Carbon nano tube (CNT) toughened TiAl/B4C ceramic matrix composite and preparation method thereof

A technology of carbon nanotubes and composite materials, which is applied in the field of engineering ceramic materials, can solve the problems of large grain boundary movement resistance, low surface tension, and high brittleness, and achieve the effects of low price, excellent toughness, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

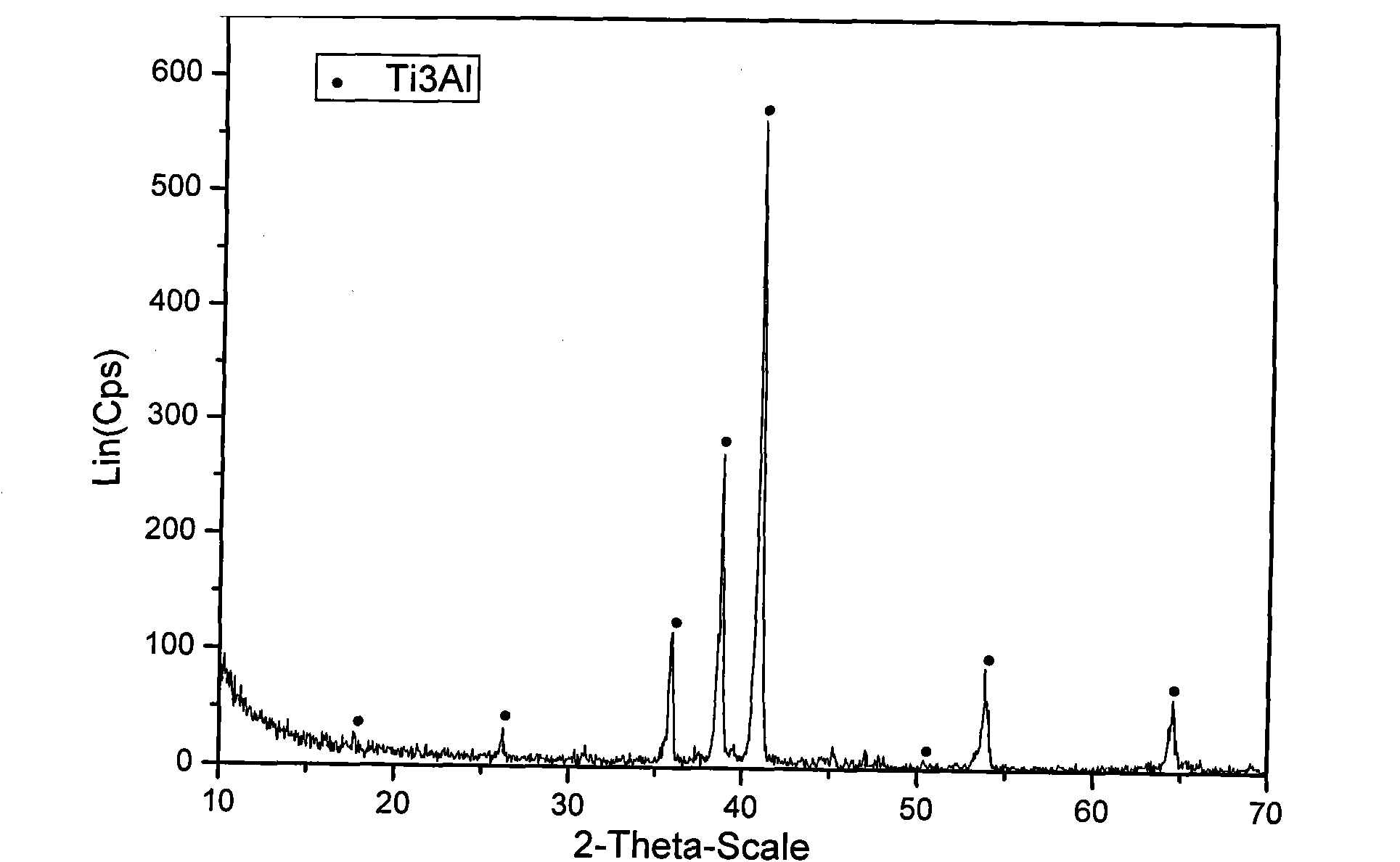

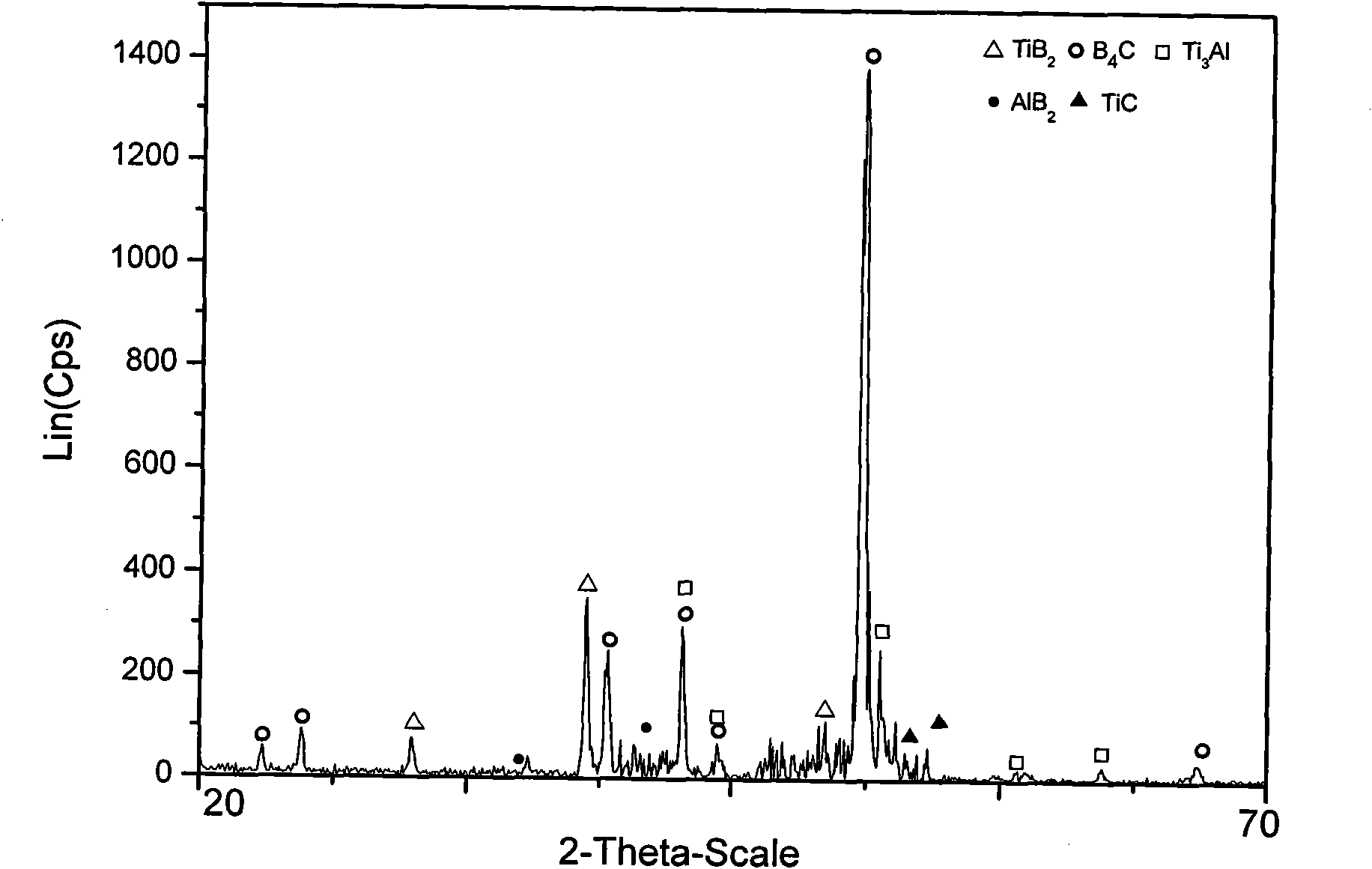

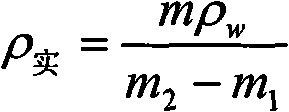

[0037] Carbon nanotube toughened TiAl / B4C ceramic matrix composite material, which is composed of carbon nanotubes, Ti-Al intermetallic compounds and B4C, the composition ratio (weight ratio) of the material is: carbon nanotubes 5%, Ti- Al intermetallic compound 20%, B4C 75%. Its preparation method is as follows: first, with Ti powder 16.8g, Al powder 3.2g and stearic acid 0.6g (ball milling aid, addition is 3% of total mass) in high-energy ball mill ball mill 30 hours, then under vacuum or nitrogen Heat treatment at 600°C under protection to form a Ti-Al intermetallic compound with the main crystal phase Ti3Al; surface oxidation treatment of carbon nanotubes is carried out with concentrated nitric acid at 60°C in conjunction with ultrasonic dispersion. Then, the Ti3Al obtained by mechanical alloying was uniformly mixed with 5 g of surface-treated carbon nanotubes and 75 g of B4C powder for 3 hours. Finally, put the mixture into a graphite mold, pressurize 30Mpa at a temperat...

Embodiment 2

[0039]The mass percentage of each component is: carbon nanotube 2%, Ti-Al intermetallic compound 30%, B4C 68%. Its preparation method is as follows: first, with Ti powder 19.1g, Al powder 10.4g, molybdenum powder 0.5g and stearic acid 1.5g (ball milling aid, add-on is 5% of total mass) in high-energy ball mill ball mill 30 hours, Then heat treatment at 600°C under vacuum or nitrogen protection to form a Ti-Al intermetallic compound (containing a small amount of Ti3Al) in the main crystal phase TiAl; the surface oxidation treatment of carbon nanotubes is carried out with concentrated nitric acid at 60°C and with ultrasonic dispersion. Then, the TiAl obtained by mechanical alloying, 2 g of surface-treated carbon nanotubes and 65 g of B4C powder were uniformly mixed for 3 hours. Finally, put the mixture into a graphite mold, pressurize 30Mpa at a temperature of 1580°C, and sinter by hot pressing under vacuum or nitrogen protection.

Embodiment 3

[0041] Carbon nanotube toughened TiAl / B4C ceramic matrix composite material, which is composed of carbon nanotubes, Ti-Al intermetallic compounds and B4C, the composition ratio (weight ratio) of the material is: carbon nanotubes 5%, Ti- Al intermetallic compound 20%, B4C 75%. Oxidation treatment of carbon nanotubes is carried out with concentrated nitric acid at 60°C in combination with ultrasonic dispersion. Its preparation method is as follows: 16.8g of Ti powder, 3.2g of Al powder, 75g of B4C powder and 2.94g of stearic acid (a ball milling aid, the addition amount is 3% of the total mass) are ball milled in a high-energy ball mill for 20 hours. Finally, add 5g of carbon nanotubes that have undergone surface oxidation treatment, and carry out uniform mixing for 3 hours. Finally, put the mixed material into a graphite mold, pressurize 30Mpa at a temperature of 1600°C, and heat press and sinter under vacuum or nitrogen protection conditions. , Preparation of carbon nanotube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com