Carbon dot with high thermal stability and preparation method thereof

A technology with high thermal stability and carbon dots, applied in chemical instruments and methods, nano-carbon, climate sustainability, etc., can solve the problem of low thermal stability of carbon dots, achieve high carbonization degree, high thermal stability, high heat The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

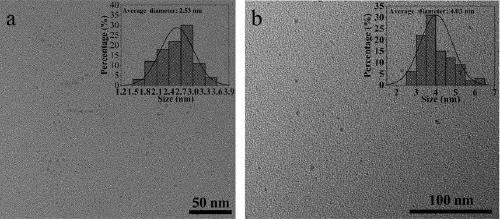

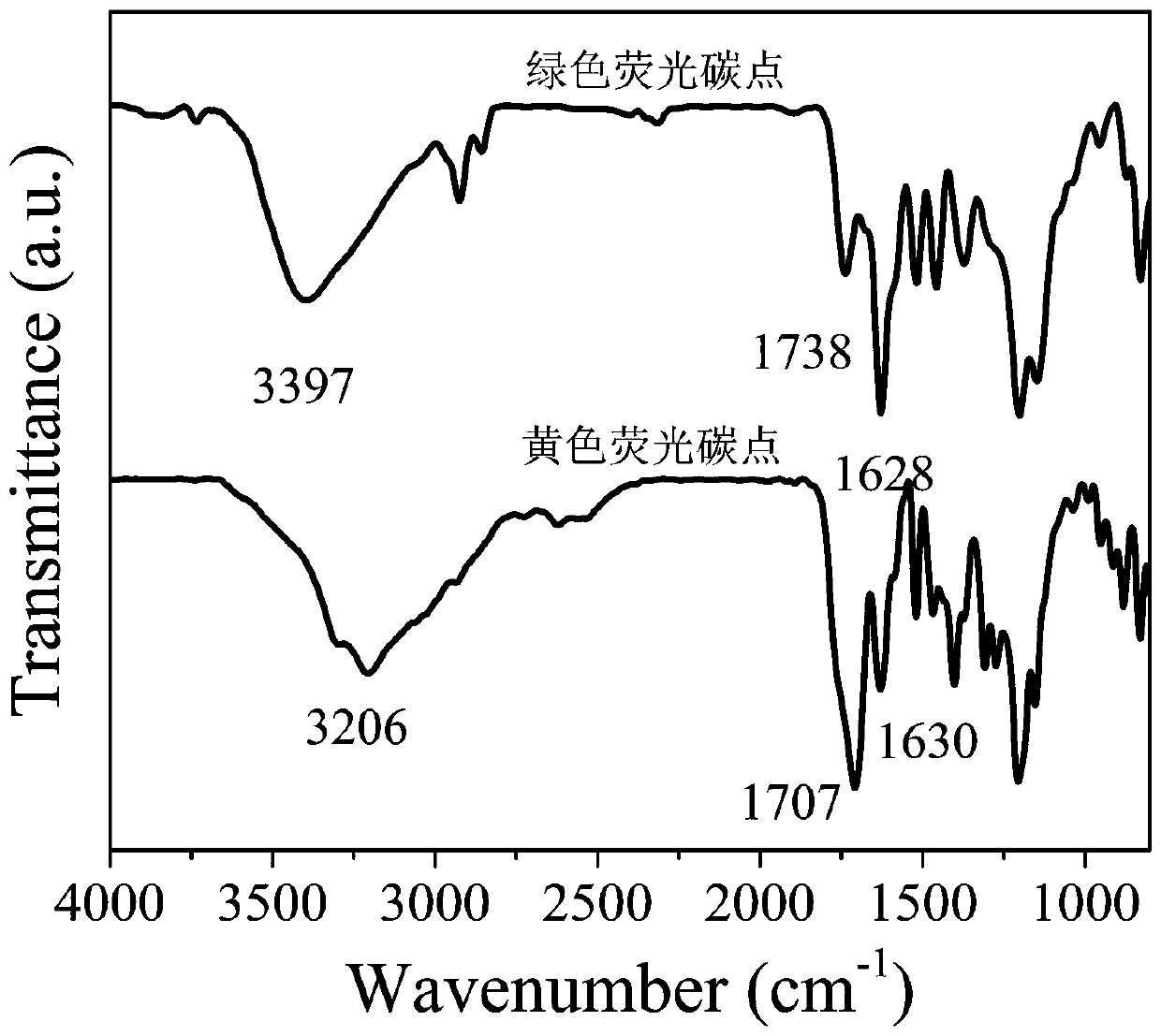

[0035] Weigh 0.2000g of citric acid and 0.2558g of 2,7-dihydroxynaphthalene, add them into 40mL of deionized water, place them in a 59KHz high-frequency ultrasonic cleaner, and process them ultrasonically for 10 minutes at room temperature to obtain a reaction solution.

[0036] The above reaction solution was placed in a 100 mL stainless steel autoclave lined with tetrafluoroethylene, and hydrothermally reacted in an oven at 200°C for 14 hours. After the reaction, cool to room temperature, take out the reaction solution, filter through a 0.22 μm microporous membrane to remove large particle reaction products, and obtain an aqueous solution of yellow fluorescent carbon dots.

[0037] At -79°C, the yellow fluorescent carbon dot aqueous solution was frozen into a solid, and the deionized water was removed by freeze-drying to obtain yellow fluorescent carbon dot powder.

[0038] Weigh 0.2g of yellow fluorescent carbon dot powder into a corundum crucible, put it into a tube furnac...

Embodiment 2

[0051] Weigh 0.02g of the green fluorescent carbon dot prepared in Example 1, dissolve it in 10mL of ethyl acetate, add 2g of polymethyl methacrylate, heat and dissolve at 50°C, pour it into a polytetrafluoroethylene mold, and let it cool naturally at room temperature. The ethyl acetate was evaporated to dryness to obtain a green fluorescent carbon dot film with green light emission.

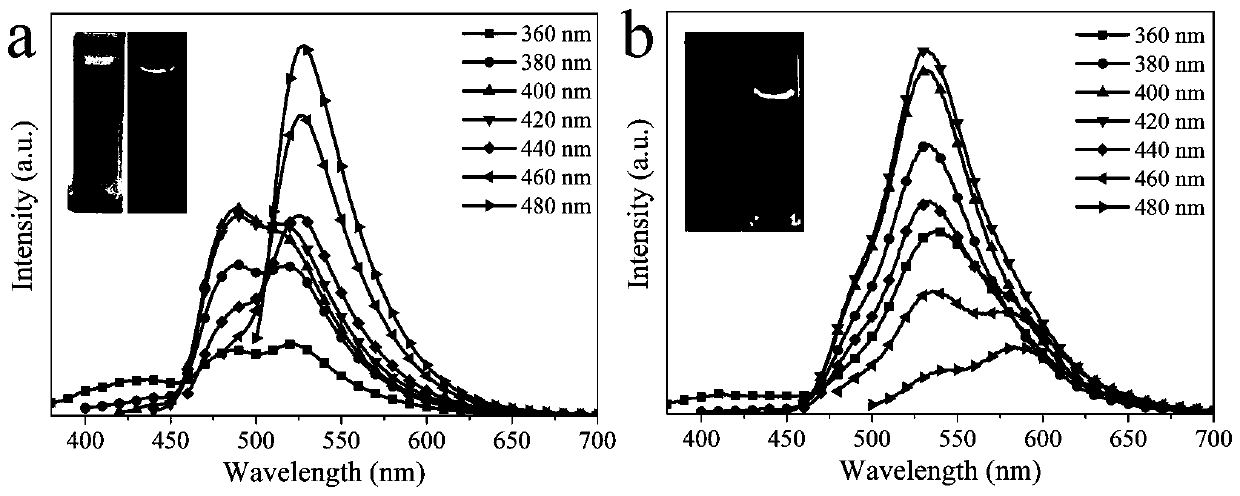

[0052] The white light LD device was assembled with the green fluorescent carbon dot film prepared above and the laser diode, and the luminous performance of the white light LD device was investigated. The results are as follows: Figure 5 .

[0053] Figure 5 (a) shows the fluorescence emission spectra of the above-mentioned green fluorescent carbon dot film at different excitation wavelengths. When the excitation wavelength is 400nm, the fluorescence intensity of the film is the highest.

[0054] Figure 5 (b) is the physical picture of the assembled white light LD device. Since laser diod...

Embodiment 3

[0057] Weigh 0.2000g of citric acid and 0.5116g of 2,7-dihydroxynaphthalene, add them into 40mL of deionized water, place them in a 59KHz high-frequency ultrasonic cleaner, and process them ultrasonically for 10 minutes at room temperature to obtain a reaction solution.

[0058] The above reaction solution was placed in a 100 mL stainless steel autoclave lined with tetrafluoroethylene, and hydrothermally reacted in an oven at 200°C for 10 h. After the reaction, cool to room temperature, take out the reaction solution, filter through a 0.22 μm microporous membrane to remove large particle reaction products, and obtain an aqueous solution of yellow fluorescent carbon dots.

[0059] At -79°C, the yellow fluorescent carbon dot aqueous solution was frozen into a solid, and the deionized water was removed by freeze-drying to obtain yellow fluorescent carbon dot powder.

[0060] Figure 6 The fluorescence spectra of the yellow fluorescent carbon dot aqueous solution prepared above u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com