Preparation method of viscose high-temperature graphite carbon fibers

A technology of high-temperature graphite and viscose fiber, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve the problem that the carbon content cannot reach 99% or even higher, it is difficult to adapt to the needs of modern technological production, and the performance of carbon fiber cannot reach the extreme, etc. problem, to achieve the effect of increasing carbonization application objects, increasing force, and high degree of carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of viscose high-temperature graphite carbon fiber comprises the following steps:

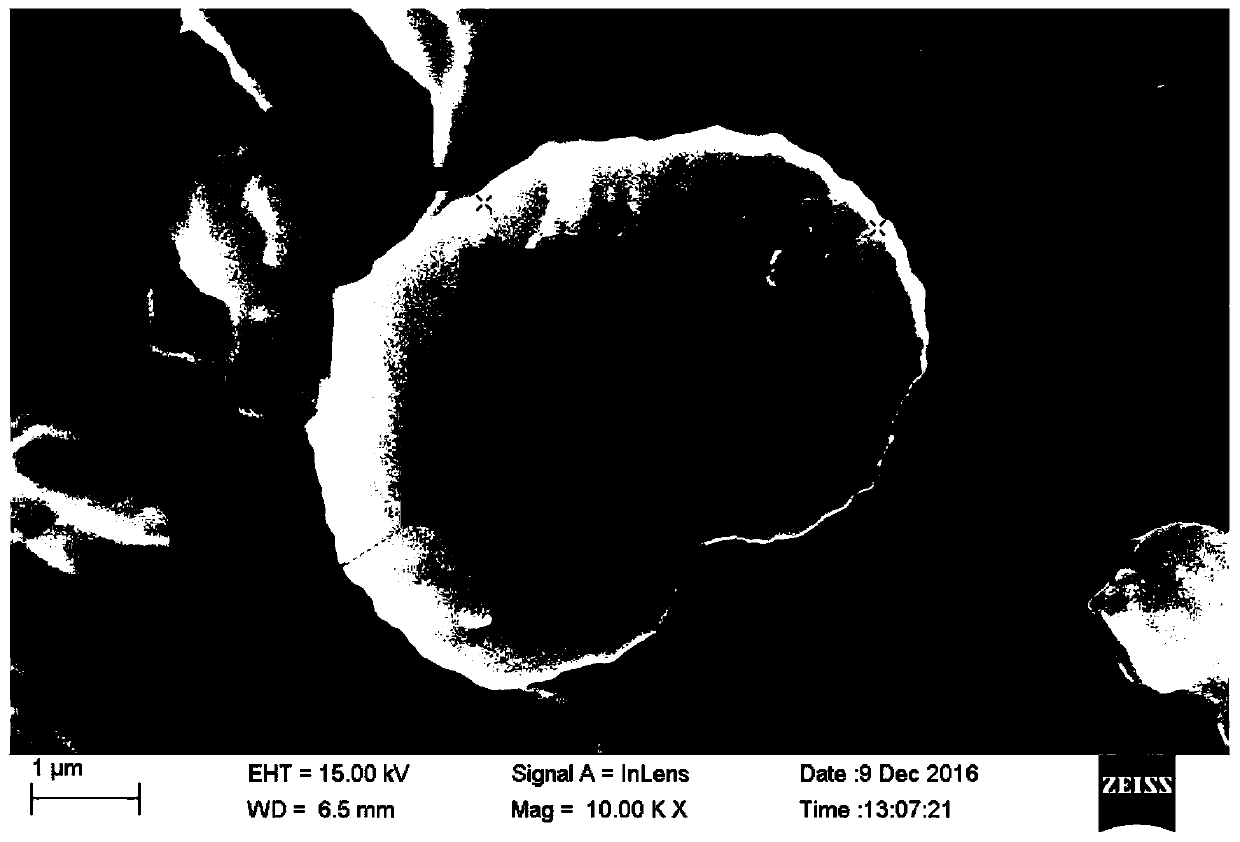

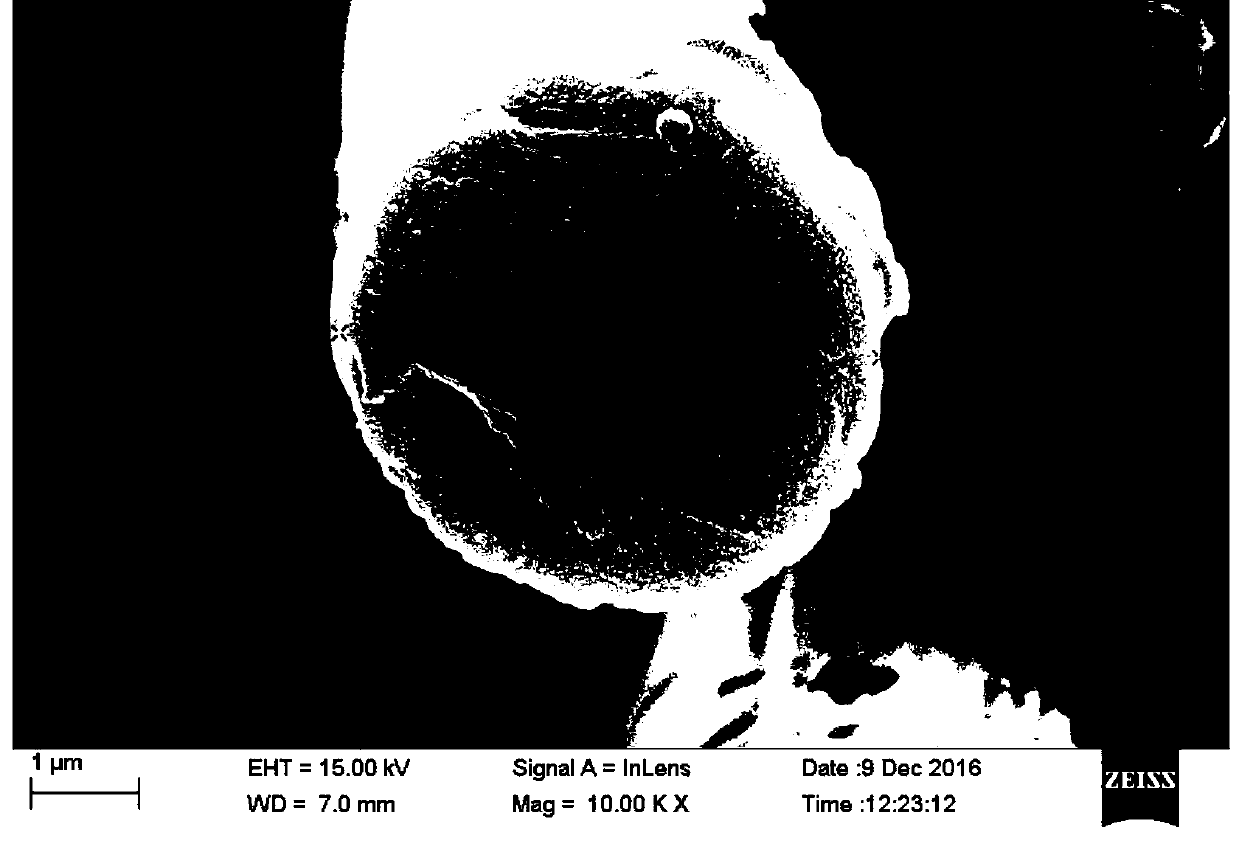

[0030] (1) Soaking medicine: at room temperature, soak the viscose fiber in diammonium hydrogen phosphate or ammonium bromide dilute solution for not less than 24 hours; diammonium hydrogen phosphate is an activated flame retardant with a concentration of 6%. Efficient activation performance, energy particles form nano-scale micropores on the surface of viscose fibers to improve its adsorption capacity; ammonium bromide is a reinforced flame retardant with a concentration of 10%, which can increase the strength of carbonized fibers and improve their tensile strength Extensibility; what adopted in the embodiment is that concentration is 10% dilute ammonium bromide solution, viscose fiber is the 5cm wide fiber cloth that is woven by the carbon fiber bundle of 1.5dtex, diameter 20 μm, 1200 bundles, and viscose fiber is purchased from Japan OMIKENSHI company.

[0031] ...

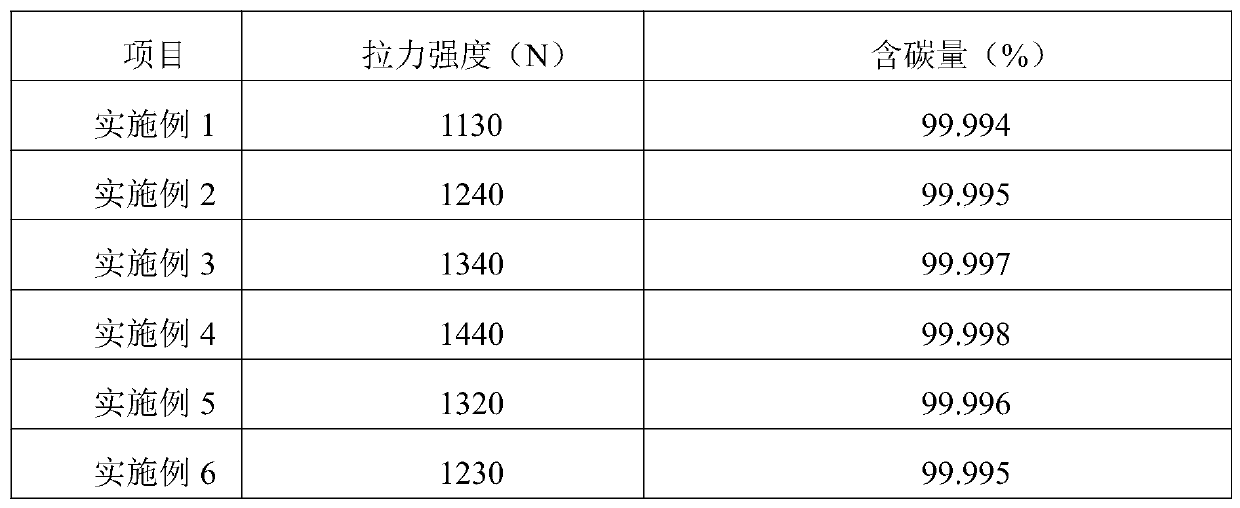

Embodiment 1

[0037] At room temperature, soak the viscose fiber in a dilute ammonium bromide solution with a concentration of 10% for 24 hours; then, dry the viscose fiber naturally and control its humidity to 10%; then dry the viscose fiber after drying Low-temperature pre-curing, the temperature is controlled at 50°C, the pre-curing feed rate of viscose fiber is controlled at 1m / min, and the mixed gas protection of nitrogen and water vapor with a volume ratio of 1:1 is filled at the same time; then, the viscose fiber Carry out medium-temperature carbonization, the temperature is controlled within 400°C, and at the same time, the mixed gas of nitrogen and water vapor with a volume ratio of 1:1 is filled for protection; finally, the viscose fiber is subjected to high-temperature carbonization, the temperature is controlled at 2400°C, and argon gas is filled Protection, the time is 72h.

Embodiment 2

[0039] At room temperature, soak the viscose fiber in a dilute ammonium bromide solution with a concentration of 10% for 30 hours; then, dry the viscose fiber naturally and control its humidity to 10%; then dry the viscose fiber after drying Low temperature pre-curing, the temperature is controlled at 60°C, the pre-curing feed rate of viscose fiber is controlled at 1m / min, and at the same time, the mixed gas protection of nitrogen and water vapor with a volume ratio of 1:1 is filled; then, the viscose fiber Carry out medium-temperature carbonization, the temperature is controlled within 350°C, and at the same time, the mixed gas of nitrogen and water vapor with a volume ratio of 1:1 is filled for protection; finally, the high-temperature carbonization of viscose fibers is carried out, the temperature is controlled at 2400°C, and argon gas is filled Protection, the time is 72h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com