Flame-retardant nano-cellulose composite aerogel with oriented structure and preparation method thereof

A nanocellulose and composite aerogel technology, applied in the field of thermal insulation materials, can solve problems such as the decline of thermal insulation performance, and achieve the effects of increased carbonization, low thermal conductivity, and excellent thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

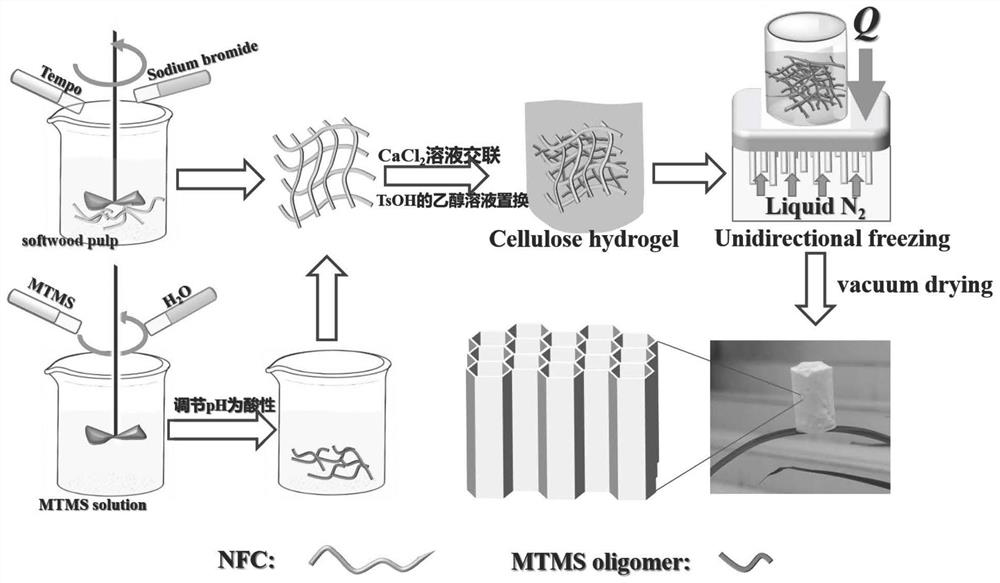

[0031] The invention provides a method for preparing a flame-retardant nanocellulose composite airgel with an oriented structure, comprising the following steps:

[0032] S1. After mixing the nanocellulose suspension with the siloxane hydrolyzate, cross-linking through a water-soluble metal salt to obtain a composite nanocellulose hydrogel;

[0033] S2. Perform solution replacement of the composite nanocellulose hydrogel in an alcohol solution containing a carbonizing agent to obtain an alcohol gel containing a carbonizing agent; the carbonizing agent is selected from p-toluenesulfonic acid, diphenylphosphine One or more of acid and trifluoromethanesulfonic acid;

[0034] S3. Perform directional freezing on the alcohol gel containing the carbonizing agent to obtain a flame-retardant nanocellulose composite airgel with a directional structure.

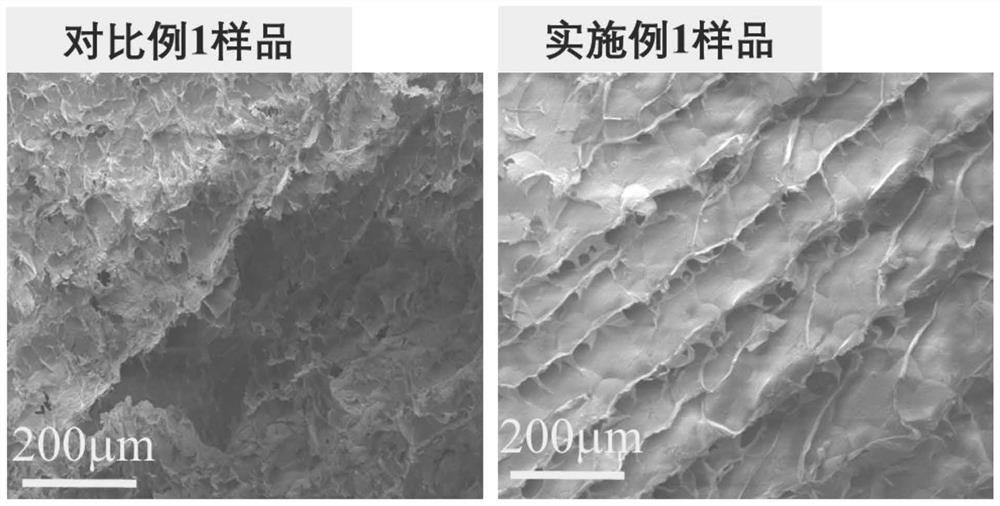

[0035] The nanocellulose composite airgel prepared by the method of the present invention has good flame retardancy, the limiting oxy...

Embodiment 1

[0049] Take 1g of cellulose raw pulp, 0.015g of tetramethylpiperidine nitrogen oxide, 0.06g of sodium bromide, and 100mL of deionized water in a beaker. After mixing and stirring evenly, add 6mL of a 10% sodium hypochlorite solution by mass fraction, Stirring was continued for 5 hours; during the reaction, the pH of the system was maintained at 10.5 by dropping 0.5 mol / L sodium hydroxide solution. Subsequently, the obtained mixture was mechanically treated with a domestic mixer at a rotational speed of 1000 r / min, and washed with deionized water after 30 minutes to obtain a nanocellulose suspension.

[0050] The obtained nanocellulose suspension and the methyltrimethoxysilane hydrolyzate obtained at pH=3 were stirred and mixed in a household mixer at a speed of 1200 r / min for 10 minutes according to a mass ratio of 1:0.1, Then slowly add 10% calcium chloride solution dropwise to obtain composite nanocellulose hydrogel.

[0051] The obtained composite nanocellulose hydrogel is...

Embodiment 2

[0056] Take 1g of cellulose raw pulp, 0.015g of tetramethylpiperidine nitrogen oxide, 0.06g of sodium bromide, and 100mL of deionized water in a beaker. After mixing and stirring evenly, add 6mL of a 10% sodium hypochlorite solution by mass fraction, Stirring was continued for 5 hours; during the reaction, the pH of the system was maintained at 10.5 by dropping 0.5 mol / L sodium hydroxide solution. Subsequently, the obtained mixture was mechanically treated with a domestic mixer at a rotational speed of 1000 r / min, and washed with deionized water after 30 minutes to obtain a nanocellulose suspension.

[0057] The obtained nanocellulose suspension and the methyltrimethoxysilane hydrolyzate obtained at pH=3 were stirred and mixed in a household mixer at a speed of 1200 r / min for 10 minutes according to a mass ratio of 1:0.25, Then slowly add 10% calcium chloride solution dropwise to obtain composite nanocellulose hydrogel.

[0058] The obtained composite nanocellulose hydrogel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com