Young's elastic modulus tester with optical lever without reflector

A Young's elastic modulus and measuring instrument technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult adjustment, difficult measurement of Young's elastic modulus, easy breakage of the plane mirror, etc. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

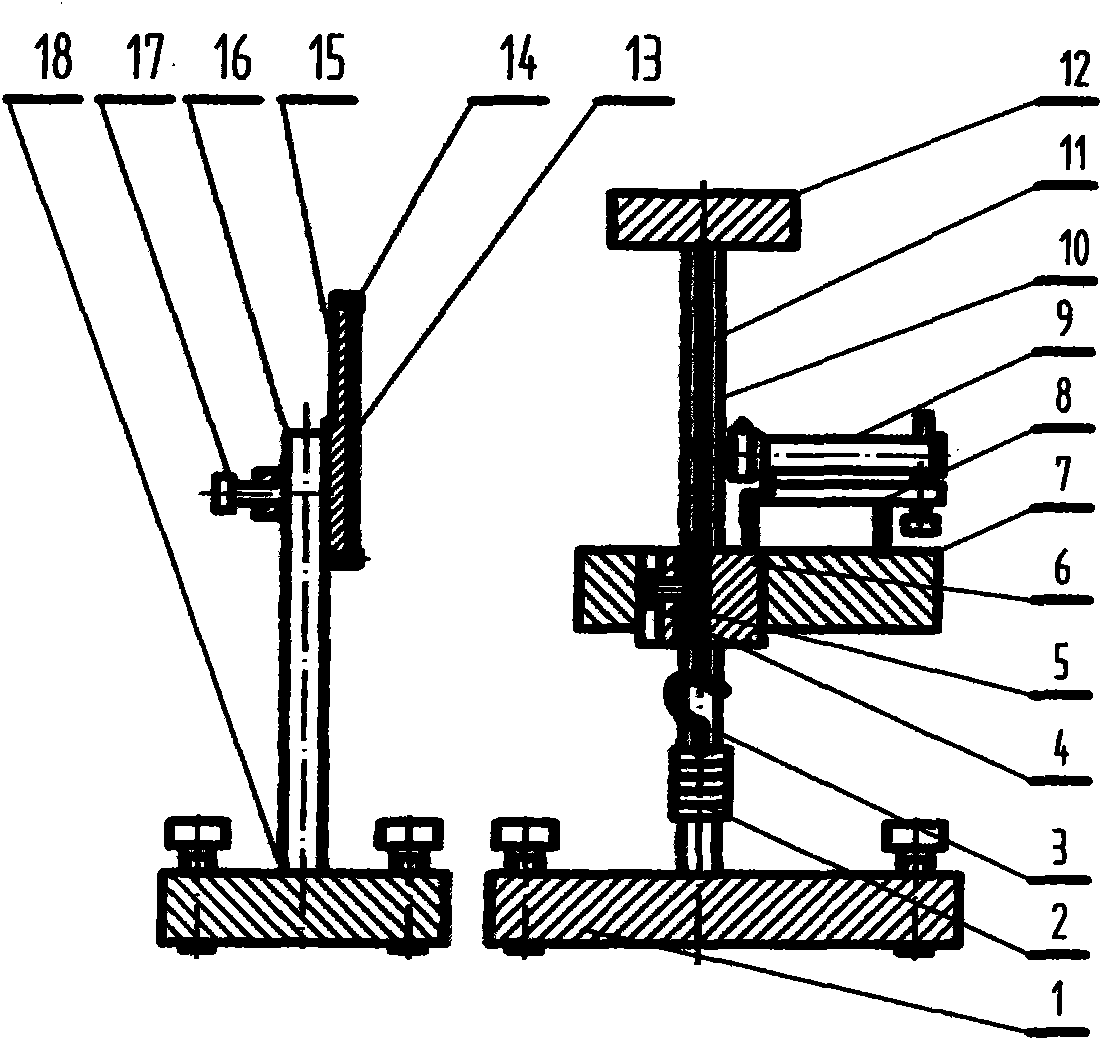

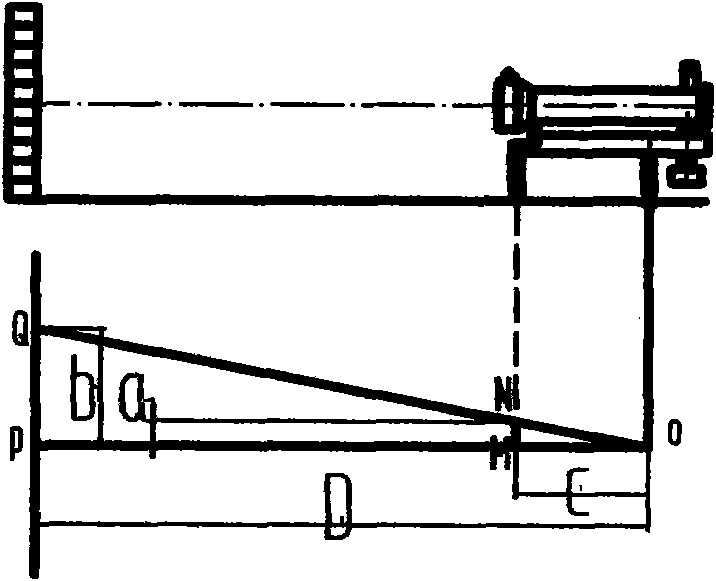

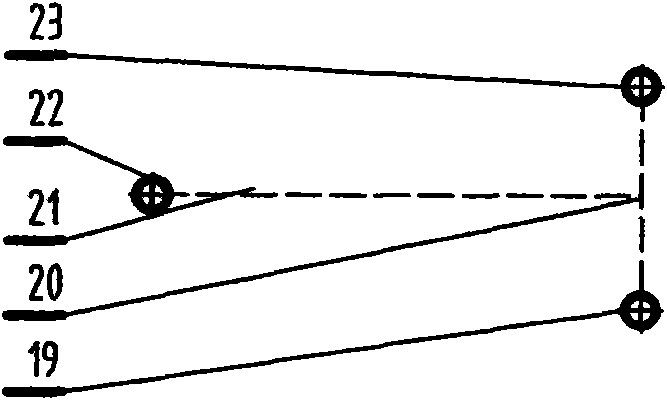

[0016] In the figure, the instrument base 1, the grooved workbench 7, the upper beam 12 and the column 10 constitute the basic frame of Young's elastic modulus measuring instrument, the upper end of the steel wire 11 to be tested is fixed on the upper beam 12, and the lower end is connected with the hook tray 3 , the steel wire movable chuck 6 is fastened on the steel wire by the steel wire pressing block 5 and the steel wire compression screw 4, the telescope is fixed on the upper end surface of the tripod bracket, the front foot 22 of the tripod bracket 8 is placed on the upper end surface of the steel wire movable chuck 6, and the tripod bracket The two rear feet 19,23 of 8 are placed in the small groove on the end face of the workbench with grooves, the optical axis of the telescope is parallel to the vertical line 21 of the connecting line 20 between the front foot 22 of the tripod bracket and the two rear feet 19,23, and the scale is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com