Preparation method of nuclear shell water-based polyurethane-acrylate composite emulsion adhesive for polyolefin film composition

An acrylate, core-shell water-based technology, applied in the direction of graft polymer adhesives, ester copolymer adhesives, hydrocarbon copolymer adhesives, etc., can solve the problem of reducing joint bonding strength and cohesive bonding performance Insufficient, poor adhesion and other problems, to achieve the effect of reducing VOC content, increasing cohesive energy, and increasing the degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

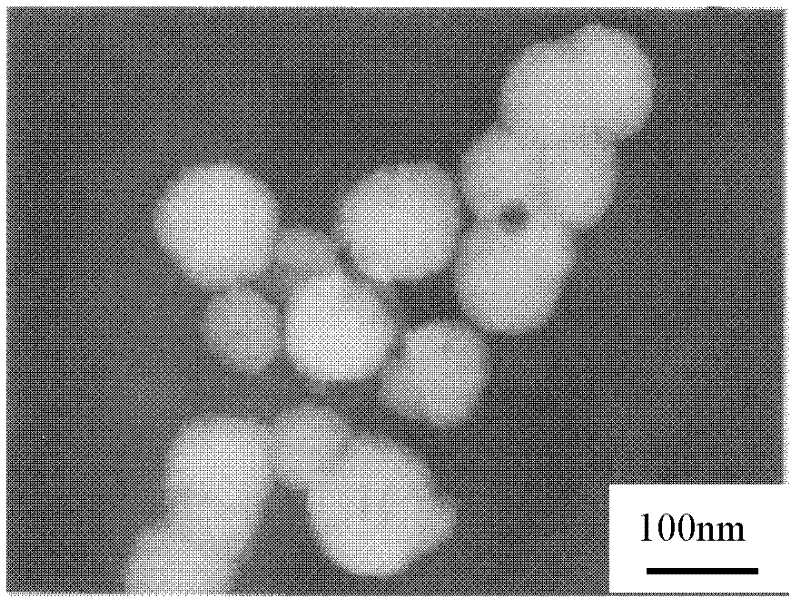

Image

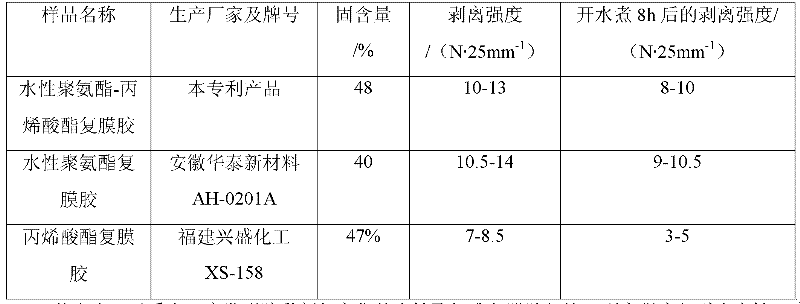

Examples

Embodiment 1

[0051] 1) Preparation of vinyl-terminated network polyurethane emulsion

[0052] Put 100 parts of PPG (molecular weight: 2000) into a three-necked flask, dehydrate in vacuum at 100°C for 2 hours; cool down to 80°C, add 3.01 parts of NPG, 1.53 parts of TMP and 59.3 parts of IPDI, and keep the temperature at 85°C for 3 hours; wait for the reaction liquid to cool to 75°C Then add 9.86 parts of DMPA and 10 parts of co-solvent NMP, and keep it warm for 2 hours at 80°C; after cooling down to 65°C, add 10.96 parts of HEMA and 0.1 part of DBTDL, and keep it warm for 1.5 hours; Then add 7.4 parts of TEA and stir for 5 minutes, and then add 370 parts of deionized water under high-speed stirring to disperse into an emulsion. After 10-15 minutes, slowly add 1.74 parts of hydrazine hydrate, 0.87 parts of DETA and 10 parts of deionized water to extend the chain, 50 Cake for 1 hour to obtain vinyl-terminated reticular polyurethane emulsion;

[0053] 2) Preparation of core layer polyurethane...

Embodiment 2

[0058] 1) Preparation of vinyl-terminated network polyurethane

[0059] Put 100 parts of PTMG (molecular weight: 2000) into a three-neck flask, dehydrate in vacuum at 100°C for 2 hours; cool down to 80°C, add 3.01 parts of NPG, 1.53 parts of TMP and 46.3 parts of TDI, keep the reaction at 85°C for 3 hours; add DMPA9 after cooling down to 75°C .86 parts and co-solvent NMP10 parts, 80 ℃ insulation reaction for 2 hours; after cooling down to 65 ℃, add 10.96 parts of HEMA and 0.15 parts of DBTDL, heat preservation reaction for 1.5 hours; after the reaction, cool down to 40 ℃, add 25 parts of BA to reduce viscosity, and then add TEA7 .4 parts were stirred for 5 minutes, then 370 parts of deionized water was added under high-speed stirring to disperse into an emulsion, and after 10-15 minutes, slowly added 4 parts of ADH, 0.87 parts of DETA and 10 parts of deionized water to extend the chain, and aged at 50°C for 1 hour. Promptly obtain the vinyl-terminated reticular polyurethane em...

Embodiment 3

[0065] 1) Preparation of vinyl-terminated network polyurethane

[0066] Put 100 parts of PCL (molecular weight: 2000) into a three-neck flask, dehydrate in vacuum at 100°C for 2 hours; add 3.01 parts of NPG, 1.53 parts of TMP and 59.1 parts of IPDI after cooling down to 80°C, and keep the reaction for 3 hours at 85°C; add DMPA9 after cooling down to 75°C .86 parts and 10 parts of co-solvent NMP, heat preservation reaction at 80°C for 2 hours; after cooling to 65°C, add 12 parts of HPMA and 0.15 parts of DBTDL, heat preservation reaction for 1.5 hours; after the reaction, cool down to 40°C, add 25 parts of BA to reduce viscosity, and then add TEA7 Stir 4 parts for 5 minutes, then add 370 parts of deionized water under high-speed stirring to disperse into an emulsion. After 10-15 minutes, slowly add 1.74 parts of hydrazine hydrate, 0.87 parts of DETA and 20 parts of deionized water to extend the chain, and mature at 50 ° C for 1 hour , That is, a vinyl-terminated network polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com