Weatherability type polyformaldehyde material and its preparation method

A polyoxymethylene material, weather-resistant technology, applied in the field of weather-resistant polyoxymethylene material and its preparation, can solve the problems of artificial accelerated weather aging test, ultraviolet light aging test, thermal oxygen aging test and hot water aging test, etc., to achieve easy The effect of industrial production, simple manufacturing method, and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

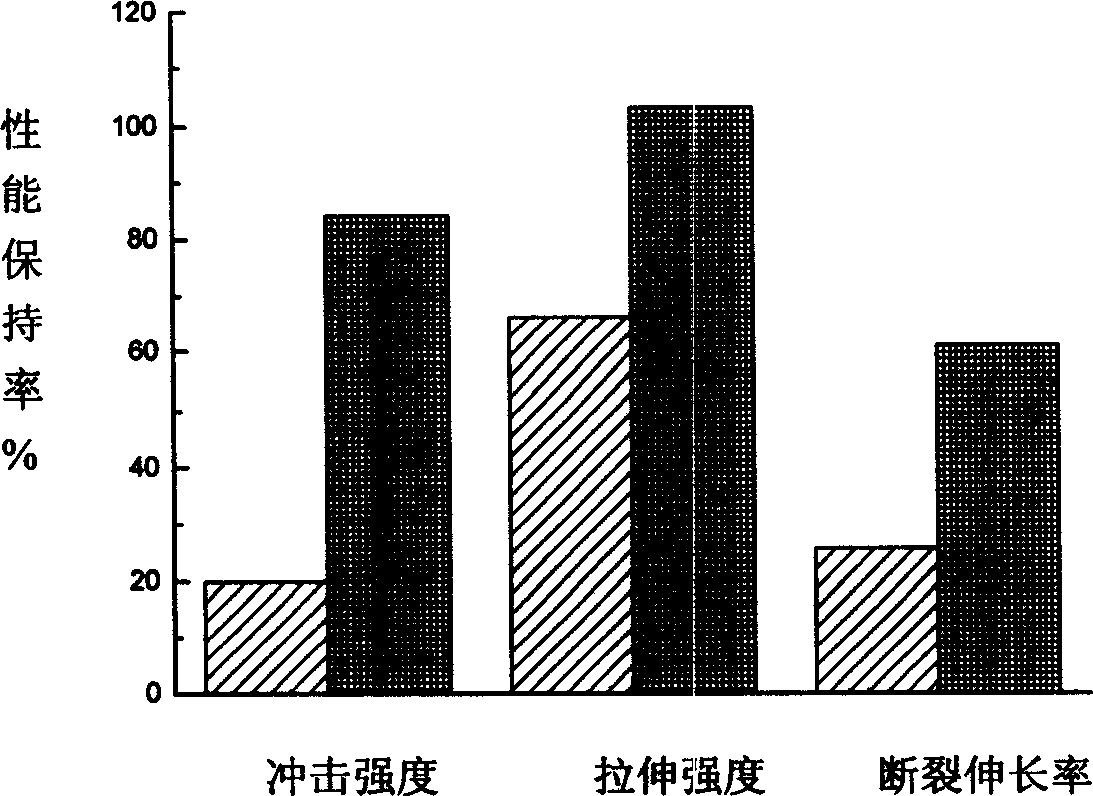

Embodiment 1

[0036] Add 1000 g of polyoxymethylene to 10 g of liquid paraffin, mix well, then add 3 g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, dilauryl thiodipropionate 1.5g, 2-(2'-hydroxy-3',5'-di-tert-butylphenyl)-5-chlorobenzotriazole 0.5g, succinic acid and 4-hydroxy-2,2,6, 0.5g of 6-tetramethyl-1-piperidinol polymer, fully stirred and mixed evenly, then placed in a twin-screw extruder, melted, blended and extruded at a temperature of 140-220°C, and then pelletized by a pelletizer , to obtain a weather-resistant polyoxymethylene material, which is injection molded at a temperature of 170-190°C.

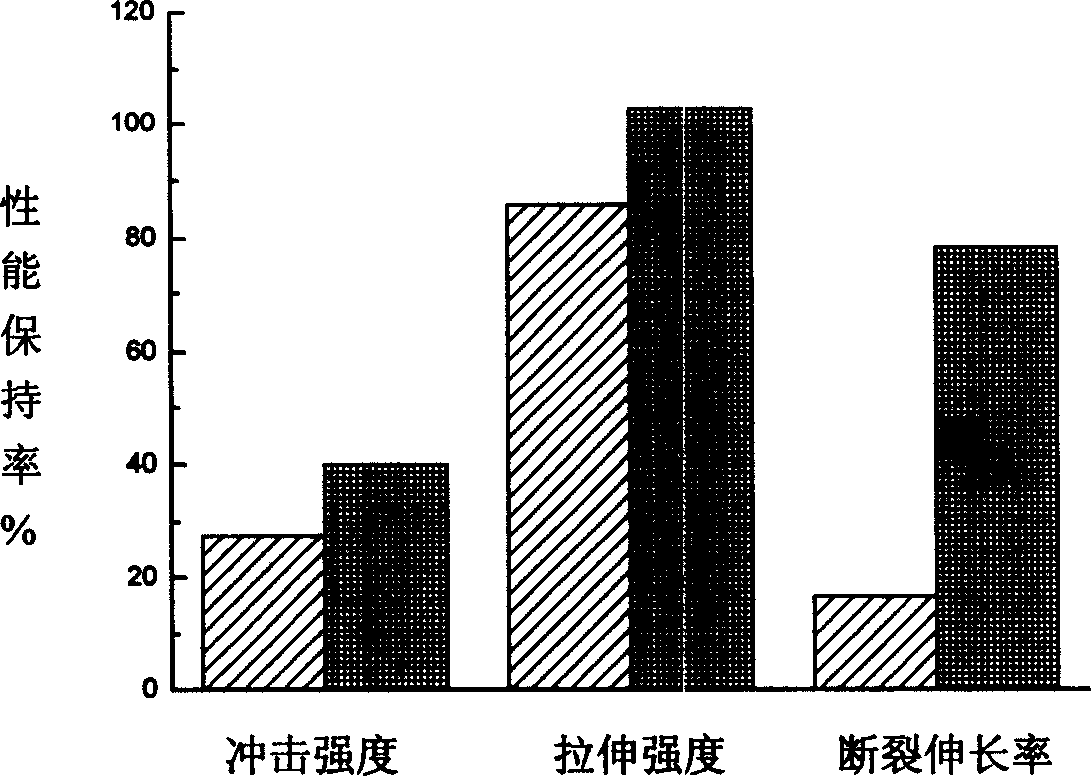

Embodiment 2

[0038] Add 1000 g of polyoxymethylene to 10 g of liquid paraffin, mix well, then add 30 g of nano-zinc oxide, 3 g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, dithiodi Dilauryl propionate 1.5g, 2-(2'-hydroxy-3',5'-di-tert-butylphenyl)-5-chlorobenzotriazole 0.5g, succinic acid and 4-hydroxy-2 , 0.5g of the polymer of 2,6,6-tetramethyl-1-piperidinol, fully stirred and mixed evenly, then placed in a twin-screw extruder, melted and blended at a temperature of 150-210°C, and then The weather-resistant polyoxymethylene material is obtained by cutting pellets with a pelletizer, and injection molding is performed at a temperature of 170-200°C.

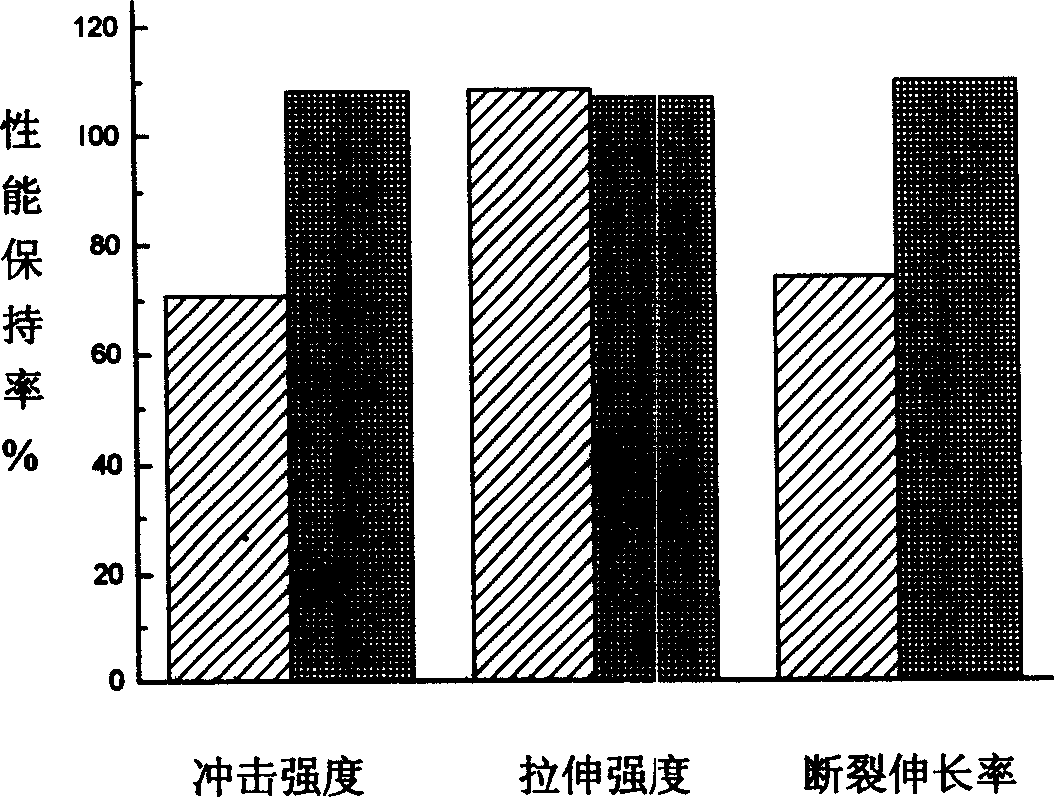

Embodiment 3

[0040] Add 1000 g of polyoxymethylene to 20 grams of liquid paraffin, mix well, then add tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 3 g, dilauryl thiodipropionate 1.5g, 2-(2'-hydroxy-3',5'-di-tert-butylphenyl)-5-chlorobenzotriazole 0.5g, stir well and mix well, then place in twin-screw extruder , melt blending and extrusion at a temperature of 140-210°C, and then pelletized by a pelletizer to obtain a weather-resistant polyoxymethylene material, which is injection-molded at a temperature of 170-200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com