Split matching and testing device for coiled tubing well logging

A testing device and oil pipe technology, which is applied in the direction of measurement, drilling pipe, casing, etc., can solve the problems of increasing the fixing of electronic components and shortening the length, etc., and achieve the effect of firm use, increased fixing, and simple and reliable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

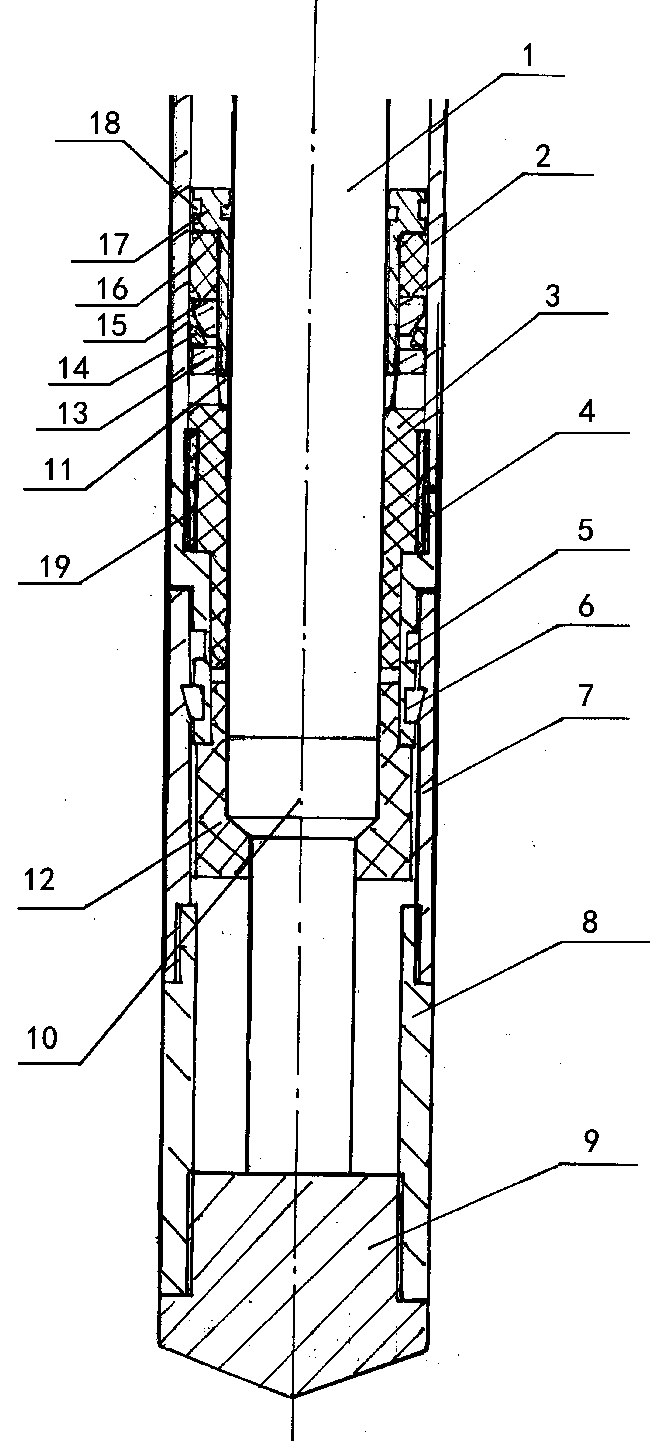

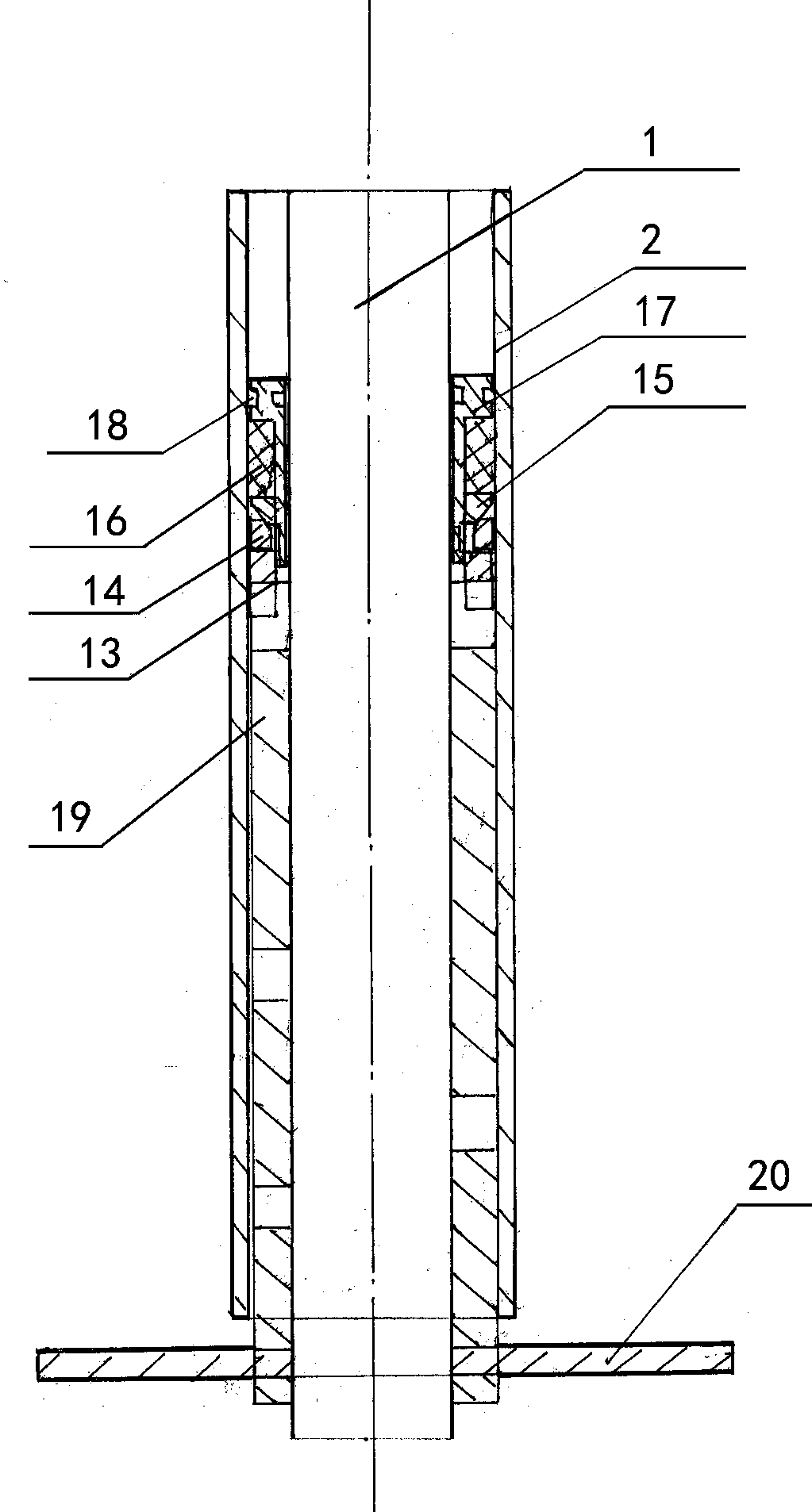

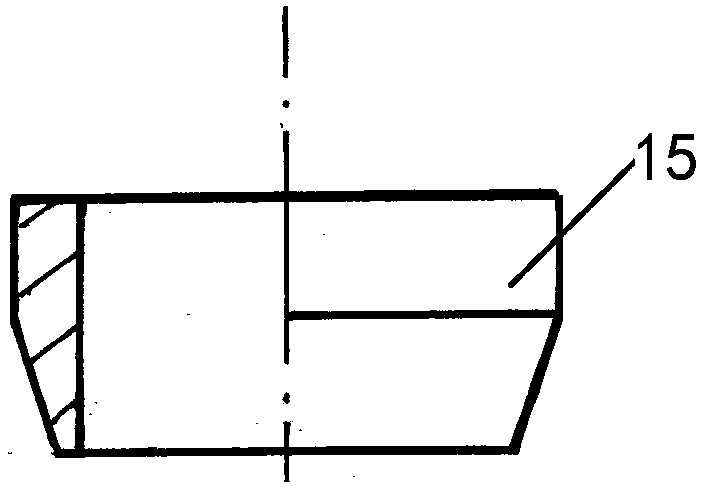

[0034] Embodiment 1, with reference to attached figure 1 , a coiled tubing logging split-coordinate testing device mentioned in the present invention, its technical scheme is: including sealing PTFE protection pad 3, transition joint 4, sealing rubber ring 5, split support ring 6, sealing protection sleeve 7 , test tube 8, guide shoe 9, test terminal 10, seat sealer 13, lock spring 14, cone 15, sealing rubber cylinder 16, liner 17, setting seal interference rubber ring 18, in coiled tubing 2 The cavity is pierced with a test cable 1, and at the end of the coiled tubing 2, a seat sealer 13, a lock spring 14, a cone 15, a sealing rubber tube 16 and a liner 17 are installed in the space between the coiled tubing 2 and the test cable 1. cavity, the seat sealer 13 is connected to the lower end of the liner 17, and then, refer to the attached figure 2 , align the seat sealer 13 with the seat seal wrench 20 and rotate, the liner 17 moves down, and the lock spring 14 drives the cone...

Embodiment 2

[0052] Embodiment 2, a coiled tubing logging split test device mentioned in the present invention, differs from Embodiment 1 in that: the cone and the lock spring are removed, and the seat sealer is changed to have ring teeth on the outer wall , the inner side is threaded with the lower end of the liner, and the ring teeth on the outer wall are fixed and supported by the coiled tubing. In this way, through the rotation of the special wrench for the seat seal, the upper surface of the seat seal is in contact with the sealing rubber cylinder 16 and squeezed Press the sealing rubber tube 16 to make it expand, thereby also realizing the long seal between the coiled tubing and the test cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com