Hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt, pressure-sensitive adhesive technology, used in adhesives, adhesive types, mineral oil-hydrocarbon copolymer adhesives, etc. Poor performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

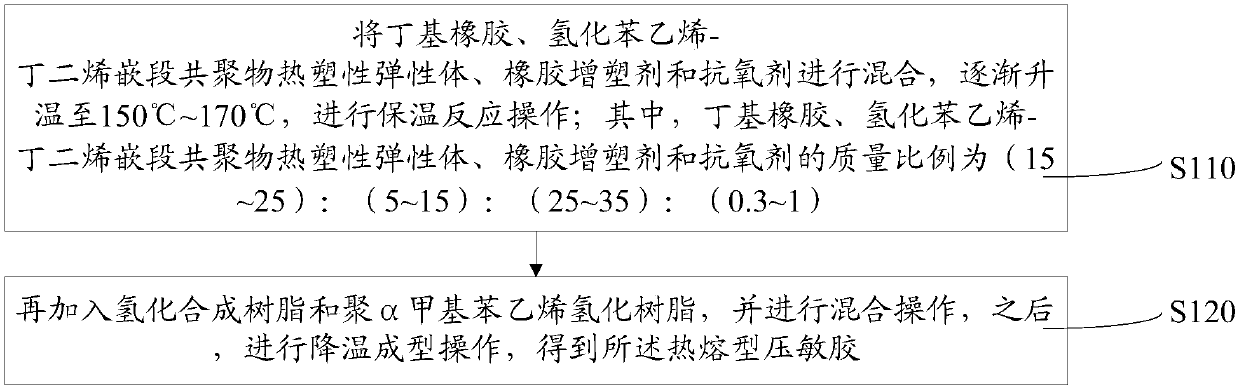

[0025] see figure 1 , the preparation method of hot-melt pressure-sensitive adhesive in one embodiment, comprises the steps:

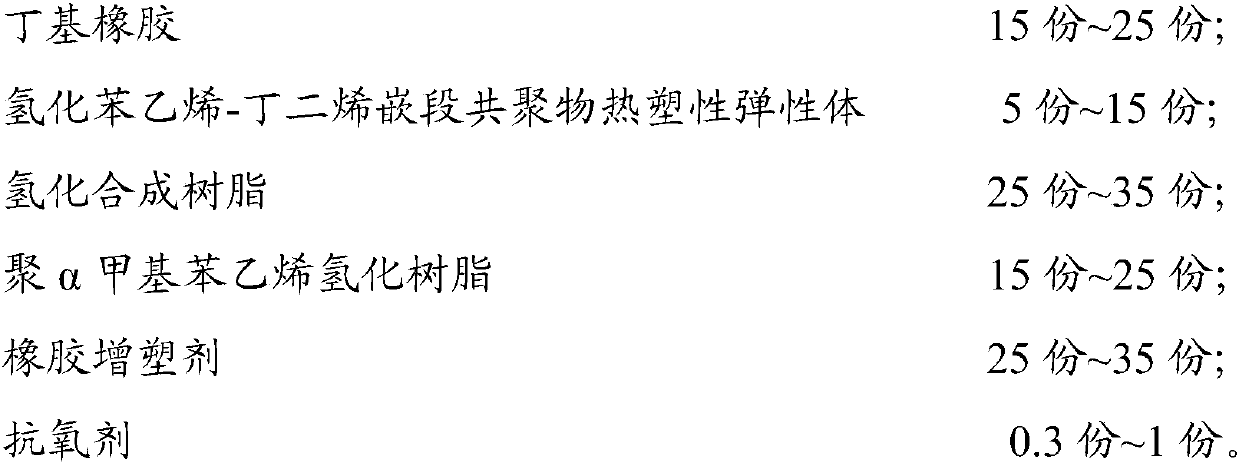

[0026] S110: Mix butyl rubber, hydrogenated styrene-butadiene block copolymer thermoplastic elastomer, rubber plasticizer and antioxidant, gradually raise the temperature to 150°C-170°C, and carry out heat preservation reaction operation; wherein, butyl The mass ratio of base rubber, hydrogenated styrene-butadiene block copolymer thermoplastic elastomer, rubber plasticizer and antioxidant is (15~25):(5~15):(25~35):(0.3 ~1).

[0027] Through the step S110, the butyl rubber, the hydrogenated styrene-butadiene block copolymer thermoplastic elastomer, the rubber plasticizer and the antioxidant can be better mixed, which is more conducive to mixing with subsequent raw materials.

[0028] S120: adding hydrogenated synthetic resin and poly-α-methylstyrene hydrogenated resin, and performing mixing operation, and then performing cooling molding operation to o...

Embodiment 1

[0034] Add 2kg of butyl rubber, 1kg of SEBS (hydrogenated styrene-butadiene block copolymer), 3.5kg of rubber plasticizer and antioxidant into the kneader according to the required ratio; then, slowly heat to 150-170 ℃, stir until all the materials are melted, and the reaction is stable for 5-20 minutes; then, under stirring, add 2.5kg of hydrogenated synthetic resin and 2.5kg of poly-α-methylstyrene hydrogenated resin according to the required ratio, and stir for 45-60 minutes ; Finally, cooling molding treatment, that is, to obtain the required self-adhesive film waterproof membrane hot-melt pressure-sensitive adhesive.

[0035] Wherein, the butyl rubber unsaturation (% / mol) is 1%, Mooney viscosity (ML 1+8 , 125°C) is 45; the styrene block content of the hydrogenated styrene-butadiene block copolymer thermoplastic elastomer is 20%; the average molecular weight of the liquid polyisobutylene rubber is 500.

Embodiment 2

[0037] Add butyl rubber 2.5kg, SEBS (hydrogenated styrene-butadiene block copolymer) 1.2kg, rubber plasticizer 3.2kg and antioxidant into the kneader according to the required ratio; then, slowly heat to 150 ~170°C, stir until all the materials are melted, and the reaction is stable for 5-20 minutes; then, under stirring, add 3.5kg of hydrogenated synthetic resin and 2.5kg of poly-α-methylstyrene hydrogenated resin according to the required ratio, and stir for a constant 45- 60 minutes; finally, cooling molding treatment, that is, to obtain the required self-adhesive film waterproof membrane hot-melt pressure-sensitive adhesive.

[0038] Wherein, the butyl rubber unsaturation (% / mol) is 1%, Mooney viscosity (ML 1+8 , 125°C) is 45; the styrene block content of the hydrogenated styrene-butadiene block copolymer thermoplastic elastomer is 20%; the average molecular weight of the liquid polyisobutylene rubber is 500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com