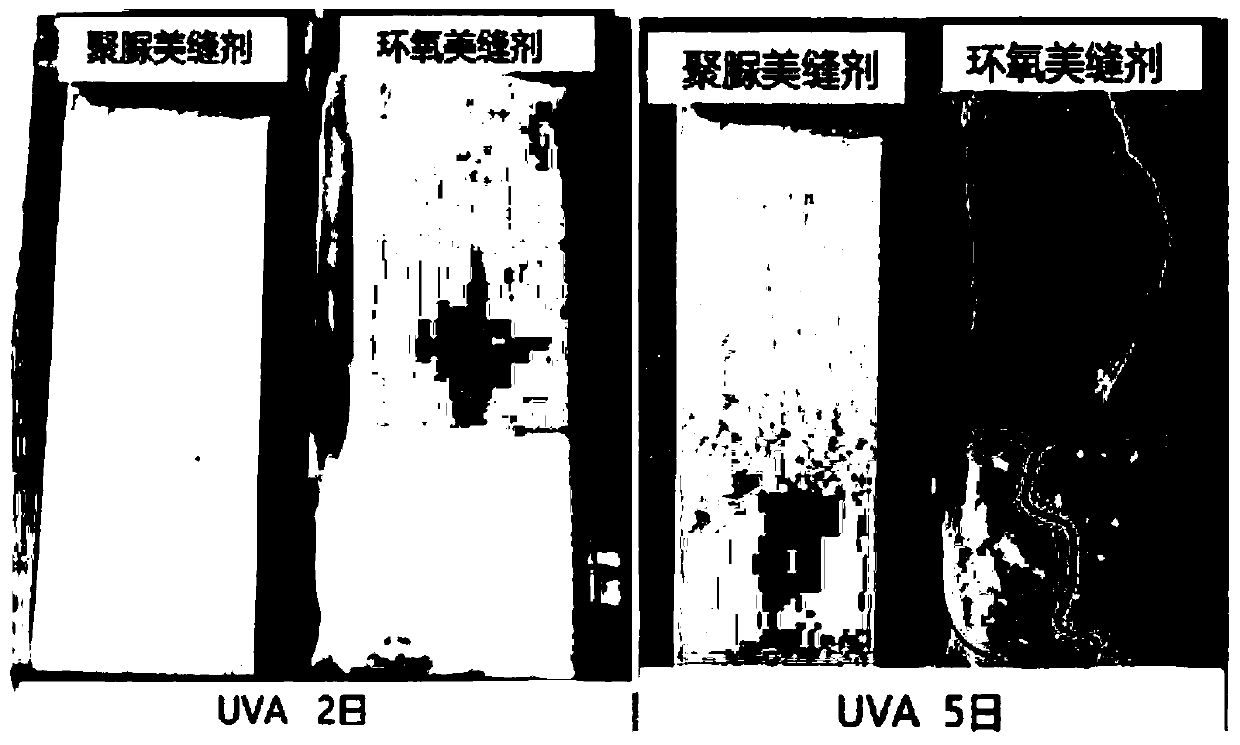

Seam beautifying agent

A technology of beautifying agent and curing agent, applied in the field of beautifying agent, can solve the problems of poor UV resistance of aromatic ring structure, poor resistance to yellowing, stripping and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

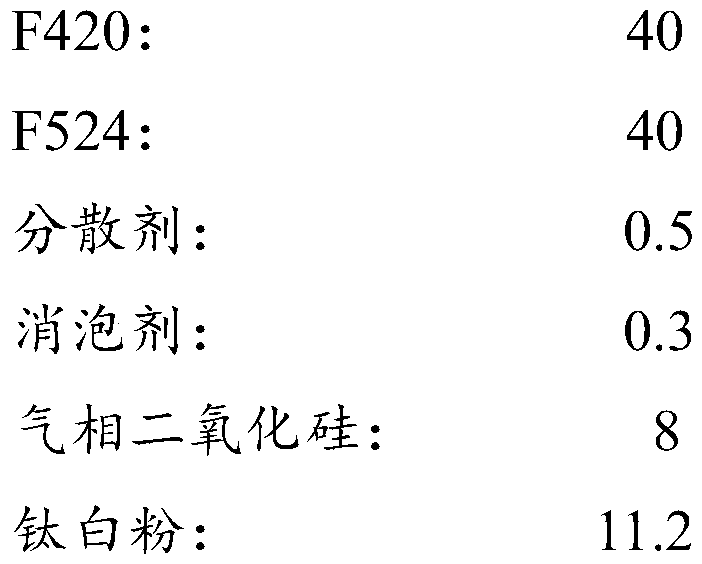

[0051] A kind of seam agent: comprising the following parts by weight component A:

[0052]

[0053] The following parts by weight component B:

[0054]

[0055] Wherein: the prepolymer is made from 7g of HDI, 33g of HMDI, and 60g of polyhydroxyisoprene adipate (molecular weight: 2000, hydroxyl value: 56mgKOH / g), and the NCO% in the prepolymer: 11.5.

Embodiment 2

[0057] Beauty seam agent: including the following parts by weight component A:

[0058]

[0059]

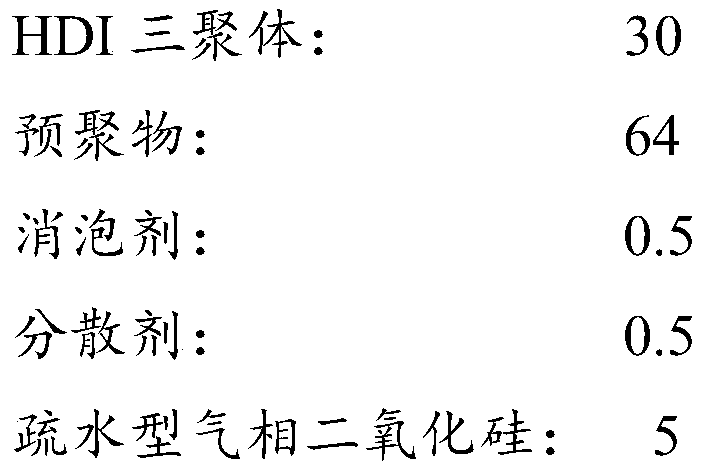

[0060] The following parts by weight component B:

[0061]

[0062] Wherein: the prepolymer is composed of 7g of HDI, 35g of HMDI, and 58g of poly-terminated hydroxymethylpropanediol adipate (molecular weight: 1000, hydroxyl value: 112mgKOH / g); NCO% in the prepolymer: 11.8.

Embodiment 3

[0064] Beauty seam agent: including the following parts by weight component A:

[0065]

[0066] Following parts by weight component B:

[0067]

[0068] Wherein: the prepolymer is composed of 9g of HDI, 38g of HMDI, and 58g of poly-terminated hydroxymethylpropanediol adipate (molecular weight: 1000, hydroxyl value: 112mgKOH / g); NCO% in the prepolymer: 12.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com