Butyl hot melt adhesive and preparation method thereof

A technology of butyl hot melt adhesive and butyl rubber, applied in the direction of adhesive, adhesive type, mineral oil hydrocarbon copolymer adhesive, etc., can solve the problems of substandard mechanical properties, low bonding strength, glass falling off, etc. , to achieve the effect of good UV aging resistance, excellent UV resistance and excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

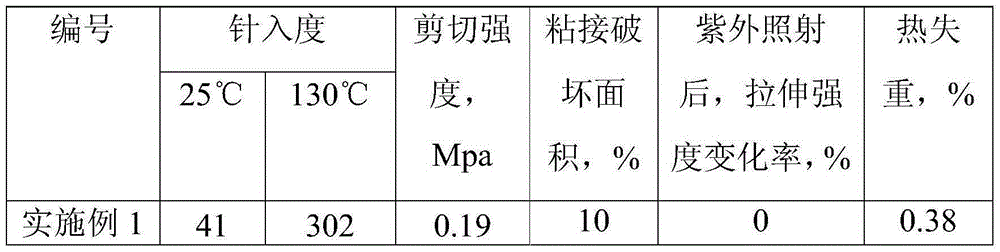

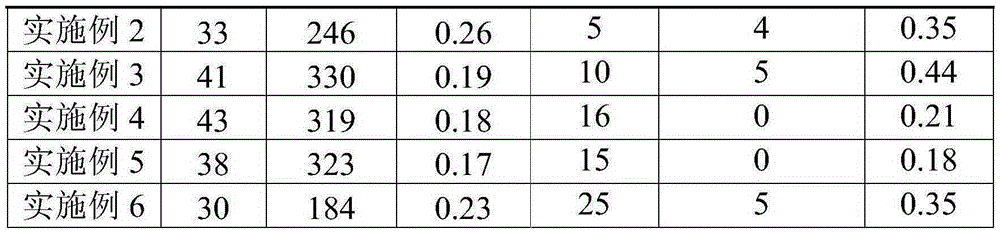

Examples

Embodiment 1

[0043] Add 210 parts by weight of polyisobutylene with a molecular weight of 50,000, 420 parts by weight of polyisobutylene with a molecular weight of 90,000, 100 parts by weight of butyl rubber with a molecular weight of 200,000, 45 parts by weight of C9 petroleum resin, and 25 parts by weight of C5 petroleum resin into the kneader Add 240 parts by weight of carbon black, 230 parts by weight of calcium, 263 parts by weight of clay, 3.15 parts by weight of zinc stearate, 3.15 parts by weight of calcium stearate, and 1 part by weight of antioxidant. 1010, vacuum and stir for 1 hour, then add 42 parts by weight of polyisobutylene with a molecular weight of 1000, vacuum and stir for 0.5 hours, then discharge.

Embodiment 2

[0045] Add 310 parts by weight of polyisobutylene with a molecular weight of 50,000, 220 parts by weight of polyisobutylene with a molecular weight of 90,000, 100 parts by weight of butyl rubber with a molecular weight of 280,000, 38 parts by weight of C5 petroleum resin, and 15 parts by weight of terpene resin into the kneader. , Heat and stir, warm up to 130°C, then add 252 parts by weight of carbon black, 316 parts by weight of calcium, 263 parts by weight of clay, 0.5 parts by weight of antioxidant 1010, 2 parts by weight of zinc stearate, 2 parts by weight of calcium stearate , Vacuum and stir for 1.5 hours, then add 42 parts by weight of polyisobutylene with molecular weight of 1300, vacuum and stir for 1 hour, then discharge.

Embodiment 3

[0047] A mixture of 210 parts by weight of 50,000 molecular weight polyisobutylene, 320 parts by weight of 90000 molecular weight polyisobutylene, 100 parts by weight of butyl rubber, 65 parts by weight of C5 resin, 15 parts of polyolefin resin, and 27 parts of terpene resin was added to the kneader Add 150 parts by weight of carbon black, 230 parts by weight of calcium, 160 clay, 3.15 parts by weight of zinc stearate, 3.15 parts by weight of calcium stearate, and then add 2 parts by weight of antioxidant 168,3 parts by weight of antioxidant 264, vacuum and stir for 2 hours, then add 80 parts by weight of polyisobutylene with a molecular weight of 1000, vacuum and stir for 0.5 hours before discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com