Heat treatment method of steel rail welding joint

A heat treatment method and technology for welding joints, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as low longitudinal hardness of rail head treads, achieve high fatigue life, ensure railway operation safety, and improve the effect of joint toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

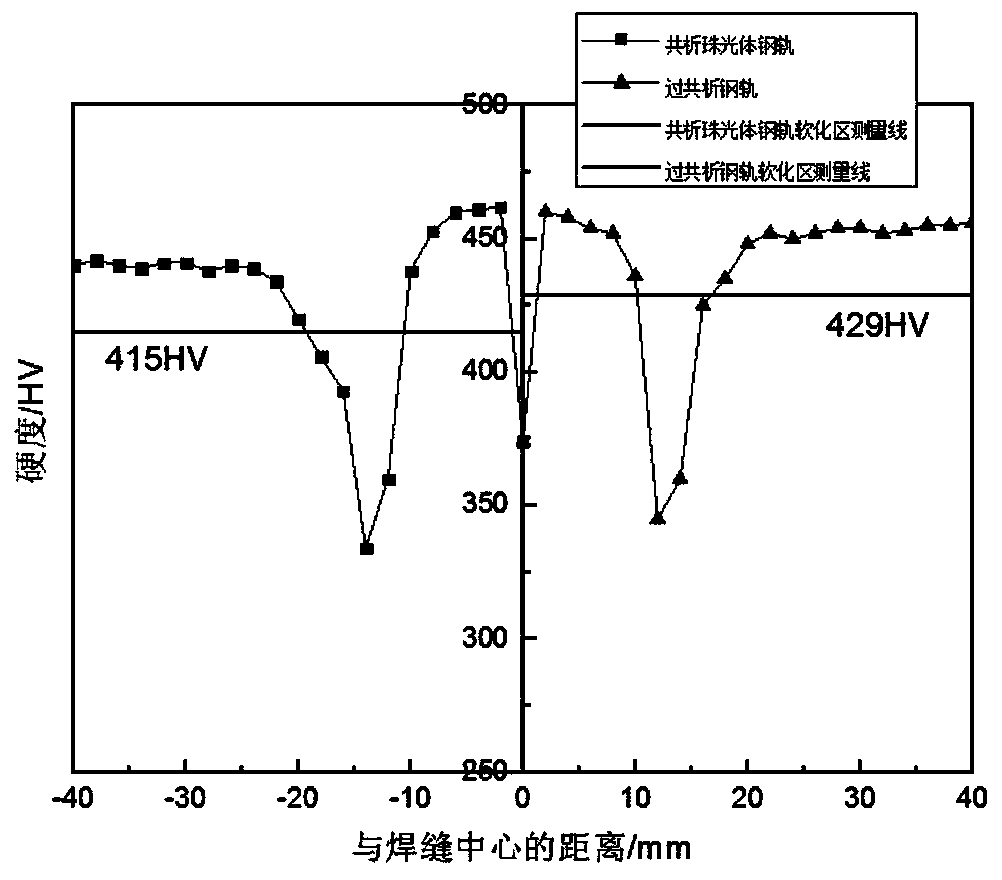

[0039] After the rail with a specification of 68kg / m has completed the upsetting and push-out during the mobile flash welding process, the welded joint is subjected to post-weld heat treatment. Firstly, the rail joint with residual temperature of 1100 °C after welding is cooled in the first stage at the first cooling rate of 7.0 °C / s to reduce the surface temperature of the rail head of the rail joint to 740 °C, and then the rail joint is cooled at 3.0 °C The second cooling rate of / s is used for second-stage cooling to reduce the surface temperature of the rail head of the rail joint to 300°C, and finally the third cooling rate of 0.7°C / s is used for the third-stage cooling of the rail joint to reduce the temperature of the rail joint The temperature of the surface layer of the rail head is lowered to the room temperature of 25° C., thereby obtaining the welded joint of the rail with post-weld heat treatment of the present invention.

[0040] In the post-weld heat treatment p...

Embodiment 2

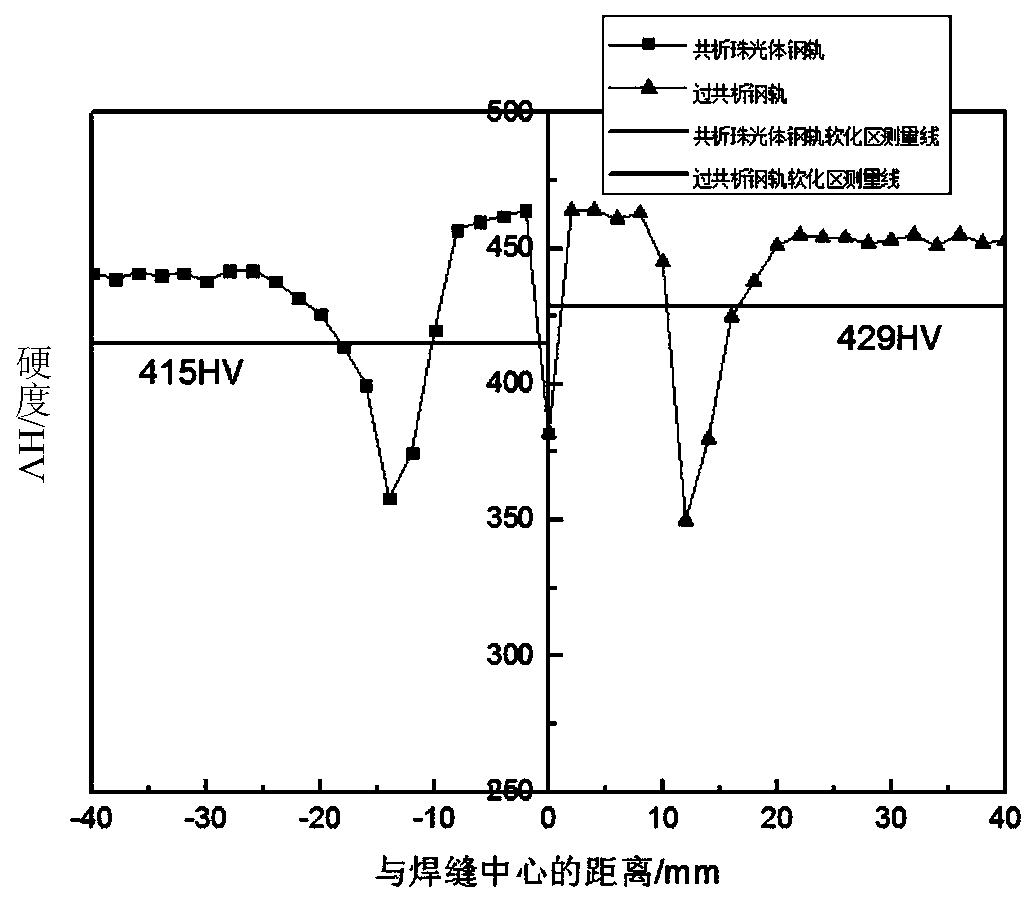

[0047] After the rails with a specification of 60kg / m have completed upsetting and push-out during the mobile flash welding process, the welded joints are subjected to post-weld heat treatment. Firstly, the rail joint with residual temperature of 1000 °C obtained by welding is cooled in the first stage at the first cooling rate of 8 °C / s to reduce the surface temperature of the rail head of the rail joint to 680 °C, and then the rail joint is cooled at 3.2 °C The second cooling rate of / s is used for the second-stage cooling to reduce the surface temperature of the rail head of the rail joint to 320°C, and finally the rail joint is subjected to the third-stage cooling at a third cooling rate of 0.70°C / s to reduce the temperature of the rail joint The temperature of the surface layer of the rail head is lowered to room temperature of 25° C., thereby obtaining the post-weld heat-treated rail welded joint of dissimilar materials of the present invention.

[0048] In the post-weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening zone width | aaaaa | aaaaa |

| Softening zone width | aaaaa | aaaaa |

| Softening zone width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com