Composite roller of particle-reinforced hot-rolled seamless steel pipe tandem mill and preparing method thereof

A technology of composite rolls and seamless steel pipes is applied in the field of roll manufacturing to meet the requirements of service conditions, improve service life, and improve the effect of spheroidization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

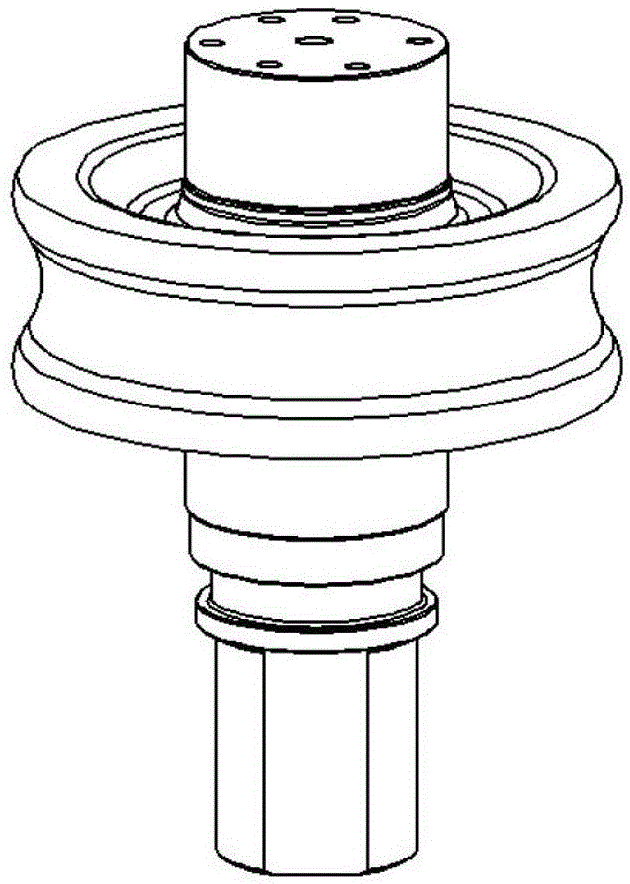

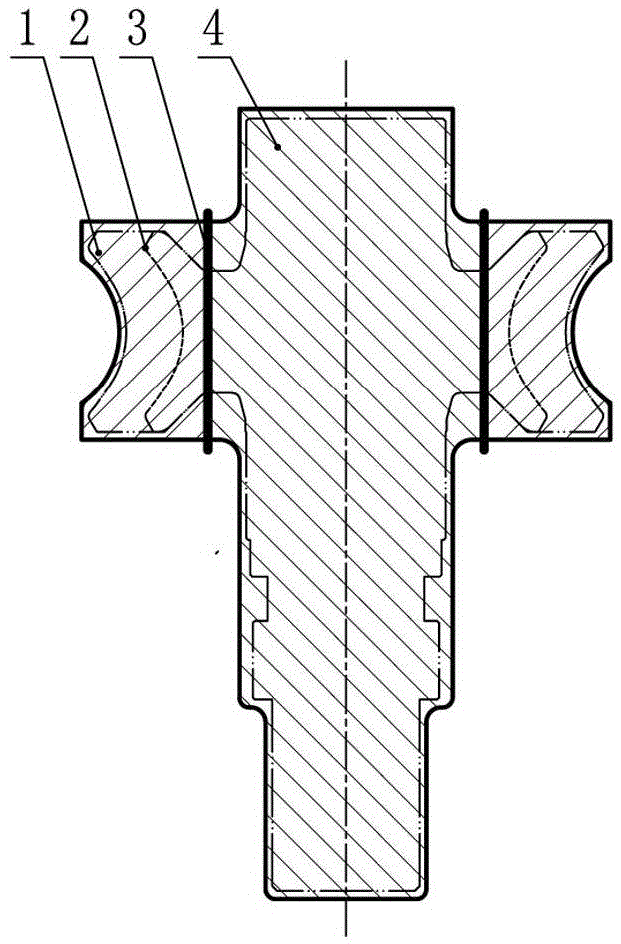

[0022] Refer to the attached figure 1 and attached figure 2 , This embodiment is for the manufacture of Φ250 hot-rolled seamless steel pipe unit with three-roller G1 continuous rolls. The slab weight is 854kg, and the theoretical casting weight of the working layer of the roll body is 314kg.

[0023] The matrix composition of this embodiment is: C: 3.6%, Si: 2.1%, Mn: 0.32%, P: 0.017%, S: 0.014%, Cu: 0.25%, Mg: 0.05%; the ratio of composite particles is: TiC16kg, WC16kg, Ni powder 2kg, Nb powder 2kg, industrial reduced iron powder 28kg, bismuth powder 0.02kg, antimony powder 0.012kg. Put the above materials in a ball mill and stir for 2 hours to mix them uniformly to form a mixed material, press the mixed material into a 5-10mm composite particle block, and preheat it to 350-400°C for use.

[0024] A steel parting ring 3 is designed to separate the mold cavity of the composite roll billet, and is prepared into two parts: the roll body working layer 1 and the mandrel 4, and...

Embodiment 2

[0029] refer to figure 1 and figure 2 , This embodiment is to use different proportions of matrix components to manufacture Φ250 hot-rolled seamless steel pipe unit three-roller G3 continuous rolls. The weight of the slab is 845kg, and the theoretical casting weight of the first part of the working layer of the roll body is 310kg.

[0030] The matrix components in this embodiment are: C: 3.7%, Si: 1.8%, Mn: 0.35%, P: 0.015%, S: 0.010%, Cu: 0.20%, Mg: 0.045%; the composite particles are respectively: TiC8kg, WC8kg, Ni powder 1kg, Nb powder 1kg, industrial reduced iron powder 14kg, bismuth powder 0.018kg, antimony powder 0.014kg; the above-mentioned raw materials were put into a ball mill and stirred for 2 hours to make them evenly mixed, and pressed into a compound of 5-10 mm. The particles are small pieces, and these small pieces are preheated to 350-400 ℃ for use.

[0031] A steel parting ring 3 is used to separate the casting billet cavity into two parts, the roll body w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com