Polyolefin packaging adhesive film, preparation method thereof and application thereof

A technology for encapsulating adhesive films and polyolefins, applied in the direction of adhesives, grafted polymer adhesives, film/sheet adhesives, etc., can solve the problem of unsuitable use between cell components and front glass, and reduce crystallization The degree of perfection, unfavorable component recycling and other issues, to achieve excellent optical properties and adhesive properties, excellent thermomechanical properties, and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

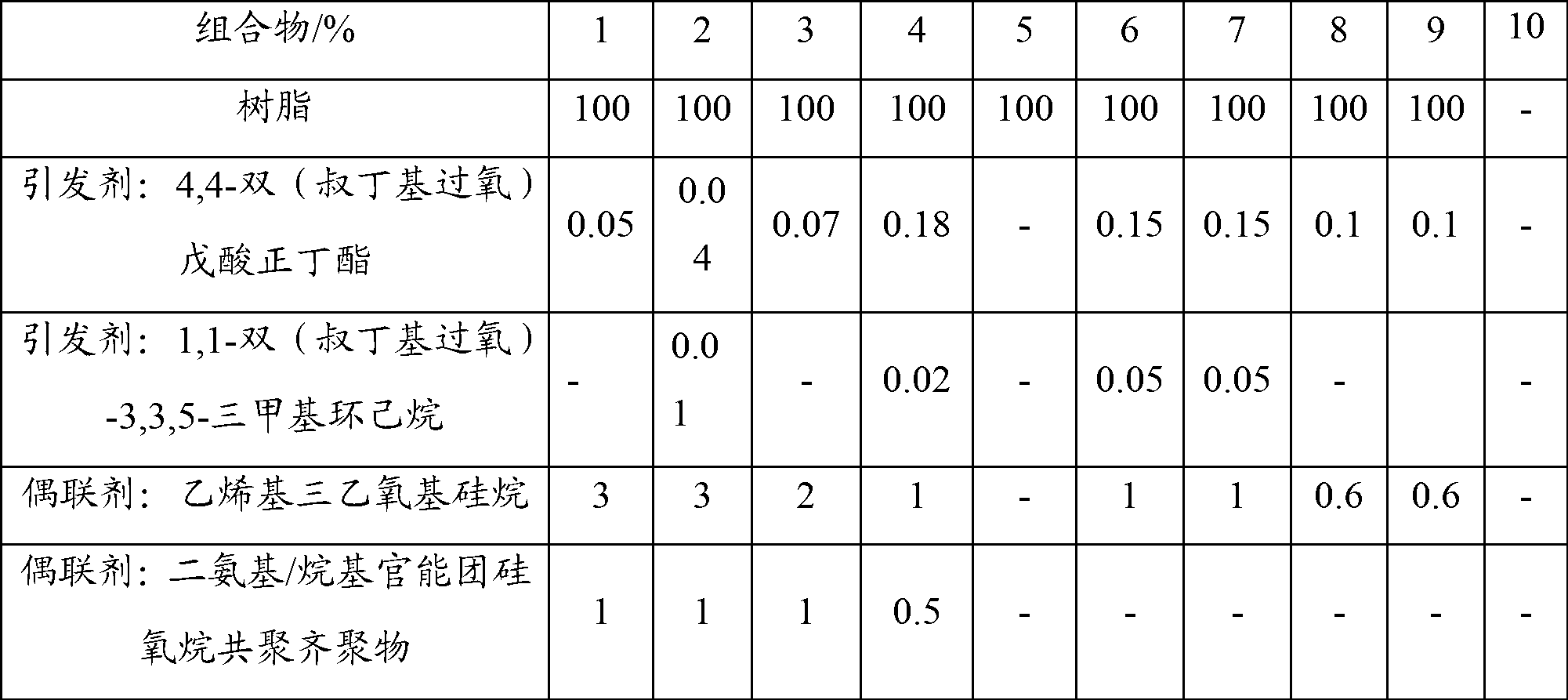

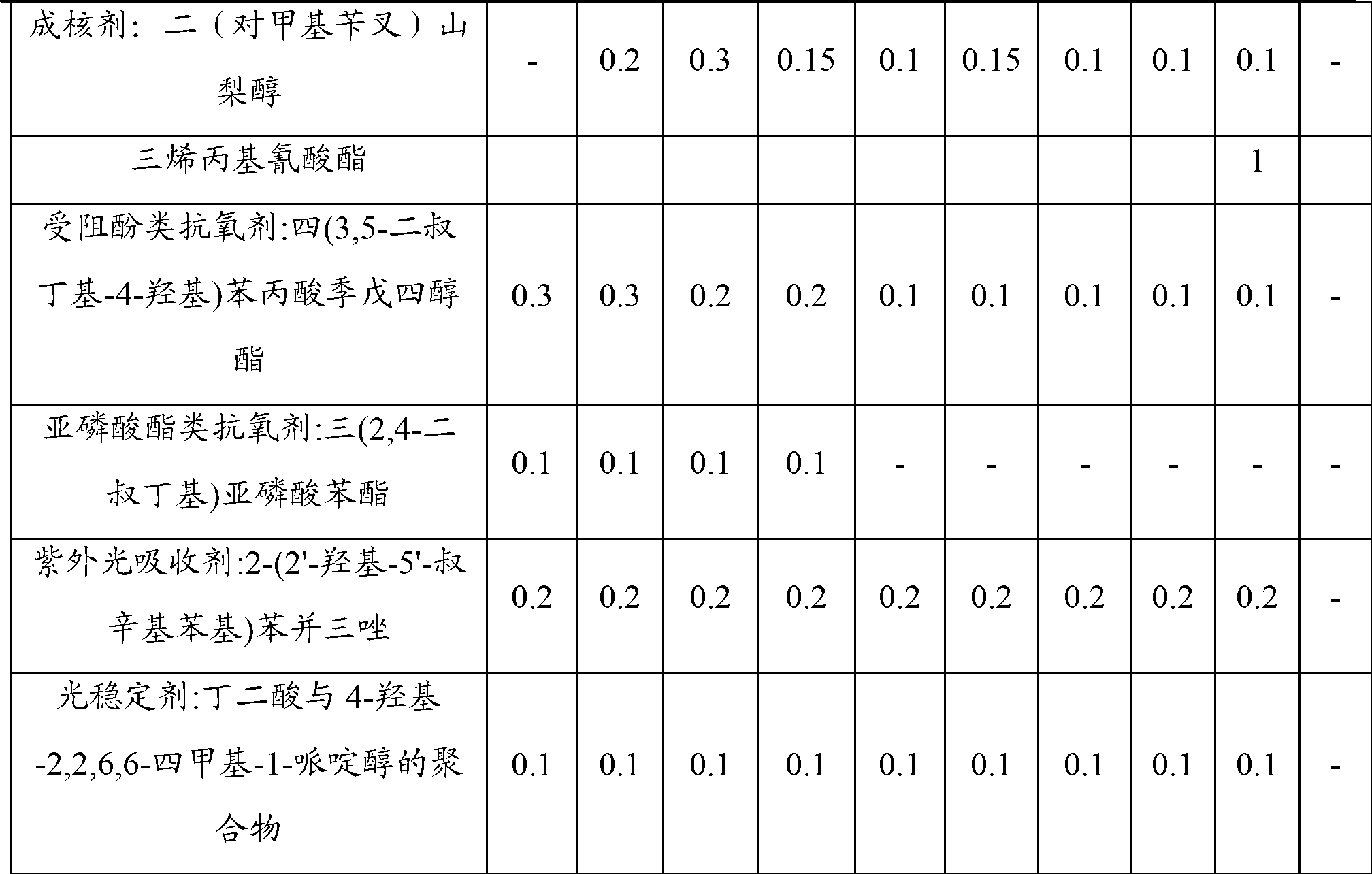

[0047] The present invention will be further described below in conjunction with the examples.

[0048] The polyolefin (A) is a metallocene α-olefin PE produced by Sumitomo Chemical Company, with a trade name of Excellen GMH GH030;

[0049] Polypropylene (B) is isotactic PP produced by Sinopec Co., Ltd., with a trade name of T30S;

[0050] The ethylene-alpha olefin copolymer is the amorphous polyolefin APAO produced by Evonik, trade name (C), or polyolefin elastomer POP produced by VESTOPLAST and DOW, trade name PF (D); or polyolefin elastomer POE produced by DOW, trade name One or a combination of two of (E);

[0051] Polyolefin Y is the ethylene butyl acrylate copolymer produced by Dupont Company, trade name AC (F) or / and the silicone-grafted polyolefin (G) of the present invention.

[0052] Polymer Z is SBS produced by Kraton, trade name TR2002 (H);

[0053] EVA: EV1050G1 packaging film produced by Guangzhou Lushan New Materials Co., Ltd.

[0054] In order to com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com