A kind of room temperature preparation method of heteroatom-doped carbon material

A heteroatom and doping-type technology, which is applied in the field of preparation of doped graphitized carbon materials, can solve the problems of limited scale and achieve the effects of easy post-processing, simple operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 1.00 g of polyvinylidene chloride, 0.60 g of potassium hydroxide, and 10 ml of N,N-dimethylformamide into a 30 ml zirconia ball mill jar, package the ball mill jar and equip it with a ball mill for ball milling For 4 hours, the frequency was set at 30.0 Hz. After the reaction is over, add water to stop the reaction, and then use washing and centrifugation to remove possible salts and unreacted strong bases. The centrifuged product is dried overnight, and the drying temperature is set at 60°C. The dried product is the target product.

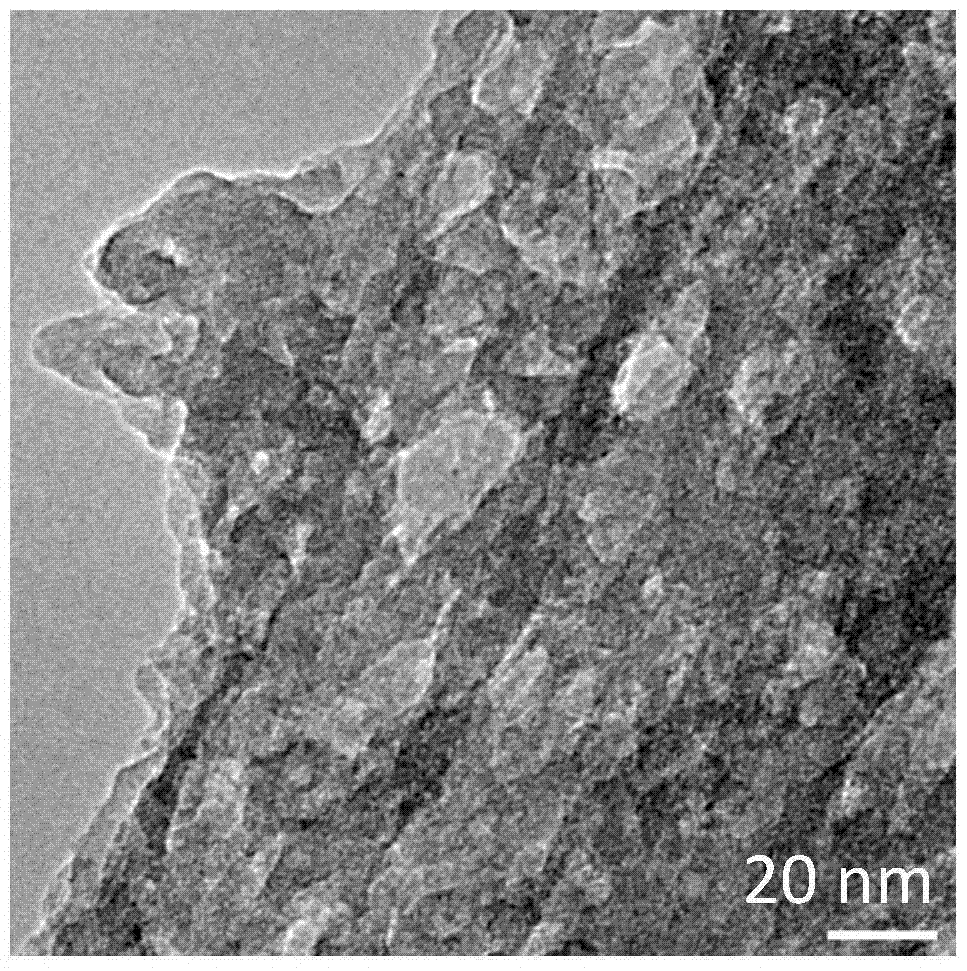

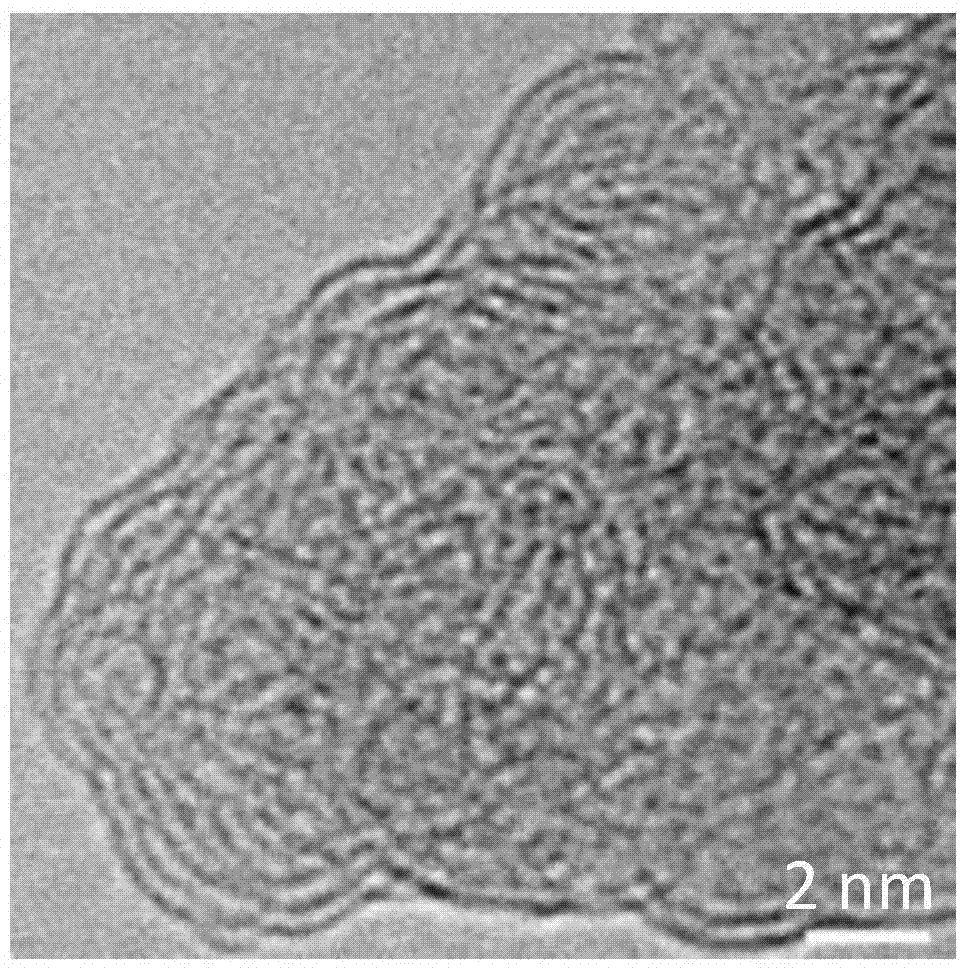

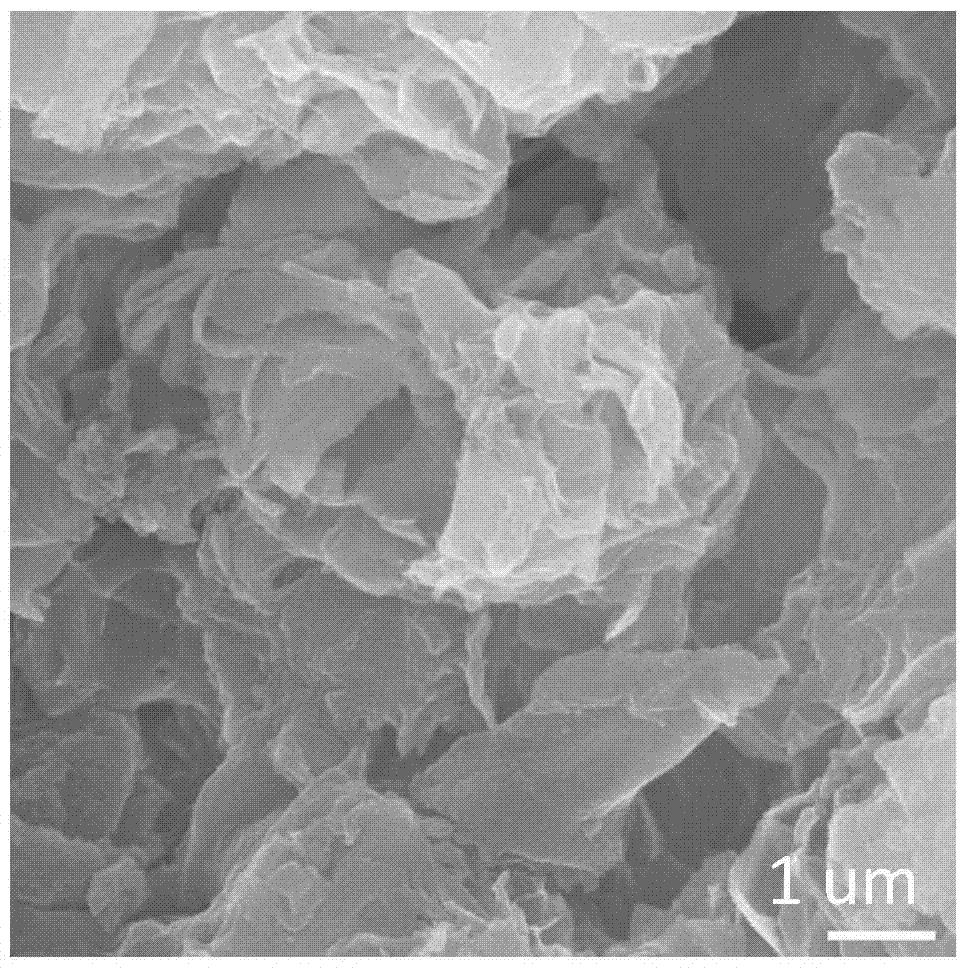

[0040] Specific data: see transmission electron microscope photos figure 1 and figure 2 . SEM photo see image 3 . C NMR spectrum see Figure 4 . Raman spectrum see Figure 5 . X-ray Photoelectron Spectroscopy See Figure 6 .

Embodiment 2

[0042] Add 1.00 g of polyvinylidene chloride, 0.60 g of potassium hydroxide, and 10 ml of N,N-dimethylformamide into a mortar, and grind continuously by hand for five minutes. Others are the same as embodiment 1.

Embodiment 3

[0044]Add 0.64 grams of polyvinylidene fluoride, 0.60 grams of potassium hydroxide, and 10 milliliters of N,N-dimethylformamide into a 30 milliliter zirconia ball mill jar, package the ball mill jar and equip it with a ball mill for ball milling . Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com