Ageing resistant type solar photovoltaic component sealing material and preparation method thereof

A solar photovoltaic and sealing material technology, which is applied in the field of room temperature vulcanized silicone sealing materials and its preparation, can solve the problems of no specific investigation on the UV aging resistance of sealants, and achieve excellent UV aging resistance, simple process, and strong adhesion Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

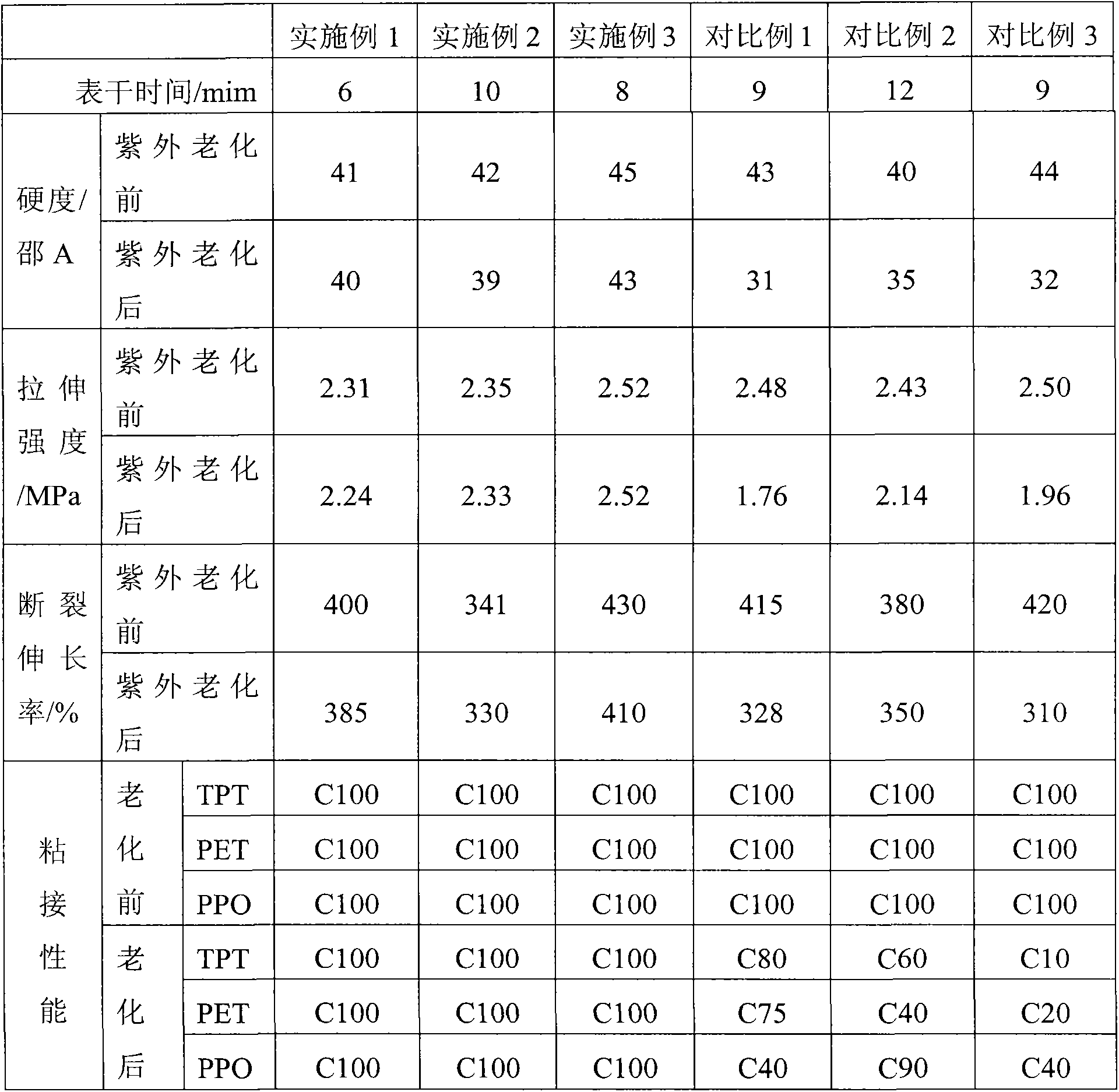

Examples

Embodiment 1

[0038] Use hydroxyl-terminated polydimethylsiloxane with a viscosity of 10000mPa·s and dimethyl silicone oil with a viscosity of 350mPa·s, the components of which are as follows:

[0039] components

Dosage

Hydroxy-terminated polydimethylsiloxane

100

8

70

Aluminum oxide

20

5

2

2-Hydroxy-4-n-octyloxybenzophenone

2

Light Stabilizer 770

8

Methyltributanoximinosilane

3

Vinyl tributylketoxime silane

7

γ-Glycidyl etheroxypropyl trimethoxysilane

1

γ-Aminopropyltrimethoxysilane

1

0.2

[0040] First disperse 2-hydroxy-4-n-octyloxybenzophenone and light stabilizer 770 in an appropriate amount of hydroxyl-terminated polydimethylsiloxane according to the ratio, and vacuum treat it in a kneader at 80-120°C for 1 After ~2 hours, the temperature was lowered ...

Embodiment 2

[0043] The selected viscosity is hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000mPa·s, and dimethyl silicone oil with a viscosity of 1000mPa·s, and its components are as follows:

[0044] components

[0045] According to the method described in the above-mentioned Example 1, an aging-resistant solar photovoltaic module sealing material was prepared.

Embodiment 3

[0047] The selected viscosity is hydroxyl-terminated polydimethylsiloxane with a viscosity of 80000mPa·s, and dimethyl silicone oil with a viscosity of 350mPa·s, and its components are as follows:

[0048] components

[0049] Silazane

[0050]According to the method described in the above-mentioned embodiment 1, an aging-resistant sealing material for solar photovoltaic modules was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com