Calcium silicate board and preparation method thereof

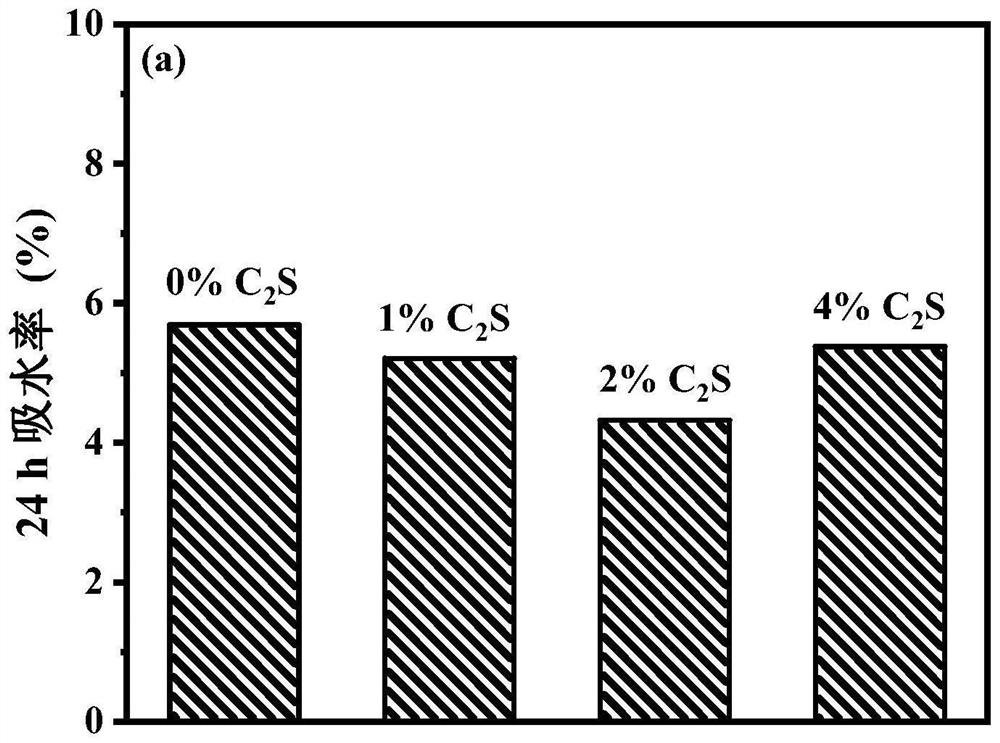

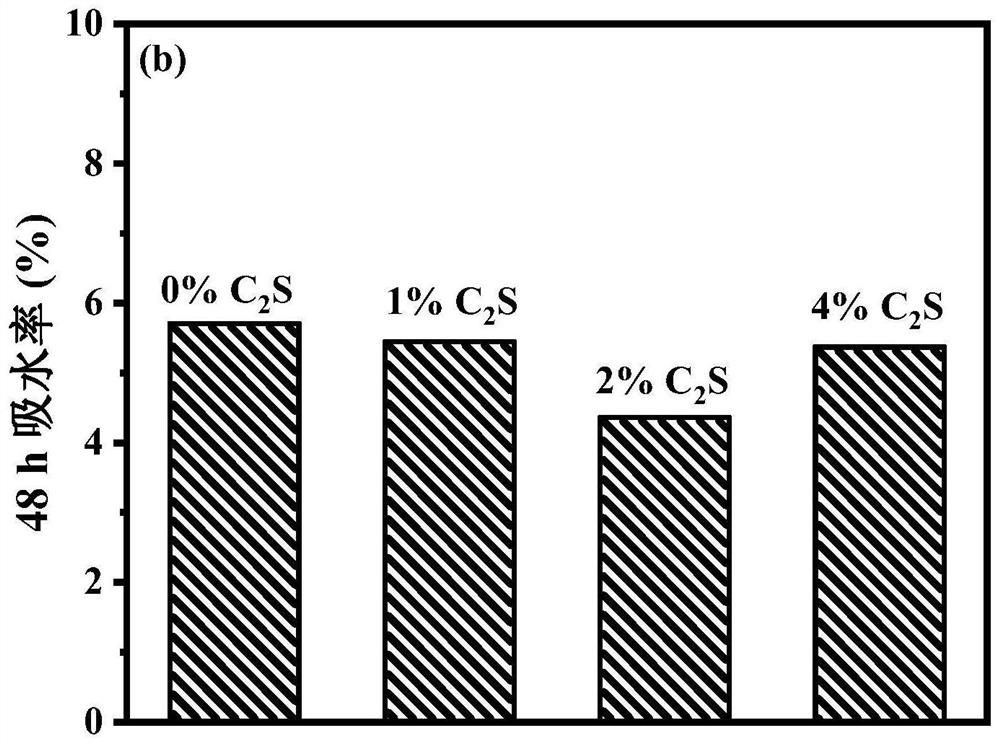

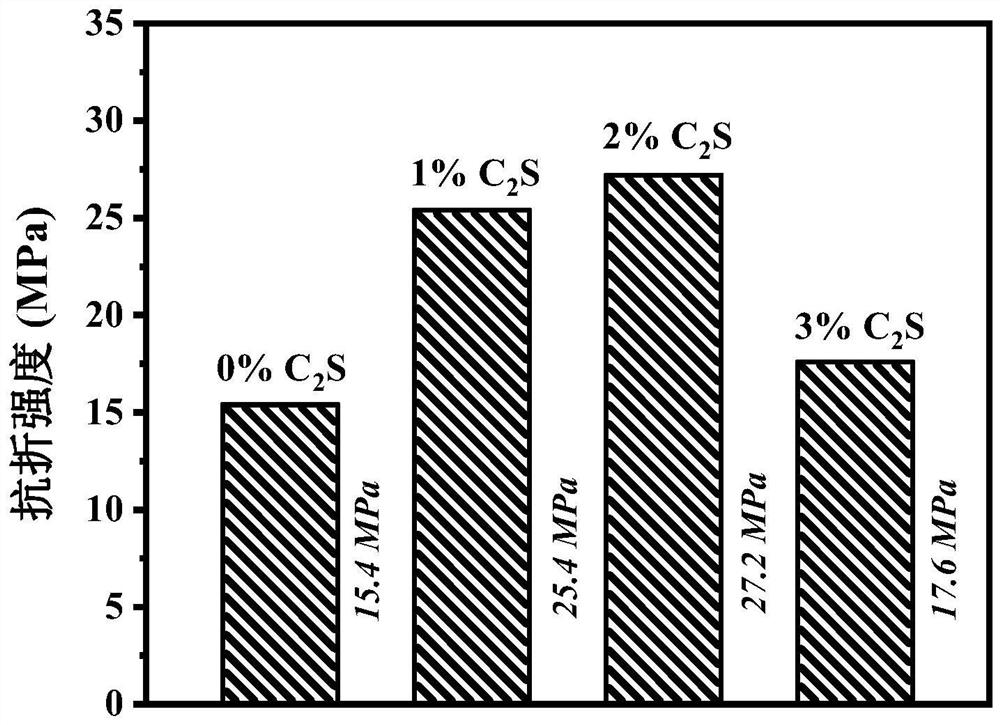

A technology of calcium silicate board and mixture, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of excellent calcium silicate board, difficult to obtain flexural strength and carbonization degree, and achieve low water absorption and high flexural strength Strong, highly carbonized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] This specific embodiment provides a kind of preparation method of calcium silicate board, comprises the following steps:

[0027] Iron oxide green, dispersant and water are mixed to obtain a mixed solution; the dispersant is one or both of polyethylene glycol solution and methyl amyl alcohol solution; the amount of the dispersant is the quality of the water 0.05%-5%;

[0028] Mix white material, tailings and stone powder to obtain a mixture; the white material is C 2 The fired material with S accounting for more than 80%, other components of the white material also include C 3 S, C 3 A.C 4 AF; the mass ratio of the white material, the tailings and the stone powder in the mixture is (25-30):(5-9):1; the added amount of the iron oxide green is 0.2 of the mass of the mixture %-6%;

[0029] Mixing the mixed liquid and the mixture to obtain a wet material; the water content in the wet material is 10%-20% of the mass of the mixture;

[0030] Put the wet material into a ...

Embodiment 1

[0036] This embodiment proposes a calcium silicate board, which is made by the following steps:

[0037] Dissolve a certain amount of iron oxide green in a small amount of absolute ethanol solution, and grind until dry;

[0038] Mix 1.6g of dried iron oxide green, 0.363g of polyethylene glycol solution and 24.24g of deionized water, and stir thoroughly to obtain a mixed solution;

[0039] Mix 128g white material, 32g gold sand tailings and 5g stone powder to obtain a mixture;

[0040] mixing the mixed liquid and the mixture to obtain a wet material;

[0041] Put the wet material into a tablet machine and press it into a green body with a pressure of 15MPa and a grinding tool of 10cm*10cm, dry the green body at 40°C for 5h until the water loss rate reaches 55%, and then take it out to obtain a calcium silicate substrate , named 1%-C 2 S;

[0042] Place the calcium silicate substrate in vacuum CO 2 Carbonization 24h under the environment obtains described calcium silicate b...

Embodiment 2

[0044] This embodiment proposes a calcium silicate board, which is made by the following steps:

[0045] Dissolve a certain amount of iron oxide green in a small amount of absolute ethanol solution, and grind until dry;

[0046] Mix 1.6g of dried iron oxide green, 0.367g of polyethylene glycol solution and 24.48g of deionized water, and stir thoroughly to obtain a mixed solution;

[0047] Mix 128g white material, 32g gold sand tailings and 5g stone powder to obtain a mixture;

[0048] mixing the mixed liquid and the mixture to obtain a wet material;

[0049] Put the wet material into a tablet machine and press it into a green body with a pressure of 12MPa and a grinding tool of 10cm*10cm, dry the green body at 60°C for 2 hours until the water loss rate reaches 50%, and then take it out to obtain a calcium silicate substrate , named 2%-C 2 S;

[0050] Place the calcium silicate substrate in vacuum CO 2 The calcium silicate plate is obtained by carbonizing for 36h under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com