Building technology for pile leg of self-elevating wind power vessel

A jack-up and wind power technology is applied in the field of construction technology of jack-up wind power ship pile legs, and achieves the effect of reducing the cumulative error of marking, satisfying the shape, and saving the cost of outfield assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

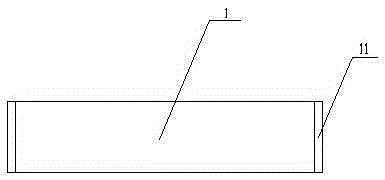

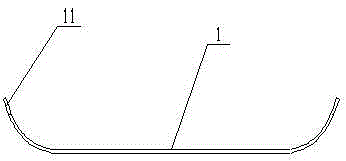

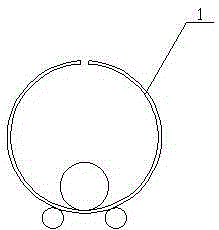

[0026] The invention discloses a construction process for the legs of a self-elevating wind power ship. The main steps are as follows: (1) Cylinder rolling: as figure 1 , figure 2 , image 3 As shown, the high-strength steel plate 1 made of E690 material with a thickness of 70mm is used to make a cylinder with a diameter of 3600mm. After the steel plate 1 adjusts the angle and enters the rolling machine, the pressure is gradually increased at both ends for rolling. Use the template to check the arcs at both ends Whether it is in place, roll the middle part after it is in place, take it off when the two ends are basically in contact, and re-enter the plate rolling machine to roll in place after completion, hang it on the rotating roller frame after tack welding, and perform longitudinal seam welding. Weld alternately inside and outside according to the actual situation to ensure that the welding deformation is controlled; finally take it off and put it into the rolling machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com