A graphene quantum dot material with high ultraviolet absorption characteristics and lipophilicity and preparation method thereof

A graphene quantum dot and external absorption technology, applied in the field of nanomaterials, can solve the problems of using more solvents, graphene quantum dot materials are difficult to dissolve non-polar solvents and polymer materials, and poor ultraviolet absorption characteristics, etc., to achieve The effect of increasing the degree of carbonization and increasing the temperature of carbonization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 2.20g of acetyl trioctyl citrate, place it in a 20mL glass microwave reaction tube, and control the temperature of the reactant at 250°C for 10 minutes under 2.45GHz and 700W microwave irradiation conditions to obtain a brown-black viscous Graphene quantum dot products with ester edge groups. After the product was cooled to room temperature, 4 mL of ethanol was added to the microwave reaction tube, and the product was uniformly dispersed in ethanol by ultrasonication and stirring. Transfer the obtained graphene quantum dot ethanol solution to a 50mL centrifuge tube, add 20mL acetone therein, make the graphene quantum dot precipitate from the ethanol-acetone mixed solution, centrifuge and precipitate the product obtained, pour to remove the supernatant, and Add 4 mL of ethanol to the precipitate, and ultrasonically disperse the precipitate in ethanol again. The precipitate was washed by centrifugation repeatedly three times, and the solvent was removed by freeze-d...

Embodiment 2

[0045] Weigh 10.00g of tributyl citrate, place it in a 100mL round-bottomed flask, and use an electric heating mantle to react the reactant at 250°C for 40 minutes under the condition of reflux condensation to obtain brown-black viscous Group graphene quantum dot products. After the product is cooled to room temperature, add 20 mL of ethanol to the flask and stir to make the product evenly dispersed in ethanol; transfer the prepared graphene quantum dot ethanol solution to multiple centrifuge tubes, and add 5 times the volume of acetone to each centrifuge tube to make the graphite Precipitation of ene quantum dots; centrifugal separation and precipitation of the obtained product. The precipitate was washed by centrifugation repeatedly three times, and the solvent was removed by freeze-drying to obtain a purified graphene quantum dot product.

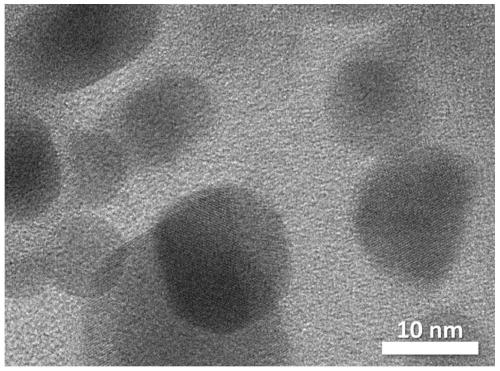

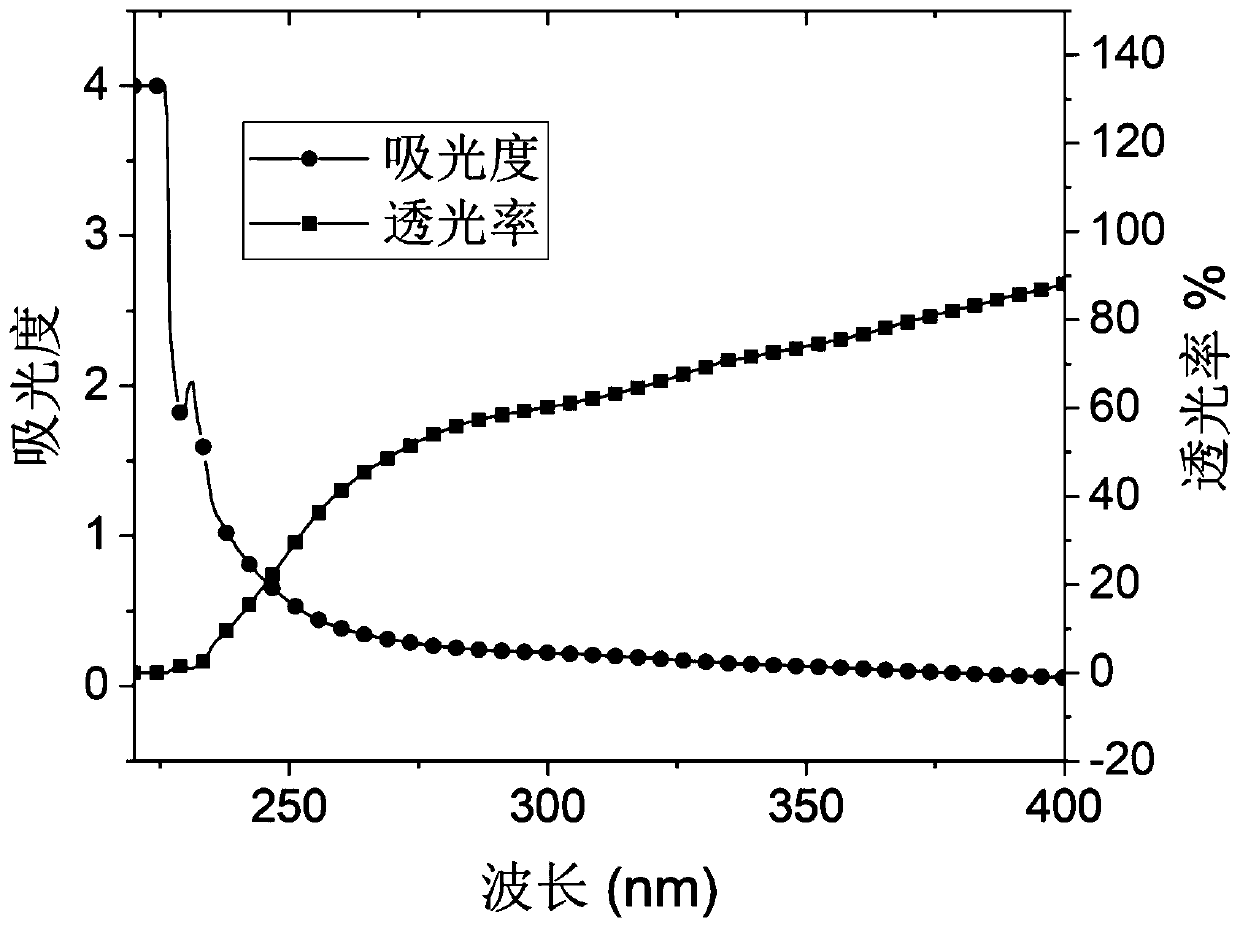

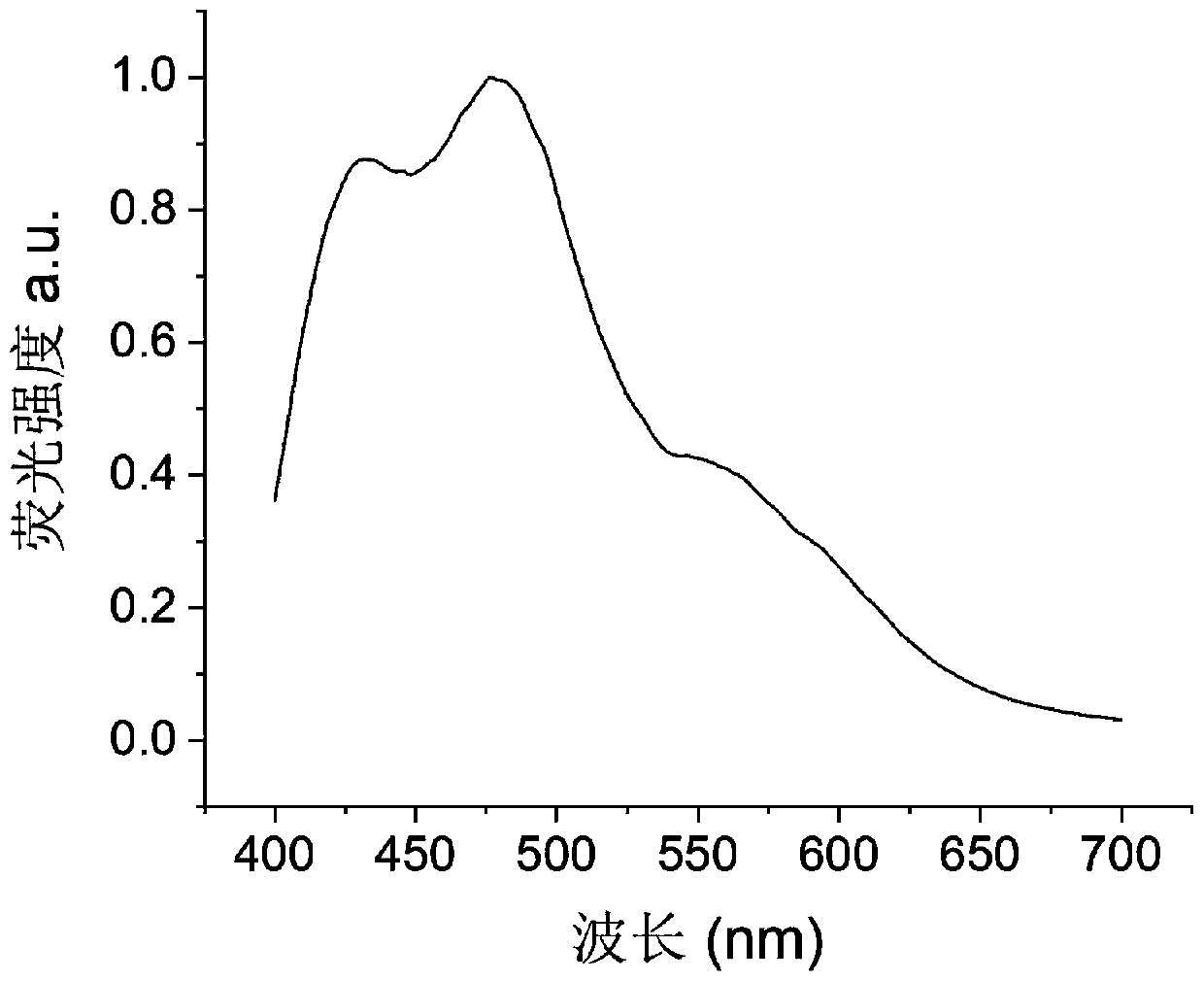

[0046] The high-resolution projection electron micrograph of the graphene quantum dot material that this embodiment makes is as follow...

Embodiment 3

[0053] Weigh 10.00g of acetyl tributyl citrate, place it in a 100mL round-bottomed flask, and use an electric heating mantle to react the reactant at 250°C for 40 minutes under the protection of a nitrogen atmosphere to obtain brown-black viscous graphene quantum dots product. After the product was cooled to room temperature, 20 mL of ethanol was added to the flask, and stirred to make the product evenly dispersed in ethanol. The prepared graphene quantum dot ethanol solution was transferred to multiple centrifuge tubes, and 5 times the volume of deionized water was added to each centrifuge tube to precipitate the graphene quantum dots. The resulting product was centrifuged and precipitated. The precipitate was washed by centrifugation repeatedly three times, and the solvent was removed by freeze-drying to obtain a purified graphene quantum dot product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com