits and environment-protective benefits of saving energdustry for many years, greatly reduces the soil quantity during the production, and simultaneously realizes multiple comprehensive economic benefits and environment-protective benefits of saving energy, reducing consumption, improving output, reducing slag discharging and reducing pollution.y, reducing consumption, improving output, reducing slag discharging and reducing pollution.

Owner:建平慧营化工有限公司

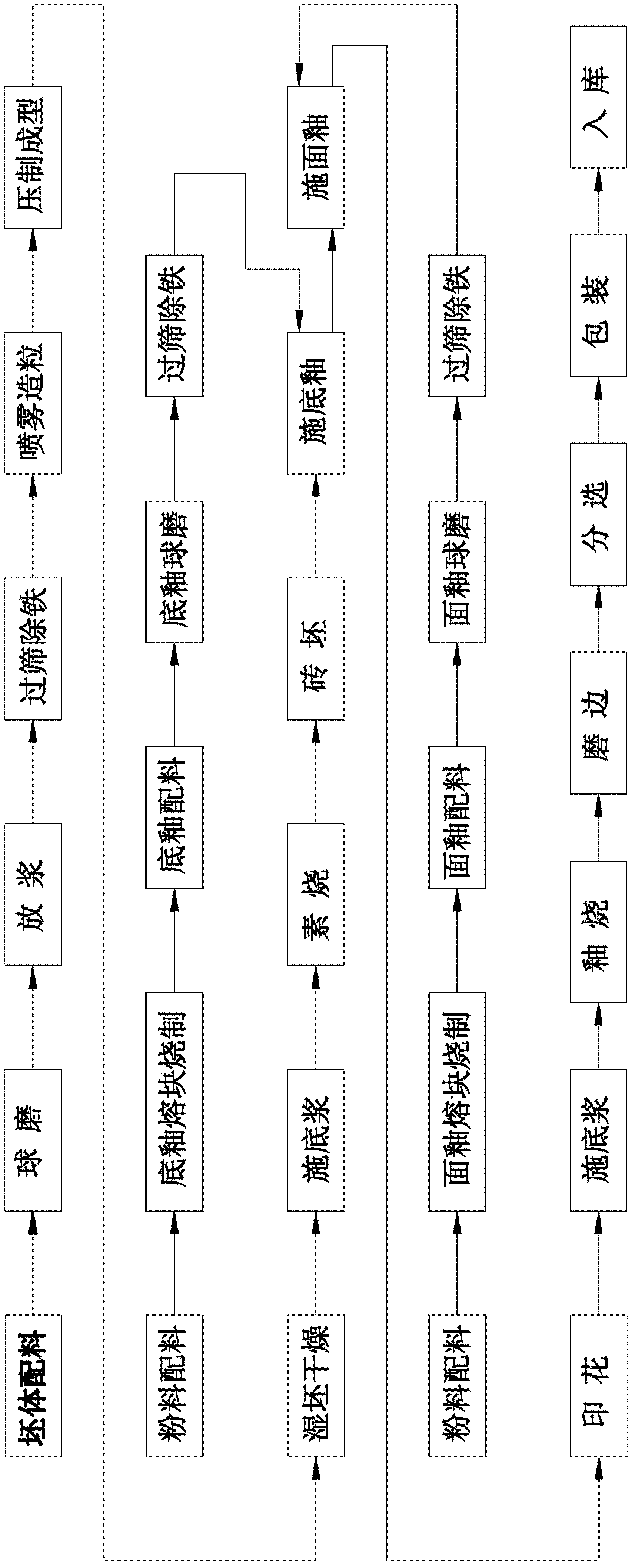

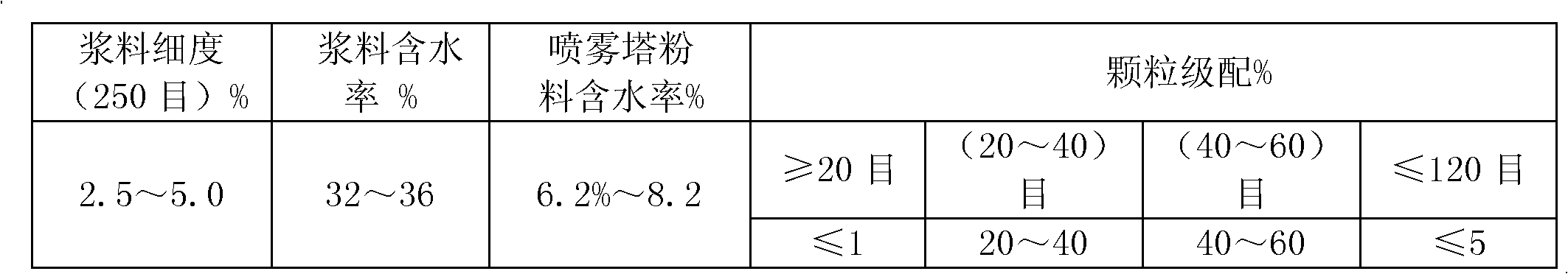

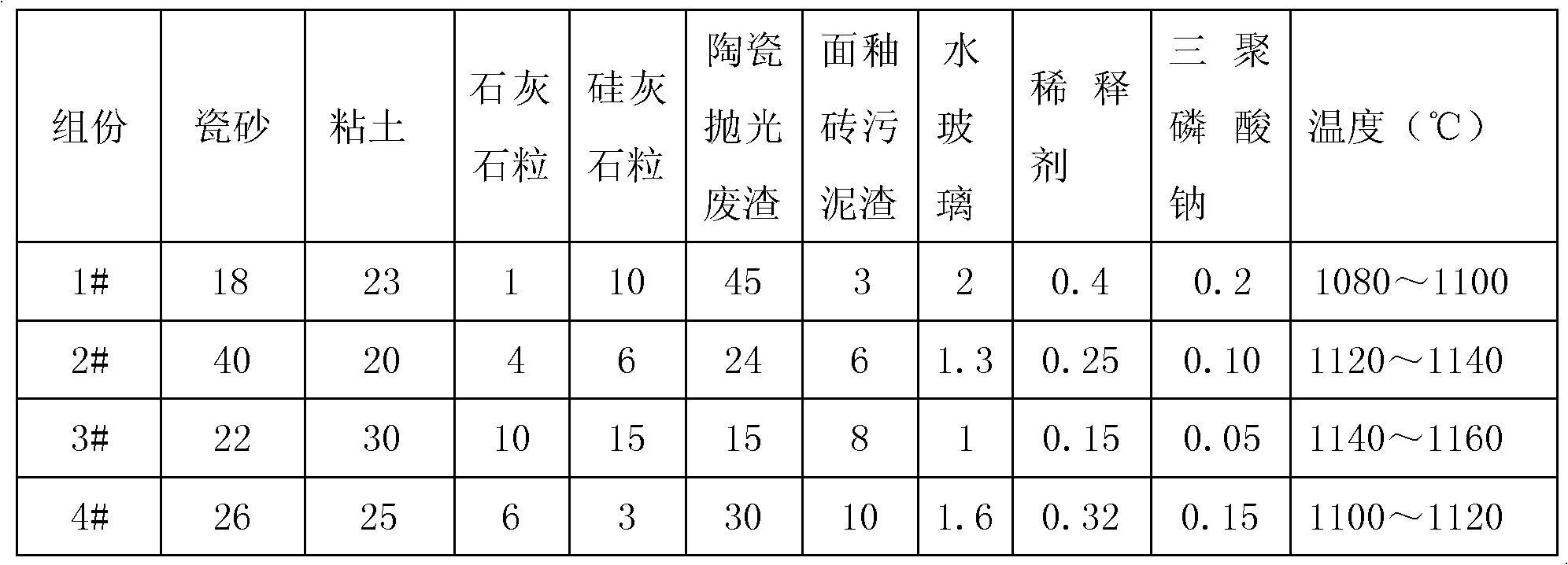

Formula and method for manufacturing ceramic tile blank bodies and glazed tiles by utilizing polished waste residues

The invention discloses a formula and a method for manufacturing ceramic tile blank bodies by utilizing polished waste residues. The formula adopts ingredients by weight portions: porcelain clays account for 18 to 40 parts, clays account for 20 to 30 parts, limestone grains account for 1 to 10 parts, wollastonite grains account for 3 to 15 parts, glazed tile sludge residues account for 3 to 10 parts, ceramic polished waste residues account for 15 to 45 parts, soluble glass accounts for 1 to 2 parts, thinners account for 0.15 to 0.4 parts, sodium tripolyphosphate accounts for 0.05 to 0.2 parts, and a proper amount of water is adopted. A manufacturing method of the ceramic tile blank bodies comprises the steps as follows: a. raw materials are put in a ball grinder for ball milling after being blended so as to form sizing agents with proper fineness and screen tailings through milling, and the sizing agents are processed through deferrization, sieving and spray drying so as to form powders; and b. the powders are put in a die cavity of a press forming machine to form waterish blanks through pressing, the waterish blanks are dried in a drying kiln, the dried waterish blanks are applied with base pulp and then enter a biscuit firing kiln, biscuit firing is carried out under the temperature ranging from 1080 to 1160 DEG C, heat preservation is carried out in an area with the temperature ranging from 1040 to 1060 DEG C, the sintering time of the area is prolonged, and the sintering process for oxidizing atmosphere can be enhanced at the same time so as to obtain the ceramic tile blank bodies.

Owner:GUANGDONG WINTO CERAMICS +1

Nitrate-free environment-friendly cast iron enamel low-temperature ground coat and preparation method thereof

The invention discloses a nitrate-free environment-friendly cast iron enamel low-temperature ground coat and a preparation method thereof, and belongs to the technical field of enamel, and the formula comprises the following components in parts by mass: 10-14 parts of quartz, 29-31 parts of anhydrous borax, 6-8 parts of sodium carbonate, 3.5-6.0 parts of potassium carbonate, 8-9 parts of barium carbonate, 7-8 parts of fluorite, 24-26 parts of potassium feldspar, 1.2-1.6 parts of magnesium carbonate, 1.2-1.4 parts of nickel oxide and 0.5-0.6 part of copper oxide. 1.2 to 1.4 parts of manganese oxide, 0.5 to 0.6 part of cobalt oxide and 0.8 to 0.9 part of aluminum oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 740-760 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing cast iron enamel low-temperature ground glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel medium-temperature transparent glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel medium-temperature transparent glaze and a preparation method thereof, and belongs to the technical field of enamel, the nitrate-free environment-friendly steel plate enamel medium-temperature transparent glaze comprises the following components by mass: 20-22 parts of borax anhydrous, 14-16 parts of potassium feldspar, 35-37 parts of quartz, 8-10 parts of sodium carbonate, 7-9 parts of sodium fluosilicate, 4-6 parts of titanium dioxide, 0.2-0.8 part of zinc oxide, and 6-8 parts of alumina. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-840 DEG C. The formula does not contain nitrate, and the major technical problem that nitrogen oxide (NOx) gas generated in the production process of the existing steel plate enamel medium-temperature transparent glaze is discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel high-temperature titanium creamy yellow cover glaze and preparation method thereof

PendingCN114349347AIncrease the oxidizing atmosphereFluxing GuaranteeNitric oxide gasPotassium carbonate

The invention discloses nitrate-free environment-friendly steel plate enamel high-temperature titanium creamy yellow cover glaze and a preparation method thereof, and the nitrate-free environment-friendly steel plate enamel high-temperature titanium creamy yellow cover glaze comprises the following components in parts by mass: 18-21 parts of quartz, 15-17 parts of anhydrous borax, 12-14 parts of rutile, 20-23 parts of potassium feldspar, 8-10 parts of trisodium phosphate, 2-4 parts of potassium carbonate and 7-9 parts of sodium fluosilicate. The raw materials are melted at the temperature of 1290 + / -10 DEG C and under the condition of pure oxygen, and the firing temperature of a finished product is 850-880 DEG C. The high-temperature titanium creamy cover glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel high-temperature titanium creamy cover glaze, nitric oxide gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel low-temperature titanium creamy yellow cover glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel low-temperature titanium creamy yellow cover glaze and a preparation method thereof, and the nitrate-free environment-friendly steel plate enamel low-temperature titanium creamy yellow cover glaze comprises the following components in parts by mass: 23-25 parts of quartz, 27-30 parts of anhydrous borax, 3-5 parts of phosphate, 12-15 parts of titanium dioxide, 9-11 parts of potassium feldspar, 1-3 parts of magnesium carbonate and 1-3 parts of potassium carbonate. 6 to 8 parts by mass of sodium fluosilicate and 0.1 to 0.15 part by mass of potassium dichromate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 760-790 DEG C. The low-temperature titanium creamy cover glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel low-temperature titanium creamy cover glaze, nitric oxide gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

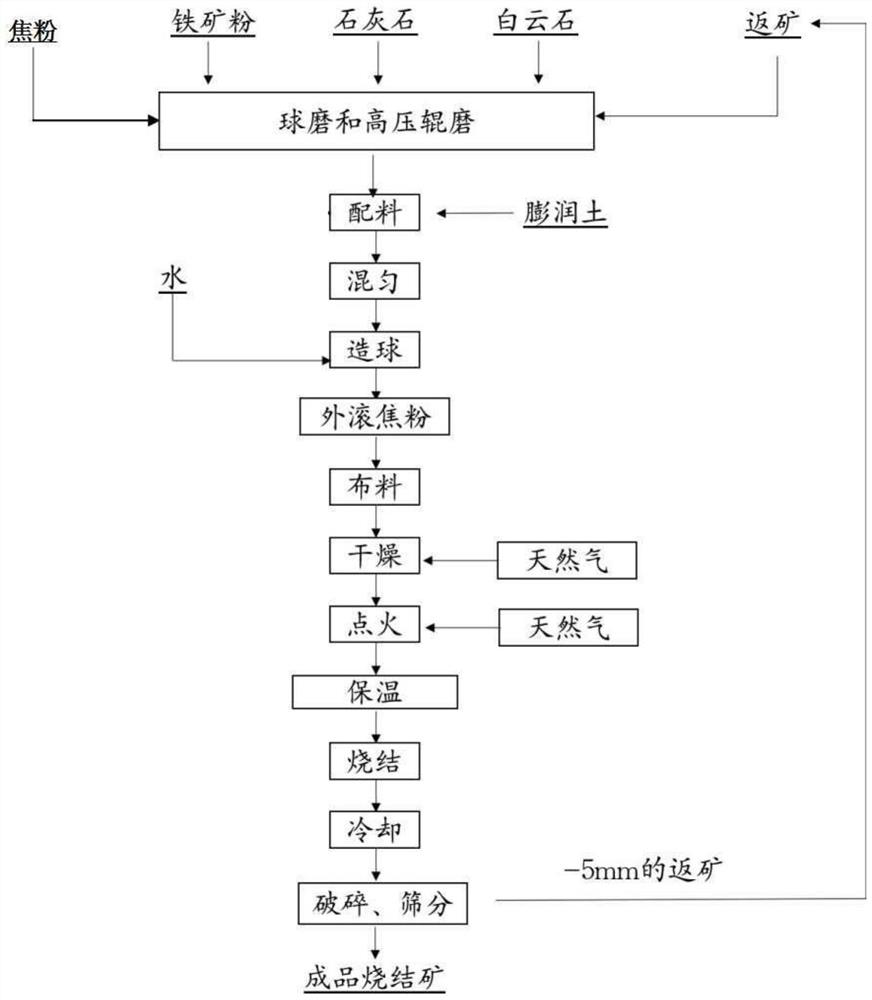

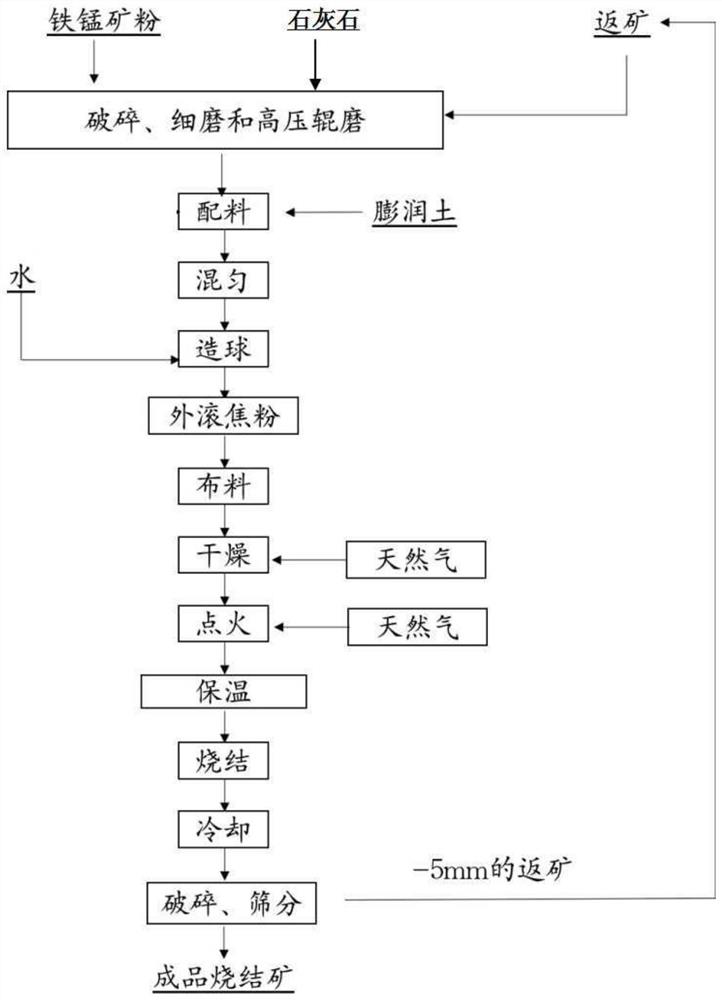

Sintering method of ferromanganese ore pellets

ActiveCN114574695AHigh specific surface areaImprove surface activityProcess efficiency improvementGrain treatmentsSolid fuelMixed materials

The sintering method comprises the following steps: S1, carrying out crushing and ball-milling treatment on coarse-grained ferromanganese ore, limestone and return mine, and then carrying out high-pressure roller milling to obtain a pretreated raw material; s2, after the pretreated raw materials are subjected to optimized ore blending, a binder is added and mixed uniformly, and a mixture is obtained; s3, pelletizing the mixture obtained in the step S2; s4, carrying out external rolling on the green pellets to obtain a solid fuel, so as to obtain a uniformly mixed material; and S5, distributing the uniformly mixed material, and then sequentially performing drying, ignition sintering, heat preservation, cooling, crushing and size stabilization to obtain finished pellets. In order to solve the problem that a liquid phase is difficult to form in the ferromanganese ore sintering process, a ball milling and high-pressure roller milling combined treatment process is utilized, the specific surface area of the ferromanganese ore is increased, the surface activity and reaction activity of the ferromanganese ore are improved, migration and activation of atoms in the high-temperature sintering process are promoted, the forming ability of a sintering liquid phase is improved, and the liquid phase amount is increased, so that the liquid phase consolidation effect of the ferromanganese ore is promoted; the sintering strength is improved.

Owner:CENT SOUTH UNIV

Nitrate-free environment-friendly cast iron enamel titanium white cover glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly cast iron enamel titanium white cover glaze and a preparation method thereof. The invention belongs to the technical field of enamel. The formula comprises the following components in parts by mass: 30-33 parts of quartz, 18-21 parts of borax anhydrous, 14-16 parts of titanium dioxide, 1-2 parts of magnesium carbonate, 2-4 parts of sodium tripolyphosphate, 6-8 parts of sodium fluosilicate, 3-5 parts of potassium carbonate, 2-3 parts of lithium carbonate and 2-3 parts of potassium feldspar. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 740-780 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing cast iron enamel titanium white cover glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly cast iron enamel high-temperature acid-resistant ground coat and preparation method thereof

PendingCN114368903AIncrease the oxidizing atmosphereFluxing GuaranteeManganese oxideMaterials science

The invention discloses a nitrate-free environment-friendly cast iron enamel high-temperature acid-resistant ground coat and a preparation method thereof, and belongs to the technical field of enamel, the formula comprises the following components by mass: 50-54 parts of quartz, 24-27 parts of anhydrous borax, 5-7 parts of sodium carbonate, 1.5-1.7 parts of manganese oxide, 0.7-0.9 part of cobalt oxide, 4.5-5.5 parts of calcium carbonate, 4-5 parts of sodium fluosilicate, 3.0-4.0 parts of titanium dioxide, and 2.0-3.8 parts of potassium feldspar. And 3.5 to 4.5 parts of lithium carbonate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1290 + / -10 DEG C, and the firing temperature of the finished product is 800-820 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing cast iron enamel high-temperature acid-resistant ground coat, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

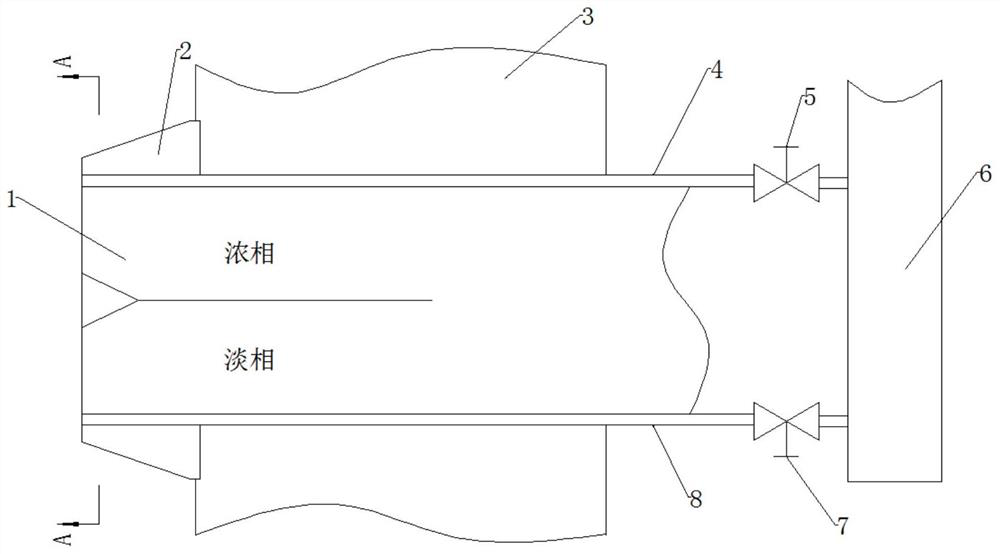

Oxygen-enriched direct-current combustor with adjustable combustion performance

PendingCN114413256AGuaranteed fire stabilityIncrease oxygen concentrationPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationThermodynamicsCombustor

The invention relates to the field of oxygen-enriched combustion, and discloses an oxygen-enriched direct-current combustor with adjustable combustion performance, which comprises a dense-thin direct-current combustor, a peripheral air chamber, a dense-phase oxygen injection pipe gun and a thin-phase oxygen injection pipe gun, the dense-phase oxygen injection pipe guns and the light-phase oxygen injection pipe guns are uniformly distributed in the dense-light side peripheral air chamber; a pipeline of the concentrated-phase oxygen injection pipe gun is provided with a concentrated-phase oxygen injection regulating valve group; a pipeline of the light-phase oxygen injection pipe gun is provided with a light-phase oxygen injection regulating valve group; and the concentrated-phase oxygen injection regulating valve group and the light-phase oxygen injection regulating valve group are used for regulating the oxygen concentration in the thick-thin direct-current burner. The problems that in the prior art, a pulverized coal burner is poor in ignition stability and insufficient in combustion in application are solved.

Owner:HARBIN BOILER

Nitrate-free environment-friendly medium-temperature pearlescent glaze for enameled steel plates and preparation method thereof

The invention discloses nitrate-free environment-friendly medium-temperature pearlescent glaze for an enameled steel plate and a preparation method, and belongs to the technical field of enamel, the nitrate-free environment-friendly medium-temperature pearlescent glaze comprises the following components in parts by mass: 38-44 parts of quartz, 12-14 parts of borax, 16-18 parts of potassium feldspar, 0.7-3 parts of potassium carbonate, 8-11 parts of titanium dioxide, 2-5 parts of calcium carbonate, 10-12 parts of sodium carbonate, 3-8 parts of sodium fluosilicate and 0.5-1 part of lithium carbonate. And 2-5 parts of talcum powder. The raw materials are uniformly mixed according to the proportion and are melted at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-840 DEG C. The formula does not contain nitrate, and the technical problem that the environment is polluted due to emission of nitrogen oxide (NOx) gas generated in the production and processing process of the existing medium-temperature pearlescent glaze for the enameled steel sheet is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel medium-temperature titanium white cover glaze and preparation method thereof

The invention discloses a nitrate-free environment-friendly steel plate enamel medium-temperature titanium white cover glaze and a preparation method thereof. The invention belongs to the technical field of enamel. The formula comprises the following components in parts by mass: 35-37 parts of quartz, 28-30 parts of borax anhydrous, 0.01-0.03 part of cobalt oxide, 16-18 parts of titanium dioxide, 2-4 parts of magnesium carbonate, 9-11 parts of trisodium phosphate, 5-7 parts of sodium fluosilicate, 3-5 parts of potassium carbonate and 1-3 parts of aluminum oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1260 + / -10 DEG C, and the firing temperature of the finished product is 800-840 DEG C. According to the present invention, the formula does not contain nitrate, such that the major technical problem of environmental pollution caused by emission of nitrogen oxide (NOx) gas generated during the production process of the existing steel plate enamel intermediate temperature titanium dioxide cover glaze is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Nitrate-free environment-friendly steel plate enamel high-temperature transparent glaze and preparation method thereof

The invention discloses nitrate-free environment-friendly steel plate enamel high-temperature transparent glaze and a preparation method thereof, and belongs to the technical field of enamel, and the formula comprises the following components in parts by mass: 21-23 parts of borax anhydrous, 36-38 parts of potassium feldspar, 19-21 parts of quartz, 6-8 parts of sodium fluosilicate, 5-7 parts of fluorite, 4-6 parts of titanium dioxide, 6-8 parts of aluminum oxide and 2-4 parts of barium carbonate. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1290 + / -10 DEG C, and the firing temperature of the finished product is 850-880 DEG C. The formula does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel high-temperature transparent glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com