Matte ultraviolet-curing coating composition used for PET (polyethylene terephthalate) metal-imitating wire drawing film

A technology for curing coatings and ultraviolet light, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc. The effect of uniform film, high matteness and excellent visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

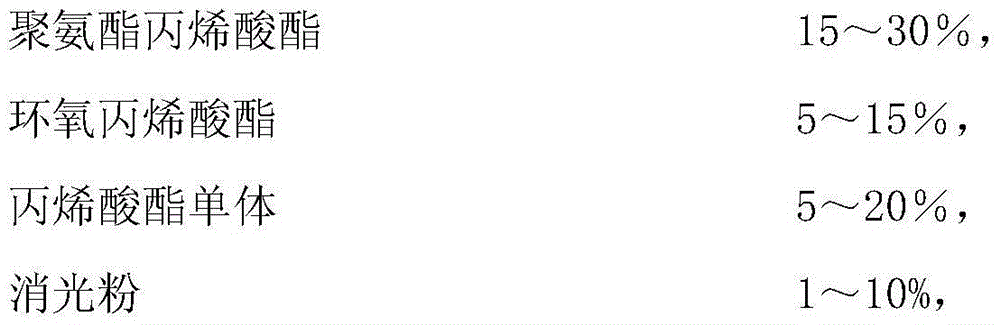

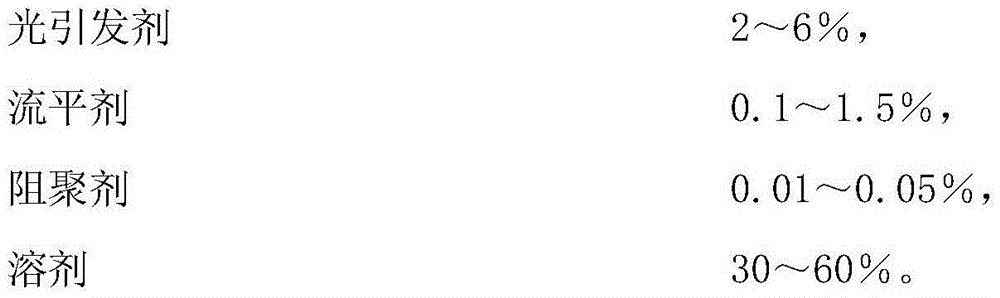

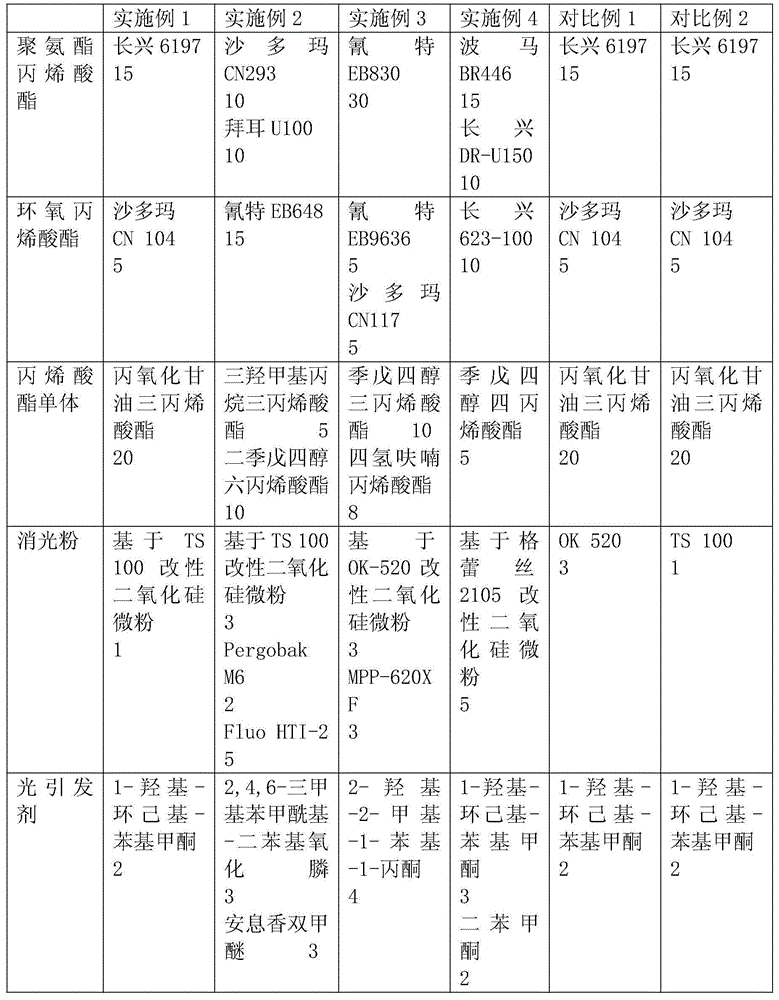

[0027] The UV-curable matte coating composition for PET imitation metal brushed film of this embodiment includes each component by weight shown in Table 1.

[0028] The coating composition is roll-coated on the PET film, and the coating dry weight is 3-5g / m 2 Between, 65 ℃ infrared leveling 1 ~ 2 minutes, through 500mj / cm 2 After the energy is cured, the adhesion fastness between the coating and the PET film is good (100 / 100), the temperature resistance exceeds 200°C, the load of 0# steel wool is 1000g, and it is wiped back and forth 200 times without trace, no cracks under cold and heat shock, and it is resistant to boiling water for 2 There is no change in hours, and there is no trace on the surface of 10% hydrochloric acid erosion for 72 hours, and the comprehensive performance is excellent.

Embodiment 2

[0030] The UV-curable matte coating composition for PET imitation metal brushed film of this embodiment includes each component by weight shown in Table 1.

[0031] Apply the coating roller to the PET film, the coating dry weight is 3~5g / m 2 Between, 65 ℃ infrared leveling 1 ~ 2 minutes, through 500mj / cm 2 After the energy is cured, the adhesion fastness between the coating and the PET film is good (100 / 100), the temperature resistance exceeds 200°C, the load of 0# steel wool is 1000g, and it is wiped back and forth 200 times without trace, no cracks under cold and heat shock, and it is resistant to boiling water for 2 There is no change in hours, and it is resistant to 10% sodium hydroxide solution for 48 hours to maintain good adhesion and excellent comprehensive performance.

Embodiment 3

[0033] The UV-curable matte coating composition for PET imitation metal brushed film of this embodiment includes each component by weight shown in Table 1.

[0034] Apply the coating roller to the PET film, the coating dry weight is 3~5g / m 2 Between, 65 ℃ infrared leveling 1 ~ 2 minutes, through 500mj / cm 2 After the energy is cured, the adhesion fastness between the coating and the PET film is good (100 / 100), the temperature resistance exceeds 200°C, the load of 0# steel wool is 1000g and wiped back and forth 100 times without trace, no cracks under cold and heat shock, and it is resistant to boiling water for 2 No change in hours, 10% hydrochloric acid resistance, 10% sodium hydroxide solution corrosion resistance for 48 hours to maintain good adhesion, excellent comprehensive performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com