A kind of preparation method of doped carbon material for supercapacitor

A carbon material and doping technology, which is applied in the field of preparation of doped carbon materials, can solve the problems of poor plasticity, failure to meet urgent requirements, and limited repeatability in the preparation process, and achieve low price, high safety, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 2.00 g of sodium ethoxide was immersed in 10 ml of azamide, along with 1.00 g of polyvinylidene chloride and 0.50 g of melamine, followed by the addition of 1.00 g of potassium hydroxide. The above mixture is processed by ball milling to make the reactants fully contact. The rotation frequency of the ball mill is about 30Hz, and the processing time is 2 hours. After the treatment, vacuum drying at 70°C was directly carried out. The obtained dried samples were calcined under the protection of nitrogen, and the calcining temperature was 700°C. The calcined product was washed three times with deionized water and dried at 60°C to obtain the doped carbon material.

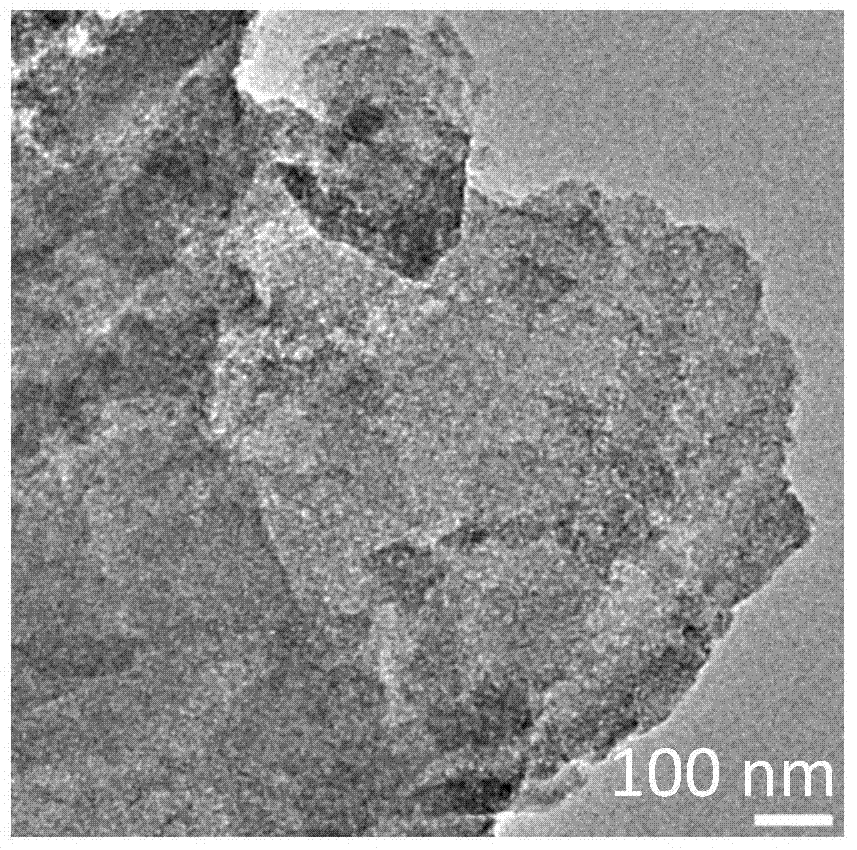

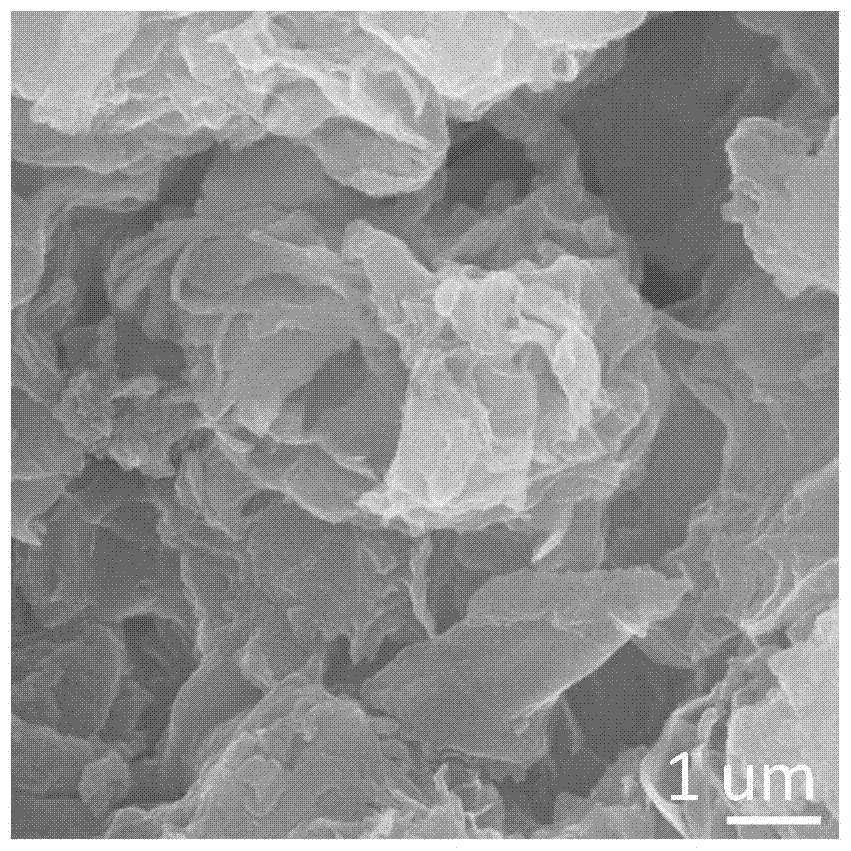

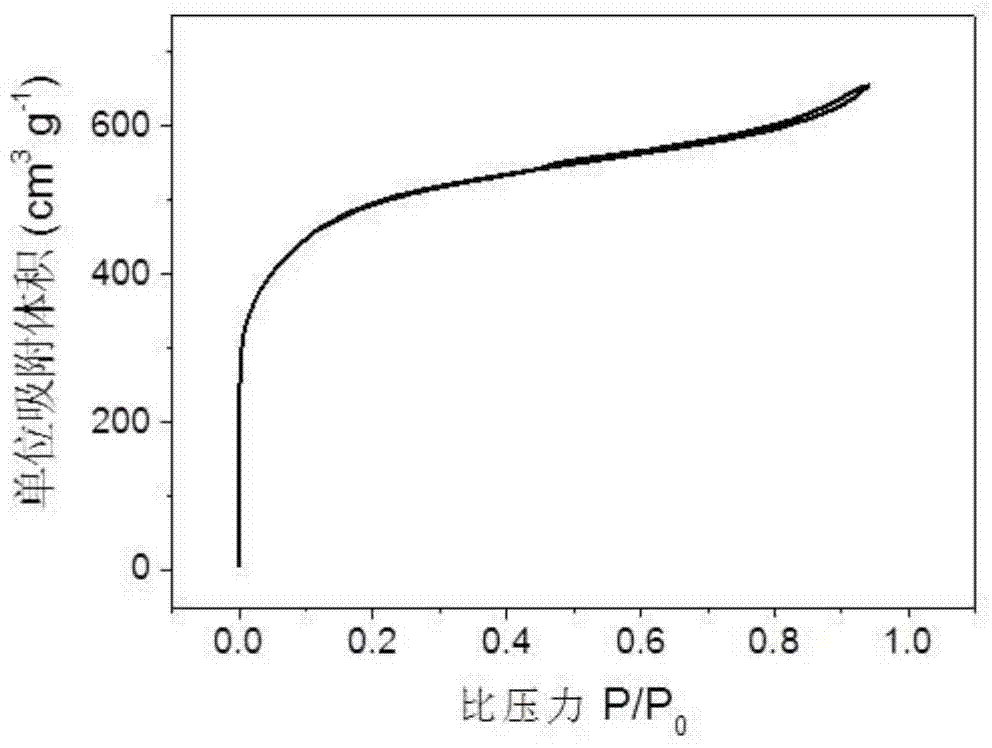

[0059] The transmission electron microscope photo of the doped carbon material obtained specifically can be found in figure 1 . The rich hollow structure in the transmission electron microscope photos shows that the prepared doped carbon material has a relatively rich pore structure. SEM photo see figure 2...

Embodiment 2

[0063] 1.00 grams of polyvinylidene chloride (abbreviated as PVDC) and 0.75 grams of melamine were immersed in 10 milliliters of nitrogen dimethylformamide, followed by the addition of 1.70 grams of zinc oxide. The above mixture was processed by ball milling to make the reactants fully contact, the rotation frequency of the ball mill was about 30 Hz, and the processing time was 4 hours. After the treatment, vacuum drying at 70°C was directly carried out. The obtained dried samples were calcined under the protection of nitrogen, and the calcining temperature was 700°C. The calcined product was washed three times with deionized water and dried at 60°C to obtain the doped carbon material.

[0064] The transmission electron microscope photo of the doped carbon material obtained specifically can be found in Figure 12 . SEM photo see Figure 13 . Electron microscope results show that the obtained doped carbon material is interconnected sheet-like porous amorphous material. Fo...

Embodiment 3

[0066] Use PVDC as a carbon source, ethylenediamine as a nitrogen doping agent, and magnesium oxide as a strong alkali dechlorination agent. The usage amounts of the three are 1.0g, 2.0mL and 3.0g respectively. in dimethylacetamide (DMA). Other processing modes are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com