Patents

Literature

54results about How to "Simple mold opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

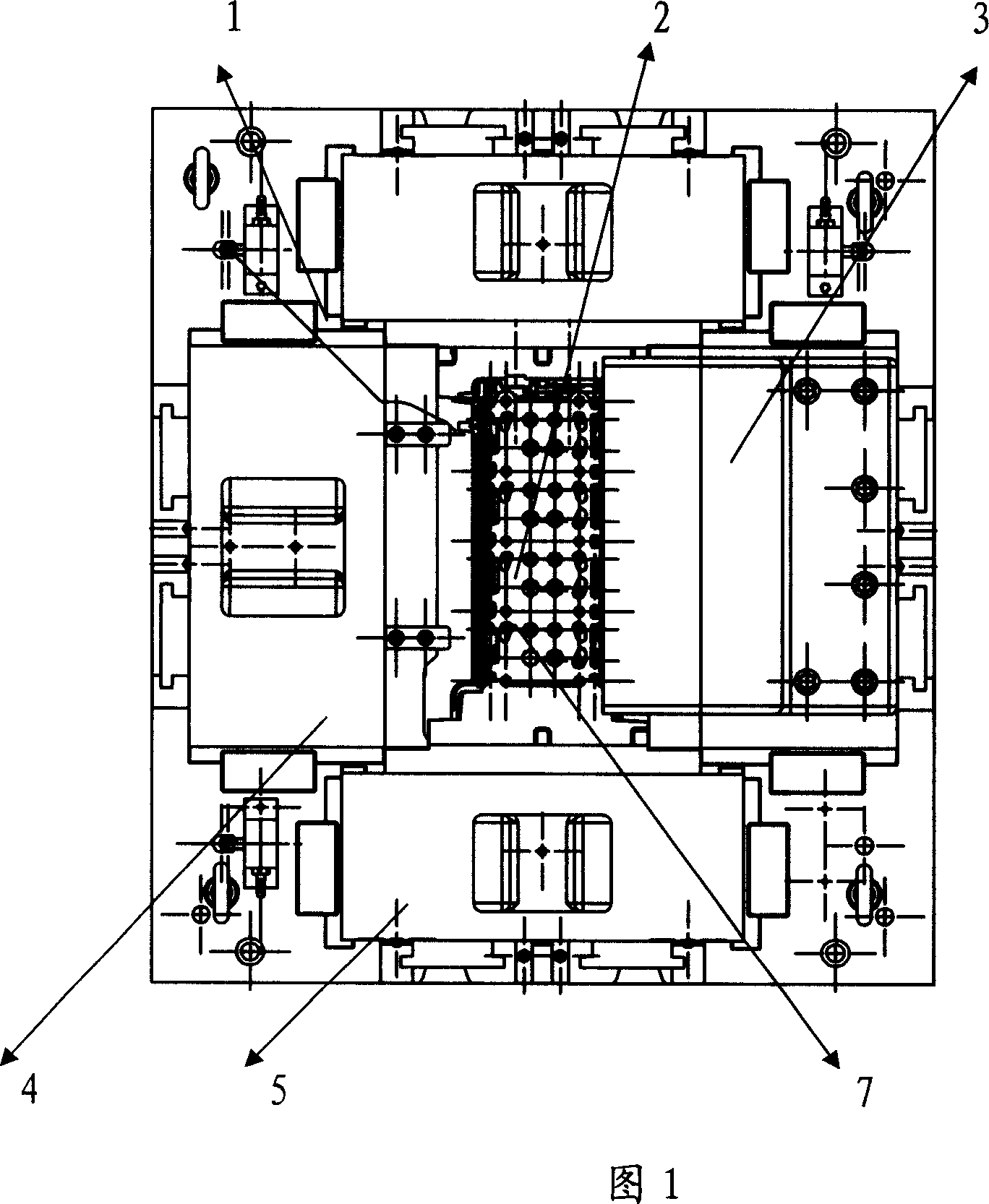

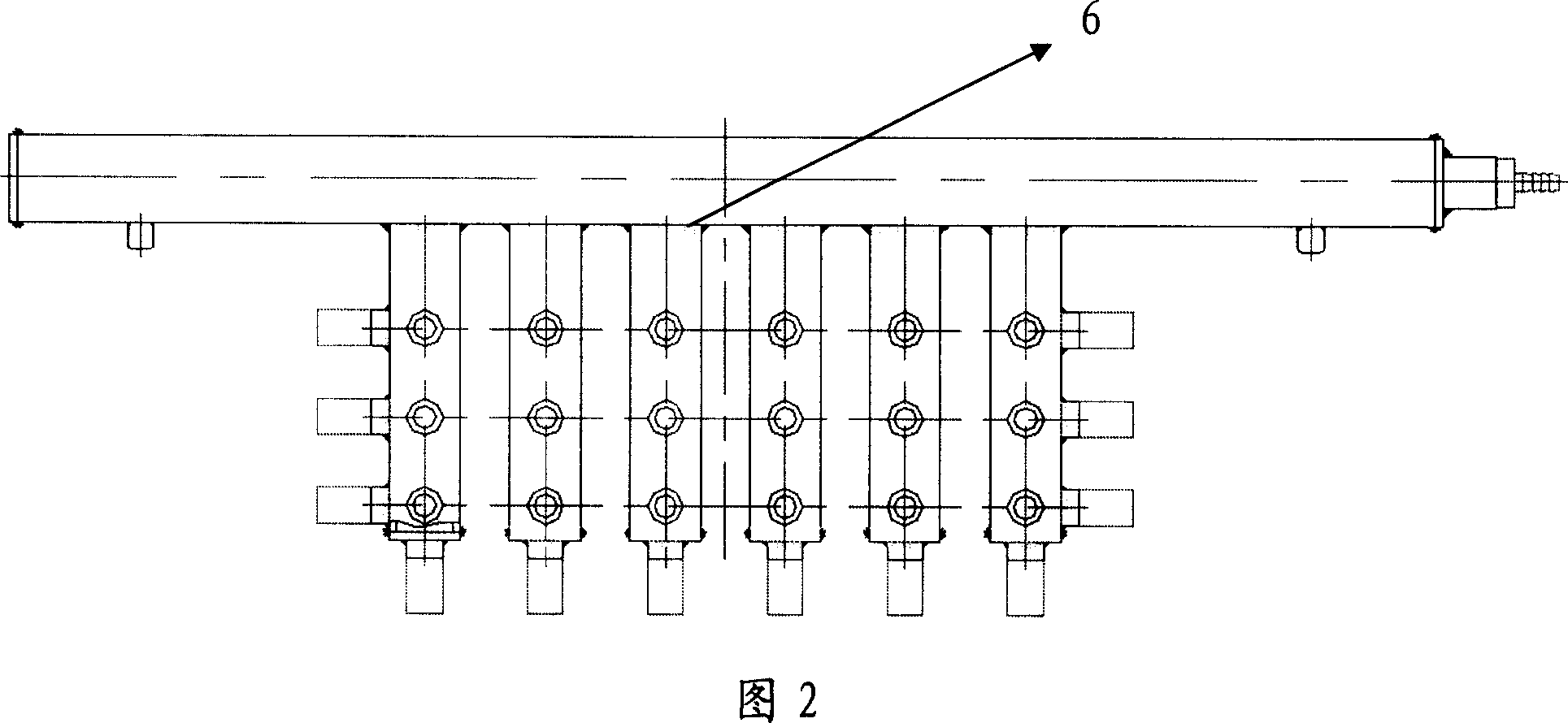

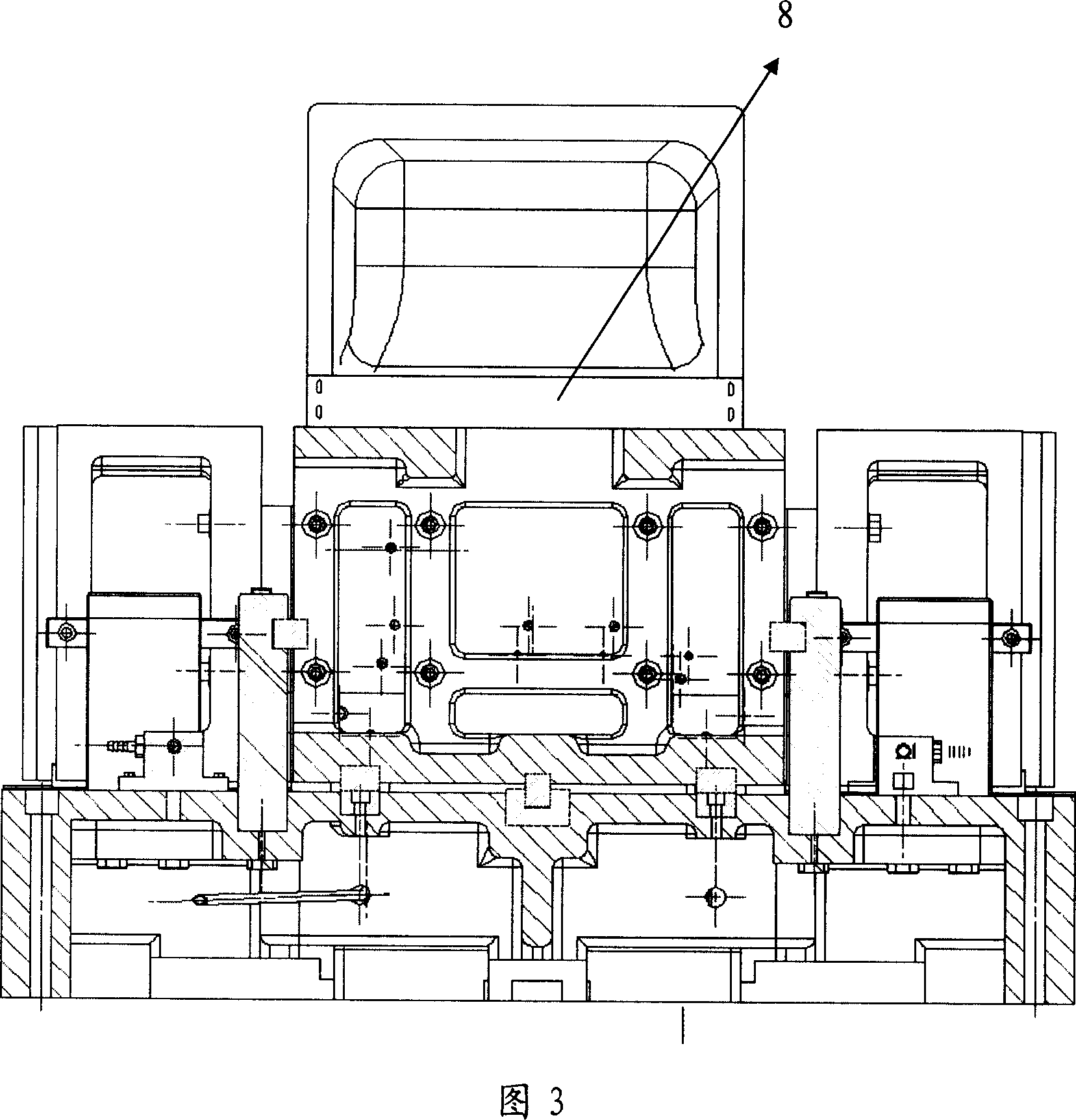

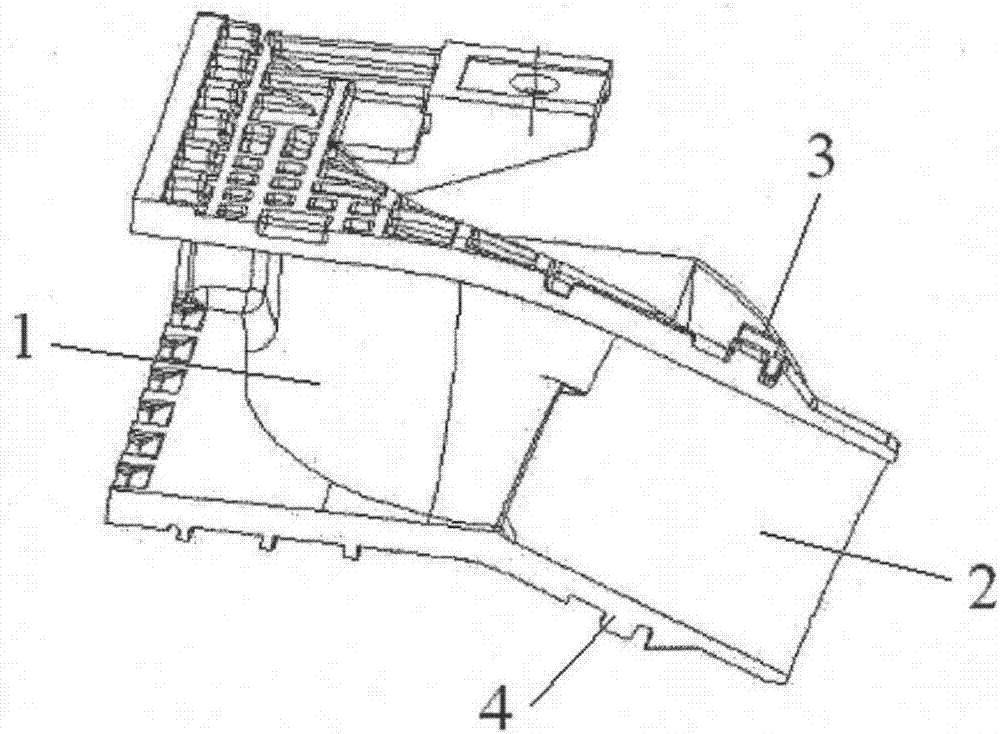

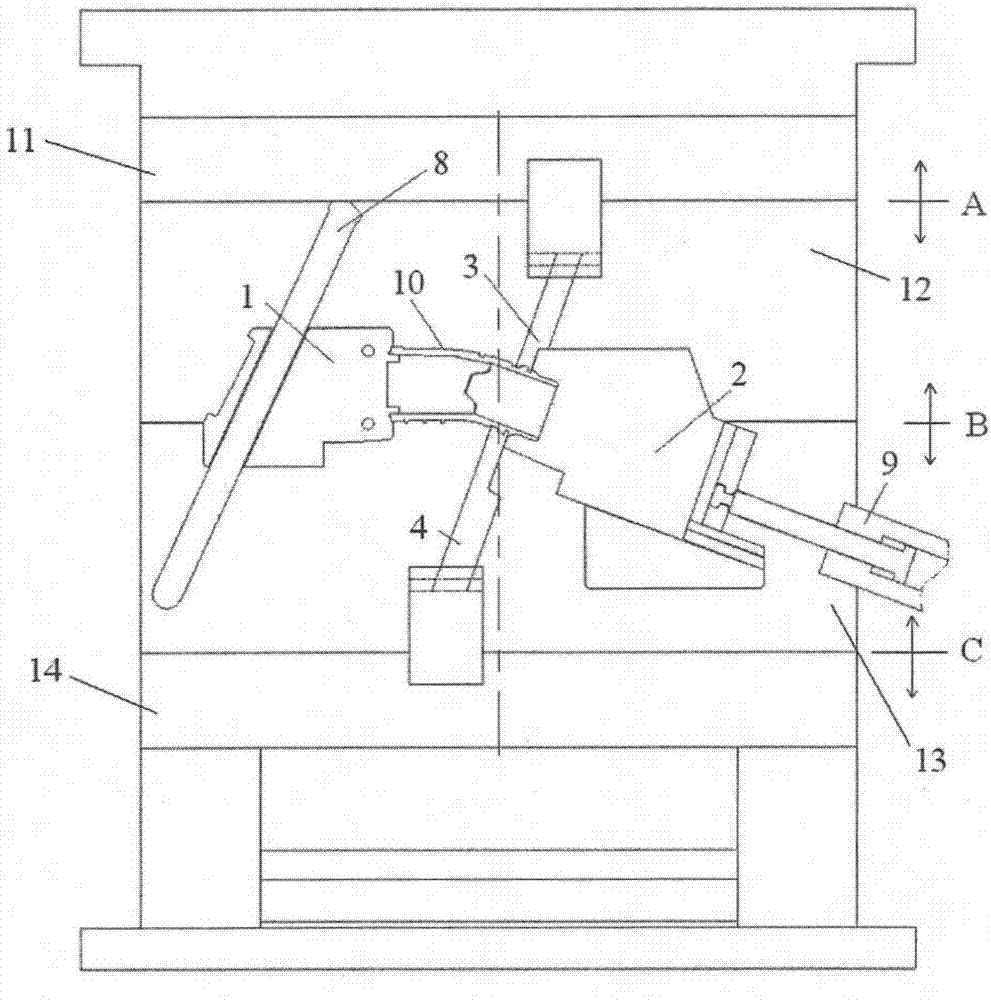

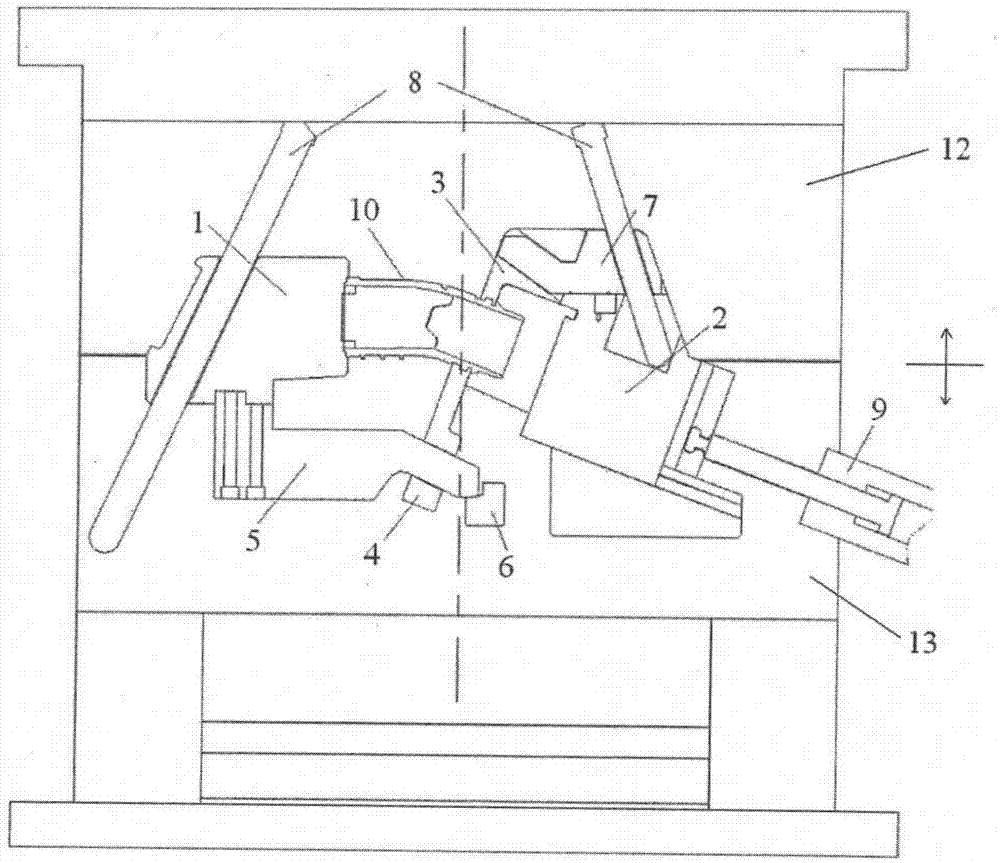

Diesel engine four-valve cylinder head gravity casting die and casting method thereof

ActiveCN1990134ASolve core problemsSimple mold openingFoundry mouldsFoundry coresProduction rateGravitation

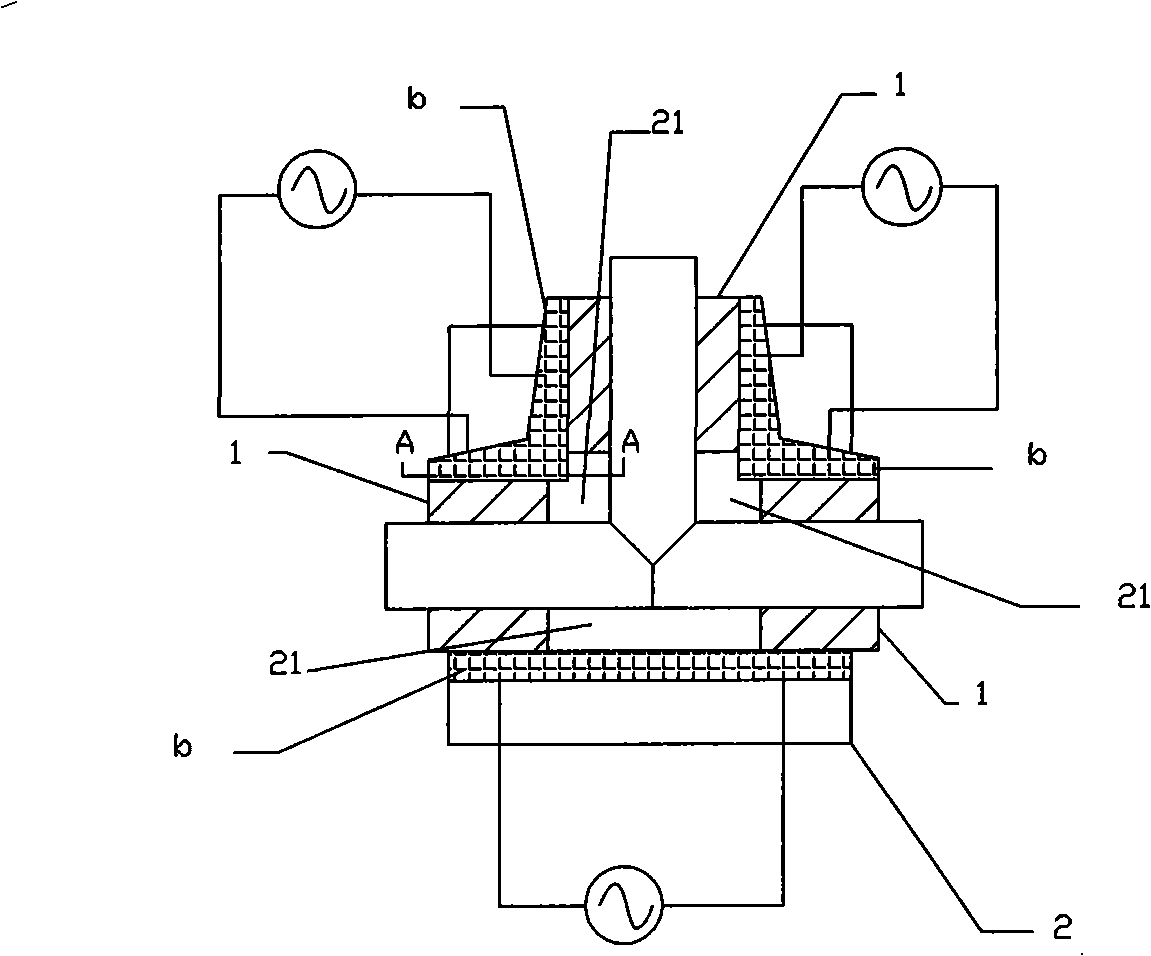

The invention discloses a diesel engine four air gate head gravity casting mold and its molding method. It uses center heater for warming appearance mold to making the mold warming rapidly and temperature uniform. It uses the head external form mold structure which combines the water cool and air cool to making the whole mold forming the reasonable temperature field of aluminum alloy order consolidation. It uses converter-type adjustable flow, pouring cup of casting and slaging at the same time, ensures the quality of castings, and raises the productivity. It uses the design of four-direction open mode cylinder head integral water sand core mold, the quality of castings in integral water sand core is good, and it is time-saving, labor-saving and easy to opening mold. The mold and methods in the invention can be used for diesel engine four air gate head gravity casting process.

Owner:GUANGXI YUCHAI MASCH CO LTD

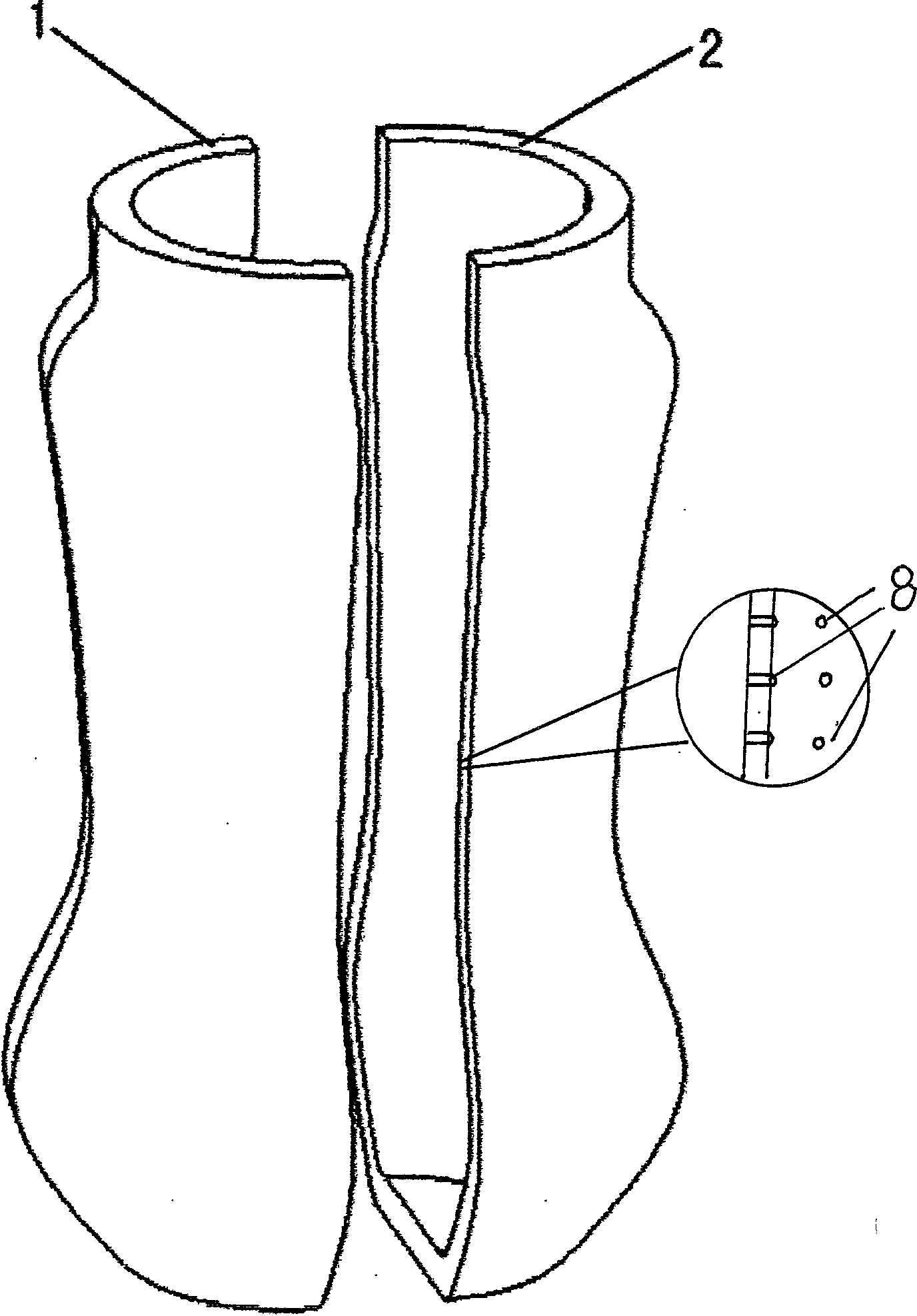

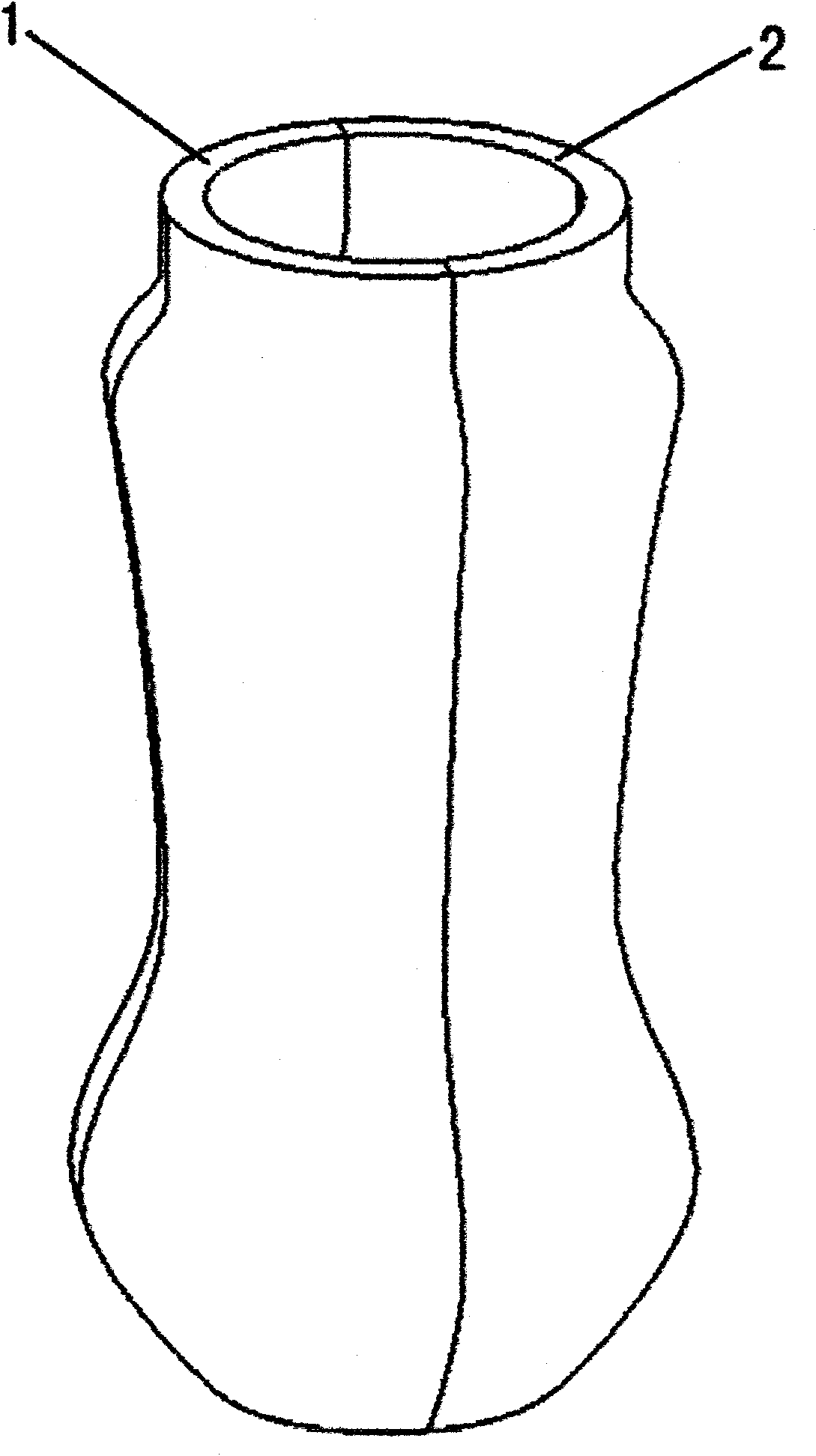

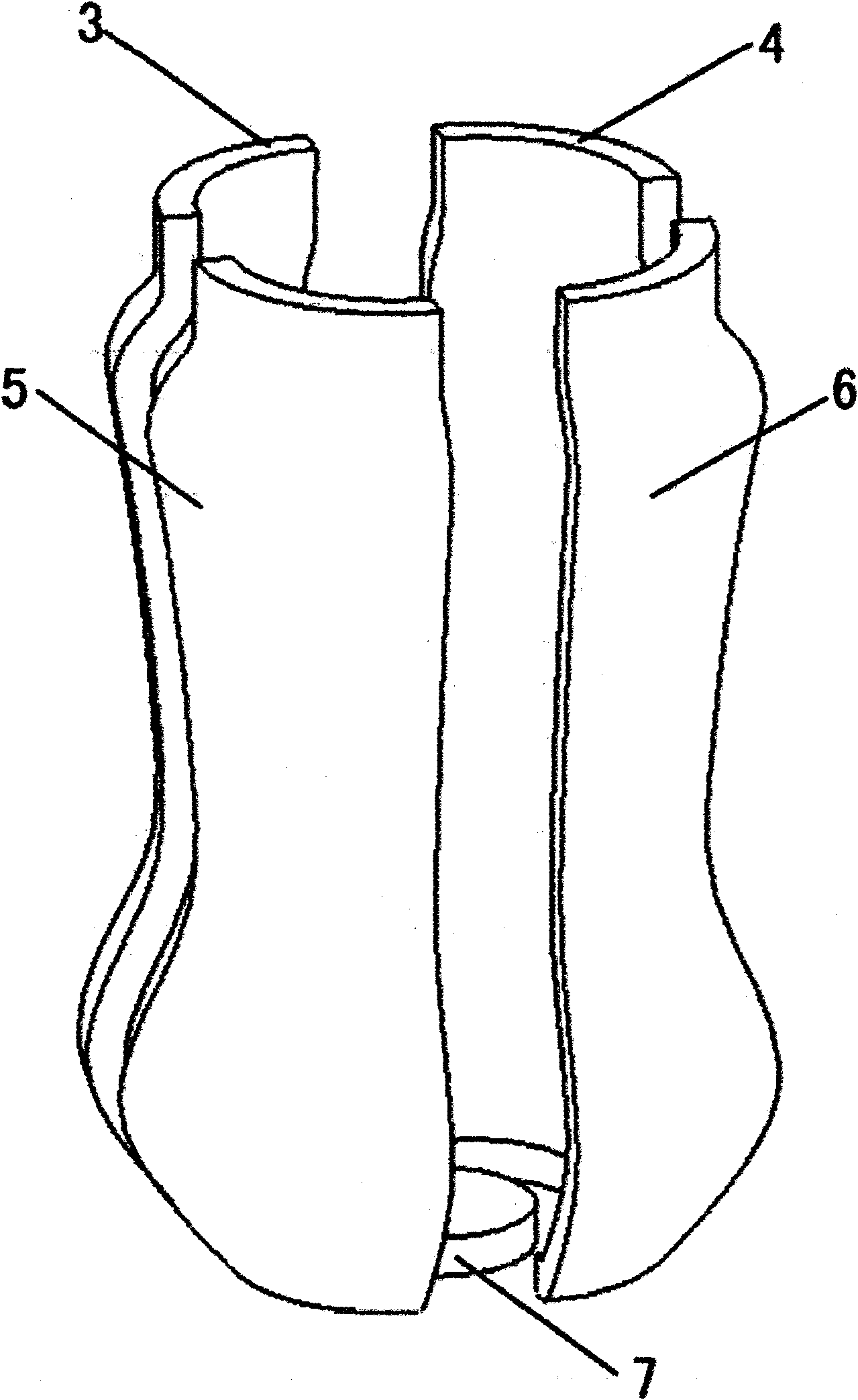

Ventilated plastic calabash master die

The invention relates to a ventilated plastic calabash master die which is made of plastics, wherein the integrated master die comprises master die vanes which are divided into several parts in the vertical direction, small ventilated holes are formed on the master die vanes, and transparent plastics can be used. Compared with the currently used gypsum master die, the plastic master die has the absolute advantages that plastic materials can be recycled but gypsum can not be recycled; the plastic master die has light weight and high strength and can be used for manufacturing finer patterns; the plastic master die has smooth surface and fine texture and can not generate bubbles; the plastic master die can prevent water and transmit light; the plastic master die can be repeatedly used for many times, can be scrubbed and can be sterilized easily; and the plastic master die has skillful manufacture and accurate positioning and can be opened easily. The transparent plastic master die can be used for observing growing process of the calabash, finding and removing the calabash of poor growth in time, correcting the culture process easily, summarizing the culture experience, increasing the pleasure of visibility, and manufacturing more three-dimensional, more beautiful and finer master die of the calabash.

Owner:黄全华

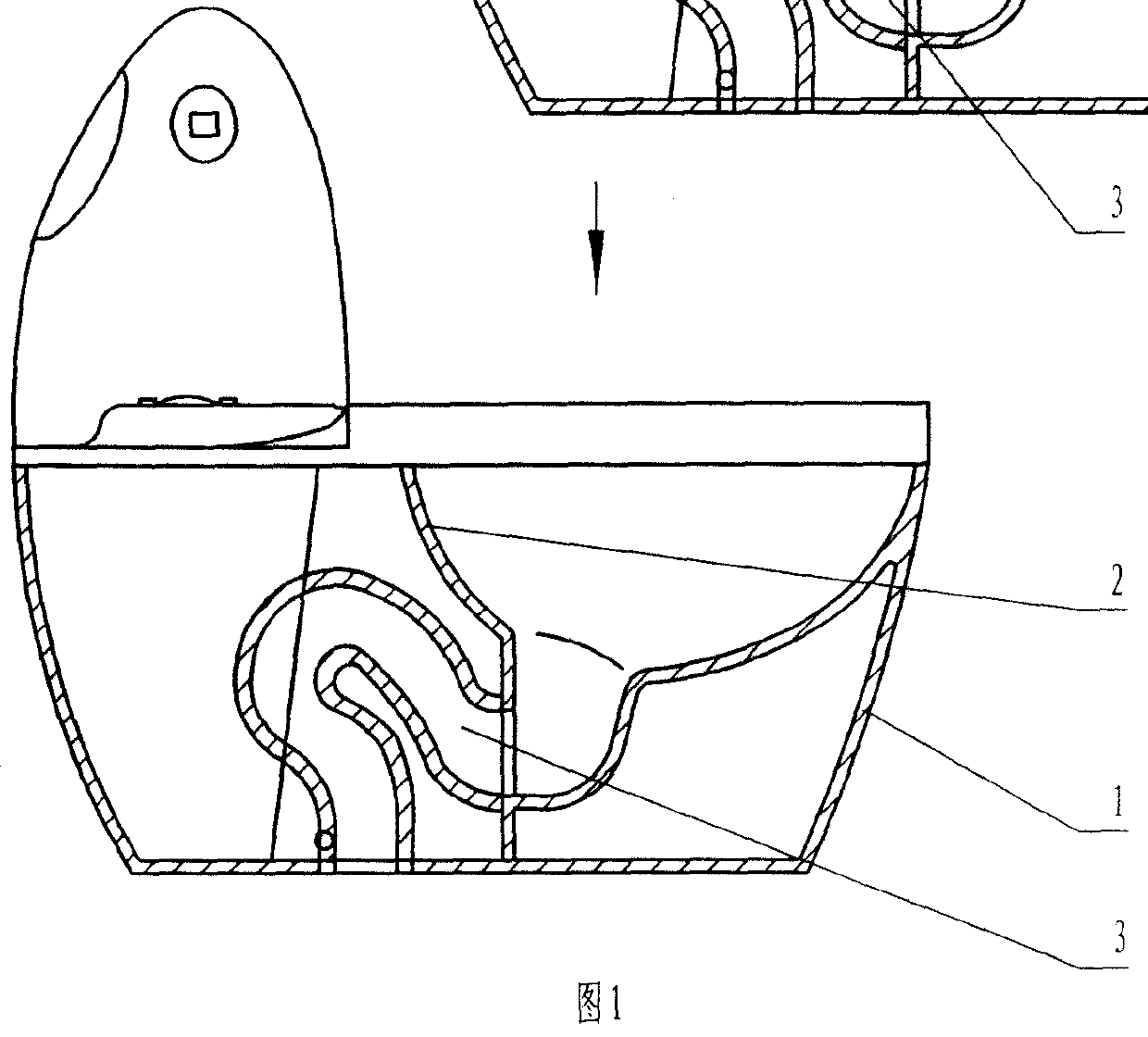

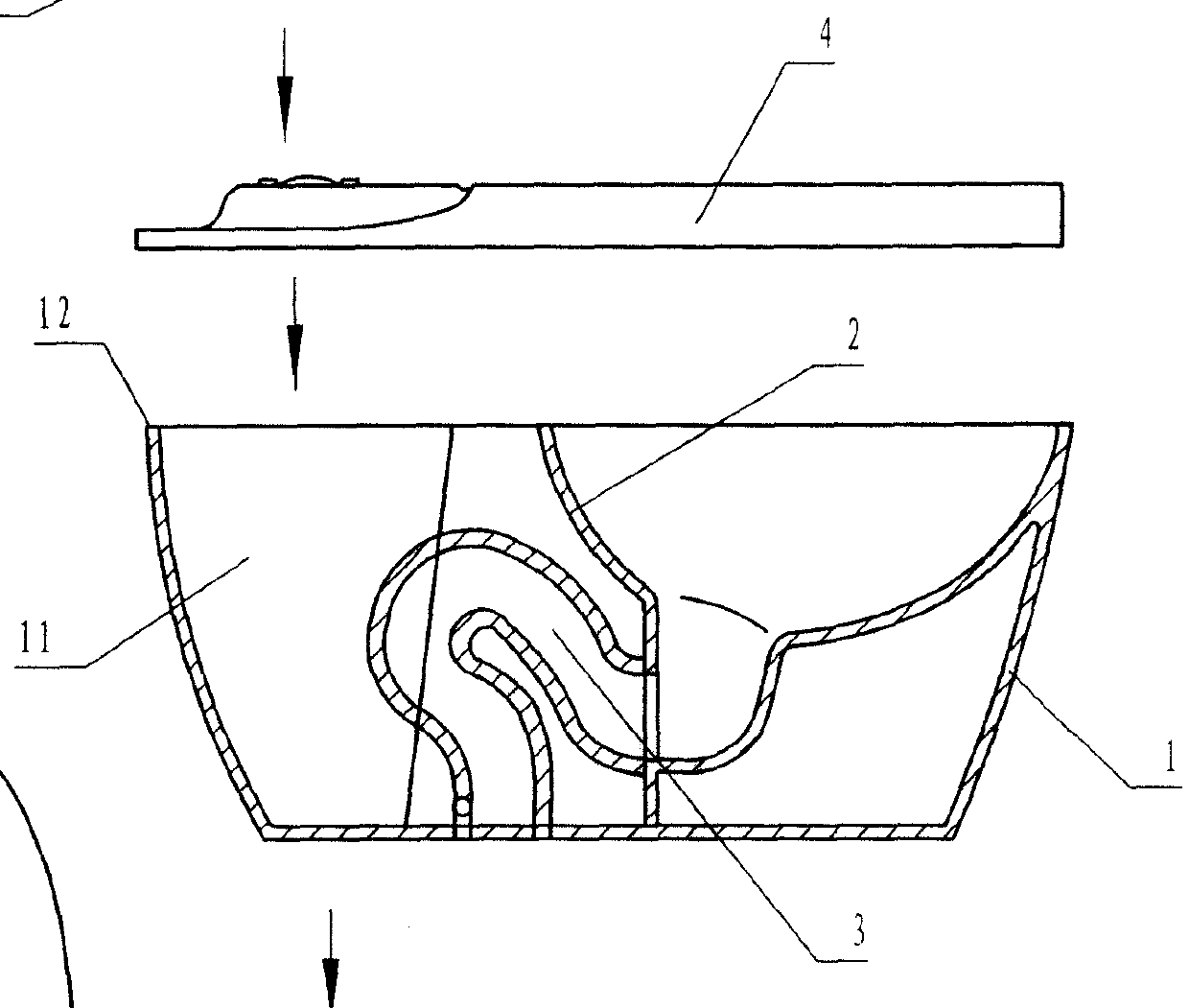

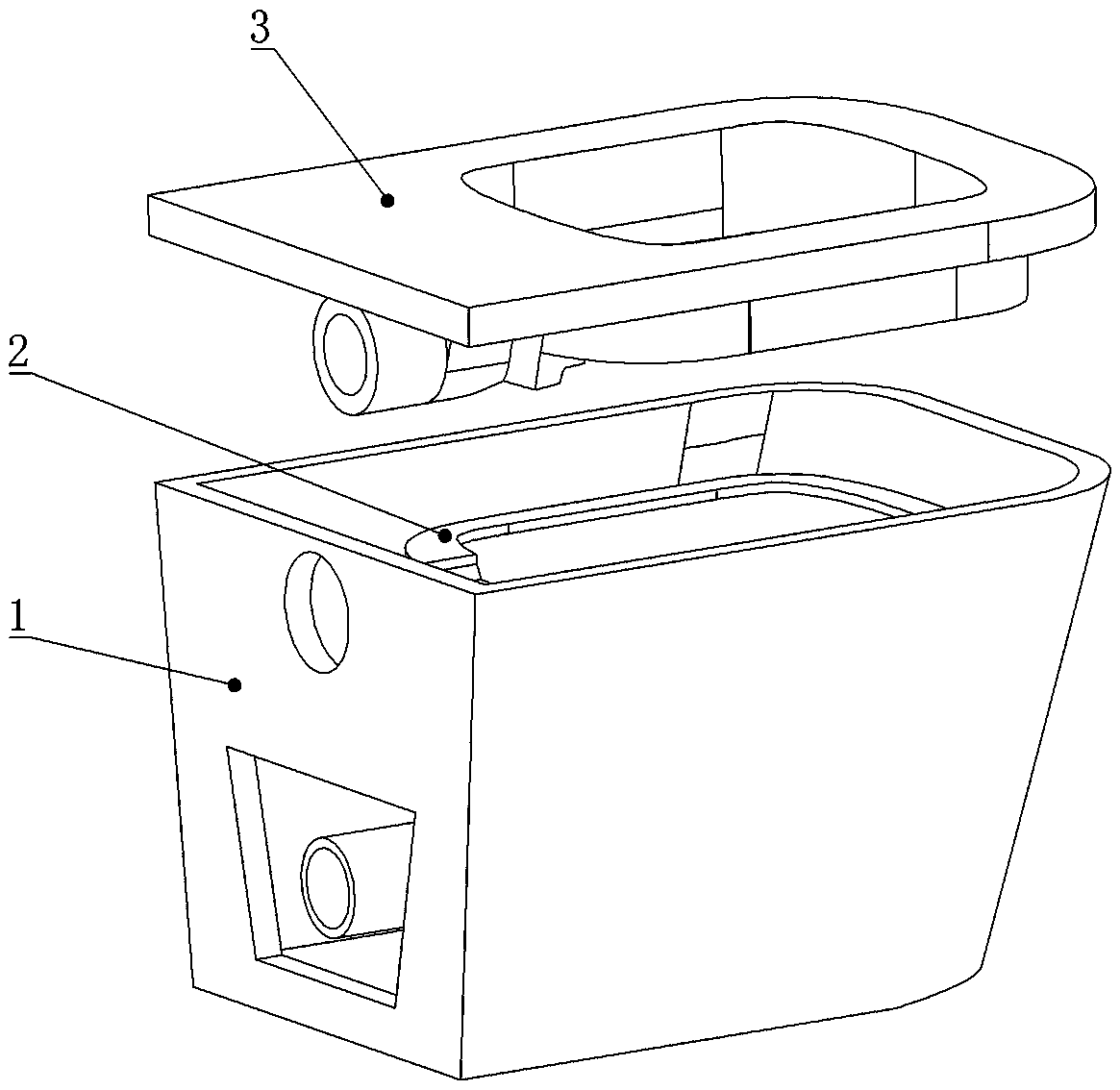

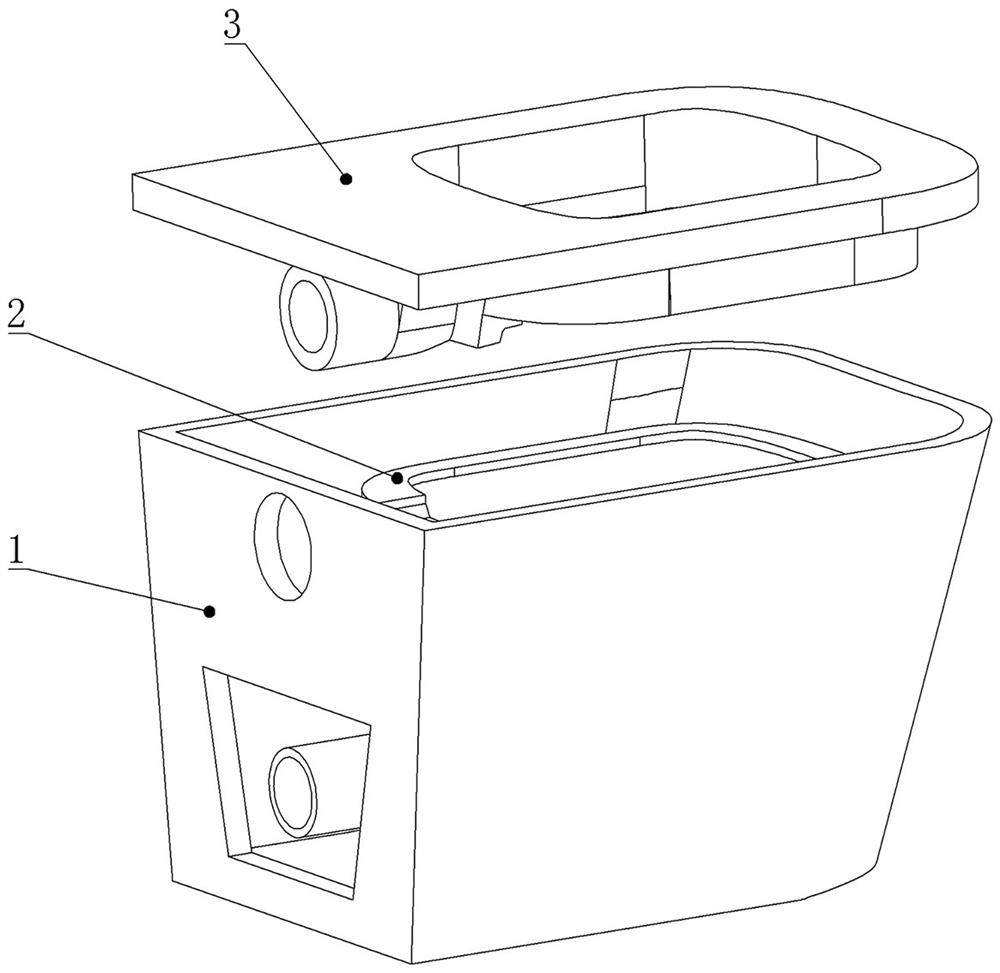

Toilet

InactiveCN101029499AQuality improvementSimple mold openingWater closetsFlushing devicesEngineeringFlush toilet

A toilet includes water box, base and face plate. The face plate is integrated with a washing device, which is fixed to the inner side of the base.

Owner:TAOJING FUJIAN IND

Instant-brewing beverage bottle with built-in solid beverage

ActiveCN104477523ASimple structureEasy mold opening and processingContainers with multiple articlesEngineeringBottle

The invention relates to an instant-brewing beverage bottle with a built-in solid beverage. According to the instant-brewing beverage bottle, a bottle body is formed through the screwed connection of an upper bottle body and a lower bottle body; an elastic membrane is arranged at the bottom of the lower bottle body, two sliding grooves are symmetrically fixed on the lower bottle body, a material box is clamped between the two sliding grooves in a sliding fit manner, a sealing film is arranged on a top opening of the material box, and a plurality of hollow or solid needle tubes are arranged on a cover plate; up-going ratchets are respectively arranged on vertical plates of the two sliding grooves, and pawls which are matched with the up-going ratchets of the sliding grooves are respectively arranged on two side faces of the material box; an isolated space for storing the solid beverage is separately formed in the bottle body, and during use, drinking water is introduced into the space to be mixed with the solid beverage, so as to form a liquid beverage. The beverage bottle has the characteristics of simple structure, low manufacturing cost and convenience and reliability in water inlet operation.

Owner:黄顺邦

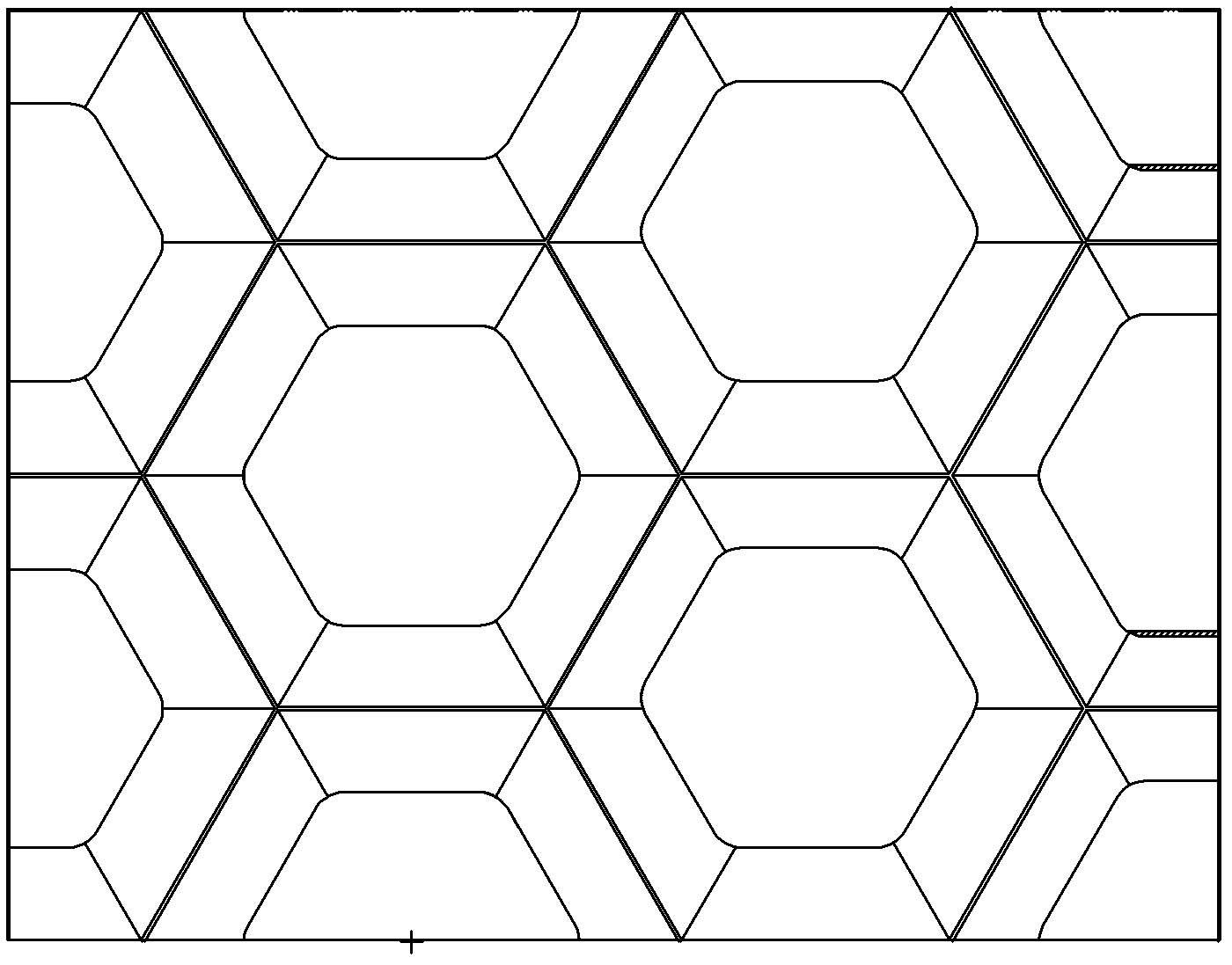

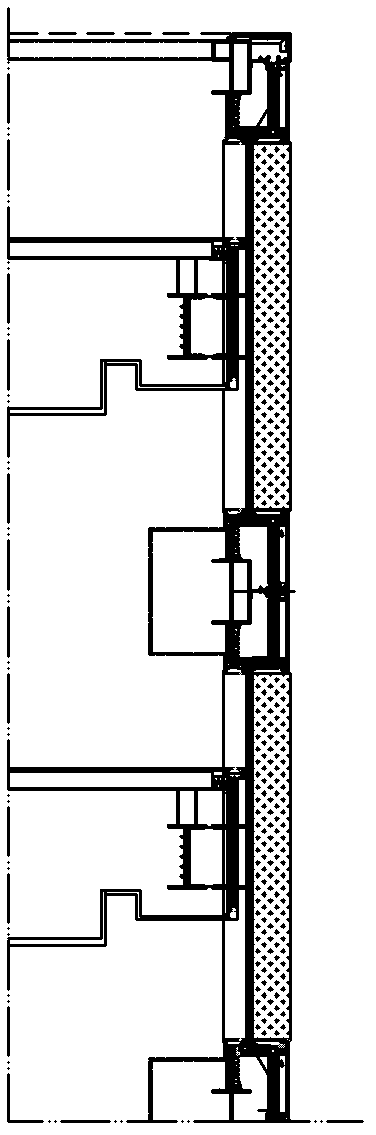

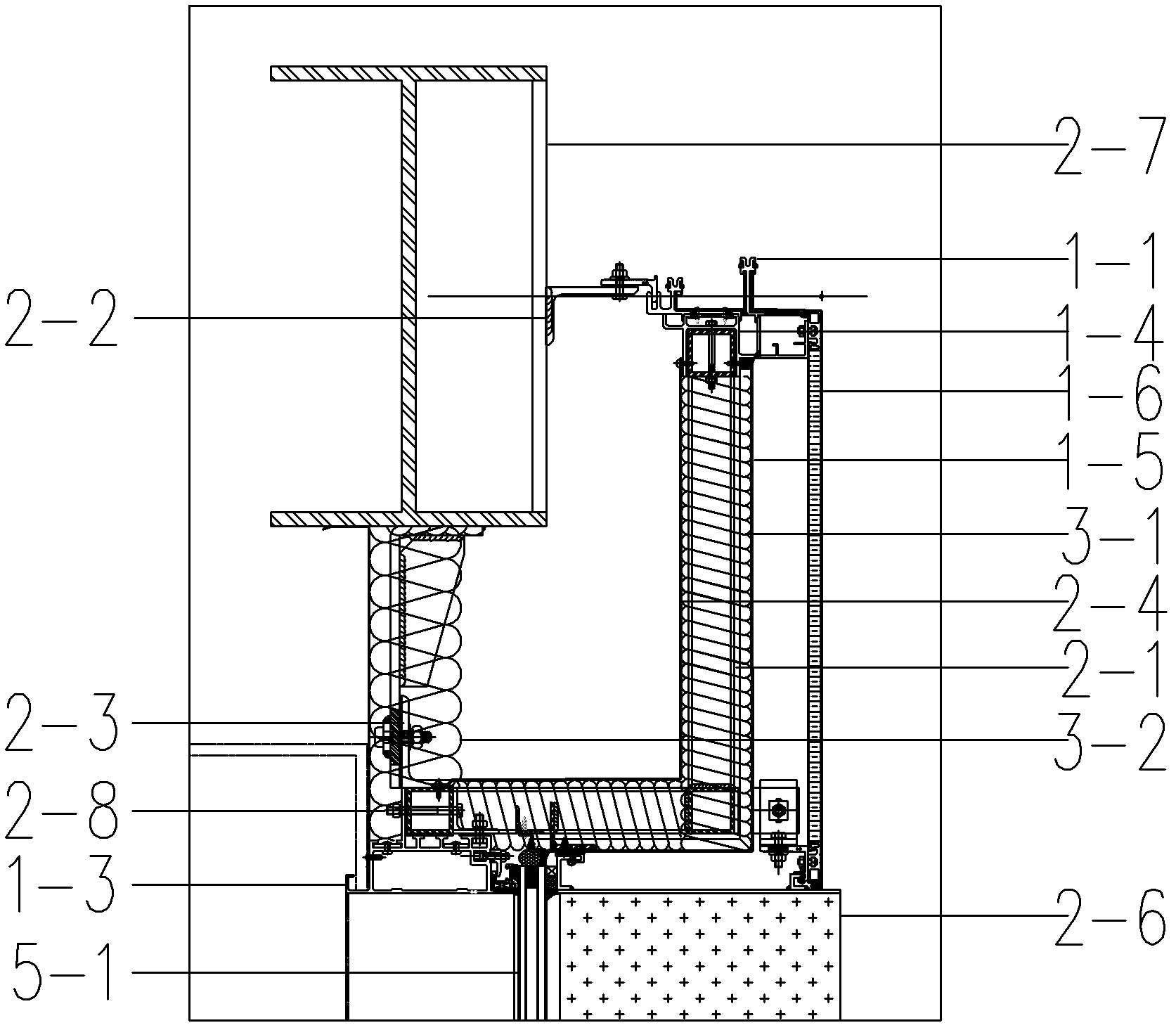

Hexagonal unit body

ActiveCN102644346AReduce air conditioning energy consumptionEnergy saving indicators improvedWallsAluminiumSteel frame

The invention provides a hexagonal unit body which comprises a hexagonal steel frame and glass arranged on the steel frame. The steel frame comprises a hexagonal small steel frame; connecting rods with equal lengths extend outwards from six vertexes of the small steel frame; a hexagonal big steel frame is formed by the outer ends of the connecting rods, which are used as the vertexes; an aluminium keel for being connected with the adjacent hexagonal unit body is arranged on the periphery of the profile of the big steel frame; and an outer decorative board is fixedly arranged on the outer lateral surface of the steel frame. A curtain wall system consisting of the hexagonal unit bodies has the advantages of simple force model, easiness for manufacturing and installing and high interchangeability. The invention also well solves the contradiction between the permeation and the energy saving of a building and provides a good waterproof structure.

Owner:CHENGDU JIANGHO CURTAIN WALL SYST ENG

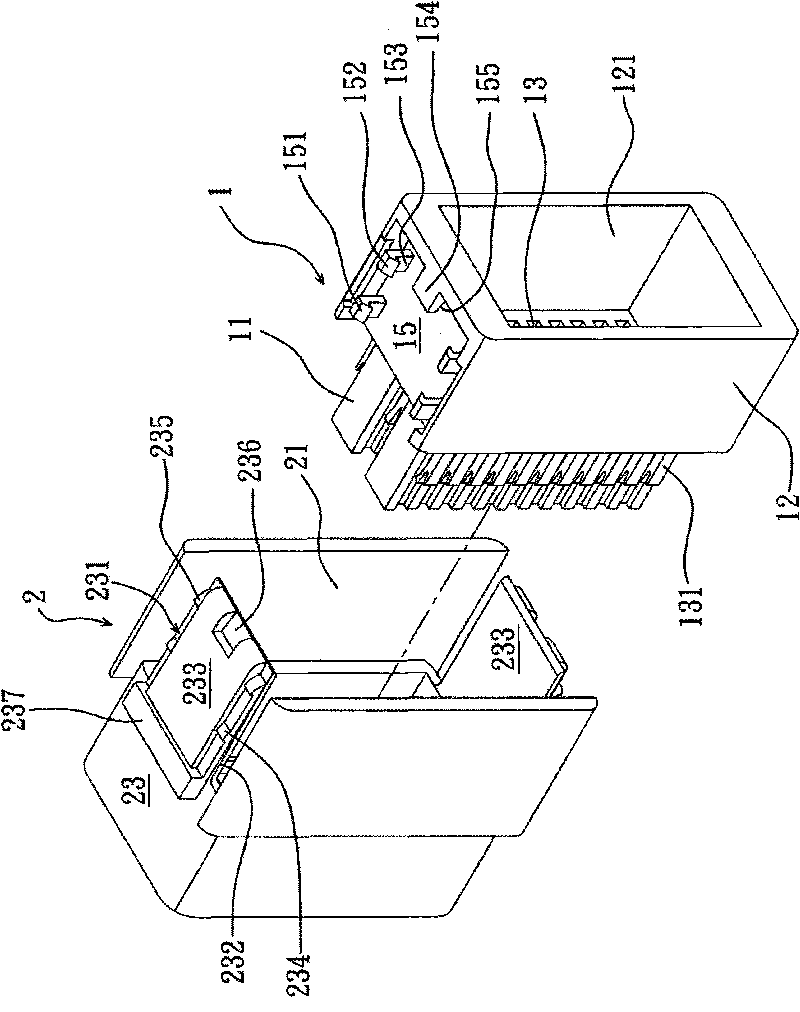

Electric connector and locking device thereof

ActiveCN101728688AStrong penetrating powerGood for pressure deformationEngagement/disengagement of coupling partsEngineeringMechanical engineering

The invention relates to an electric connector locking device which comprises a body and a positioning cover that are mutually sleeved, wherein a rail formed by at least one pair of guide hooks at a left side and a right side is arranged on the lateral wall of the body so as to be beneficial to the penetration of an insertion piece which extends from the front side of the lateral wall of the positioning cover; the insertion piece is a tongue piece which extends backwards and obliquely at the front end of a basal plate, an oblique included angle is arranged between the basal plate and the tongue piece so that a backstop edge at the rear end of the tongue piece is converted into a flat and straight state from a tilting state after at least one pair of blocking hooks at the left and right sides of the tongue piece are buckled and pressed by the guide hooks arranged oppositely so as to be beneficial to promoting a splicing piece inside the positioning cover to press a pressing piece of a terminal slot inside the body to deform, therefore, all contact terminals are positioned and locked in the terminal slot so as to be beneficial to promoting the combination between a complementary connector and the electric connector.

Owner:东莞胡连电子科技有限公司 +1

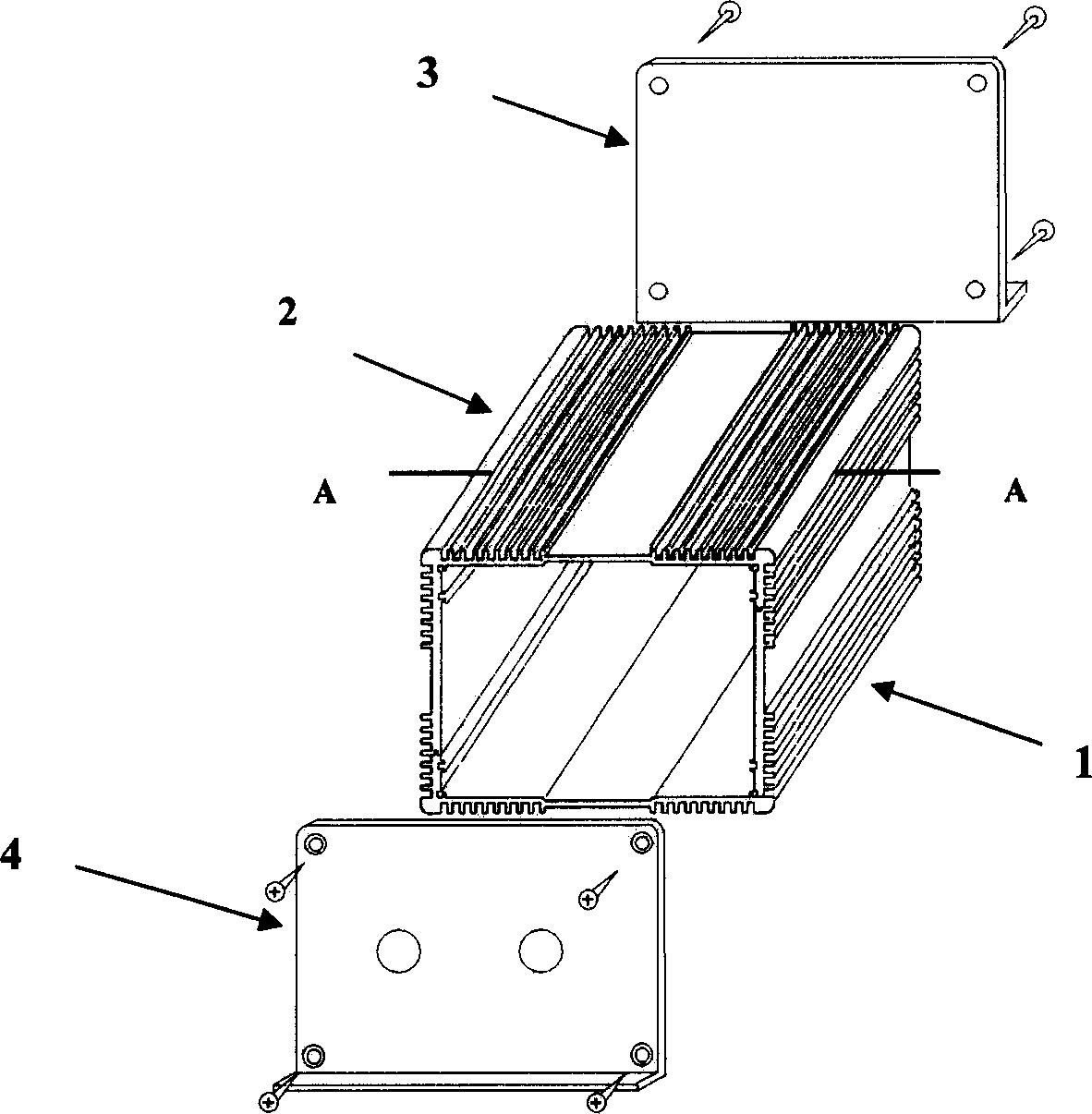

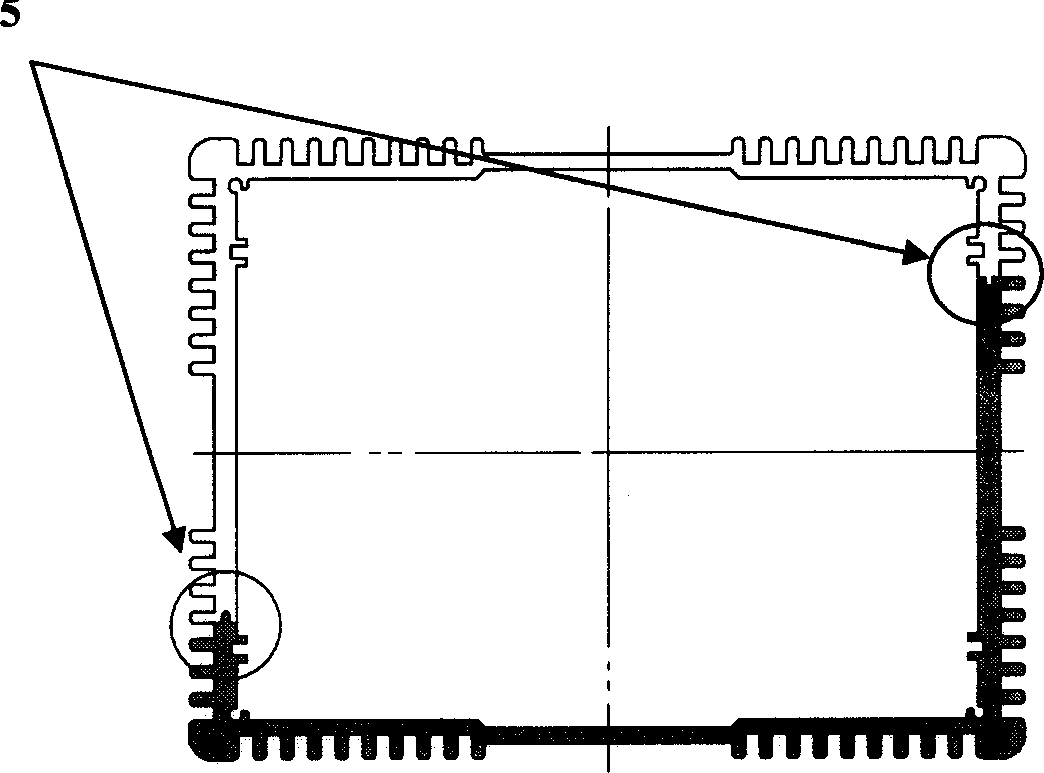

Dual L seamless high power electronic amperite housing

InactiveCN1767712AIncrease surface cooling effectEasy to installElectric lighting sourcesCooling/ventilation/heating modificationsEngineeringBallast

This invention relates to a shell of a double-conjugated L-shaped large power electronic ballast including: a lower L-shaped shell, an upper L-shaped shell, a first side cover, a second side cover, two convex / concave points, in which, the two L-shaped shells in a same shape and size form a master shell by conjugating the two points, the end surfaces of both sides of the master shell are square, the two side covers are fixed at the cross sections of both ends and the two conjugated points are in the shape of the nominal convex / concave .

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Compression molding butt-fusion forming method for large-sized plastic pipe joint

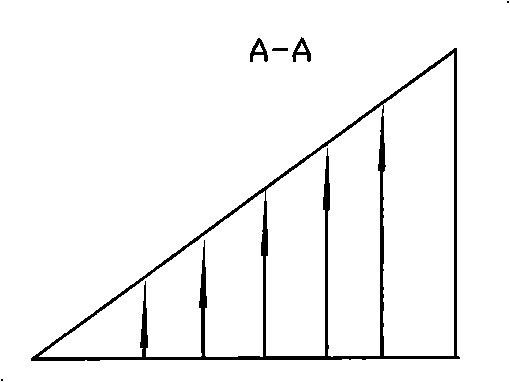

The invention discloses a compaction fusion molding method of a large plastic pipe joint which comprises the following steps: straight tubes which are matched with the diameter of a pipeline matching a tube joint is used as the breeches pipe of the tube joint; a variable temperature die of a die cavity which is provided with the shape of the tube joint is prepared, and the front end parts of the breeches pipe are mutually connected; the straight tubes are arranged in the variable temperature die, and the die cavity corresponding to the parts of the straight tubes required to be deformed is heated to lead to the softening and the melting of the front parts of the straight tubes; the tail parts of the straight tubes are pressured to lead to the deformation of the melting parts of the straight tubes to be filled in the die cavity of the die, and the front parts are mutually integrated into one body to become the shape of the tube joint; the variable temperature die is cooled to lead to the cooling and setting of products, and the die is opened. The compaction fusion molding method of the large plastic pipe joint has the advantages of simple equipment, low processing fee, small power consumption and fast molding speed.

Owner:UNION PLASTIC HANGZHOU MACHINERY

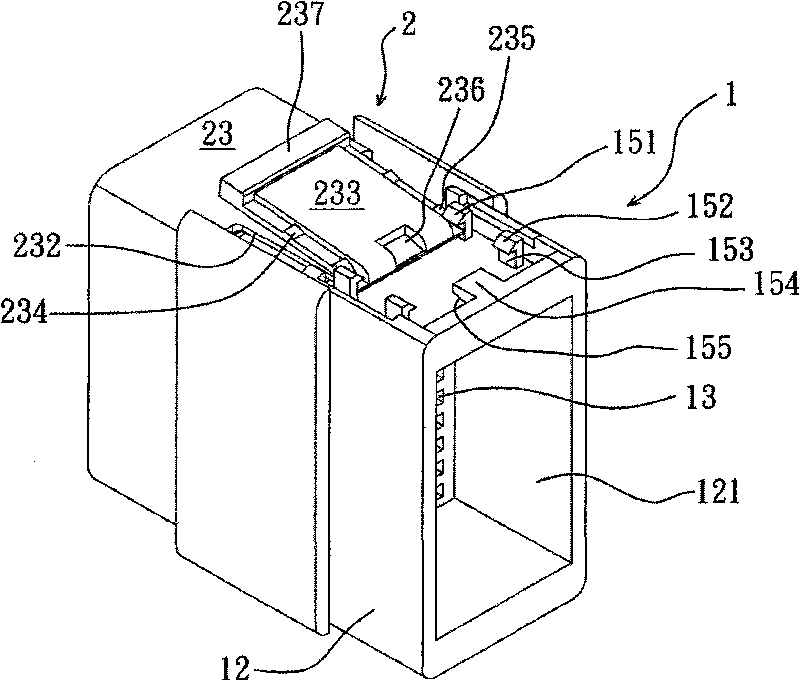

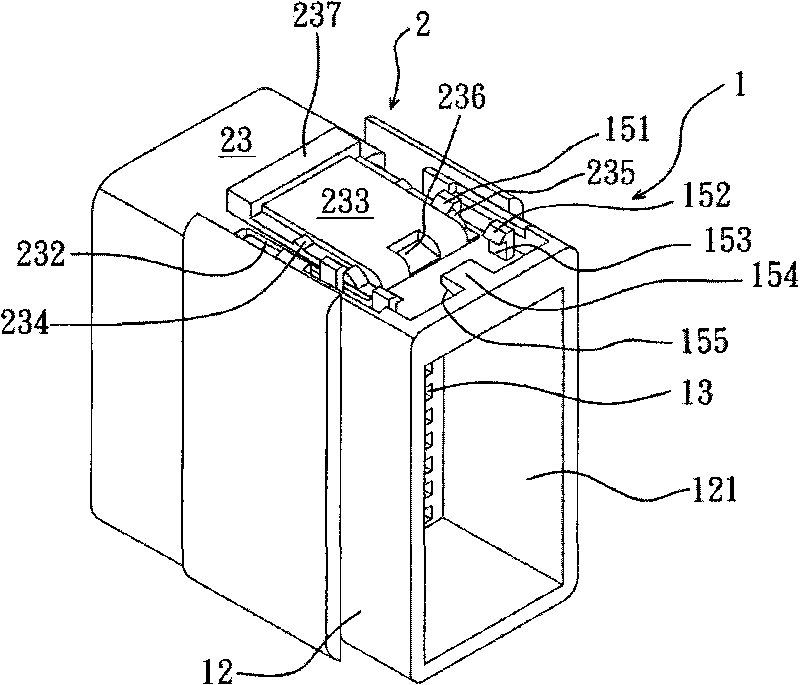

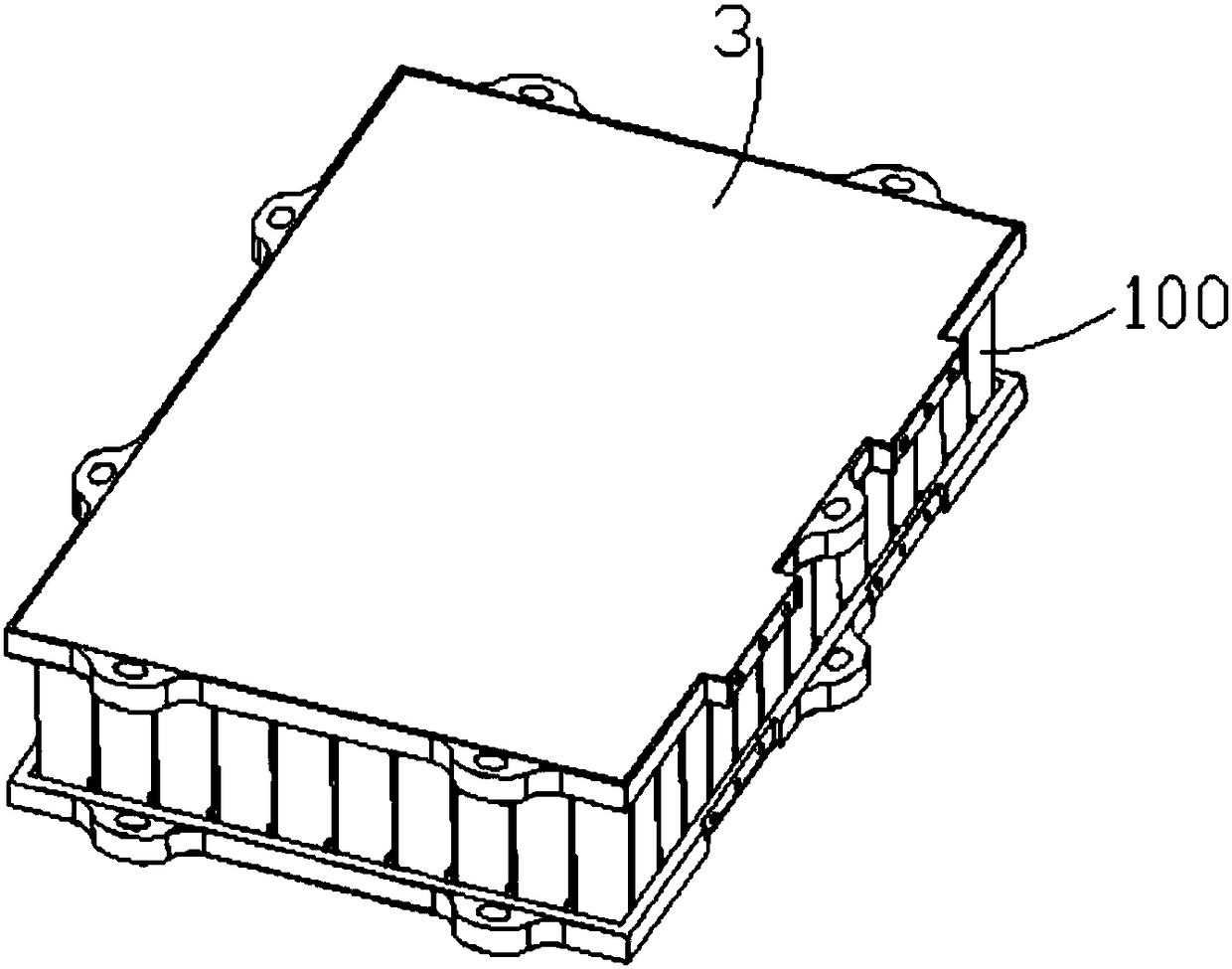

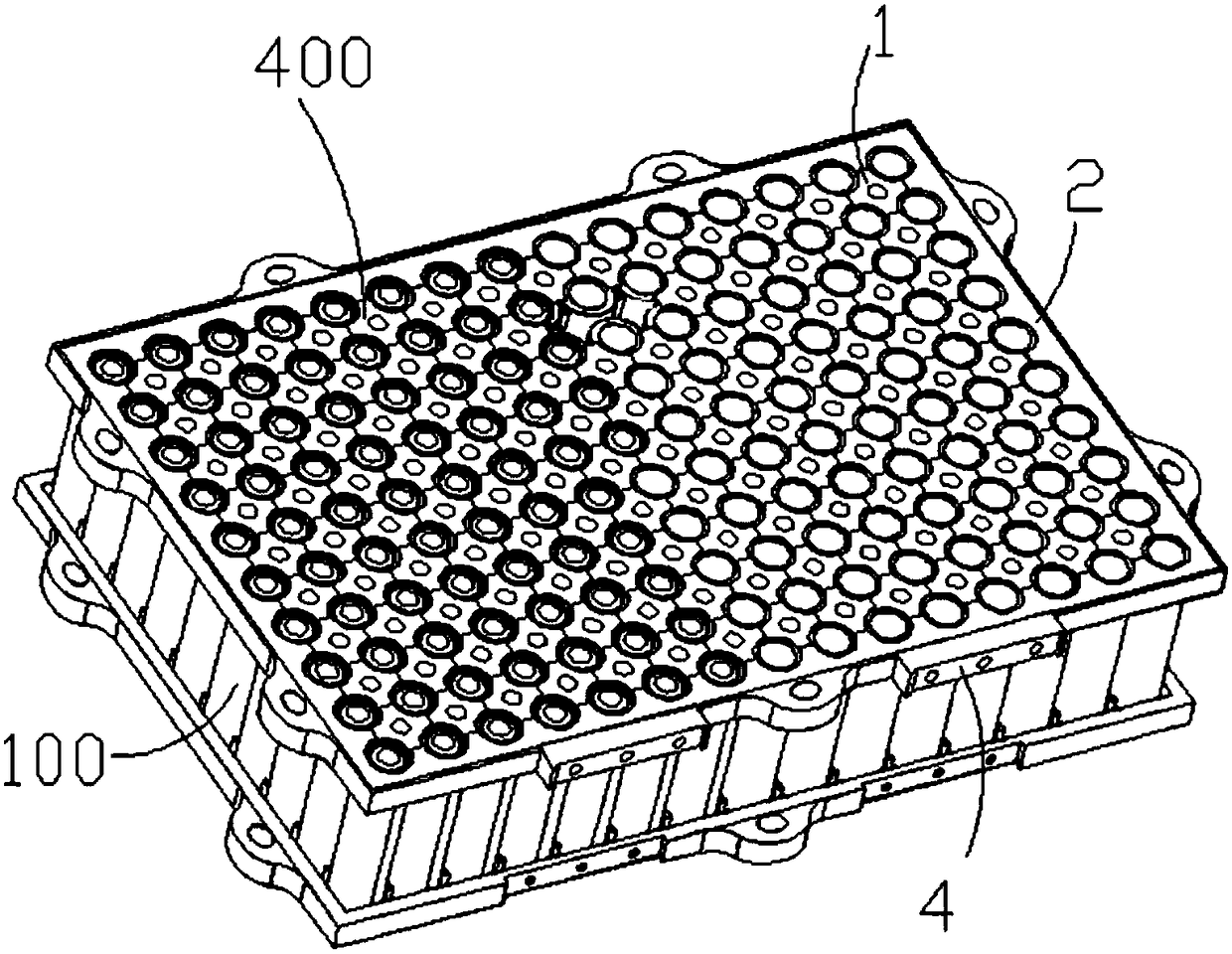

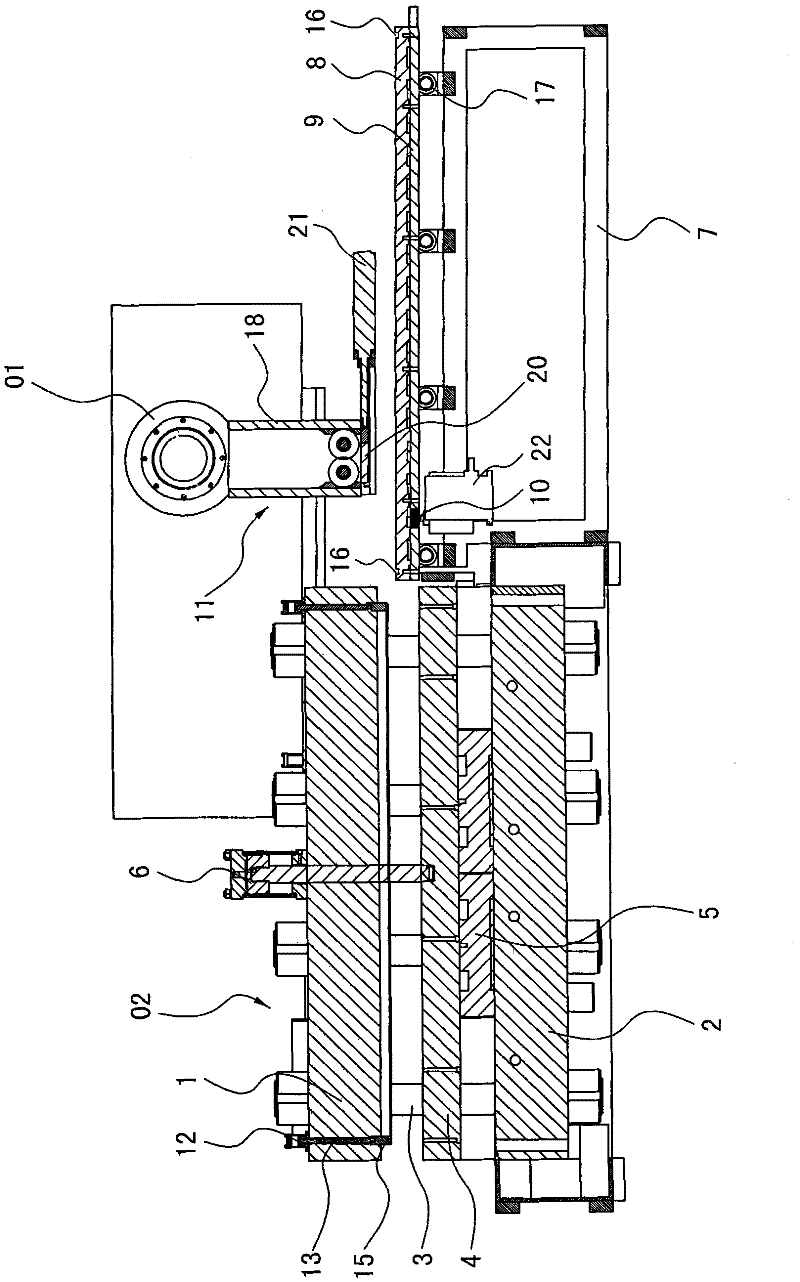

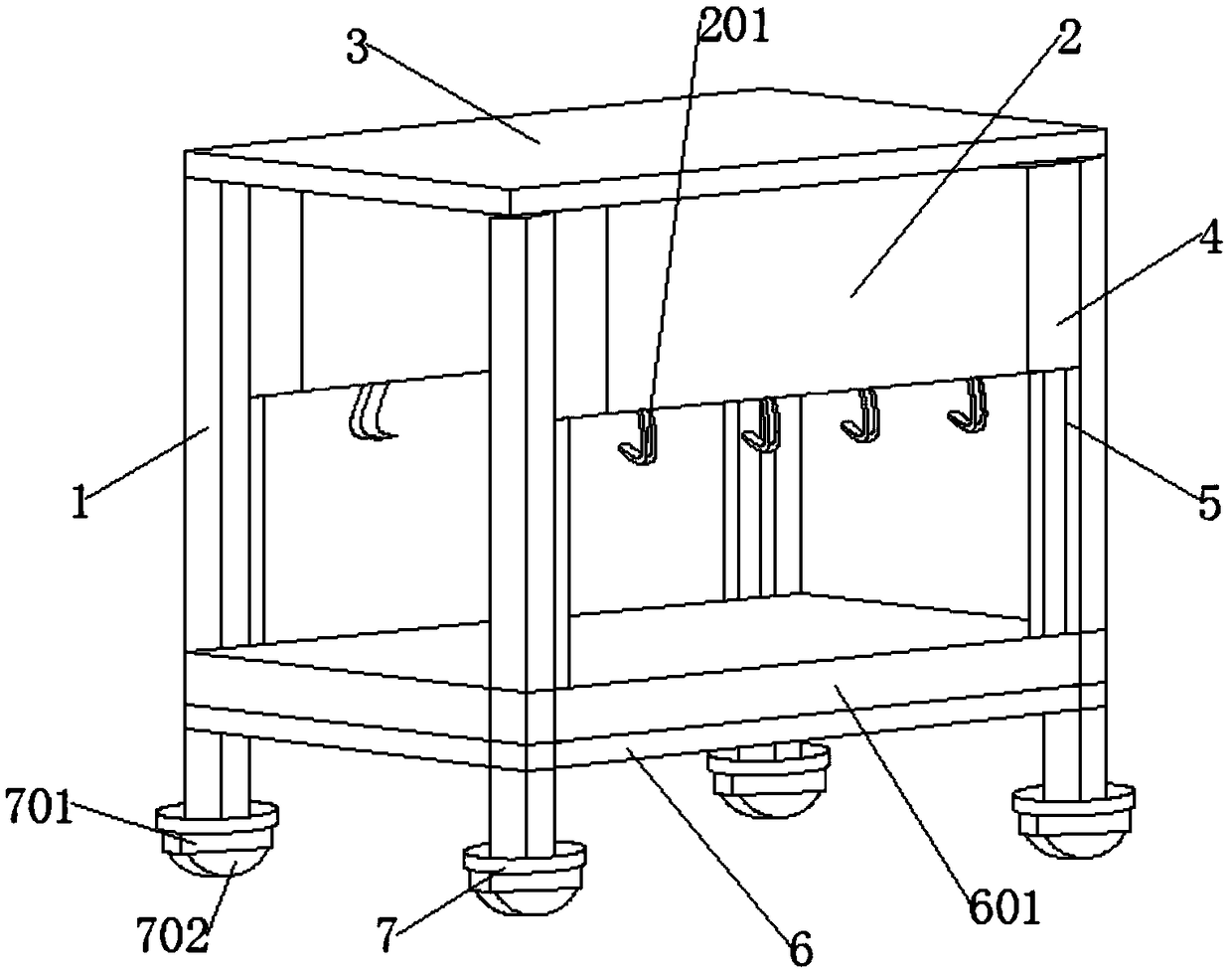

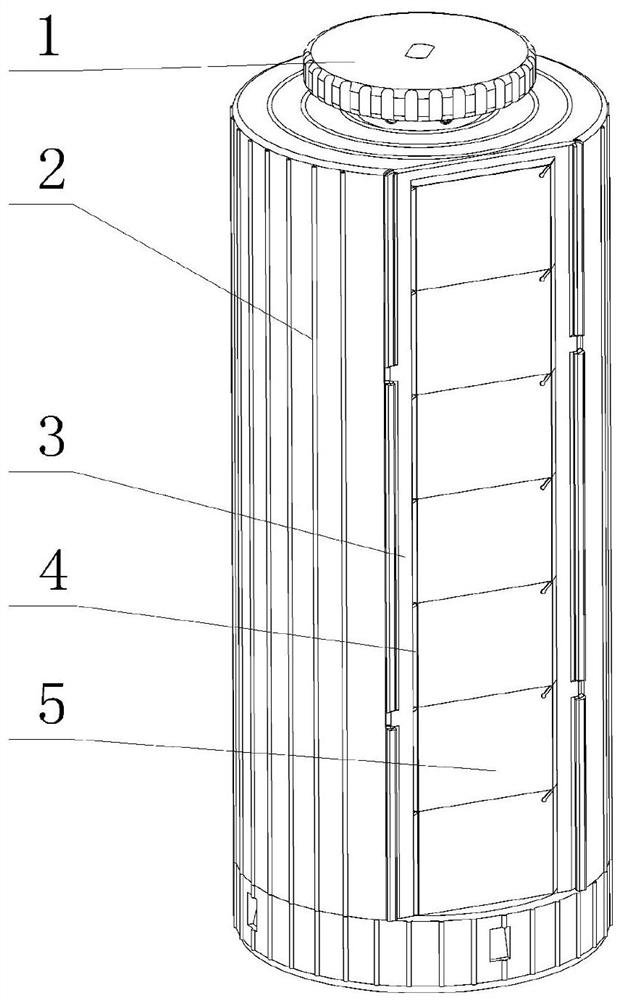

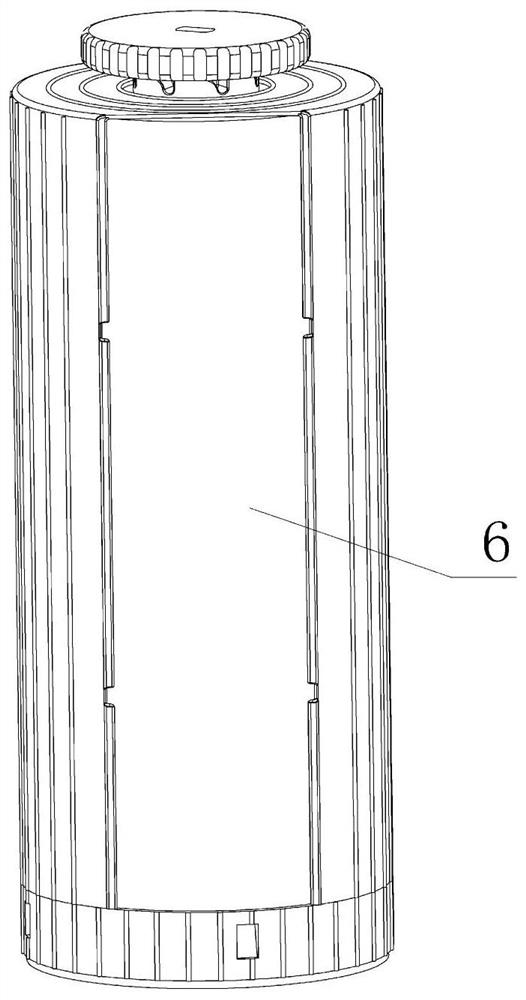

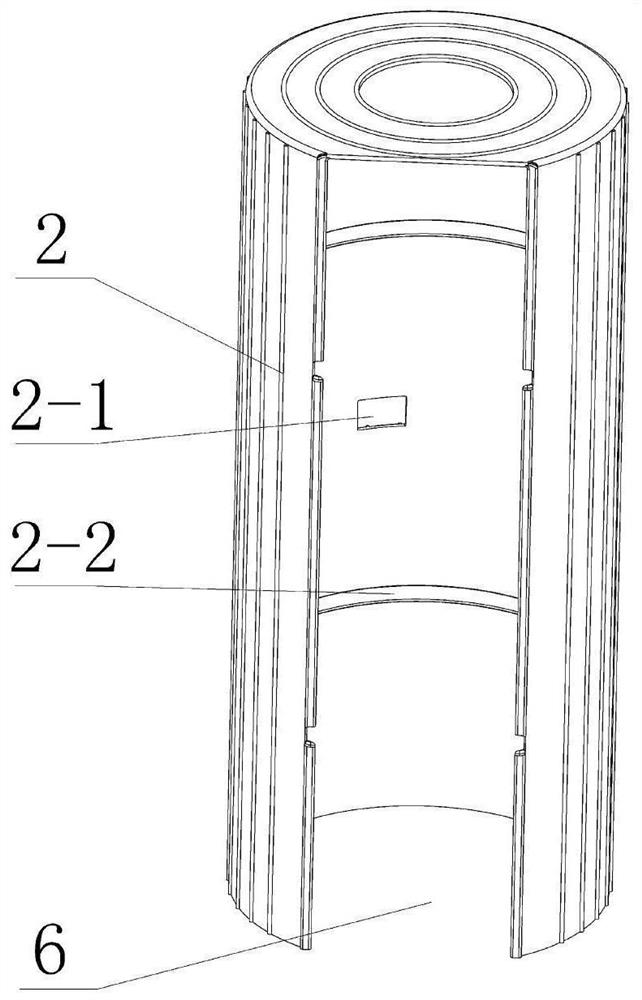

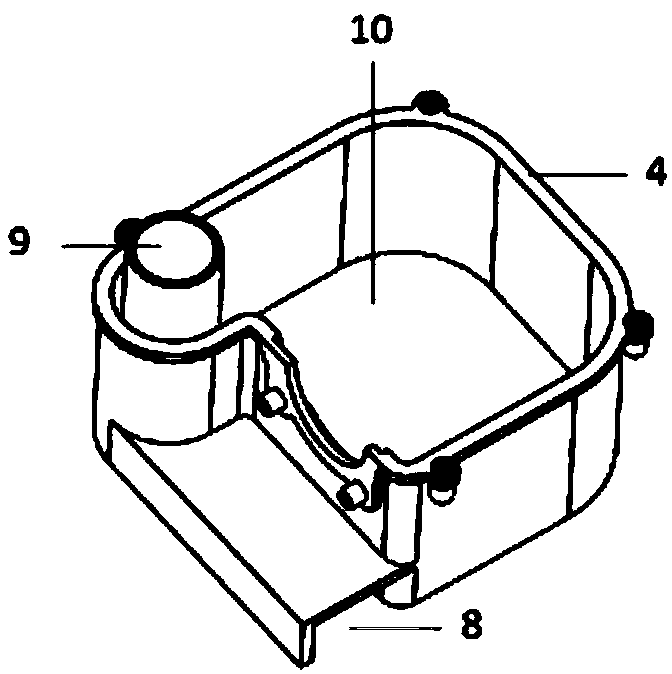

Installation structure of cylindrical battery pack

PendingCN108461669ASimple mold openingEasy to form a groupCell component detailsElectricityElectrical battery

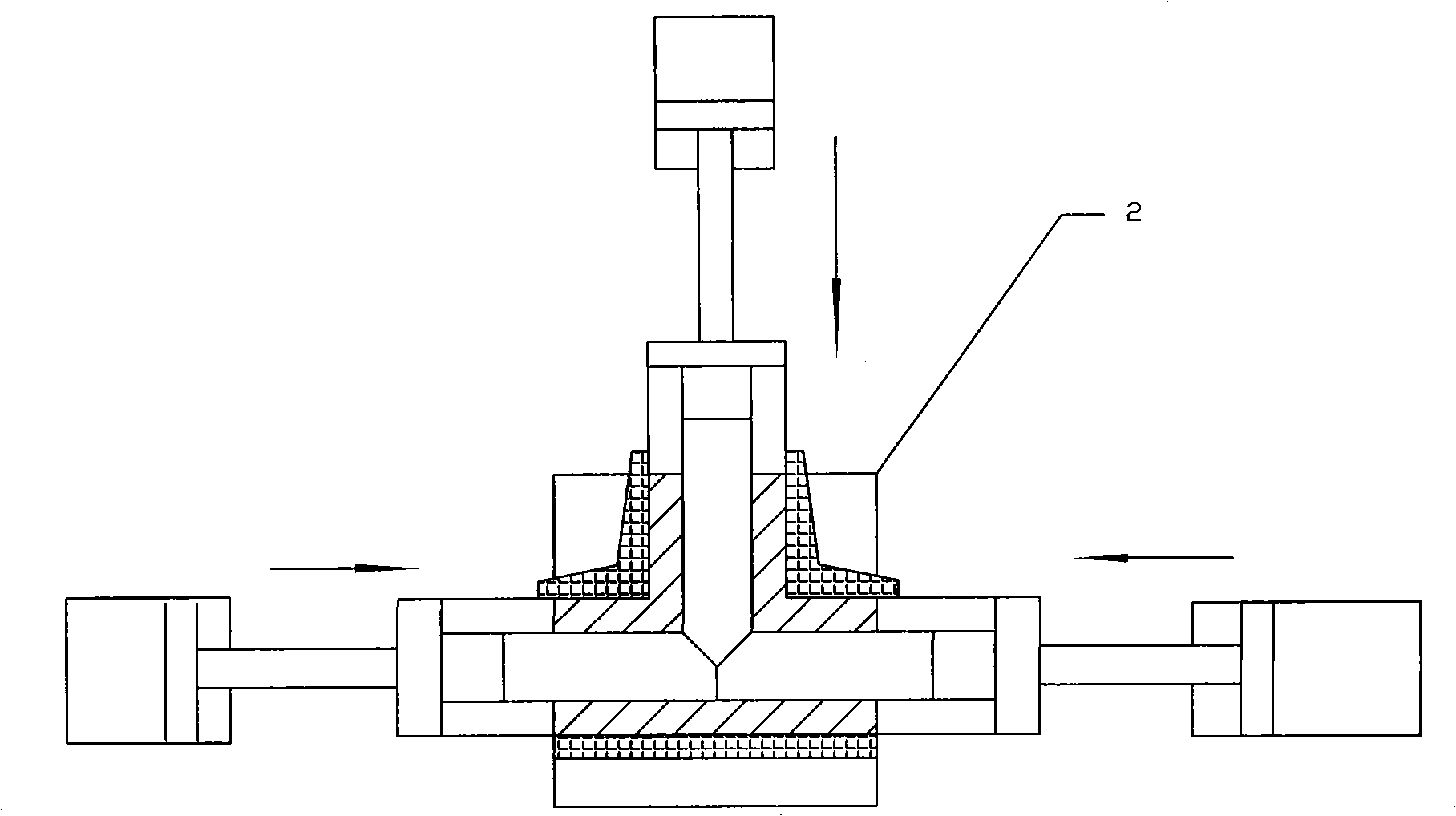

The invention discloses an installation structure of a cylindrical battery pack. According to the installation structure, two external frame supports are arranged on the two sides of a battery pack; two battery module group supports are arranged in the two external frame supports in a corresponding manner through clamping; the cathode and the anode of each cylindrical battery core in the battery pack are arranged on the two battery module group supports respectively through clamping; two electrical connecting supports are arranged on the two battery module group supports in a corresponding manner through clamping; a switch connection support is connected with the electrical connecting support at the cathode terminals of the cylindrical battery cores; two insulation plates are arranged on the external sides of the two electrical connecting supports; and the two external frame supports are fixedly connected through bolts. The installation structure is used for cylindrical battery cores,is invented based on independent battery core supports, and simple low-cost moulds; mould group assembling mode is flexible; electrical connecting mode is flexible and changeable; dismounting and maintenance cost is relatively low; and automatic and semi-automatic equipment development is low in difficulty.

Owner:NANJING SKYSOURCE POWER TECH CO LTD

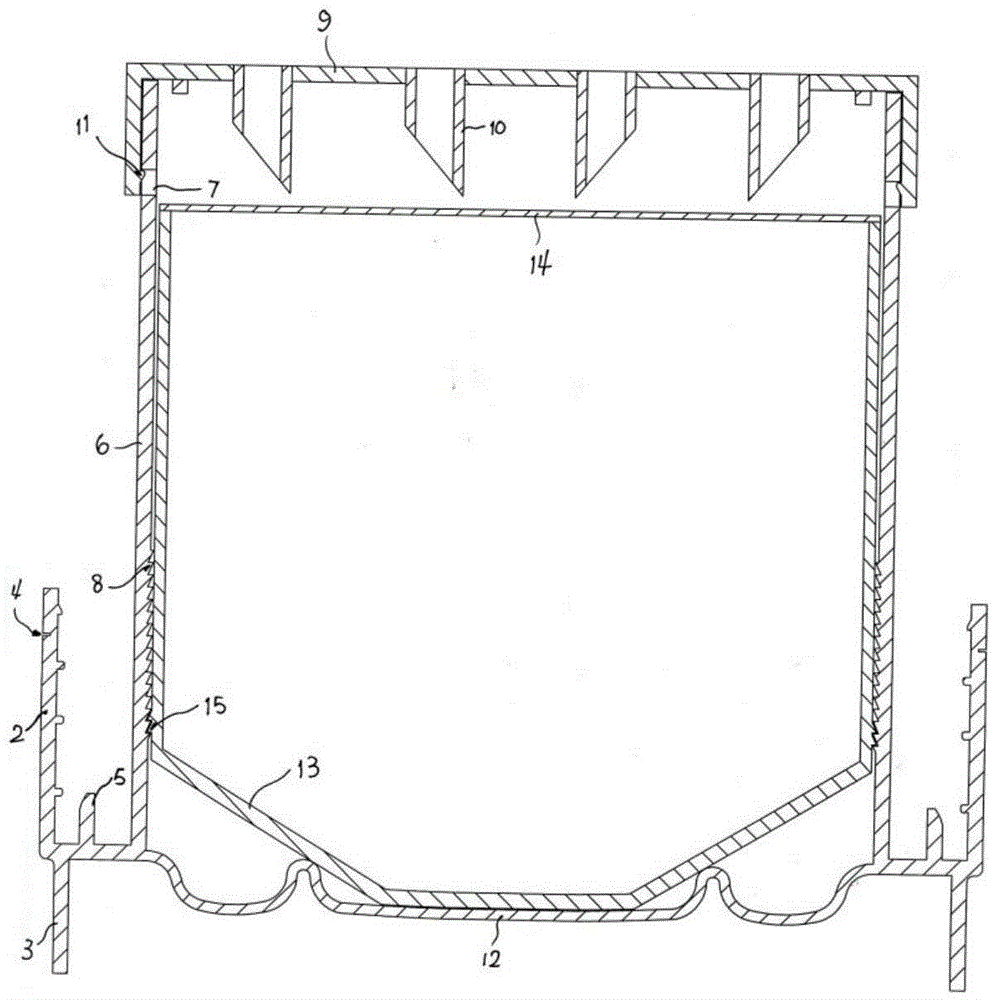

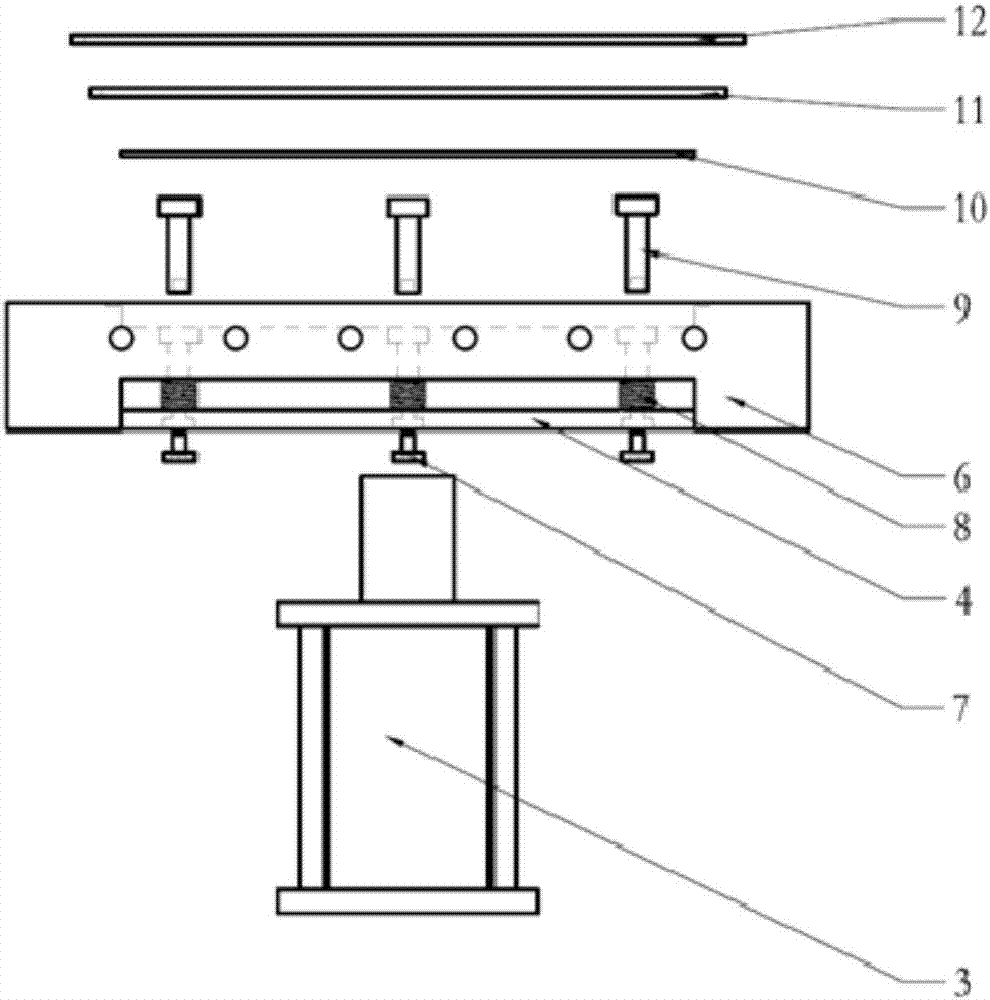

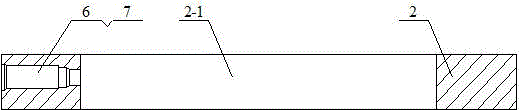

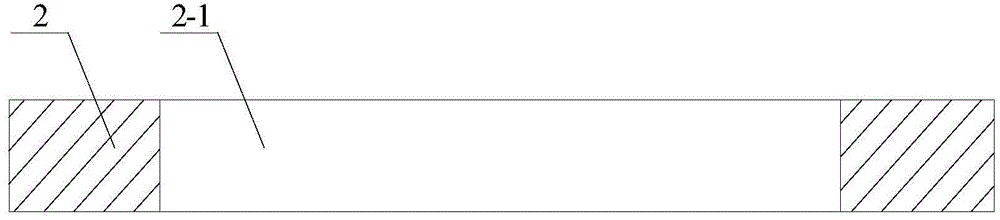

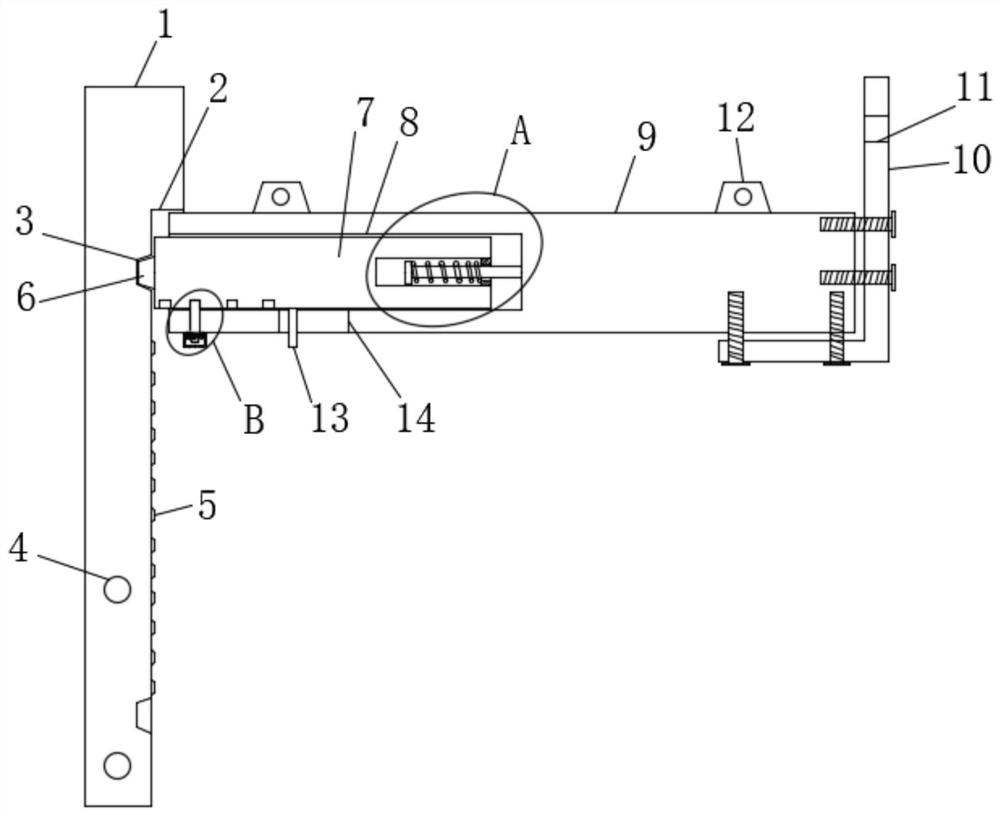

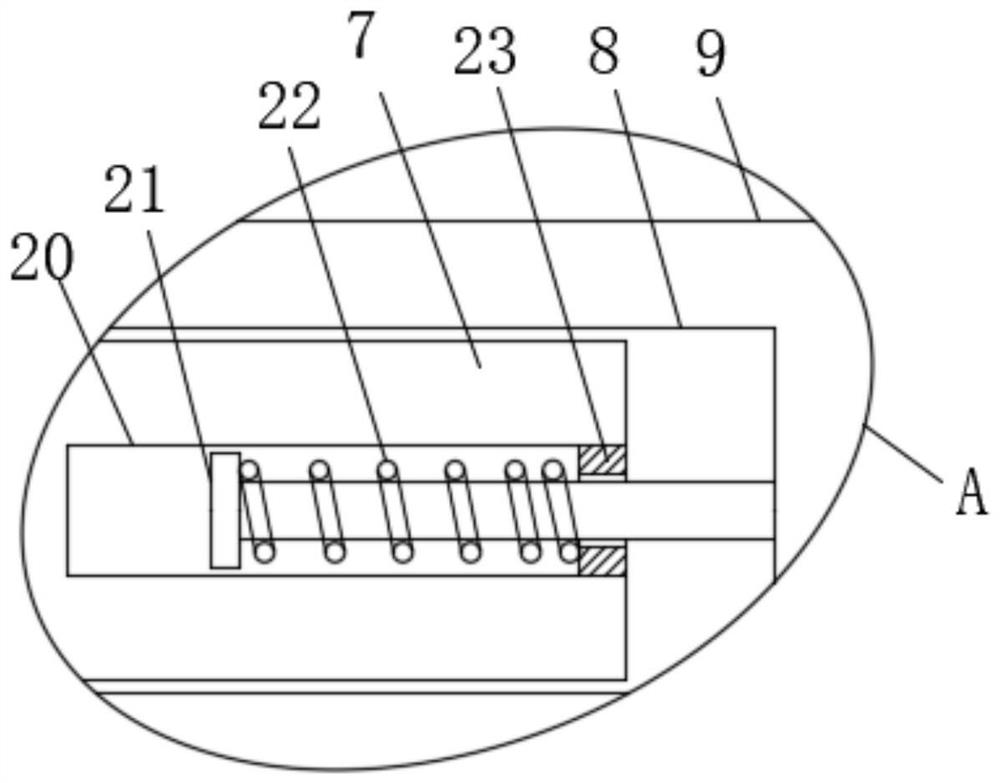

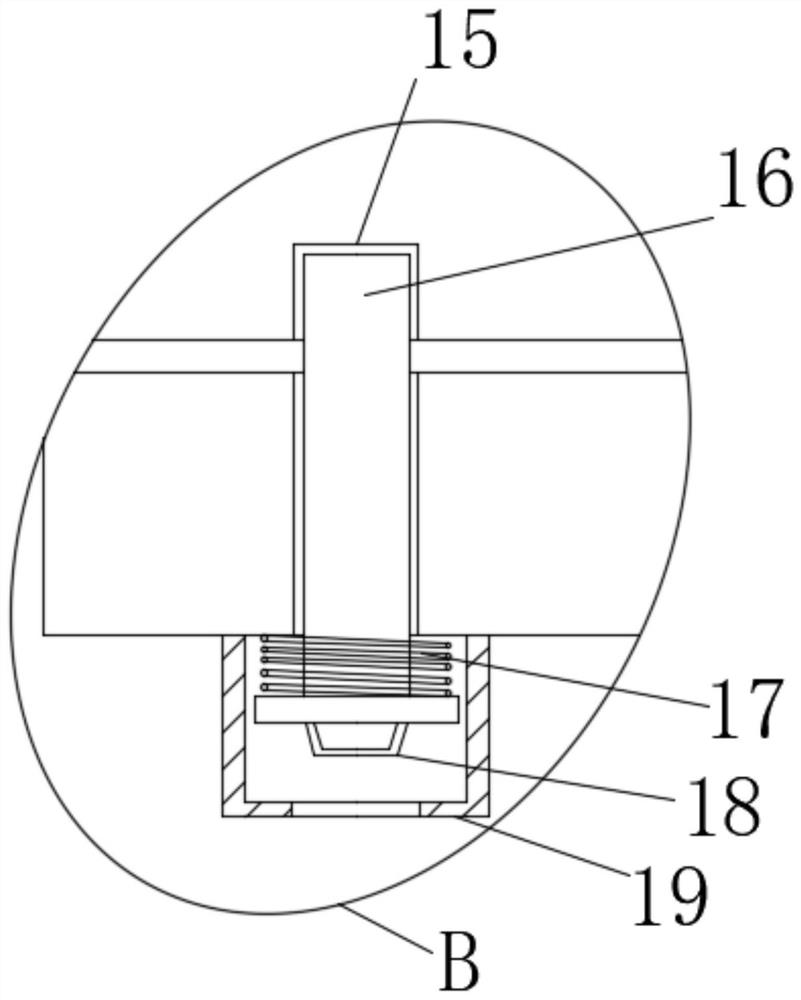

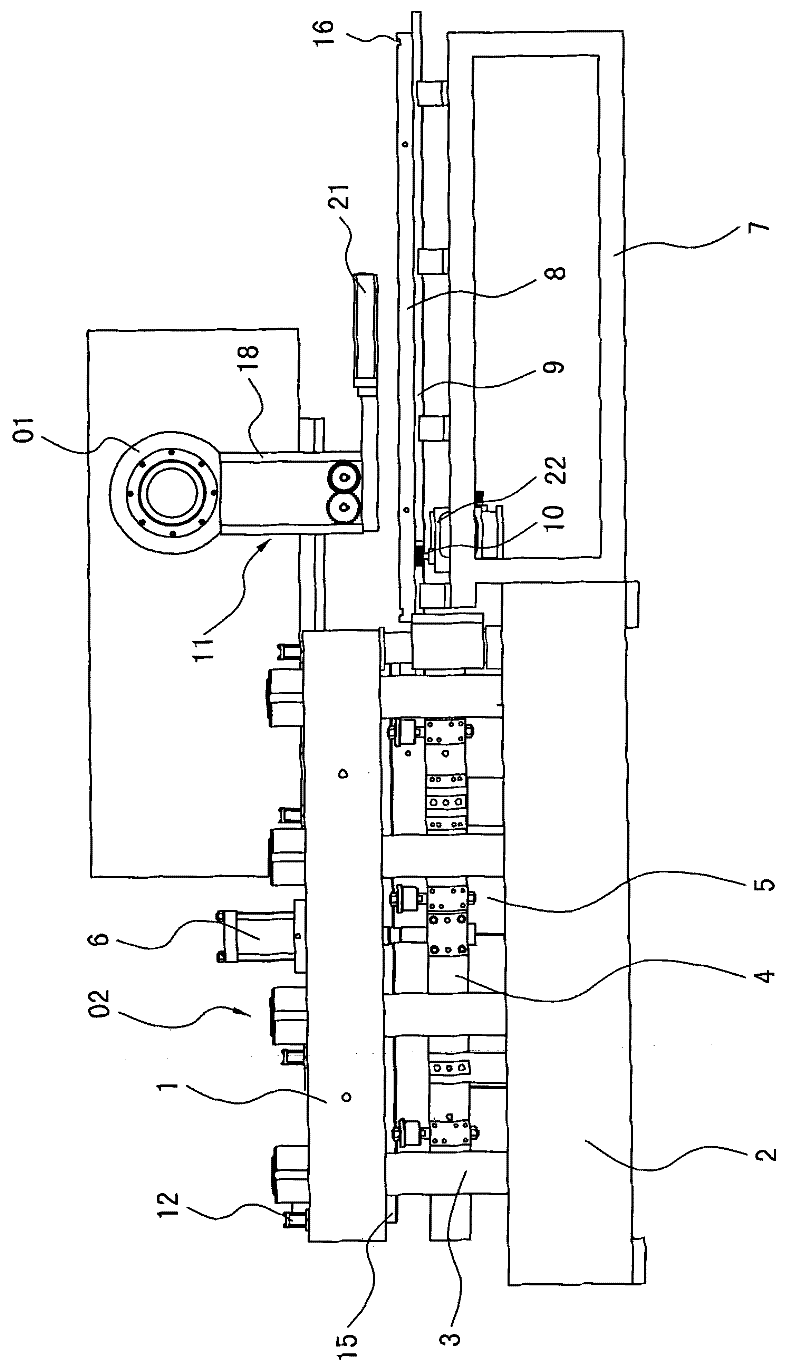

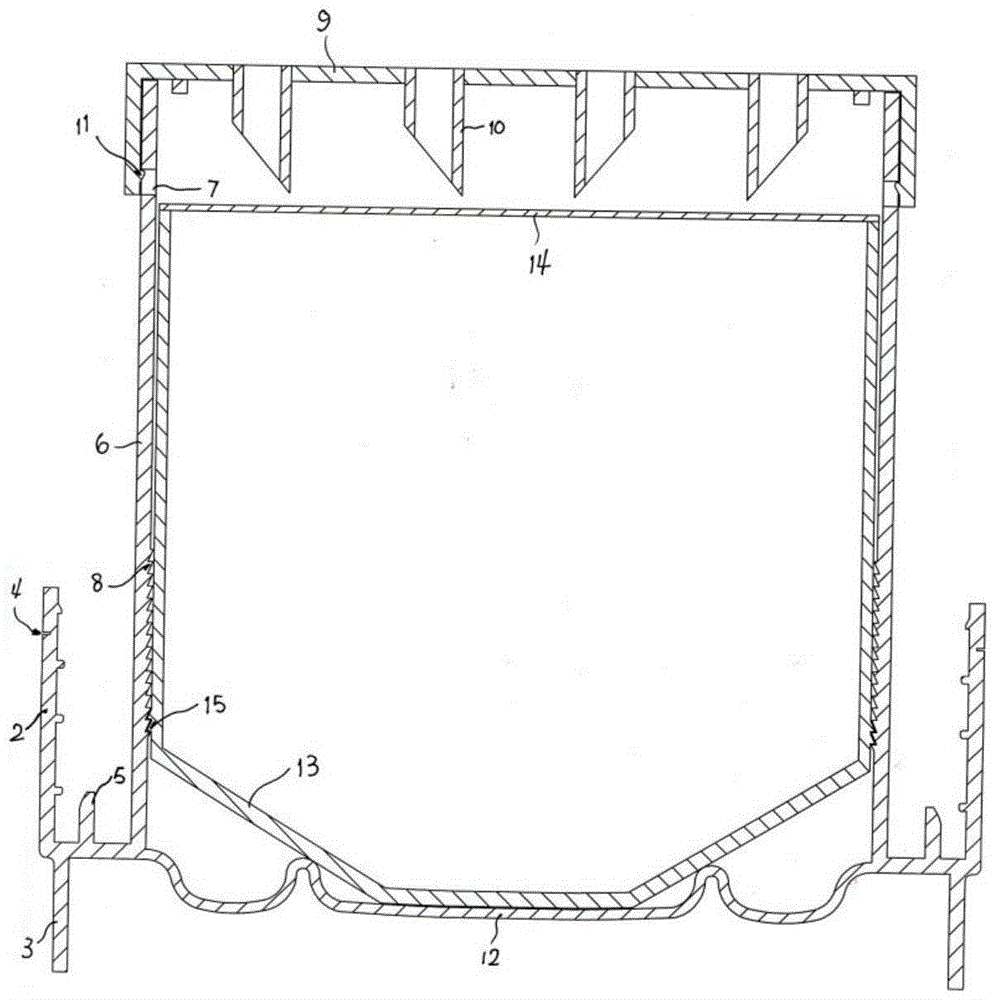

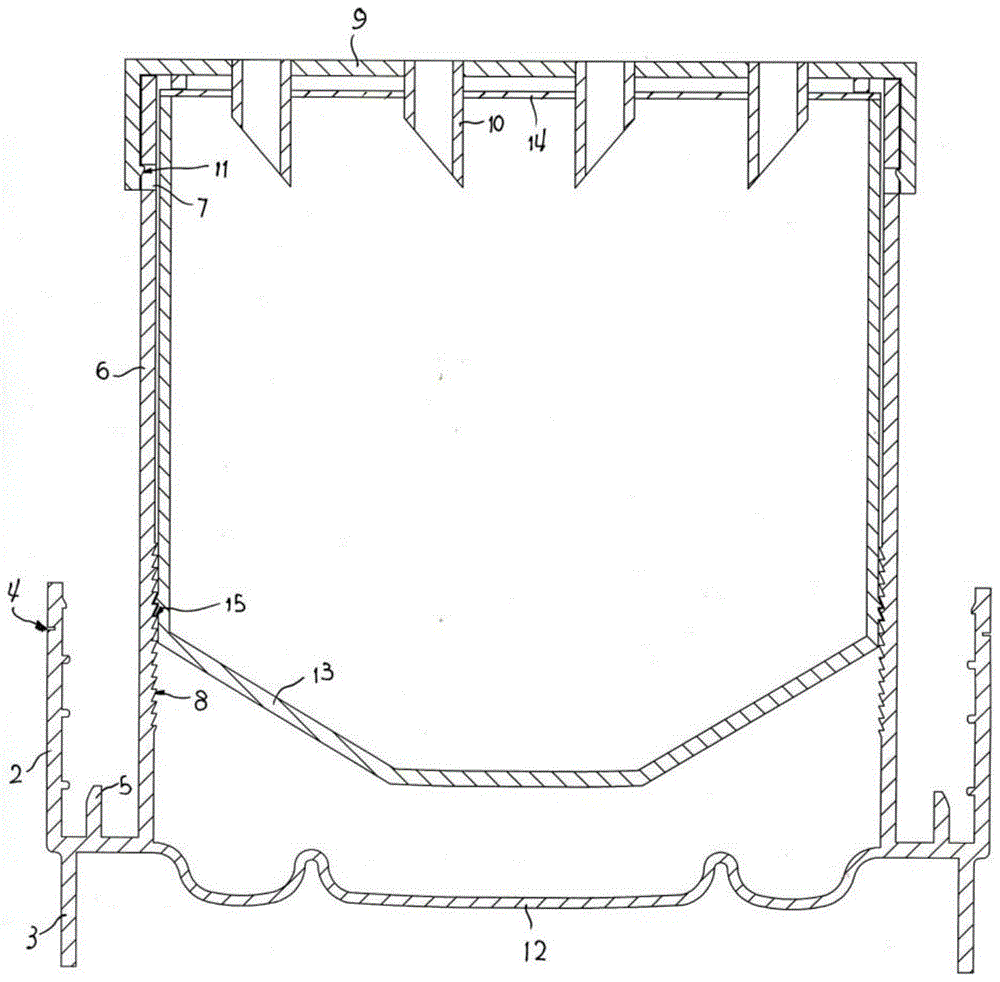

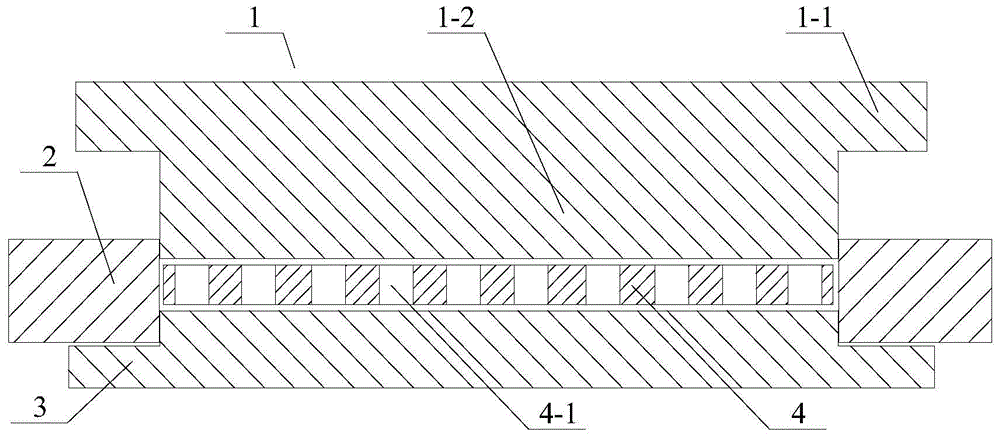

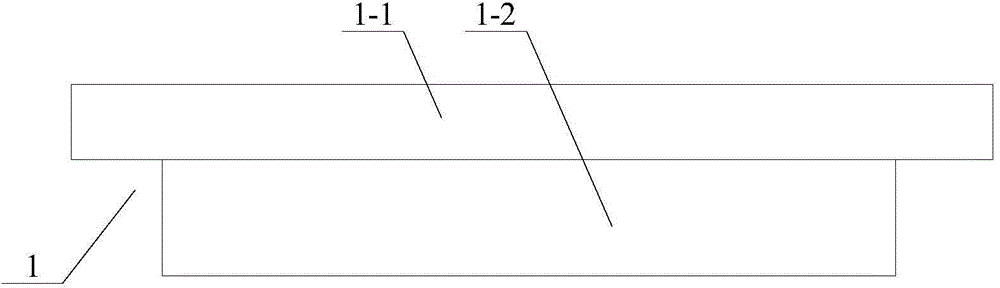

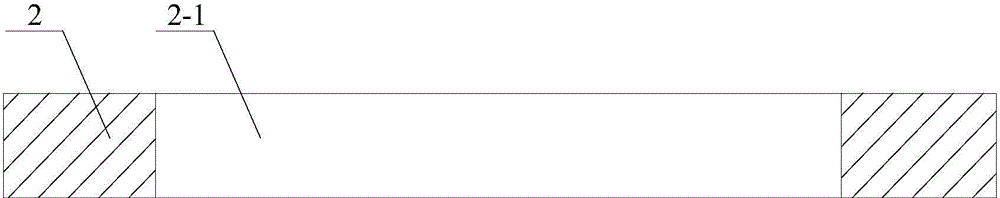

Plate thickness self-adaption adjustable RTM mold and plate preparation method

The invention relates to a plate thickness self-adaption adjustable RTM mold and a plate preparation method. A groove is formed in the middle part of a lower template (6); after an upper template (15) is closed with the lower template (6), the upper template (15) and the lower template (6) form a molding cavity in the groove; a channel for moving a push rod (9) up and down is formed in the bottom of the groove; a molding cavity height control plate is put in the molding cavity; an extension rod of an extension device is connected with an ejection plate (4); the ejection plate (4) is connected with the push rod (9); the push rod (9) is sleeved with a spring (8); the lower end and the upper end of the spring (8) respectively butt against the ejection plate (4) and the lower template (6); and the push rod (9) can linearly move in the channel formed in the bottom of the groove of the lower template (6). The plate thickness self-adaption adjustable RTM mold can realize a function of manufacturing multi-thickness composite material plate products, is liable to open, reduces the product defects, and improves the product quality.

Owner:HUNAN UNIV

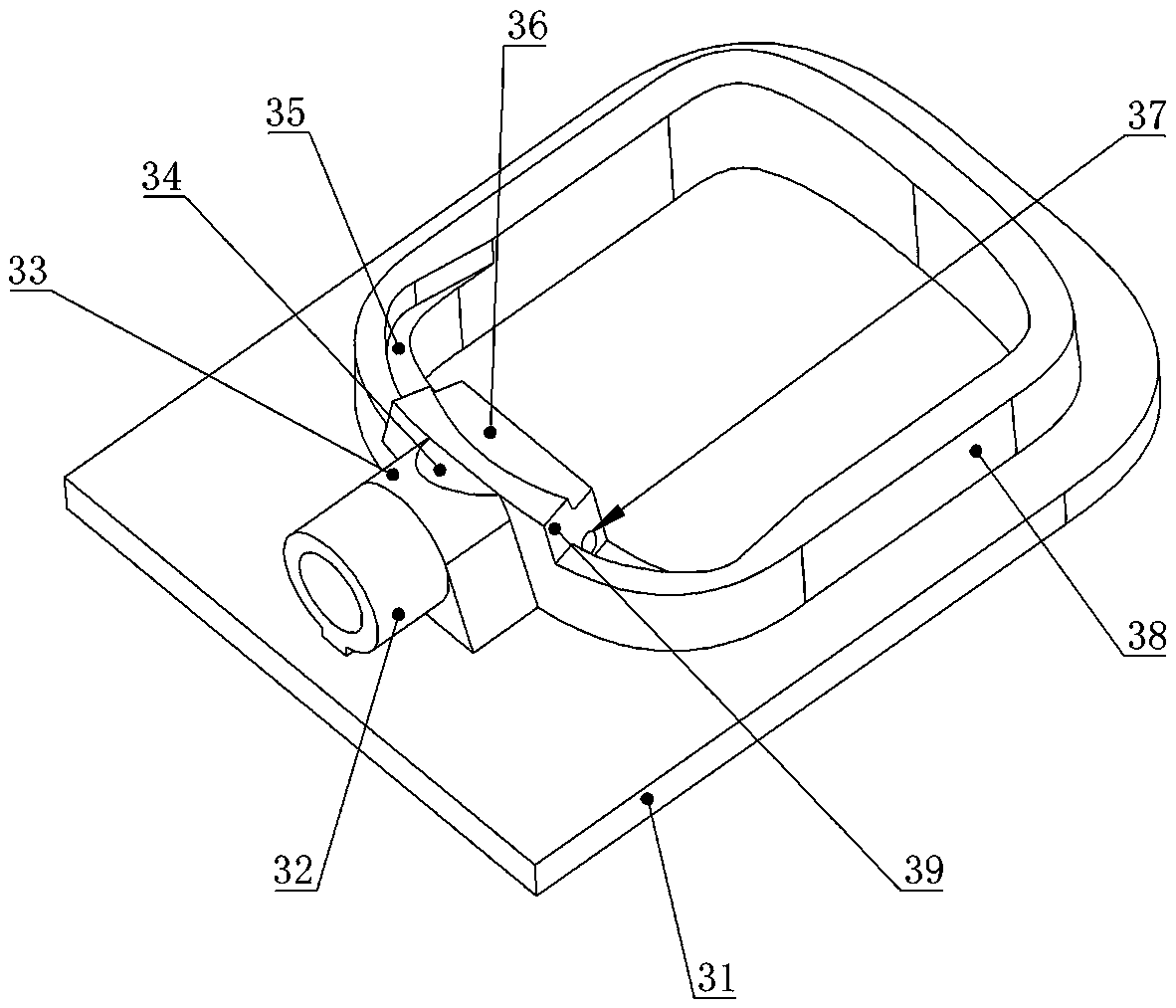

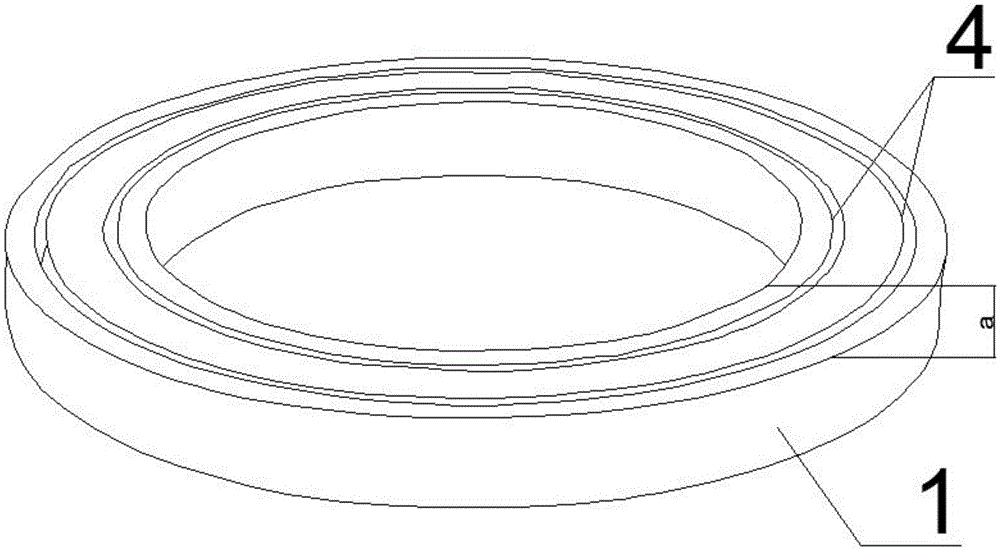

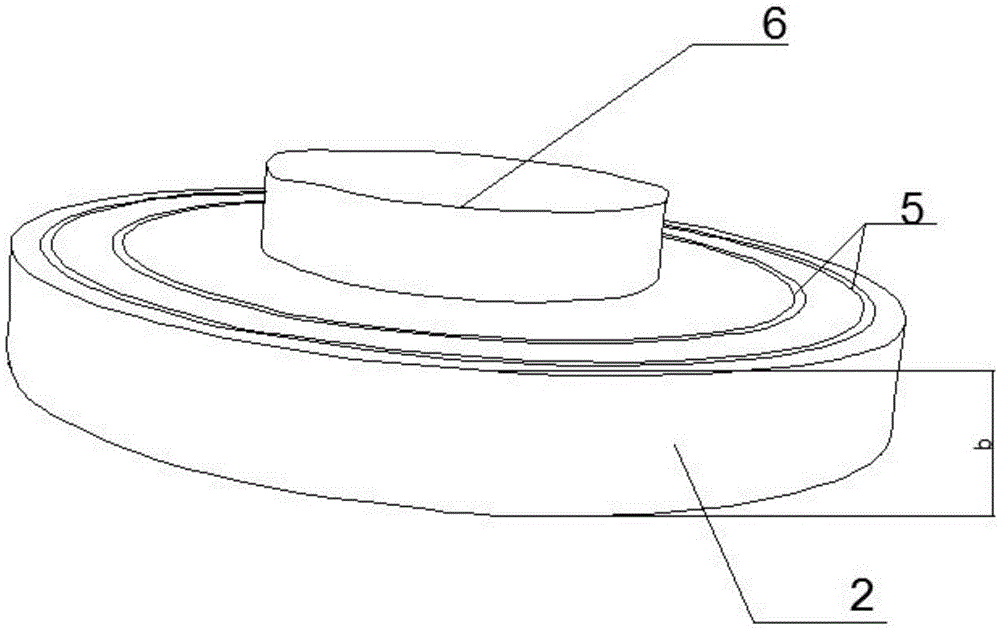

Toilet bowl seat ring and split type formation method thereof

ActiveCN111571767ASimple structureSimple mold openingSlip casting mouldsSlurryMechanical engineering

The invention relates to the technical field of toilet bowl production, in particular to a toilet bowl seat ring and a split type formation method thereof. The split type formation method of the toilet bowl seat ring comprises the steps that firstly, the prototype of the seat ring and the prototype of a water inlet are manufactured first of all, high pressure molds, which are two open molds, are manufactured by means of the two prototypes, slurry is poured into the high-pressure molds, the slurry is hardened, then a seat ring mud blank and a water inlet mud blank which are mutually independentare obtained at the same time, a water hole and a seat hole are drilled on the seat ring mud blank, and then the two mud blanks are stuck together to obtain the toilet bowl seat ring. By the adoptionof the split type formation method, the mold structure is simple, mold making is easy, workers can conveniently conduct operation, the labor intensity is low, and the production efficiency is high.

Owner:ZHONGTAO SANITARY WARO MFG CO LTD OF TANGSHAN

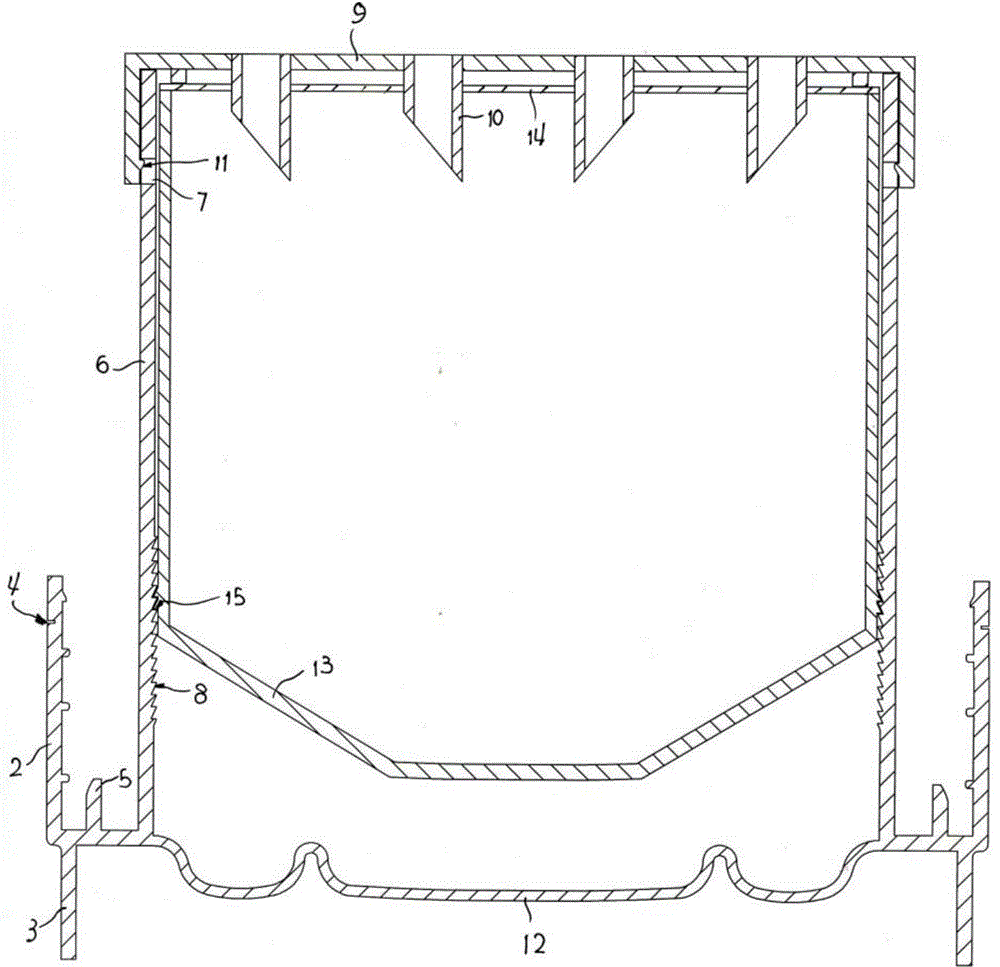

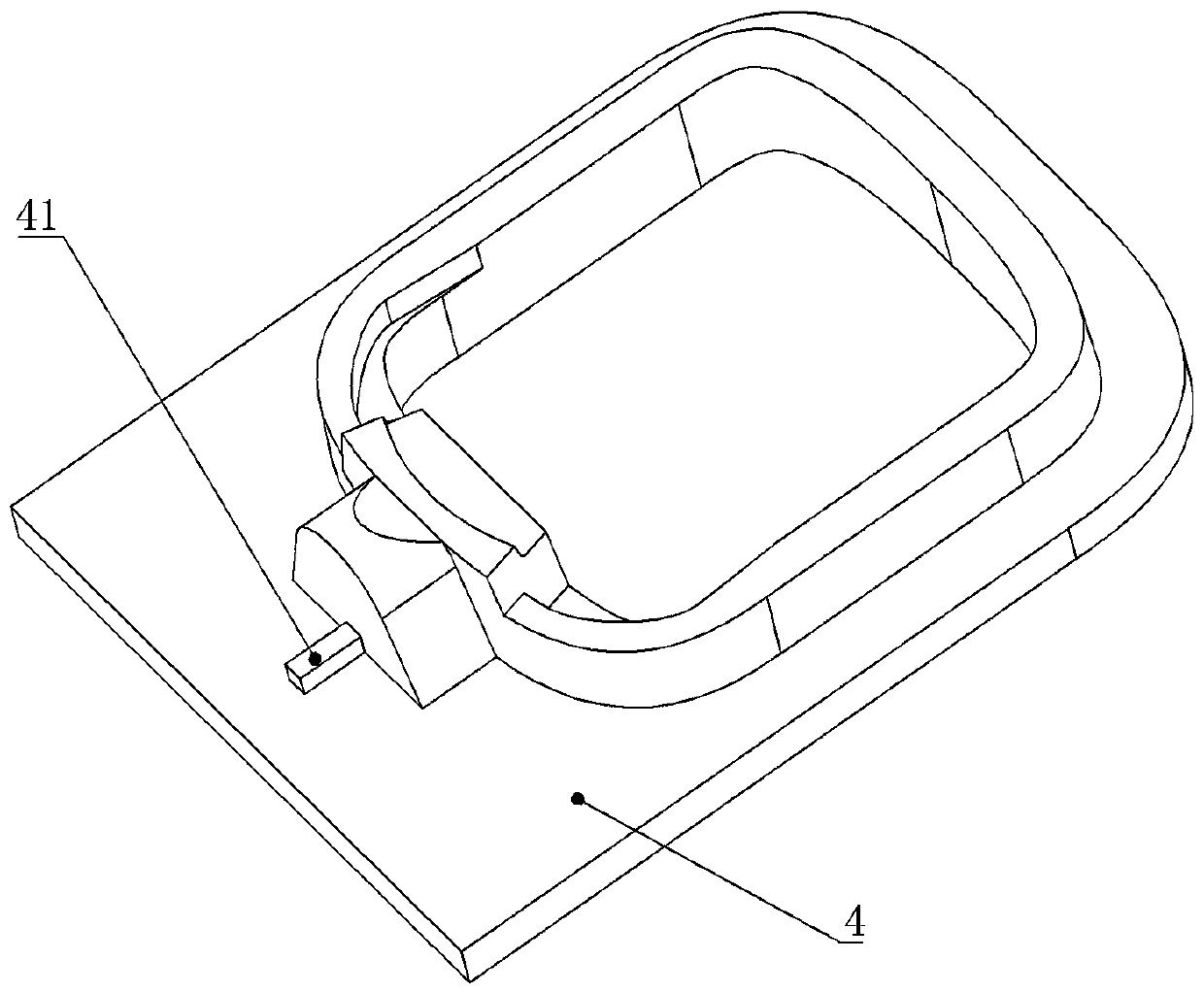

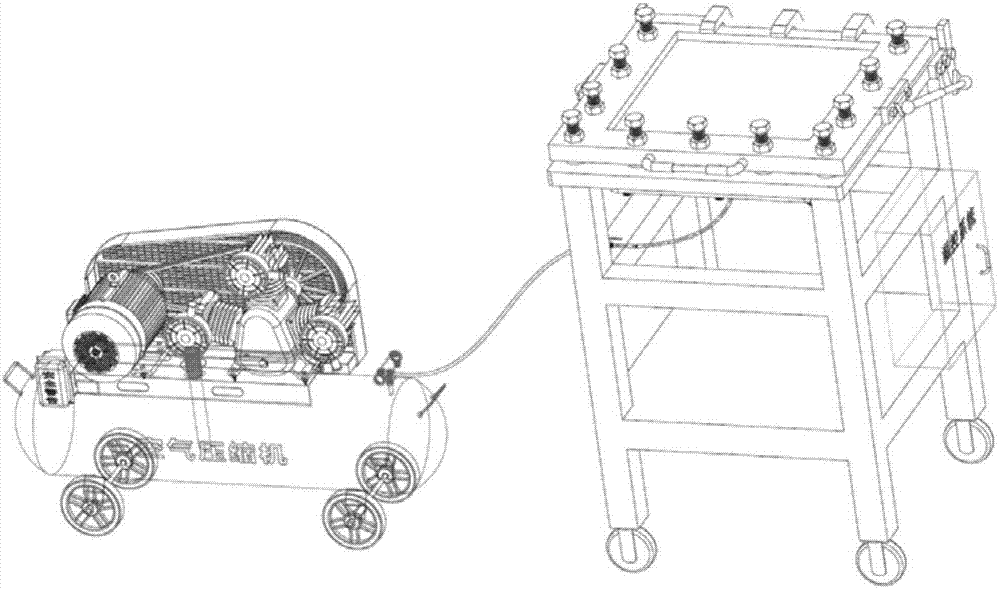

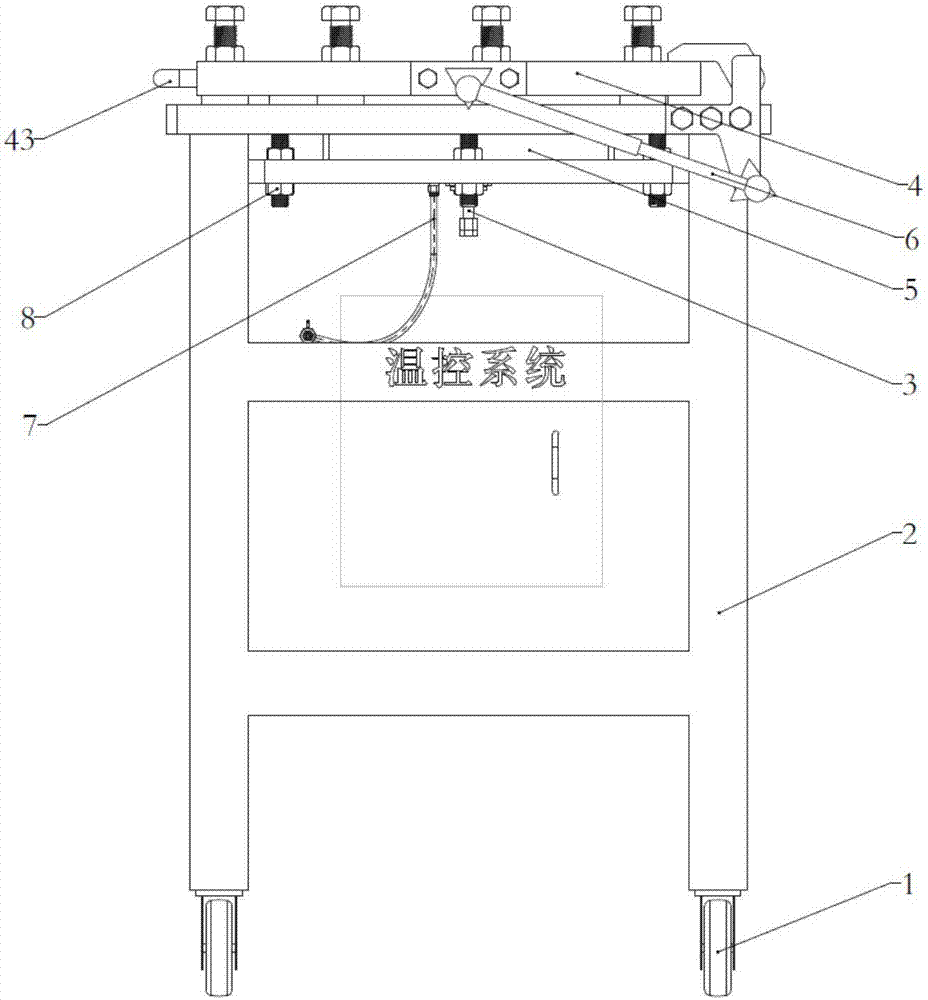

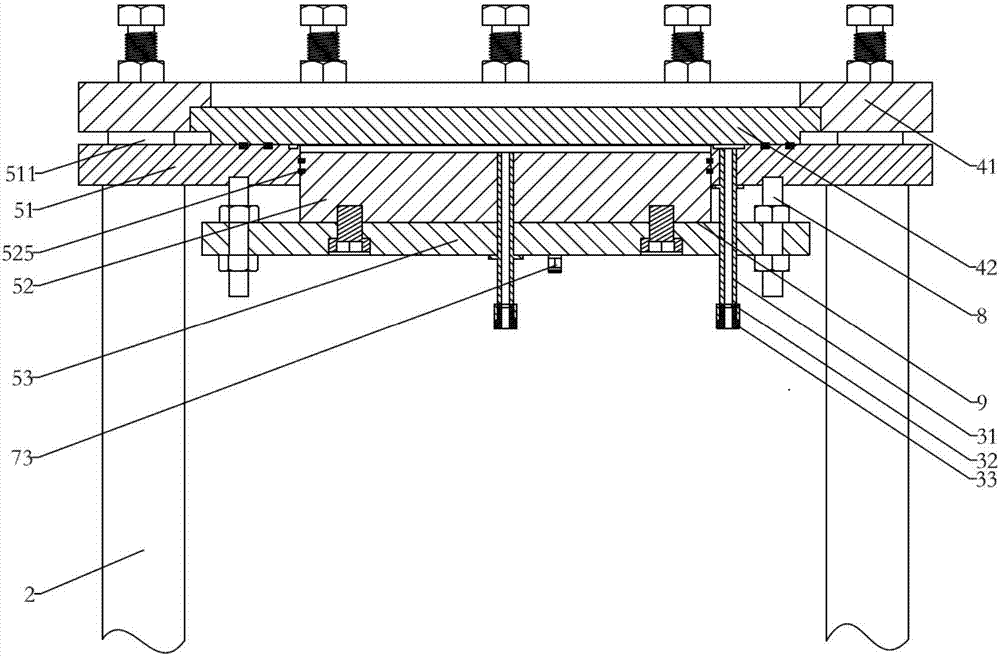

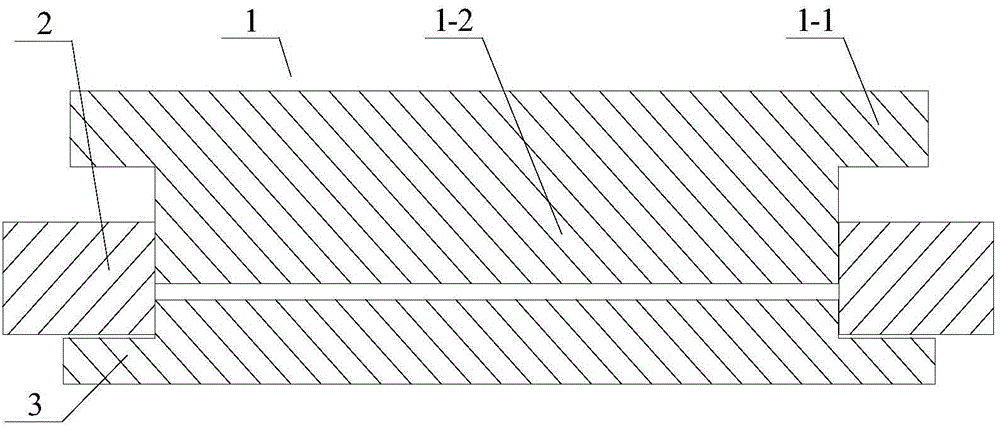

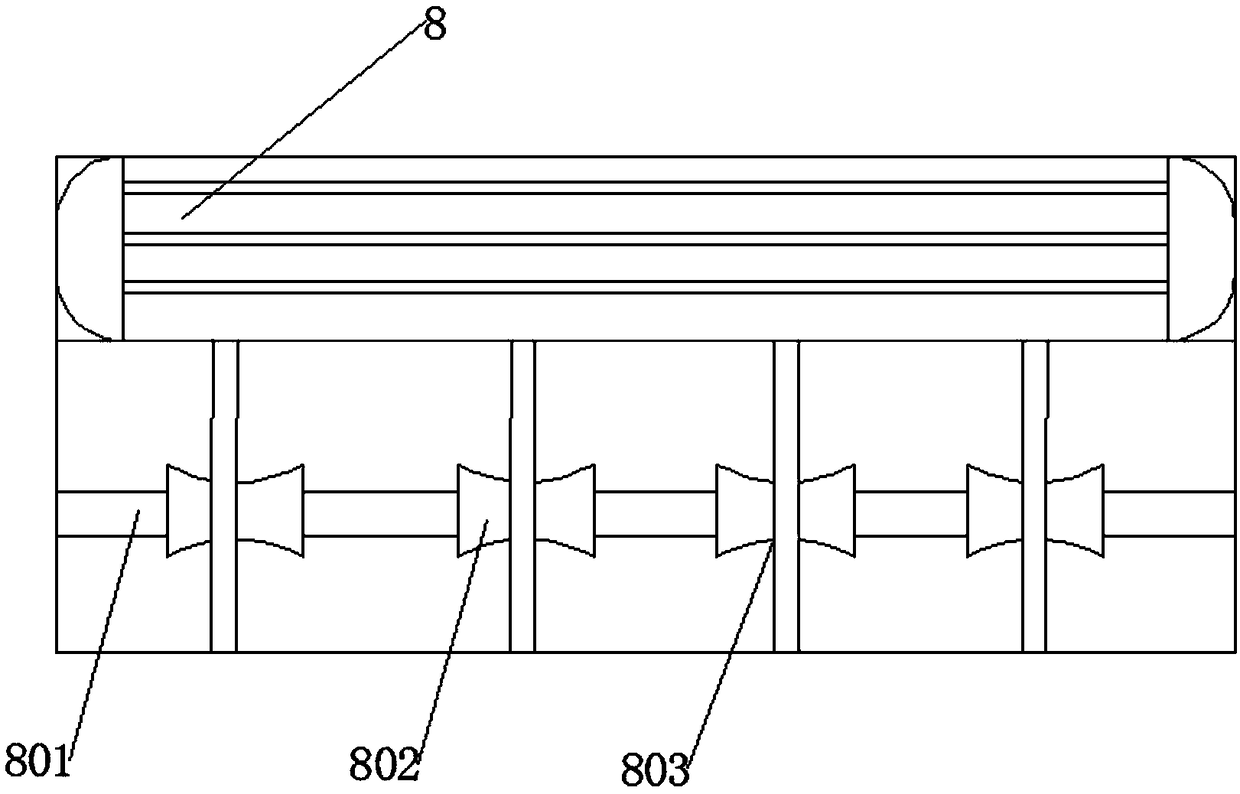

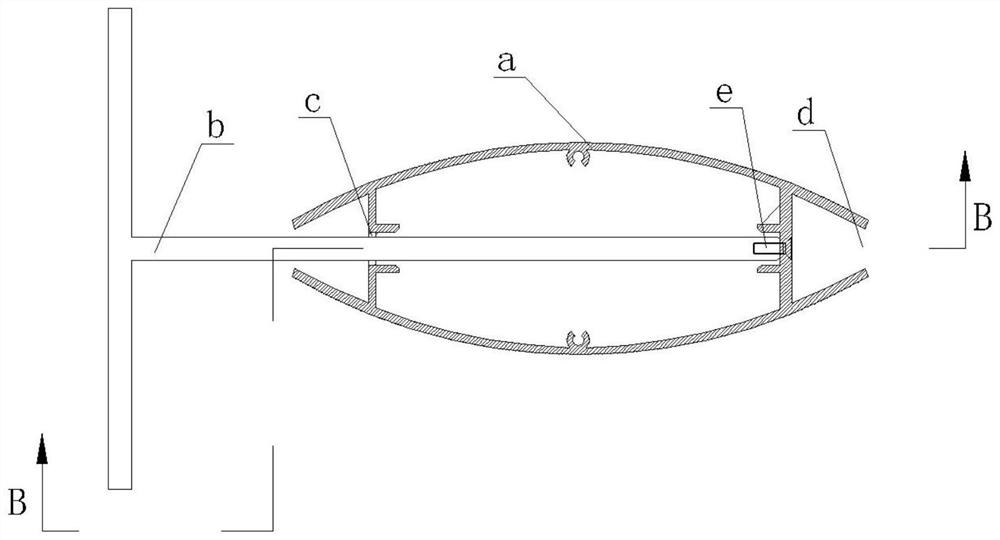

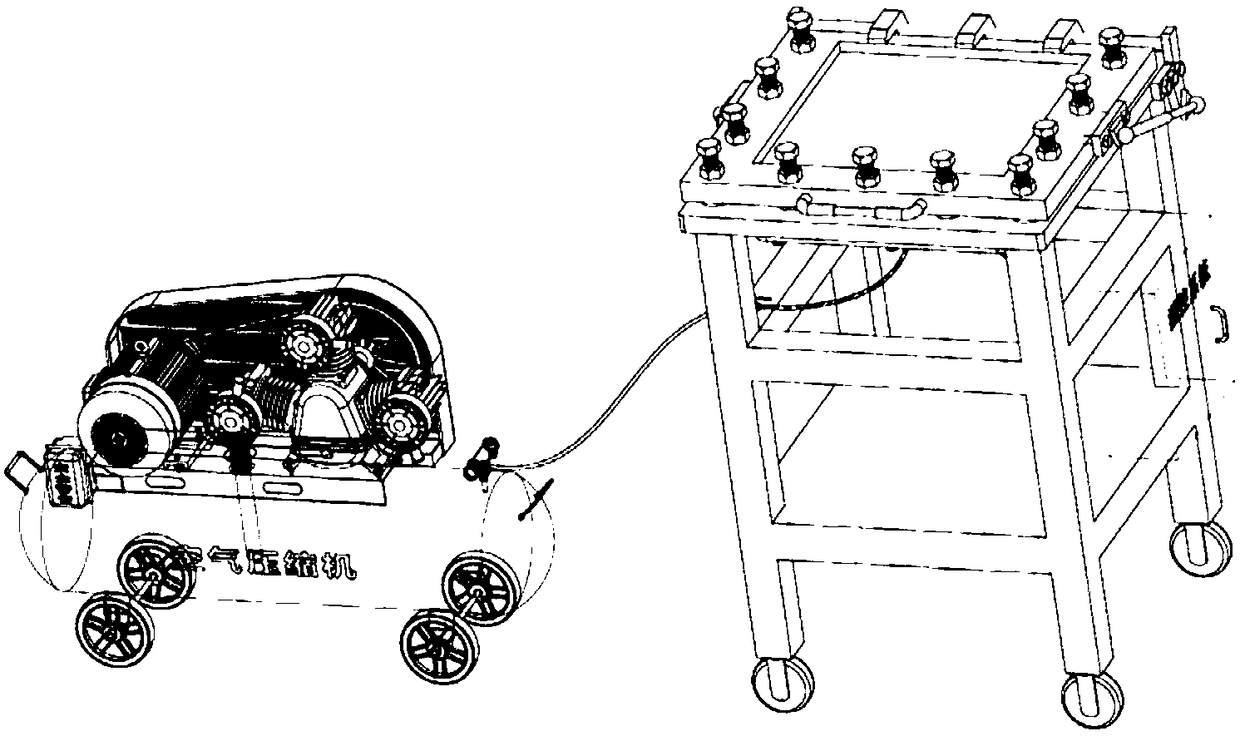

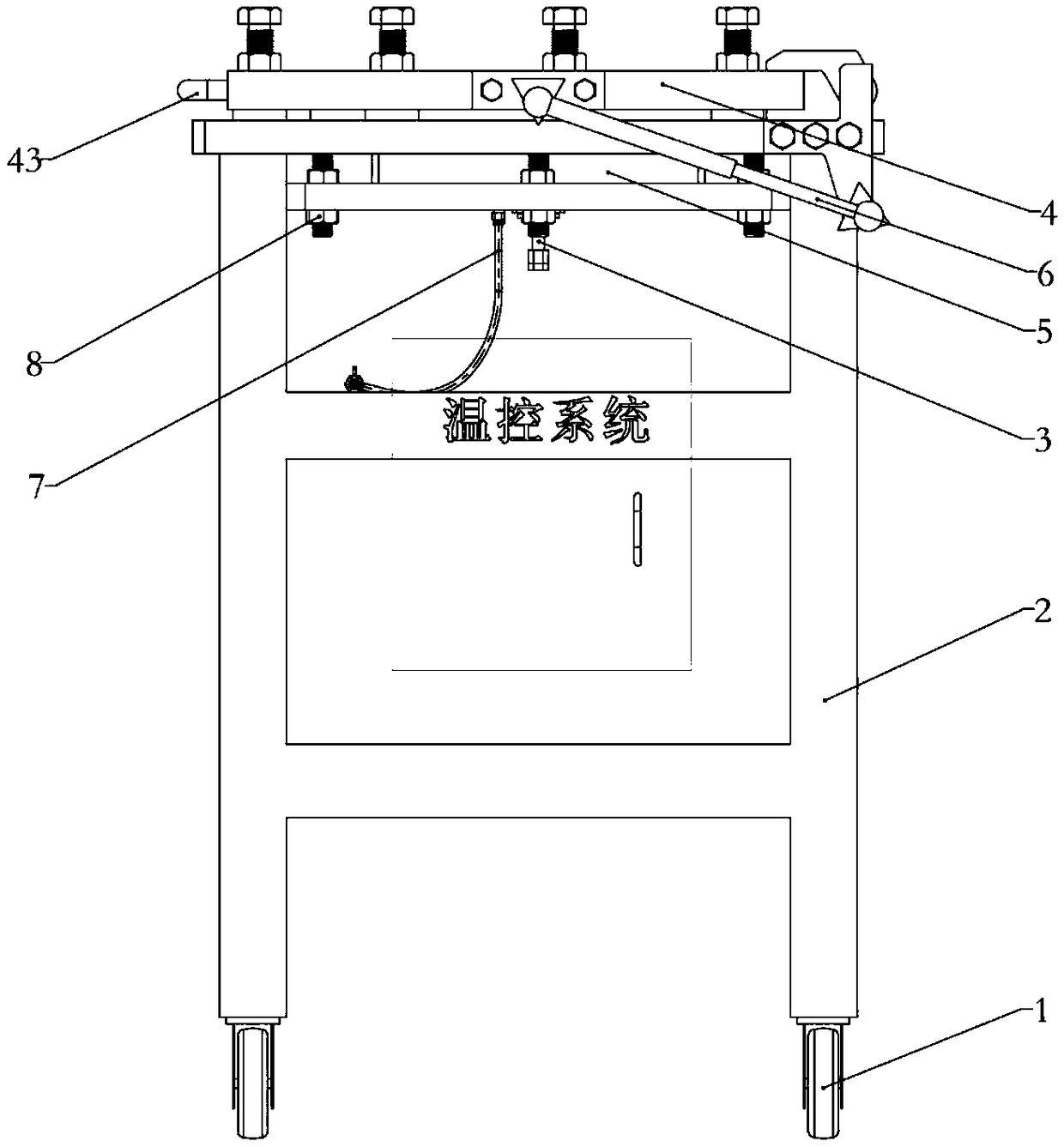

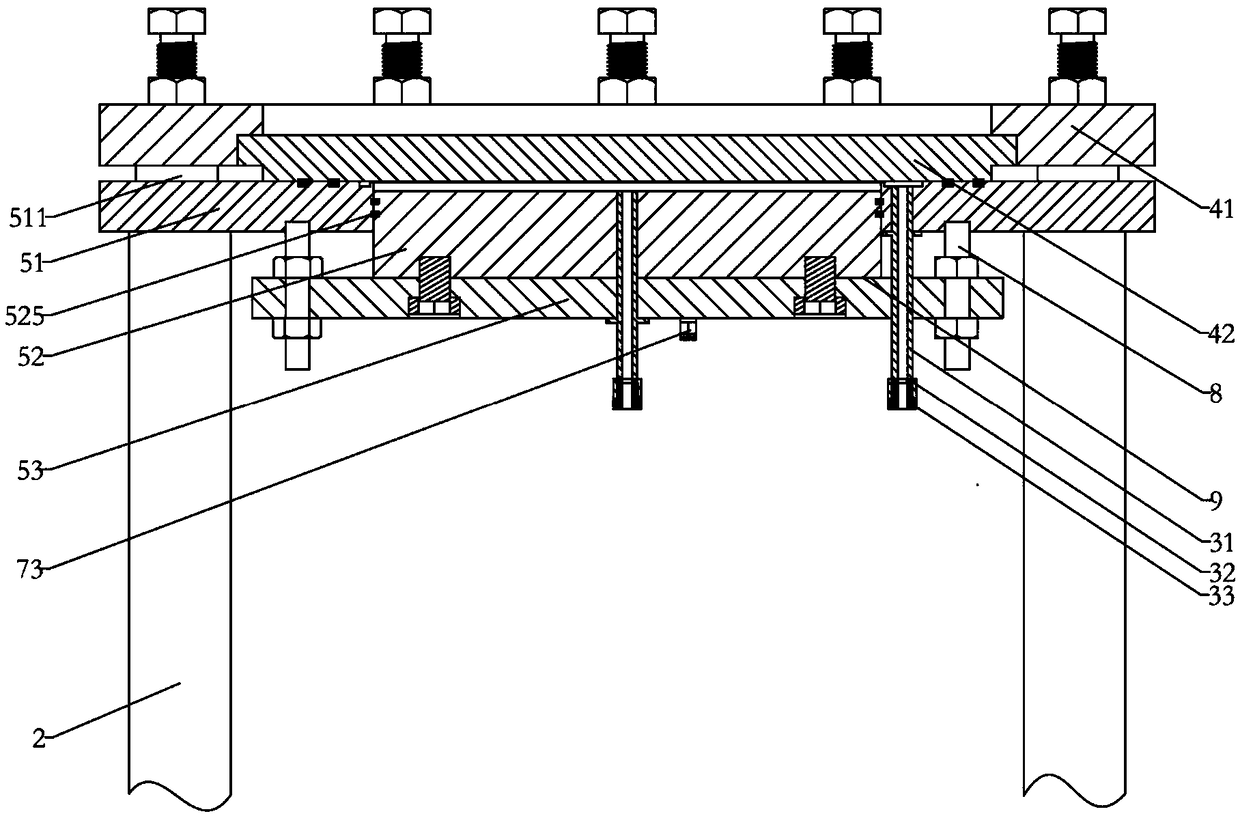

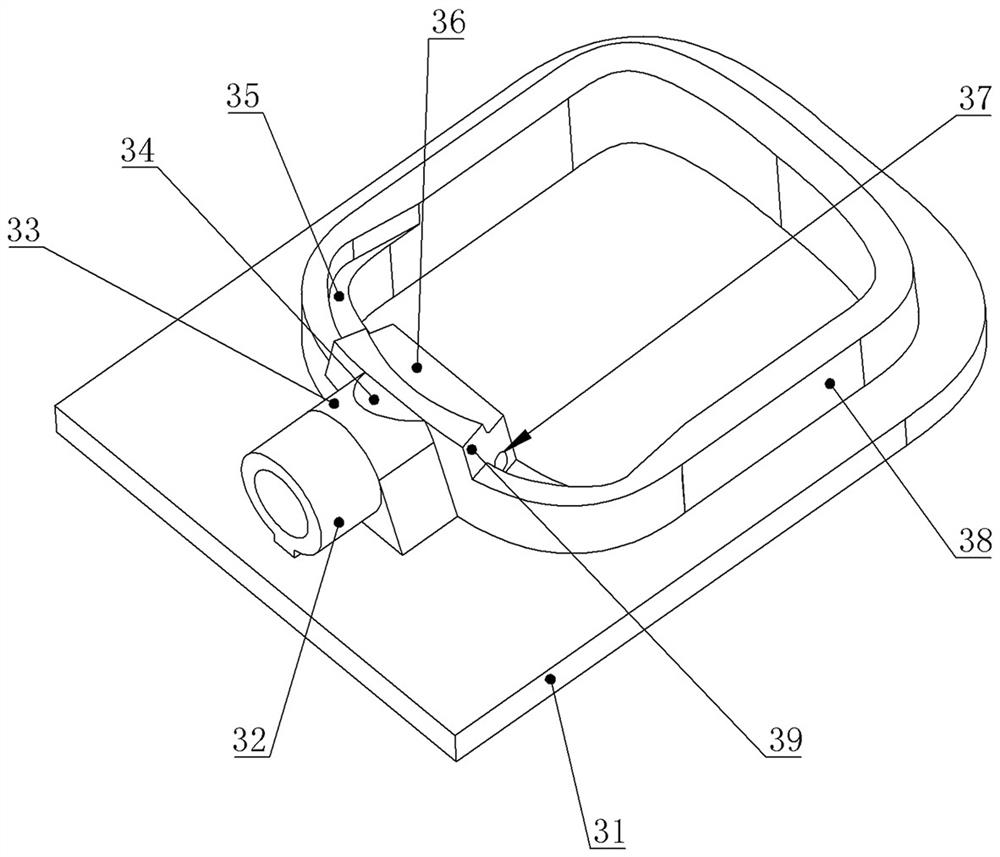

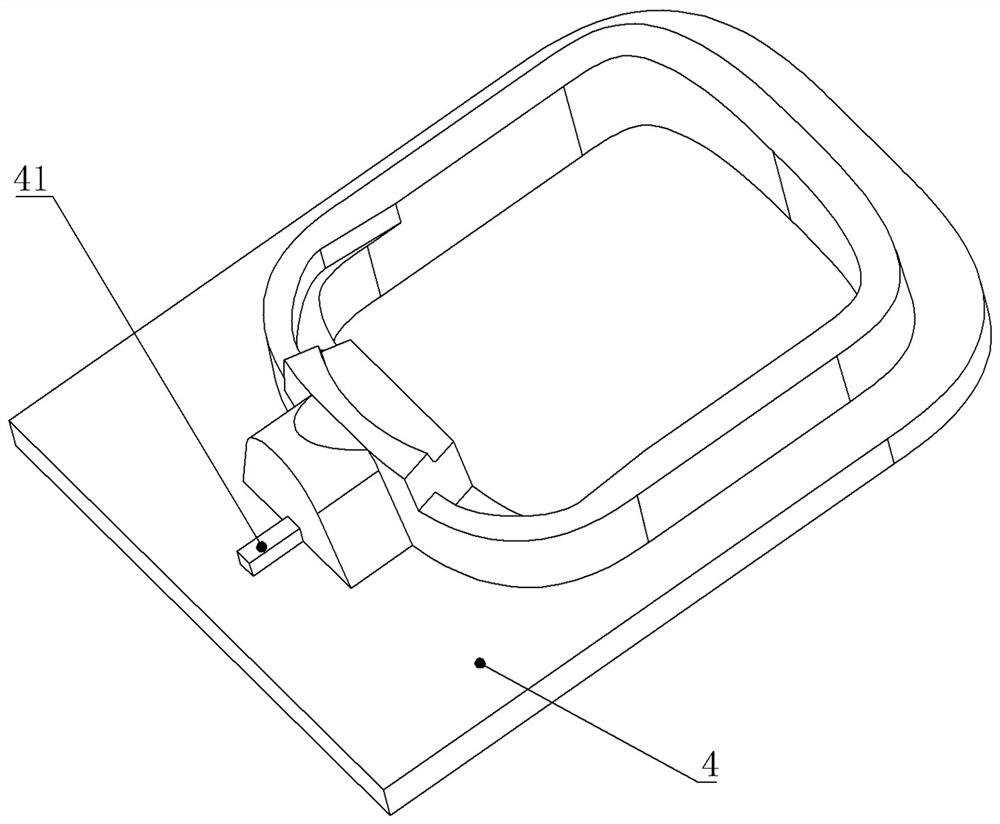

Visual RTM mould capable of infinitely adjusting thickness of composite plate

The invention relates to a visual RTM mould capable of infinitely adjusting the thickness of a composite plate. Toughened glass (42) is embedded in an upper mold plate (4), and a lower mold plate (5) is fixed to a rack through a fixed part (51). A sliding part (52) is arranged in the fixed part (51), a linkage part (53) is fixed to the bottom surface of the sliding part (52), and a cavity regulating mechanism (8) used for driving the linkage part (53) and the sliding part (52) to move up and down is arranged on the linkage part (53). Glue injection holes (521) and glue discharge hole (522) are formed in the ) sliding part (52) and the linkage part (53). Runners (523) are formed around the upper end of a middle through hole, leading to a closed cavity, of the fixed part (51) and communicate with the glue injection holes (521). The visual RTM mould can infinitely adjust and control the thickness of the composite plate through the cavity regulating mechanism, and has the advantages of high precision, self locking function, etc. The toughened glass used in the upper mold plate is used as an observation window, so that a user can observe resin filling and flowing.

Owner:HUNAN UNIV

Easily-opened rubber vulcanizing mold capable of detecting internal pressure of mold cavity in real time

The invention provides an easily-opened rubber vulcanizing mold capable of detecting the internal pressure of a mold cavity in real time and belongs to the technical field of molds. The easily-opened mold provided by the invention is composed of five parts namely three molds for a vulcanizing process and two sets of mold opening devices for drawing after vulcanizing. By virtue of the two sets of mold opening devices for drawing after vulcanizing, the problems of high difficulty in drawing, labor consumption in drawing and the like are well solved. The whole process is simple and is easy to operate. The mold can be simply and conveniently opened, and the test pieces cannot be damaged. After vulcanizing is completed, a sensing head of a pressure sensor is taken down from the mold cavity, three sets for vulcanizing are taken down and are placed on cylindrical cavity barrels of the two sets of mold opening devices, and a molding head is pressurized, so that a cylindrical base and a sizing material are separated from the mold cavity. The remaining two sets of devices which are not separated are turned over and are placed on the cylindrical cavity barrels of the mold opening devices, and the molding head is pressurized by a solid cylinder so as to be separated from a cylindrical sleeve, so that mold opening is completed.

Owner:HARBIN INST OF TECH

Easy-to-open dumbbell-type vulcanized rubber specimen processing mold

Owner:HARBIN INST OF TECH

Unit curtain wall vertical decorative wing aligning device

The invention relates to the technical field of curtain wall mounting devices, in particular to a unit curtain wall vertical decorative wing aligning device. The device comprises an aluminum alloy support, an edge groove is formed in the surface of the aluminum alloy support, a clamping groove is formed in the surface of the edge groove, a stirring hole is formed in the surface of the aluminum alloy support, a rack is arranged on the surface of the edge groove, a clamping strip is inserted into the surface of the clamping groove, the clamping strip is fixed to the surface of an aluminum alloy translation seat, and the aluminum alloy translation seat is inserted into a storage groove. The unit curtain wall vertical decorative wing alignment device has the beneficial effects that the unit curtain wall vertical decorative wing alignment device is a whole composed of aluminum alloy and stainless steel screws, material mold opening is simple, the whole device is simple, and the force borne by decorative wing limiting alignment is completely met in the mechanical function; and the unit curtain wall vertical decorative wing alignment device is divided into two parts, installation and adjustment are flexible, the decorative wing can be freely disassembled, installation and disassembly are convenient, and the cost can be reduced.

Owner:CHINA CONSTR EIGHTH ENG DIV

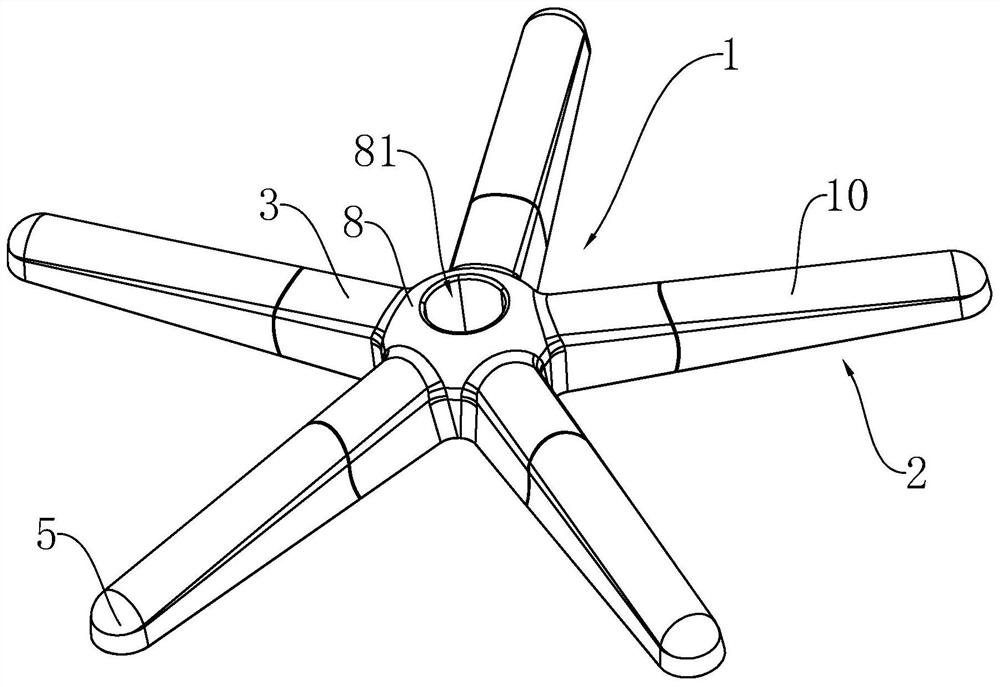

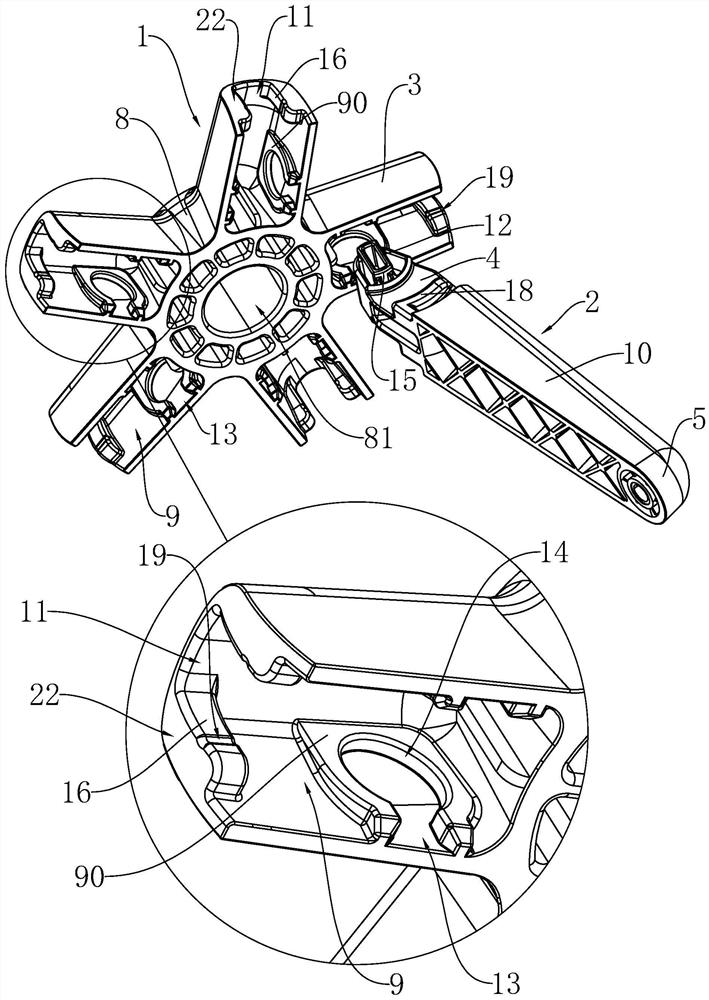

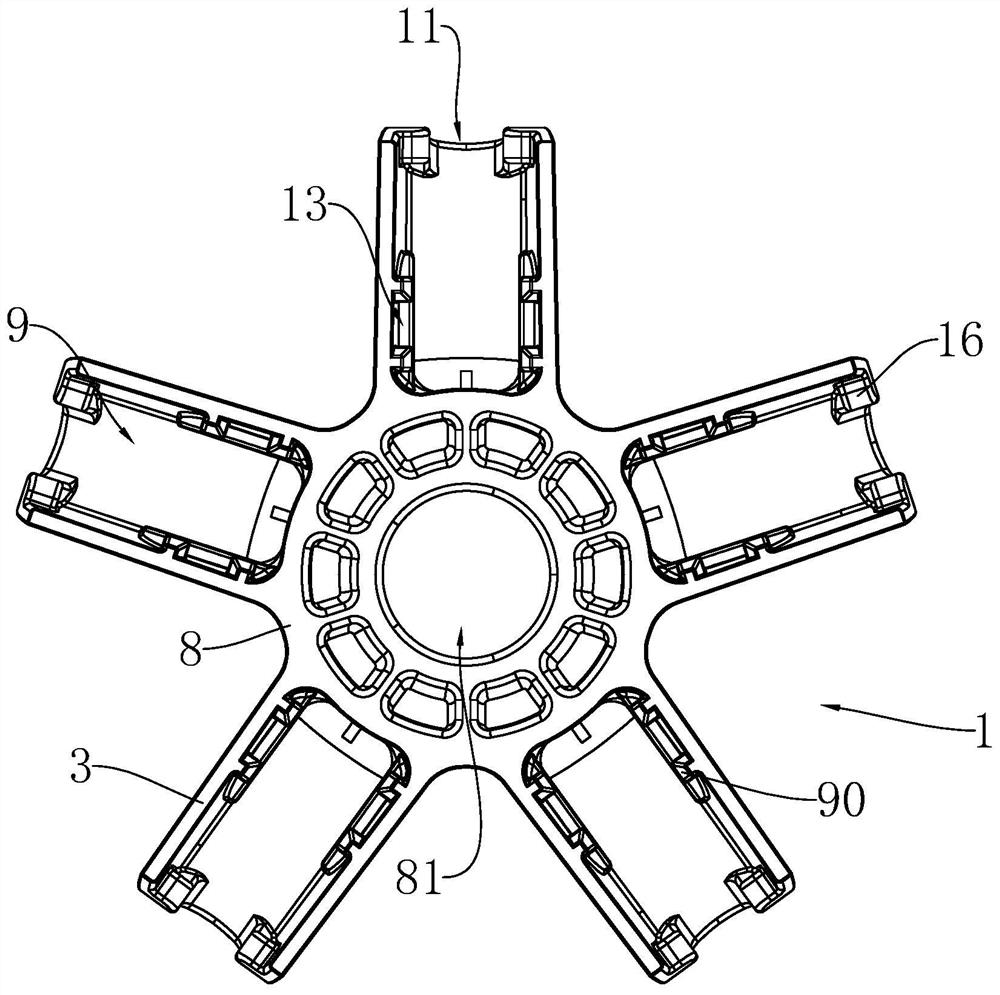

Detachable chair leg

PendingCN113116071ARealize disassemblyImprove applicabilityDismountable chairsFoldable chairsPhysical medicine and rehabilitationMedicine

The invention discloses a detachable chair leg which comprises a connecting seat and a plurality of supporting legs radially arranged on the connecting seat, and the connecting seat comprises mounting parts uniformly arranged at intervals in the circumferential direction; each supporting leg comprises an access part located at the end; the access part is mounted in the mounting part, and the supporting legs are detachably connected to the connecting seat; an insertion rotating structure and a fixed limiting structure are arranged between the access part and the mounting part, and the insertion rotating structure is configured to enable the access part and the mounting part to be matched in an insertion manner and rotationally connected; the fixed limiting structure is configured to relatively fix the access part and the mounting part and prevent the access part and the mounting part from being separated; compared with the prior art, the connecting seatand the supporting leg are inserted through the insertion rotating structure and are in rotating fit, then the supporting leg is rotated till the fixing limiting structure enables the connecting seat and the supporting leg to be relatively fixed, and assembling is easy and convenient; the shape of the connecting seat is not limited, and the number of the supporting legs can be selected at will as long as the supporting legs are detachably connected with the connecting seat and the seat can be stably supported.

Owner:UE FURNITURE CO LTD

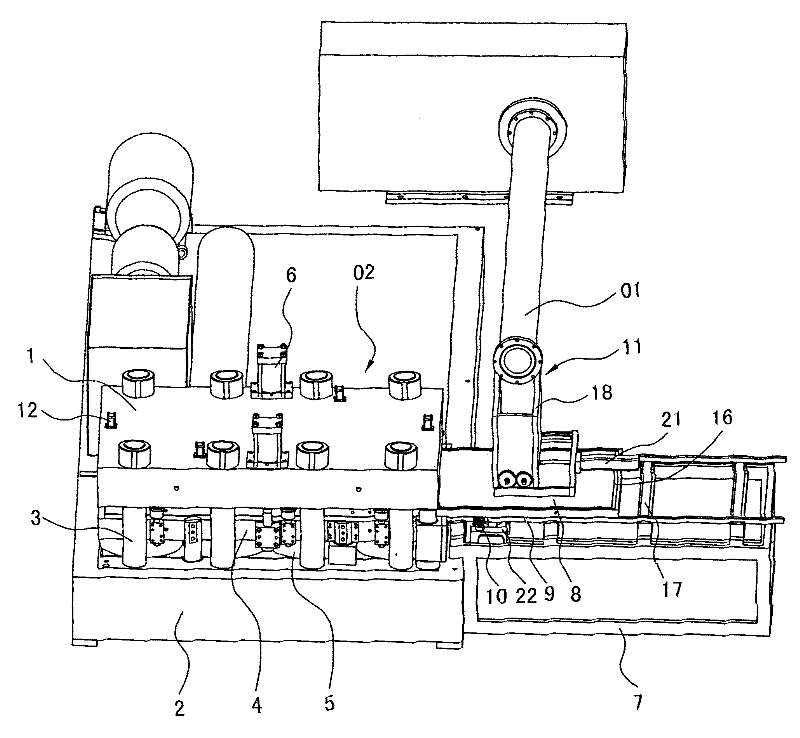

Movable distribution plastic mixture compression molding machine

InactiveCN102233633AEasy to moveIncrease productivityFlat articlesCompression moldingPlastic injection molding

The invention relates to a movable distribution plastic mixture compression molding machine. The machine is characterized in that: the machine comprises a mold-closing molding mechanism; the mold-closing molding mechanism comprises an upper fixed die plate and a lower fixed die plate; the upper fixed die plate is connected with the lower fixed die plate through a pull rod; a movable die plate is arranged on the lower fixed die plate; the movable die plate comprises a die-closing oil cylinder and die-opening oil cylinder; a model plate is arranged on the movable die plate; and the movable die plate is characterized in that the model plate has a mobile device, the mobile device drives the model plate to move out of the die-closing molding mechanism and move into the die-closing molding mechanism, a material distributor is arranged on the model plate which is out of the die-closing molding mechanism, and a material discharge port of the material distributer blanks materials to the model plate. According to the scheme which adopts a mode of simultaneously moving the model plate and blanking, the materials are uniformly distributed on the model plate, and then are subject to compression molding. Compared with hot press molding and injection molding, the plastic injection molding pressure does not need to be considered, phenomena that materials are cold and material injection is not in place do not occur, the materials are uniformly distributed, the overall strength of compressed products is good, the specification is neat, so the machine of the present invention is especially suitable for large-area thin-wall product molding.

Owner:蔡业

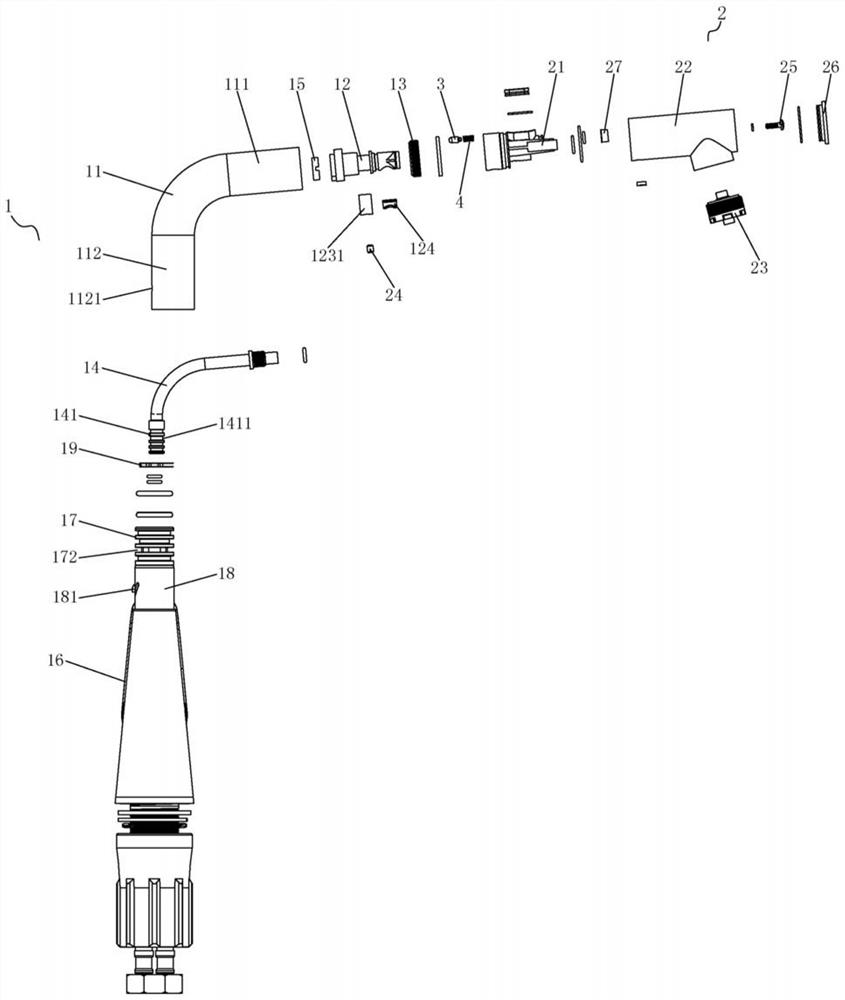

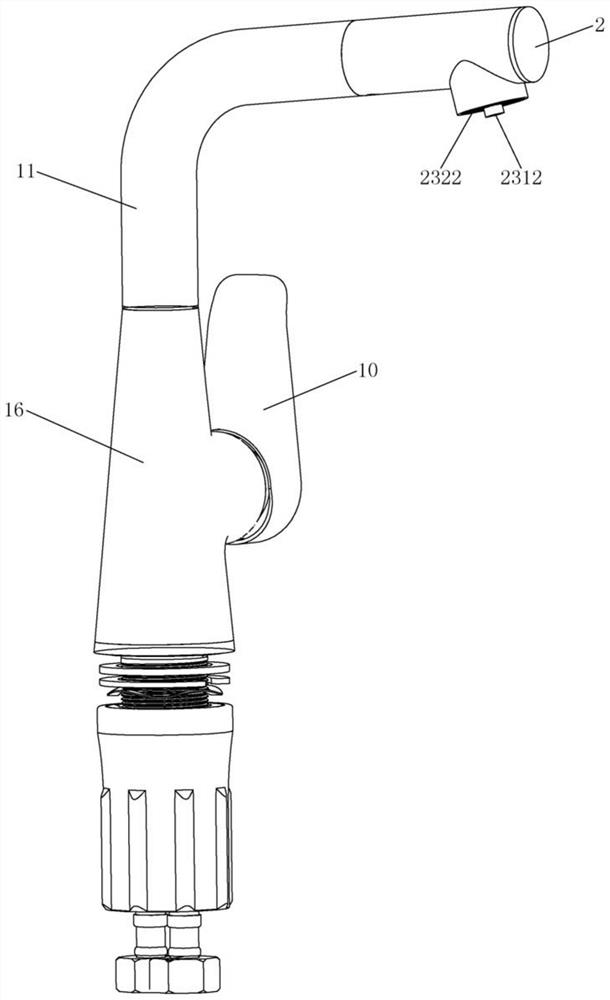

Faucet

PendingCN113833877AEasy to operateEasy to useDomestic plumbingEqualizing valvesOutfallMechanical engineering

The invention discloses a faucet. The faucet comprises a faucet body and a water discharging assembly. The faucet body is provided with a water passing part; the water passing part is provided with a water passing path; the water discharging assembly is rotationally connected to the water passing part and provided with a first water distribution opening, a second water distribution opening, a first water outlet and a second water outlet. The first water distribution opening and the second water distribution opening are oppositely arranged in the direction perpendicular to a rotating shaft of the water discharging assembly and are suitable for being switched to be communicated with the water passing path when the water discharging assembly rotates; the first water outlet is arranged around the periphery of the second water outlet and is communicated with the first water distribution opening to form a first water discharging path; the second water outlet is communicated with the second water distribution opening to form a second water outlet path; and the first water outlet and the second water outlet incline towards the front lower portion and incline towards the front lower portion respectively when the water passing path is communicated with the first water distribution opening and the second water distribution opening. The faucet can output water flows in two different forms, the structure is simple, mold opening is convenient, the attractiveness is good, and a valve does not need to be closed when water paths are switched.

Owner:JOMOO KITCHEN & BATHROOM

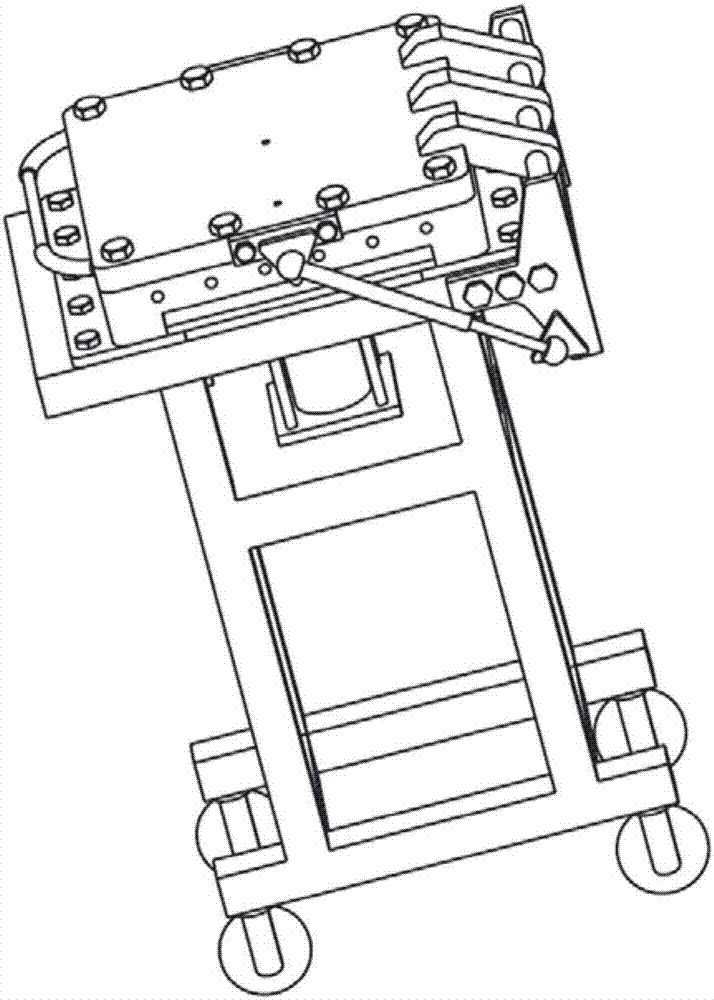

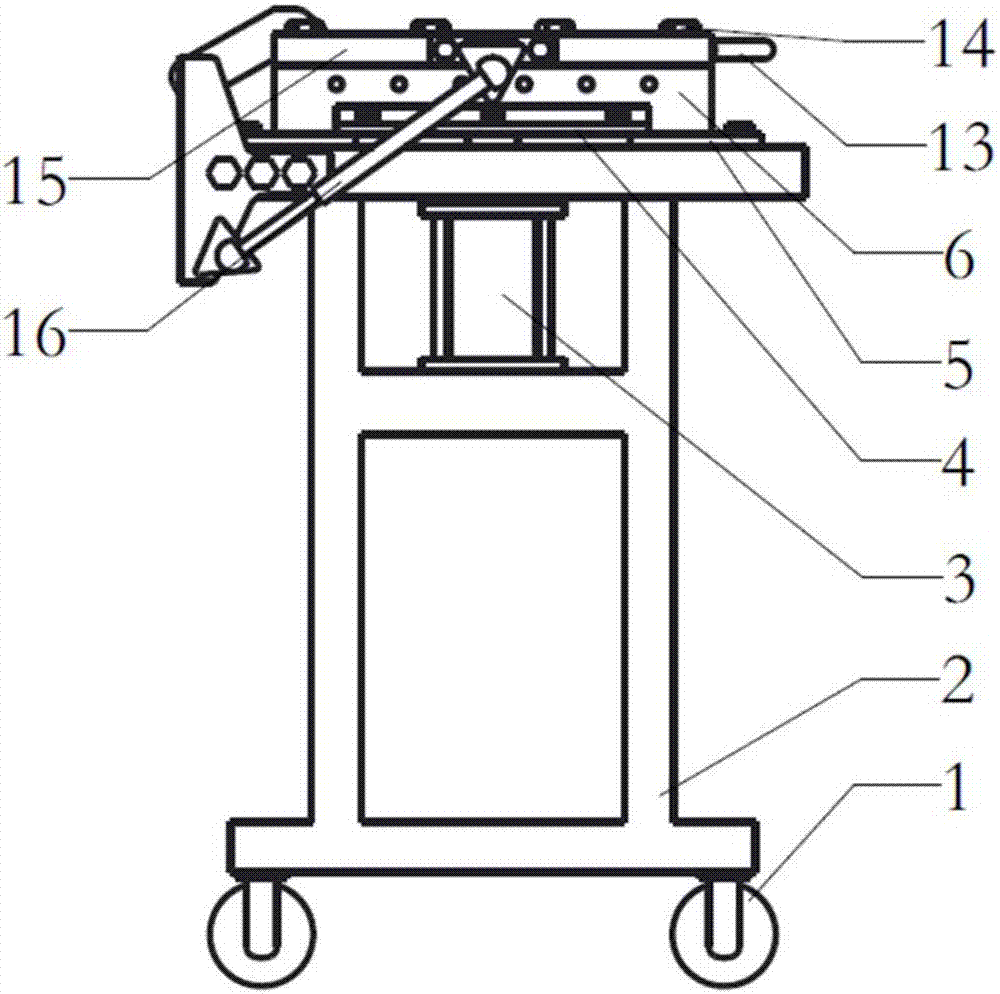

Mould-opening mould base for car mould

InactiveCN108372242AReasonable structureEnsure safetyShaping toolsShaping safety devicesManufactured ObjectBolster

The invention discloses a mould-opening mould base for a car mould. The mould-opening mould base for the car mould comprises support frames and a machine box, the machine box and a sliding seat is arranged between the support frames, the machine box is movably connected with the support frames through sliding seats, sliding paths are arranged on the side faces of the support frames, and the sliding paths are fixedly connected with the support frames. A base is arranged between the support frames, the base is fixedly connected with the support frames, an intelligent control device is arranged above the support frames, and the intelligent control device is tightly attached with the support frames. The mould-opening mould base for the car mould is provided with a bolster, a bolster is specially arranged on the top of the base to prevent a lower mould from falling off when a upper mould is pulled up, the lower mould can be effectively prevented from losing the stability due to the departure of the upper mould when the mould is opened, so that the lower mould and finished products are prevented from falling off to the ground and damaging the lower mould and the finished products, and the safety of the lower mould and the finished products is greatly improved; and the mould-opening mould base for the car mould is simple and convenient in mould opening, and has good development prospects in the future.

Owner:WUXI SANZHONG MOLD CO LTD

Preparation method of rubber concrete panel with rough surface

ActiveCN109265067AImprove driving safetyHigh surface friction coefficientShaping press ramRough surfacePolymer science

The invention provides a preparation method of a rubber concrete panel with a rough surface, and belongs to the field of compound materials. The method specifically includes the steps that treated stone and rubber compound particles are packed into a mold after being mixed evenly, then the mold is covered by a plastic panel with an area equal to that of an upper mold cavity and the thickness of 2-5 mm, an upper mold panel is closed, at 150-180 DEG C, firstly, preheating is conducted for 30-90 seconds, then mold pressing is conducted at 8-18 MPa, and finally, vulcanization is conducted for 10-40 minutes to prepare the rubber concrete panel with the rough surface. The preparation method of the rubber concrete panel with the rough surface has the beneficial effects that through the method, apart of stone on the rubber concrete surface can be made to be raised, not only is the rubber concrete material surface wear resistance improved, but also a surface friction coefficient of a materialcan be increased, and the anti-skid performance is improved, so that the safety of passengers and driving is improved; meanwhile, mold opening after vulcanization is conducted can be made to be easier.

Owner:XUZHOU COLLEGE OF INDAL TECH

An instant beverage bottle with built-in solid beverage

ActiveCN104477523BSimple structureEasy mold opening and processingContainers with multiple articlesEngineeringBottle

The invention relates to an instant-brewing beverage bottle with a built-in solid beverage. According to the instant-brewing beverage bottle, a bottle body is formed through the screwed connection of an upper bottle body and a lower bottle body; an elastic membrane is arranged at the bottom of the lower bottle body, two sliding grooves are symmetrically fixed on the lower bottle body, a material box is clamped between the two sliding grooves in a sliding fit manner, a sealing film is arranged on a top opening of the material box, and a plurality of hollow or solid needle tubes are arranged on a cover plate; up-going ratchets are respectively arranged on vertical plates of the two sliding grooves, and pawls which are matched with the up-going ratchets of the sliding grooves are respectively arranged on two side faces of the material box; an isolated space for storing the solid beverage is separately formed in the bottle body, and during use, drinking water is introduced into the space to be mixed with the solid beverage, so as to form a liquid beverage. The beverage bottle has the characteristics of simple structure, low manufacturing cost and convenience and reliability in water inlet operation.

Owner:黄顺邦

Artistic flowerpot

The invention relates to an artistic flowerpot. The artistic flowerpot comprises a flowerpot top, a flowerpot bottom and a decoration cylinder, wherein the flowerpot top, the decoration cylinder and the flowerpot bottom are arranged from top to bottom in sequence, the upper end of the decoration cylinder is fixed around the bottom surface of the flowerpot top, and the lower end of the decoration cylinder is fixed around the top surface of the flowerpot bottom. The artistic flowerpot has the advantages that raw materials are saved to a certain degree, molding and mold opening are easy, and the manufacturing cost of the flowerpot is reduced; the defect of singleness of traditional flowerpots is overcome, and the ornamental value of the flowerpot is increased. A light is installed in the artistic flowerpot so as to achieve illumination in dark or at night, and the colors of patterns on the decoration cylinder can become richer and more colorful through the irradiation of the light.

Owner:李尔龙

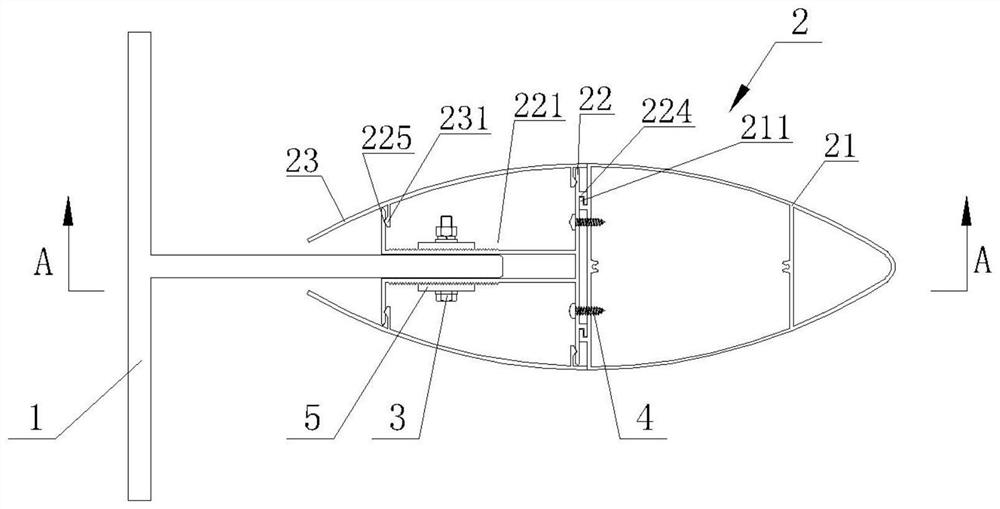

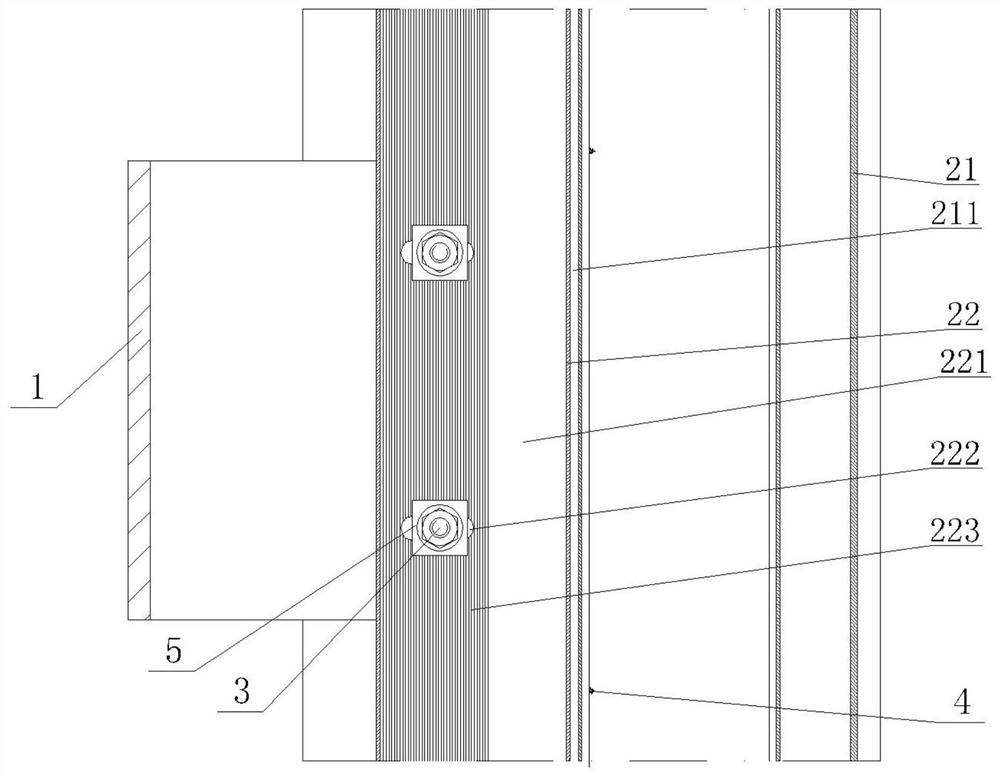

Fusiform grid and mounting method thereof

PendingCN112523408AGuaranteed aestheticsDoes not affect appearanceWallsStructural engineeringMechanical engineering

The invention discloses a fusiform grid and a mounting method thereof. The fusiform grille comprises a T-shaped base and a fusiform decoration strip body, the fusiform decoration strip body comprisesa semi-fusiform shell, a connecting piece and two arc-shaped buckle plates, two through grooves which are symmetrically distributed and provided with openings in the side faces are formed in the rearportion of the connecting piece, the extending end of the T-shaped base is arranged between the two through grooves, the T-shaped base and the connecting piece are connected into a whole through boltassemblies, the semi-fusiform shell is detachably connected to the front end of the connecting piece through a buckle and connected into a whole through a screw, the arc-shaped buckle plates are detachably connected to groove openings of the through grooves through buckles, and the front end faces of the two arc-shaped buckle plates are connected with the rear end face of the semi-fusiform shell to form a full-fusiform shape. According to the fusiform grille, an existing integral full-fusiform profile is split into four parts, effective connection of all the parts is completed through mechanical connection of the buckles and the invisible bolt assemblies at the rear ends, and mold opening is easier, construction is more convenient, and the fusiform grille can better adapt to deformation ofstructural errors while the appearance effect is not affected.

Owner:中建五局装饰幕墙有限公司

A visual rtm mold capable of steplessly adjusting the thickness of composite material sheets

The invention relates to a visual RTM mould capable of infinitely adjusting the thickness of a composite plate. Toughened glass (42) is embedded in an upper mold plate (4), and a lower mold plate (5) is fixed to a rack through a fixed part (51). A sliding part (52) is arranged in the fixed part (51), a linkage part (53) is fixed to the bottom surface of the sliding part (52), and a cavity regulating mechanism (8) used for driving the linkage part (53) and the sliding part (52) to move up and down is arranged on the linkage part (53). Glue injection holes (521) and glue discharge hole (522) are formed in the ) sliding part (52) and the linkage part (53). Runners (523) are formed around the upper end of a middle through hole, leading to a closed cavity, of the fixed part (51) and communicate with the glue injection holes (521). The visual RTM mould can infinitely adjust and control the thickness of the composite plate through the cavity regulating mechanism, and has the advantages of high precision, self locking function, etc. The toughened glass used in the upper mold plate is used as an observation window, so that a user can observe resin filling and flowing.

Owner:HUNAN UNIV

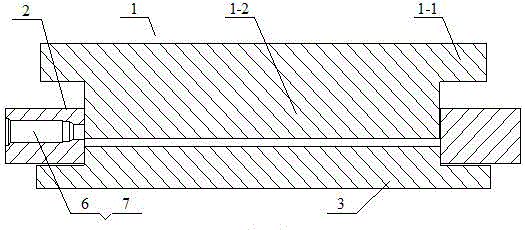

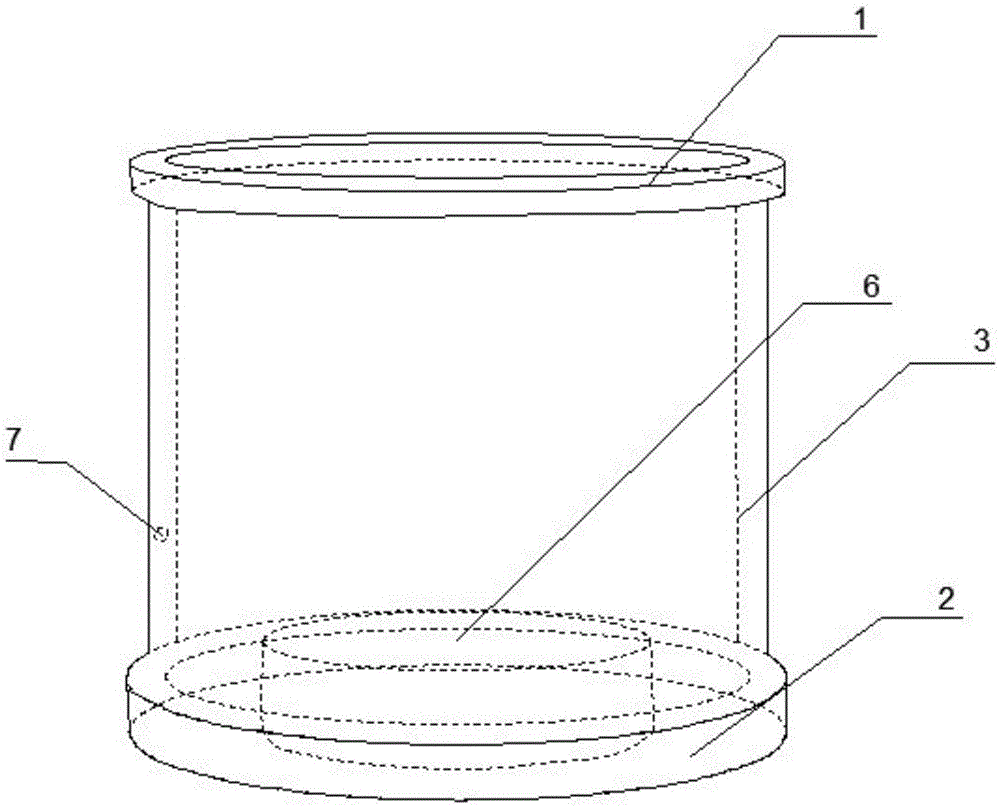

Easy-to-open cylindrical vulcanized rubber specimen processing mold

The invention provides an easily-opened mold for processing cylindrical vulcanized rubber test pieces. When the mold is used, a rubber material is vulcanized by using a flat vulcanizing machine. A cylindrical base and a cylindrical sleeve are placed on the flat vulcanizing machine in a combination mode, a circular mold for processing the cylindrical test pieces is placed into a mold cavity, mixed rubber compounds are added into cylindrical through holes in the circular mold, and then a molding head is placed for heating, pressurizing and vulcanizing. The mold is composed of six parts namely four molds for a vulcanizing process and two devices for drawing after vulcanizing. By virtue of the two devices for drawing after vulcanizing, the problems of high difficulty in drawing, labor consumption in drawing and the like are well solved. Moreover, a disk mold comprising a plurality of small cylindrical holes is designed, so that dozens of cylindrical test pieces can be obtained by vulcanizing at one time; due to the fact that the number is large, later experiments are facilitated. When the mold is used, the whole process is simple; the mold is easy to operate and simple and convenient to open, and the test pieces cannot be damaged.

Owner:HARBIN INST OF TECH

Stepping window rotating bin type portable medicine box with easy-to-tear films

PendingCN113855556AAvoid misuseRealize one-way stepping functionPharmaceutical containersMedical packagingEngineeringTear tape

The invention discloses a stepping window rotating bin type portable medicine box with easy-to-tear films. The problem that in the prior art, the function of a portable medicine box still needs to be improved is solved. The stepping window rotating bin type portable medicine box comprises an outer sleeve shell, an inner cylinder sleeve, a medicine grid cylinder, a one-way limiting device, a rotary button and medicine bin tearing layers, wherein the outer sleeve shell is arranged on the outer surface of the inner cylinder sleeve in a sleeving mode; the inner cylinder sleeve is arranged on the outer surface of the medicine grid cylinder in a sleeving mode; the outer sleeve shell and the inner cylinder sleeve are provided with medicine taking windows which correspond to each other; the inner cylinder sleeve is arranged on rotary rods at two ends of the medicine grid cylinder through fixing holes in the two ends in a sleeving mode; one ends of the rotary rods extend out of the outer sleeve shell to be sleeved with the middle of the rotary button, the other ends of the rotary rods are arranged on the middle of a bottom clamping base in a sleeving mode; a plurality of medicine grids are annularly and evenly distributed on the medicine grid cylinder; and the medicine bin tearing layers are arranged at openings of the medicine grids. By means of the technology, it is guaranteed that the patient does not rotate to an empty medicine grid bin where the medicine is taken, misoperation of the patient is avoided, and the overall stability of the device is guaranteed. Each tearing tape head is designed along the frame and diagonally, so that the medicine bin tearing layers can be torn off uniformly and quickly.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

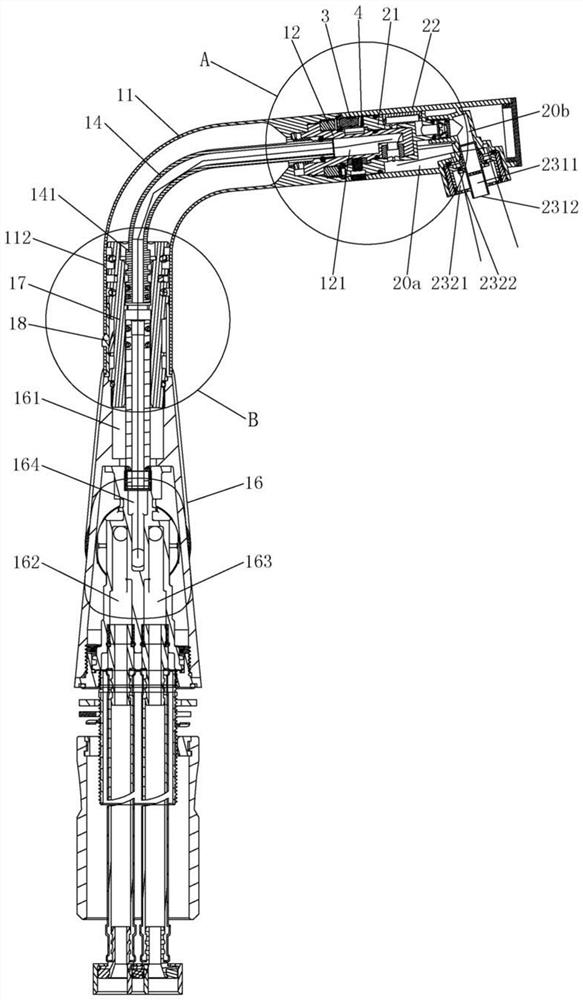

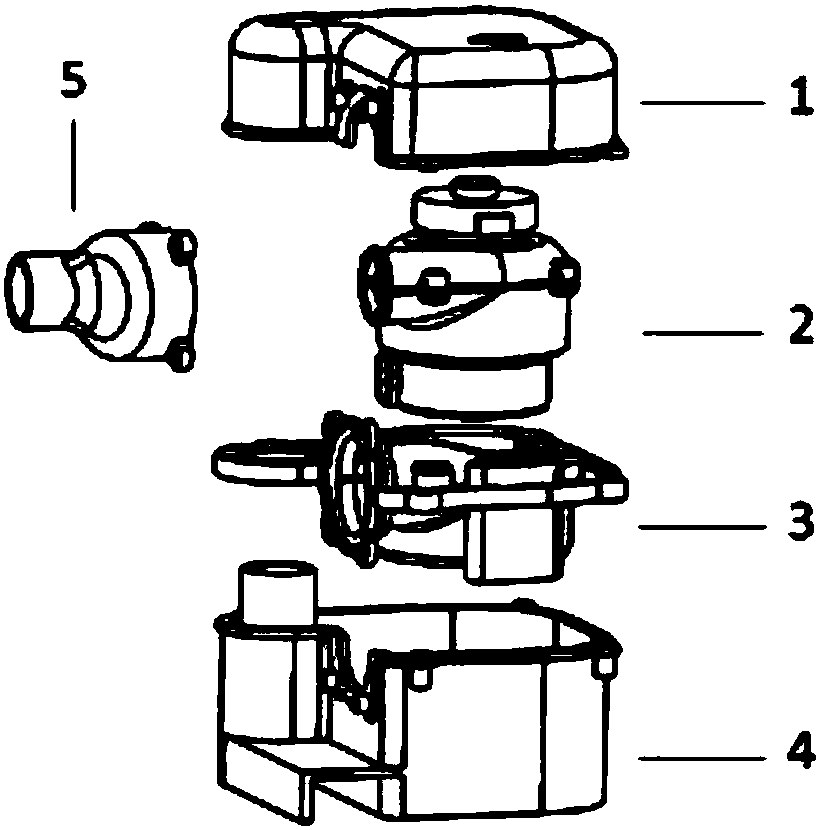

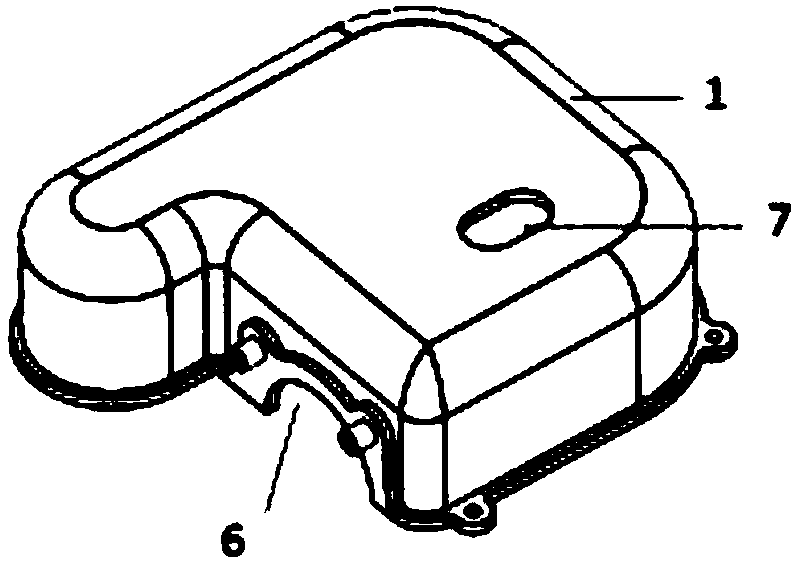

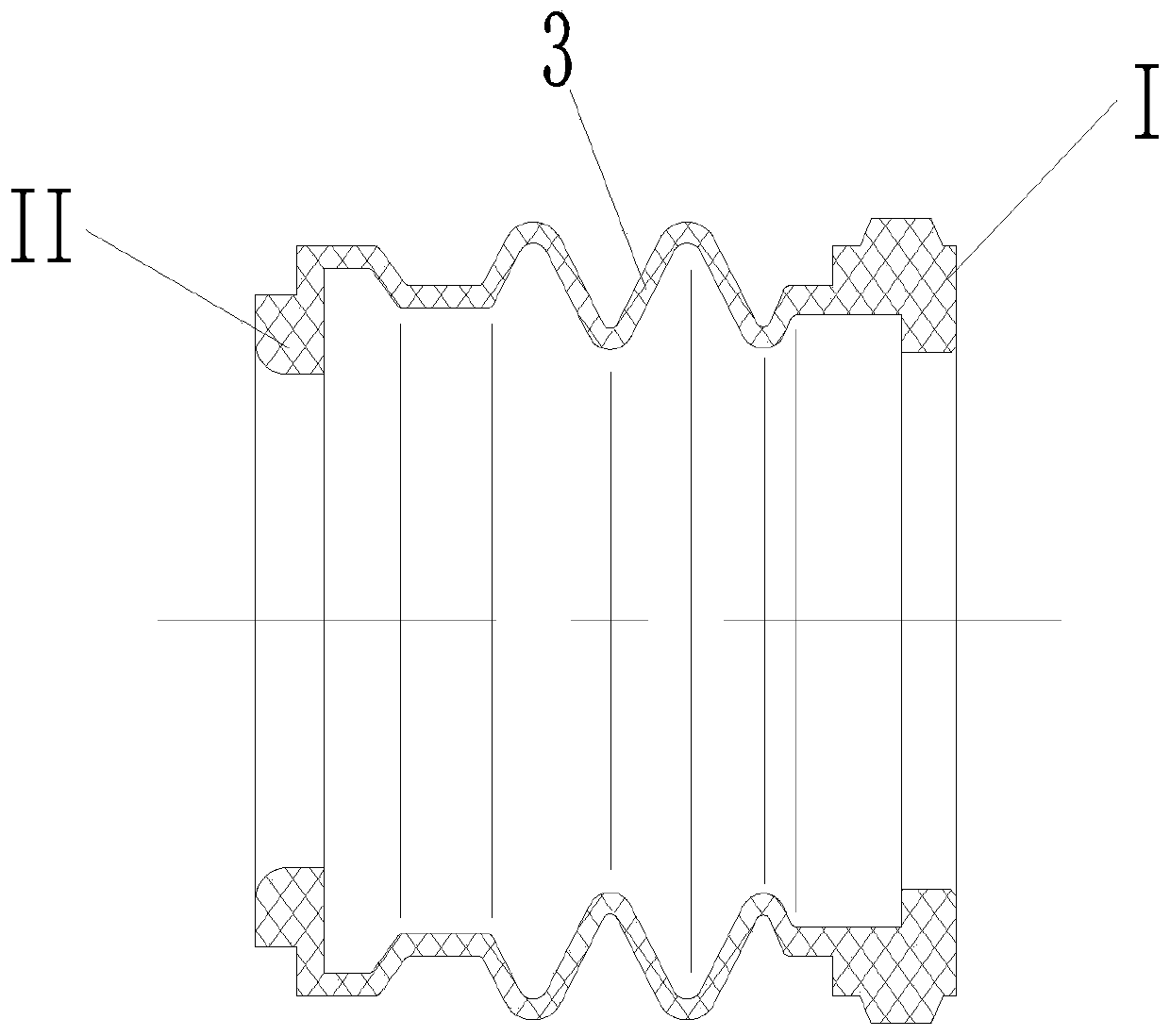

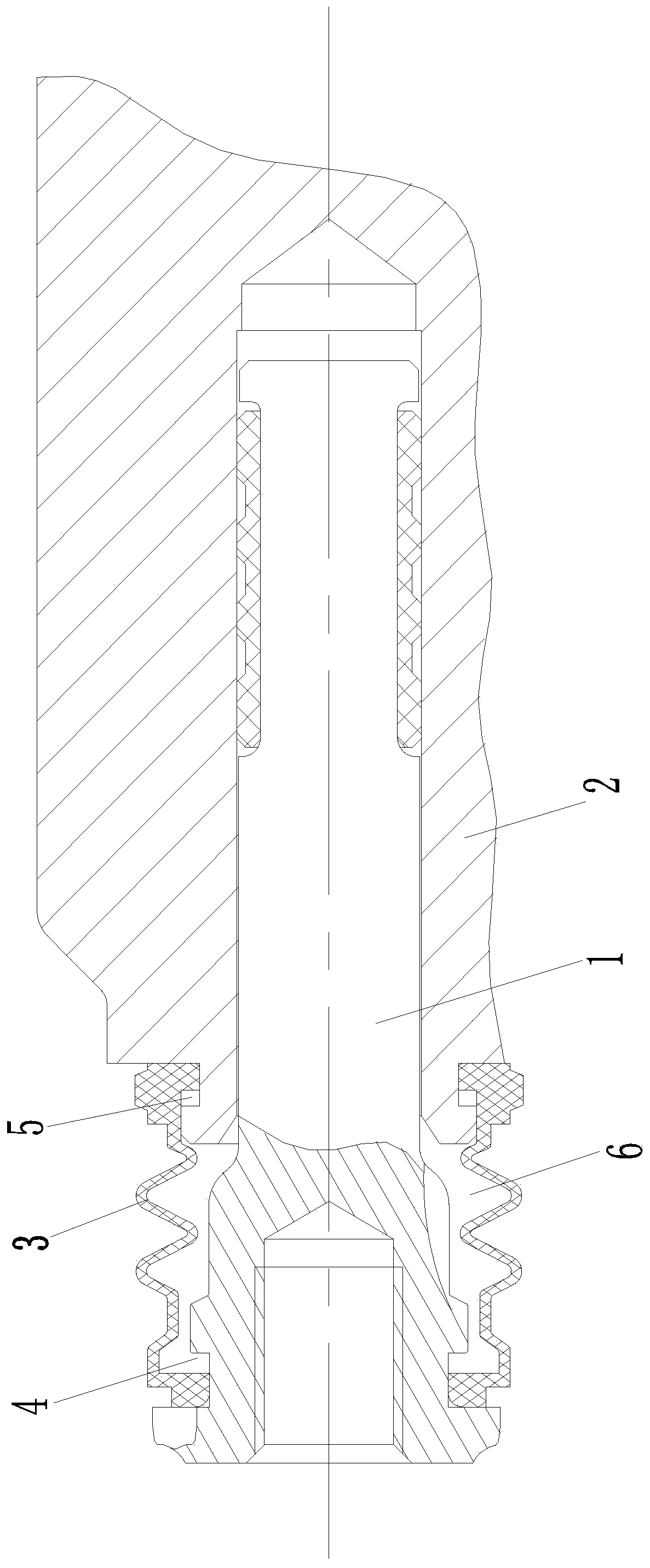

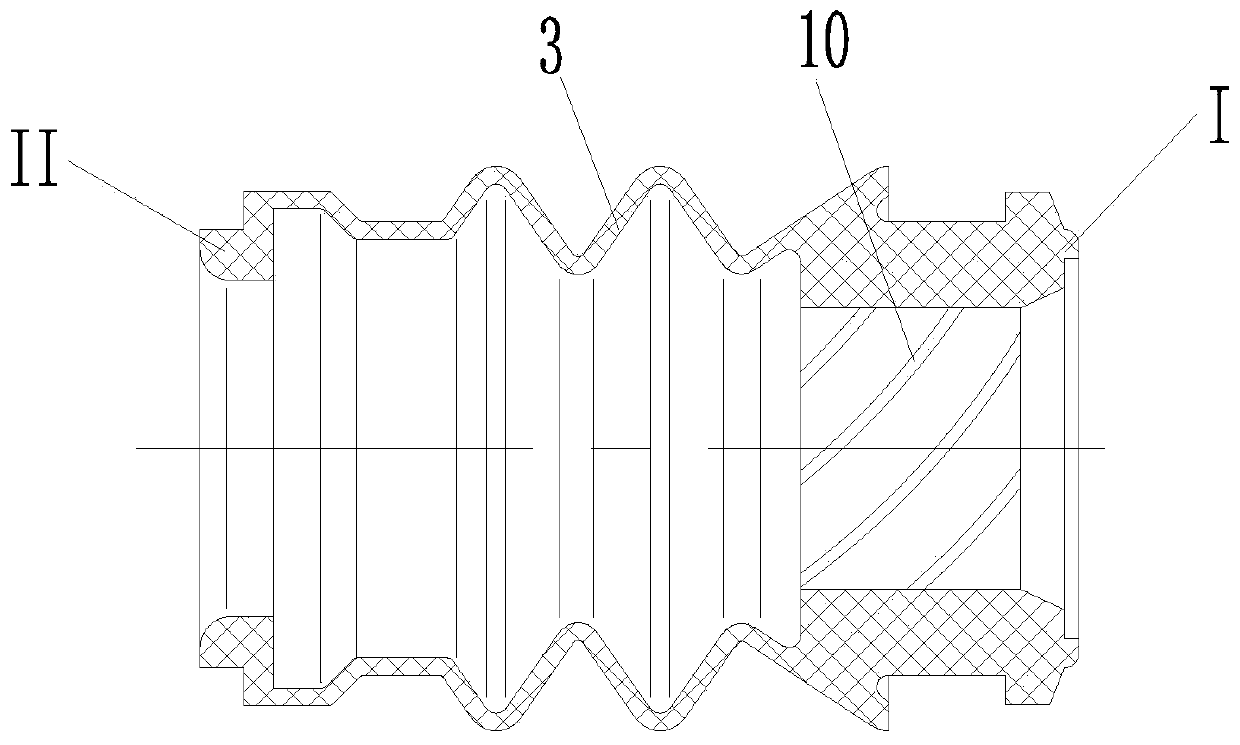

Breathing machine and blower fan noise reduction device thereof

The invention discloses a breathing machine and a blower fan noise reduction device thereof. The breathing machine comprises an upper housing, a blower fan damping sleeve, a lower housing, and an airoutlet rectifying device. A centrifugal fan of the breathing machine is arranged in the blower fan damping sleeve. The blower fan damping sleeve is clamped between the upper housing and the lower housing. The air outlet rectifying device is arranged on an air outlet of the centrifugal fan. The blower fan damping sleeve is arranged between the upper housing and the lower housing and divides a cavity formed by the upper housing and the lower housing into an upper cavity and a lower cavity. The upper cavity is a first static pressure cavity. The lower cavity is a second static pressure cavity. The noise reduction device can reduce about 8 dB(A) noise of the centrifugal fan, and is characterized by low windage resistance, easy mold opening, convenient assembly, high reliability, and good shockabsorption effect.

Owner:深圳市大雅医疗技术有限公司

Easily produced and assembled disc type brake caliper assembly and assembling method

PendingCN110762140AEliminates exhaust problemsLow costEngine sealsBraking elementsGas passingEngineering

The invention relates to an easily produced and assembled disc type brake caliper assembly and an assembling method. The easily produced and assembled disc type brake caliper assembly comprises an axle pin, a bracket and an axle pin dust cover for sealing connection of the axle pin and the bracket. The axle pin comprises a pin body, a neck part and an end part integrally formed. The bracket is provided with a bracket pin hole, the pin body is inserted into the bracket pin hole and is in clearance fit to the bracket pin hole, a dust cover groove of the bracket pin is formed in the periphery ofthe mouth of the bracket pin hole, a dust cover groove of the axle pin is arranged between the neck part and the end part of the axle pin, two ends of the dust cover of the axle pin are hermetically clamped to the dust cover groove of the bracket pin and the dust cover groove of the axle pin, and an exhaust groove of the axle pin is formed in the neck part of the axle pin. When the axle pin, the dust cover of axle pin and the bracket are assembled, gas in the dust cover of the axle pin is discharged from an air storage cavity through the exhausting groove of the axle pin, so that the problem of exhausting in a brake caliper assembling process in the current market is solved, and the production efficiency is improved and the personnel cost is lowered greatly.

Owner:GUANGZHOU ZHONGBO BRAKE SYST CO LTD

Core pulling structure for stripping composite sliding blocks from front mold and rear mold

Owner:SHANGHAI TIANHAI ELECTRONICS

A toilet seat and its separate forming method

ActiveCN111571767BSimple structureSimple mold openingSlip casting mouldsMechanical engineeringIndustrial engineering

The invention relates to the technical field of toilet production, in particular to a toilet seat and a separate forming method thereof. First make the prototype of the toilet seat and the water inlet, and then use the above two prototypes to make a high-pressure model with two open molds, and then inject grout into the high-pressure model, and the slurry will harden to obtain independent toilet seat mud and water inlet mud and then drill water holes and eyelets to the toilet seat mud, and finally bond the two mud blocks together to obtain a toilet seat. The split forming method has simple model structure, easy mold opening, convenient operation for workers, low labor intensity and high production efficiency.

Owner:ZHONGTAO SANITARY WARO MFG CO LTD OF TANGSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com