Polyester resin used for beta-hydroxyl alkyl amide solidified powdery paint having good water resistance and preparation method thereof

A hydroxyalkylamide, powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problem of poor water resistance and boiling resistance of the coating film, affecting the surface decoration performance of the coating film, and affecting the durable protection of the coating film. performance and other issues, to achieve the effect of improving flexibility, excellent decorative performance and protective performance, and improving impact resistance and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0036] The concrete synthesis process is: (1) in the 5000ml reactor that is equipped with heating device, stirrer and distillation column, the mass number that adds formula quantity is 1665 parts of polyol component A (wherein 1665 parts are neopentyl glycol ), the normal pressure is heated up to 110-130 ℃; the mass fraction of adding formula quantity again is 2575 parts of polyacid component B (wherein 2200 parts are terephthalic acid, 300 parts are isophthalic acid and 75 parts are adipic acid acid) and 5 parts by mass of esterification catalyst component D (wherein 5 parts of monobutyltin oxide), gradually warming up while stirring. (2) The temperature of the material rises to 165-175°C, the esterification reaction begins, and the esterification water begins to be generated and steamed out through the distillation column. The steam temperature at the top of the distillation column is controlled at 99°C ± 2°C; Esterification water is distilled out, and when the temperature o...

Embodiment B

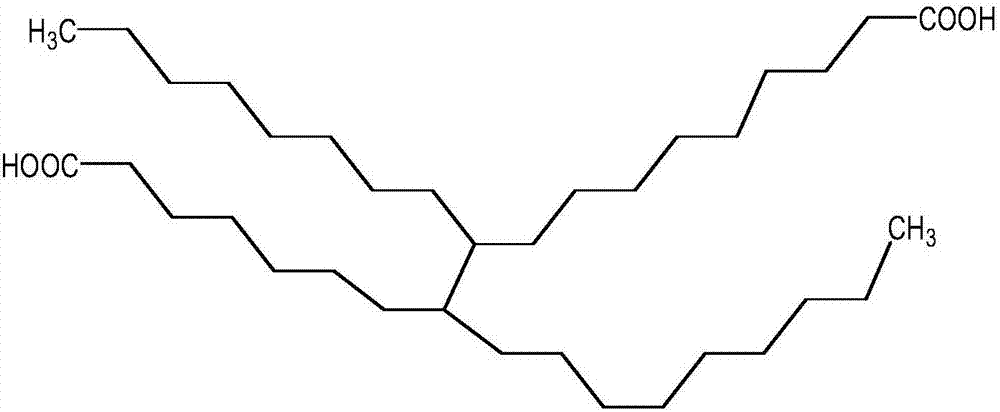

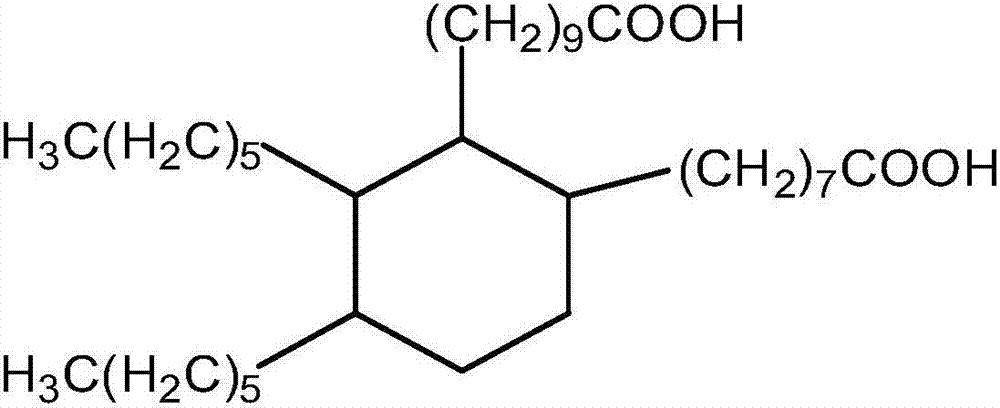

[0038] The specific synthesis process is: (1) in a 5000ml reactor equipped with a heating device, a stirrer and a distillation column, the polyol component A (wherein 1512 parts are neopentyl glycol) in which the mass parts of the formula amount are 1612 parts , 100 parts are 2-methyl-1,3-propanediol), normal pressure is heated up to 110-130 ℃; Add the polyacid component B (wherein 2200 parts are terephthalic acid components) in the mass parts of 2500 parts Formic acid, 300 parts is isophthalic acid), mass parts are 90 parts of hydrogenated dimer acid component C (wherein 90 parts are hydrogenated dimer soybean oil fatty acid) and mass parts are 5 parts of esterification catalyst component D (wherein 5 parts are monobutyltin oxide), gradually heat up while stirring. (2) The temperature of the material rises to 165-175°C, the esterification reaction begins, and the esterification water begins to be generated and steamed out through the distillation column. The steam temperature...

Embodiment C

[0040] The specific synthesis process is: (1) in a 5000ml reactor equipped with a heating device, a stirrer and a distillation column, the polyol component A (wherein 1540 parts are neopentyl glycol) is added with a formula quantity of 1620 parts by mass , 80 parts are 2-butyl-2-ethyl-1,3-propanediol), and the temperature is raised to 110-130 °C under normal pressure; then the mass parts of the formulation amount are 2440 parts of polyacid component B (wherein 2200 part is terephthalic acid, 240 parts are isophthalic acid), mass parts are 100 parts of hydrogenated dimer acid component C (wherein 50 parts are hydrogenated dimerized tall oil fatty acid, 50 parts are hydrogenated dimerized vegetable Seed oil fat number) and mass parts are 5 parts of esterification catalyst component D (wherein 4 parts are monobutyl tin oxide, 1 part is stannous oxalate), while stirring, gradually heat up. (2) The temperature of the material rises to 165-175°C, the esterification reaction begins, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl equivalent | aaaaa | aaaaa |

| Melting range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com