Thin layer paving material for wet road and bridge surface, and preparation method thereof

A pavement material, road and bridge deck technology, applied in the field of pavement pavement materials, can solve the problem of road and bridge deck moisture curing, water-resistant aging has not been studied, water-resistant aging, heat-resistant aging has not been studied, and pavement thin-layer pavement cannot be applied, etc. problems, to achieve the effects of low mechanical strength, improved curing reaction rate, and good resistance to boiling and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

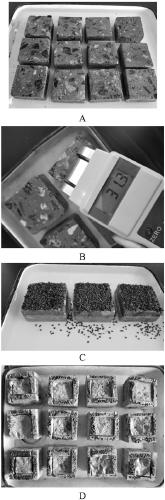

Image

Examples

Embodiment 1

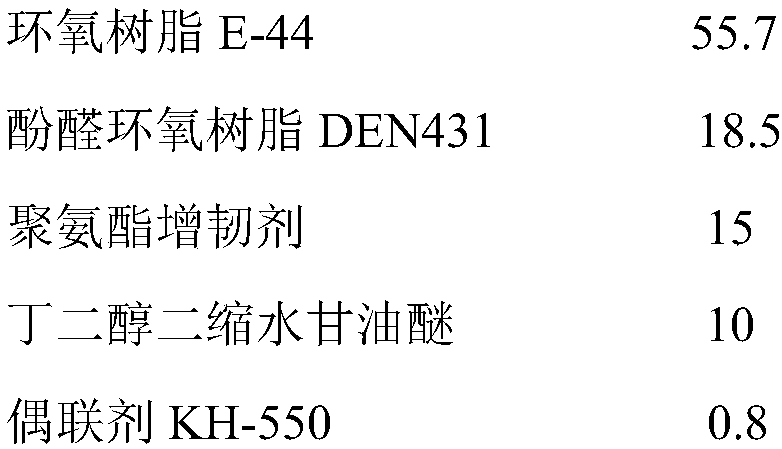

[0049] The thin-layer pavement material suitable for wet road and bridge decks provided in this embodiment includes epoxy resin binder and wear-resistant aggregate, wherein the epoxy resin binder includes A component and B component with a mass ratio of 1:0.5 Components, the specific dosage of each component is as follows:

[0050] Epoxy resin binder composition (mass parts):

[0051] A component:

[0052]

[0053] Wherein novolak epoxy resin DEN431 includes but not limited to available from Dow Chemical.

[0054] B component:

[0055] DMP-30 5

[0056] Phenalkamide Curing Agent 65

[0057] 4,4′-Diaminodiphenylmethane 30

[0058] The wear-resistant aggregate is ceramic aggregate, the Mohs hardness is greater than 7, and the dust content is less than 1wt%. The mass percentages of particles with different particle sizes are:

[0059] Particle size 1.18mm~2.36mm 5%

[0060] Particle size 2.36mm ~ 4.75mm 95%.

[0061] The preparation method of the thin-layer paving mate...

Embodiment 2

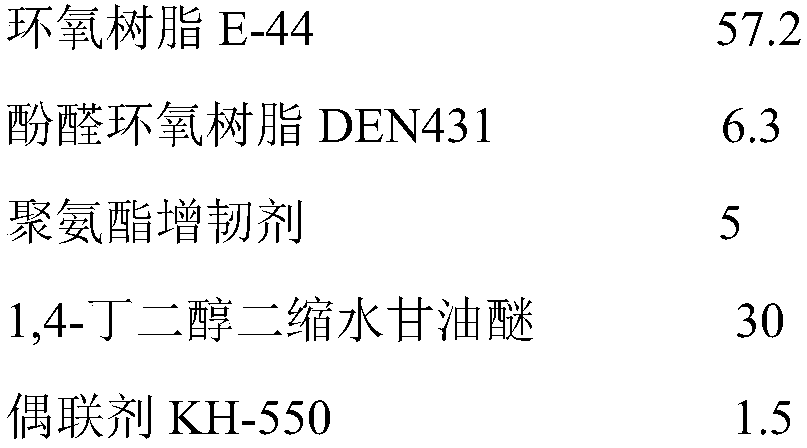

[0066] The thin-layer pavement material suitable for wet road and bridge decks provided in this embodiment includes epoxy resin binder and wear-resistant aggregate, wherein the epoxy resin binder includes A component and B component with a mass ratio of 1:0.65 Components, the specific dosage of each component is as follows:

[0067] Epoxy resin binder composition (mass parts):

[0068] A component:

[0069]

[0070] B component:

[0071] DMP-30 8

[0072] Phenalkamide Curing Agent 70

[0073] ZY1050 modified alicyclic amine 22

[0074] The wear-resistant aggregate is corundum, the Mohs hardness is greater than 7, and the dust content is less than 1wt%. The mass percentages of particles with different particle sizes are:

[0075] Particle size 1.18mm~2.36mm 35%

[0076] Particle size 2.36mm ~ 4.75mm 65%.

[0077] The preparation method of the thin-layer paving material suitable for wet road bridge decks is as follows:

[0078] (1) According to the above dosage relati...

Embodiment 3

[0082] The thin-layer pavement material suitable for wet road and bridge decks provided in this embodiment includes epoxy resin binder and wear-resistant aggregate, wherein the epoxy resin binder includes A component and B component with a mass ratio of 1:0.75 Components, the specific dosage of each component is as follows:

[0083] Epoxy resin binder composition (mass parts):

[0084] A component:

[0085]

[0086] B component:

[0087] DMP-30 6

[0088] Phenalkamide Curing Agent 80

[0089] ZY1050 modified cycloaliphatic amine 14

[0090] The ZY1050 modified alicyclic amine curing agent includes but is not limited to those purchased from Xuzhou Zhongyan Technology Industry Co., Ltd.

[0091] The wear-resistant aggregate is basalt, the Mohs hardness is greater than 7, and the dust content is less than 1wt%. The mass percentages of particles with different particle sizes are:

[0092] Particle size 1.18mm~2.36mm 20%

[0093] Particle size 2.36mm ~ 4.75mm 80%.

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com