Polyolefin packaging adhesive film for photovoltaic module

A technology for encapsulating film and photovoltaic modules, applied in photovoltaic power generation, adhesives, electrical components, etc., can solve problems such as poor thermal creep resistance, and achieve the best resistance to heat and humidity aging, UV aging, and optical performance. The effect of adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

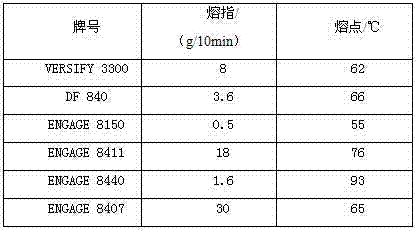

Examples

Embodiment 1

[0048] DF 840 90g

[0049] ENGAGE 8150 10g

[0050] LUPEROX 101 0.2g

[0051] z-6300 0.7g

[0052] CHIGUARD BP-12 0.3g

[0053] CHIGUARD 101 0.2g

[0054] DEOX 1035 0.2g

[0055] Mix the raw materials evenly in the mixer according to the above ratio. After the additives are completely absorbed and wrapped by polyolefin, they are added to the single-screw extruder, and the extruded product is cast, cooled, drawn, and crimped. Polyolefin film can be obtained.

[0056] The polyolefin film was tested, and the test results are listed in Table 1.

Embodiment 2

[0058] DF 840 75g

[0059] ENGAGE 8150 20g

[0060] VERSIFY 3300 5g

[0061] LUPEROX TBEC 0.1g

[0062] LUPEROX 101 0.2g

[0063] z-6030 0.5g

[0064] z-6300 0.5g

[0065] CHIGUARD BP-12 0.3g

[0066] DEOX 1035 0.2g

[0067] Mix the raw materials evenly in the mixer according to the above ratio. After the additives are completely absorbed and wrapped by polyolefin, they are added to the single-screw extruder, and the extruded product is cast, cooled, drawn, and crimped. Polyolefin film can be obtained.

[0068] The polyolefin film was tested, and the test results are listed in Table 1.

Embodiment 3

[0070] DF 840 80g

[0071] ENGAGE 8440 20g

[0072] LUPEROX 101 0.4g

[0073] z-6030 0.5g

[0074] DEOX 1035 0.1g

[0075] Mix the raw materials evenly in the mixer according to the above ratio. After the additives are completely absorbed and wrapped by polyolefin, they are added to the single-screw extruder, and the extruded product is cast, cooled, drawn, and crimped. Polyolefin film can be obtained.

[0076] The polyolefin film was tested, and the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com