Hot wind oxygen-enriched sintering equipment and method thereof

A sintering device and oxygen-enriched technology, which is applied in the maintenance of heating chambers, lighting and heating equipment, furnaces, etc., can solve problems that have not been reported in the literature, and achieve the effects of improving the strength of the drum, reducing fuel consumption, and improving the oxidation atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

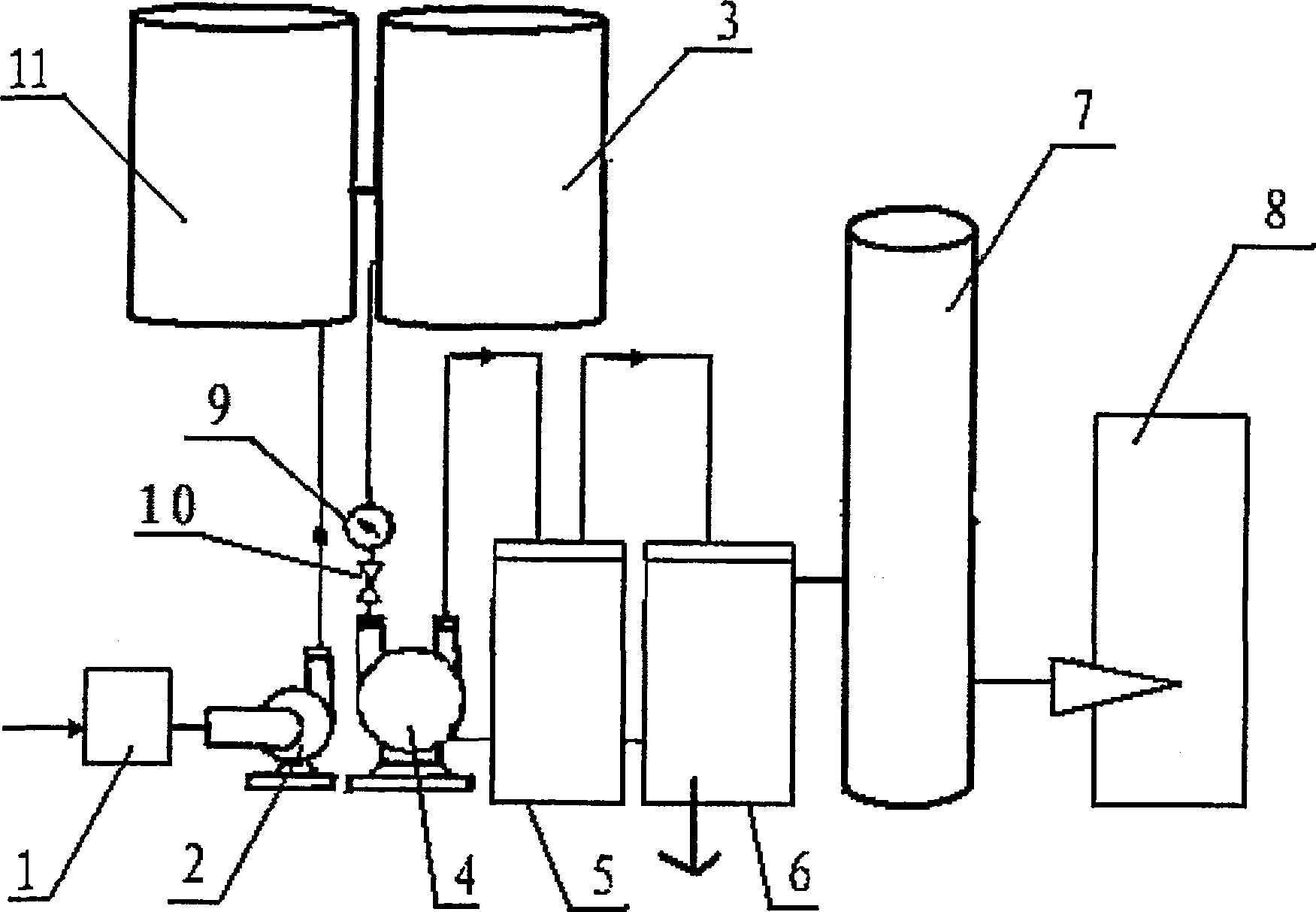

[0023] The device of the present invention is as figure 1 As shown, it includes filter device 1, blower 2, cooler 11, membrane module 3, air pump 4, separation device 5, nitrogen-rich tank 6, buffer tank 7 and oxygen-rich tank 8, filter device 1, blower 2, cooler 11. Membrane modules 3, air pumps 4, separation devices 5, nitrogen-enriched tanks 6, buffer tanks 7 and oxygen-enriched tanks 8 are connected through gas pipelines in sequence.

[0024] The filter device 1 is connected with the cooling machine of the sintering machine.

[0025] An air pressure gauge 9 and an air extraction valve 10 are provided between the membrane module 3 and the air extraction pump 4 .

[0026] The separation device 4 is a membrane oxygen-enriched separation device.

[0027] The nitrogen-enriched tank 5 is provided with a nitrogen outlet.

[0028] The oxygen-enriched tank 8 is connected with the hot air hood of the head of the sintering machine.

[0029] Utilize above-mentioned hot-air oxygen-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com