Bicomponent carbamide polyaspartate hard adhesive and use method and application thereof

A kind of aspartic acid ester, two-component technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of strict construction requirements, poor construction performance, low construction efficiency, etc., and achieve good UV aging resistance, resistance to sunlight, and the effect of firm bonding of aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

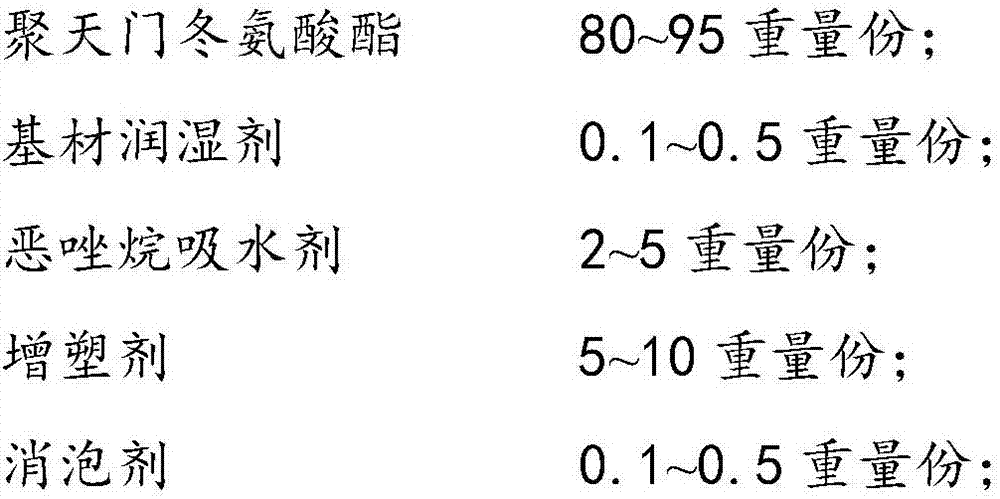

[0024] Example 1 This example discloses a two-component polyaspartate urea rigid adhesive, the adhesive components are as follows:

[0025] A component formula:

[0026] 90.2 parts by weight of N,N'-(methylene di-4,1-cyclohexanediyl) diaspartic acid tetraethyl ester;

[0027]

[0028]

[0029] Component B is equal to component A, including trimer curing agent Bayer 3900, HMDI modified curing agent and IPDI modified curing agent, and the weight ratio of the three is 22:38:40.

[0030] Among them, the HMDI modified curing agent is synthesized by adding 100g of HMDI, dropwise adding 75g of PCL500, controlling the temperature at 80°C for 4hrs, then raising the temperature to 90°C for 4hrs, and detecting the NCO content: 11.1% and discharging.

[0031] The IPDI modified curing agent is 100g of IPDI, and 225g of PPG1000 is added dropwise to react until the NCO content: 5.8% is discharged.

[0032] This embodiment also discloses the use method of the two-component polyasparti...

Embodiment 2

[0034] Example 2 This example discloses a two-component polyaspartate urea rigid adhesive, the adhesive components are as follows:

[0035] A component formula:

[0036] 90.2 parts by weight of N,N'-(methylene di-4,1-cyclohexanediyl) diaspartic acid tetrabutyl ester;

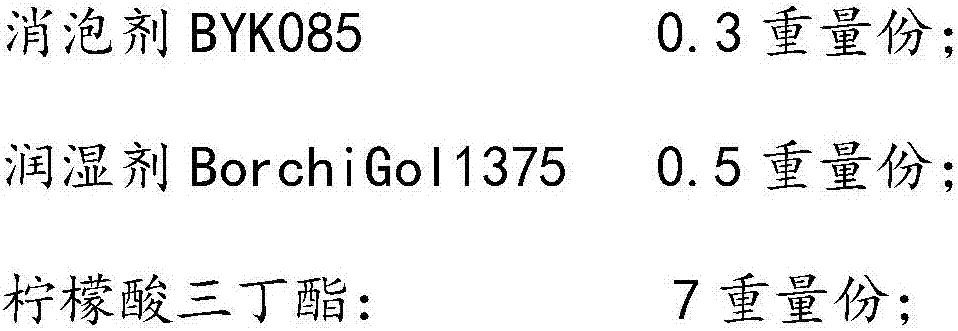

[0037]

[0038] Component B is equal to component A, including trimer curing agent Bayer 3900 and HMDI modified curing agent, the weight ratio of the two is 22:78;

[0039] The HMDI modified curing agent is synthesized by adding 100g of HMDI dropwise with 100g of PPG2000 and 60g of PPG400 under temperature control until the NCO content is 6.2%.

[0040] This embodiment also discloses the use method of the two-component polyaspartic ester urea rigid adhesive, and the steps of the method are as follows: mix the A component and the B component according to the corresponding parts by weight Stir evenly, trowel and apply on the asphalt surface with a thickness of 1-1.5mm, and then quickly spread the wear-resista...

Embodiment 3

[0042] Example 3 This example discloses a two-component polyaspartate urea rigid adhesive, the adhesive components are as follows:

[0043] A component formula:

[0044] 80 parts by weight of N,N'-(methylene bis-(1-methyl,-4,1-cyclohexanediyl)) diaspartic acid tetraethyl ester;

[0045]

[0046] The same amount of component B and component A, including trimer curing agent Bayer 3900 and HMDI modified curing agent, the weight ratio of the two is 10:90;

[0047] The HMDI modified curing agent is synthesized by adding 100g of HMDI dropwise with 100g of PPG2000 and 60g of PPG400 under temperature control until the NCO content is 15%.

[0048] This embodiment also discloses the use method of the two-component polyaspartic ester urea rigid adhesive, and the steps of the method are as follows: mix the A component and the B component according to the corresponding parts by weight Stir evenly, trowel and apply on the asphalt surface with a thickness of 1-1.5mm, and then quickly sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com