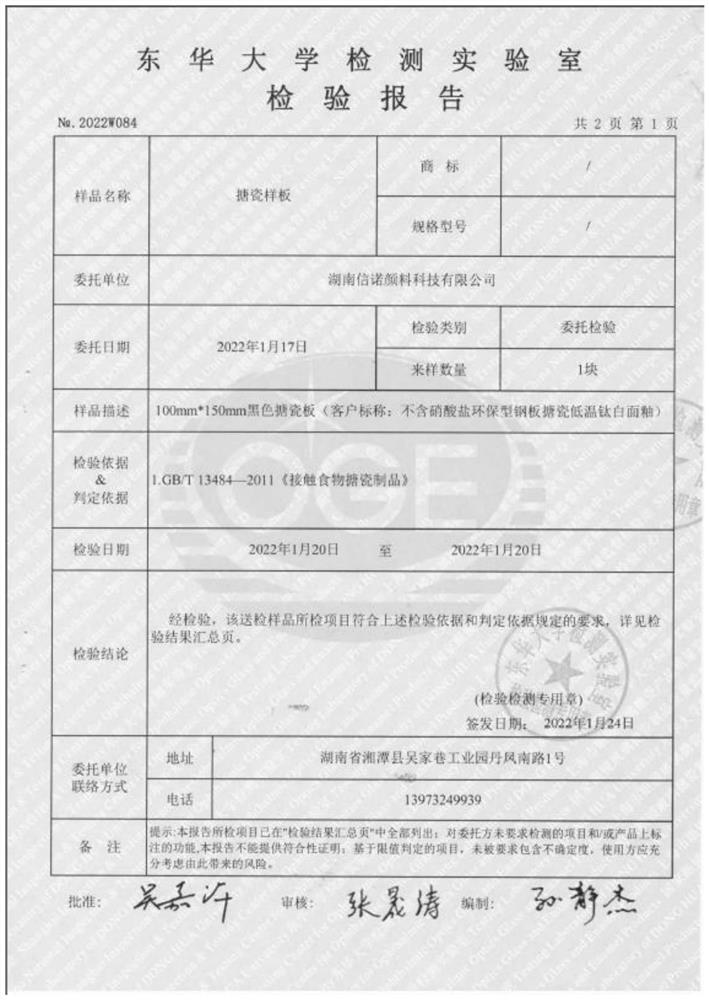

Nitrate-free environment-friendly steel plate enamel low-temperature titanium dioxide cover glaze and preparation method thereof

An environmentally friendly, nitrate-based technology for enamel applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Take the raw materials by the mass parts of the following components:

[0044] Quartz 39KG, Zero Water Borax 33KG, Cobalt Oxide 0.012KG, Titanium Dioxide 15KG, Magnesium Carbonate 2KG, Sodium Tripolyphosphate 3.6KG, Sodium Fluosilicate 8KG, Potassium Carbonate 6KG, Aluminum Oxide 1.8KG.

[0045] (2) Stir and mix the above raw materials evenly.

[0046] (3) Put the uniformly mixed material into the melting furnace, and melt it under the condition of pure oxygen, and control the melting temperature at 1230±10°C.

[0047] (4) After the above materials are completely melted, the borosilicate glass body is obtained, and the molten borosilicate glass body is brazed, and quickly drawn into a glass filament of 1.2 to 1.5 meters for detection. The detection requirement is: within 1 meter of the glass filament. The knot is the completion of melting.

[0048] (5) Quenching (water quenching) the melted borosilicate glass body to obtain the product.

Embodiment 2

[0050] The preparation process of this embodiment and embodiment 1 is basically the same, the difference is:

[0051] The mass parts of each component in the step (1) are: quartz 39KG, zero-water borax 34KG, cobalt oxide 0.012KG, titanium dioxide 15KG, magnesium carbonate 2KG, sodium tripolyphosphate 3.6KG, sodium fluorosilicate 7KG, potassium carbonate 5.5 KG, alumina 1.8KG.

[0052] In step (5), rapid cooling of the melted borosilicate glass body adopts a tableting process.

Embodiment 3

[0054] The preparation process of this embodiment and embodiment 1 is basically the same, the difference is:

[0055] The mass parts of each component in the step (1) are: quartz 39KG, zero-water borax 35KG, cobalt oxide 0.012KG, titanium dioxide 15KG, magnesium carbonate 2KG, sodium tripolyphosphate 3.6KG, sodium fluorosilicate 6.5KG, potassium carbonate 5KG, alumina 1.8KG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com