Movable distribution plastic mixture compression molding machine

A mobile and mixture technology, applied in the field of plastic machinery, can solve problems such as limited injection pressure of injection molding machines, affecting product appearance and internal quality, and insufficient injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

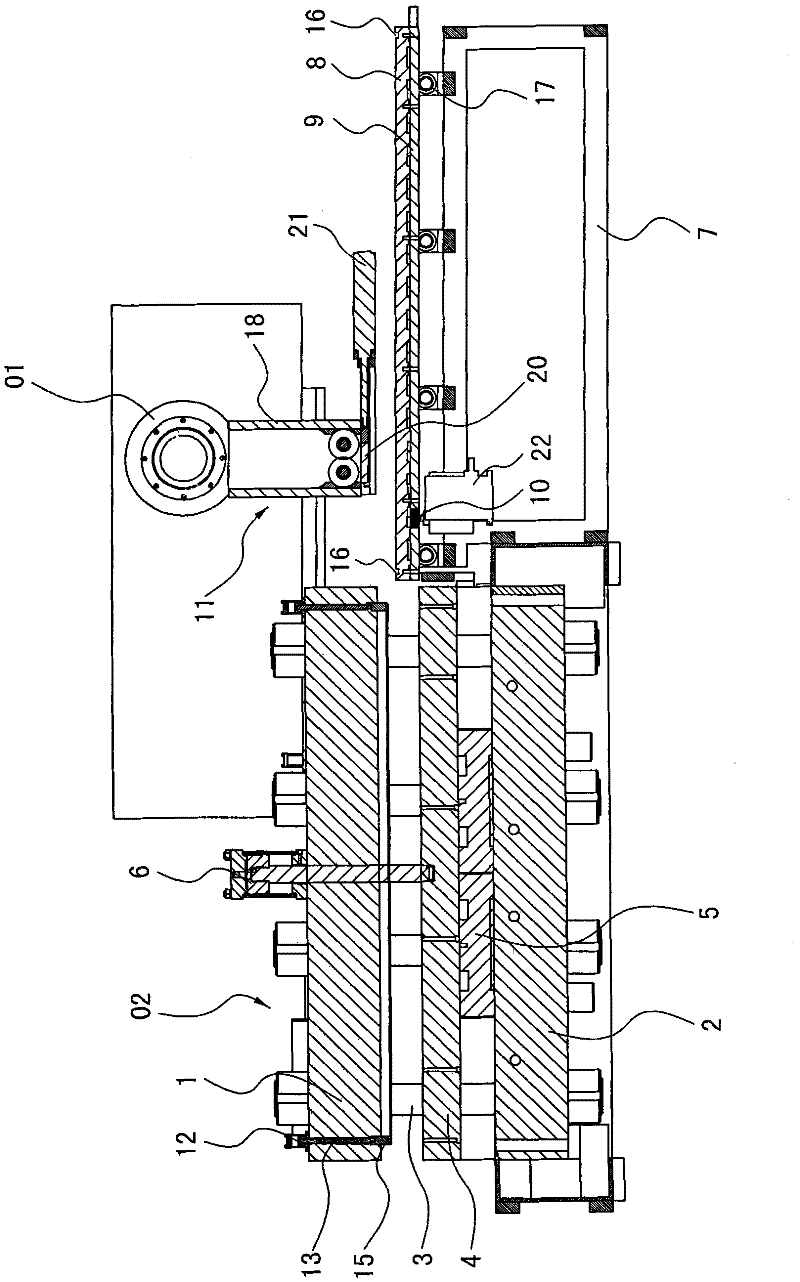

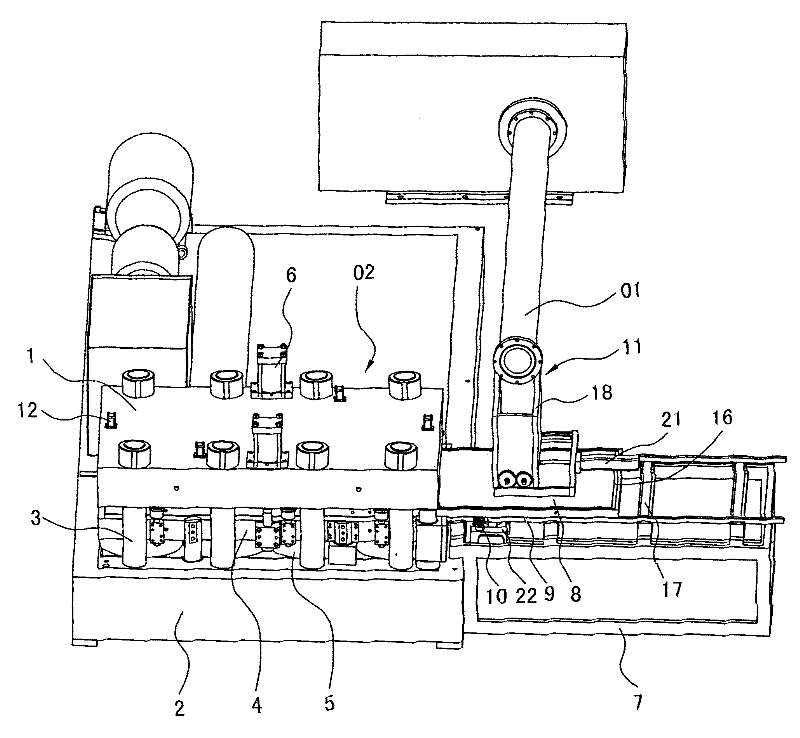

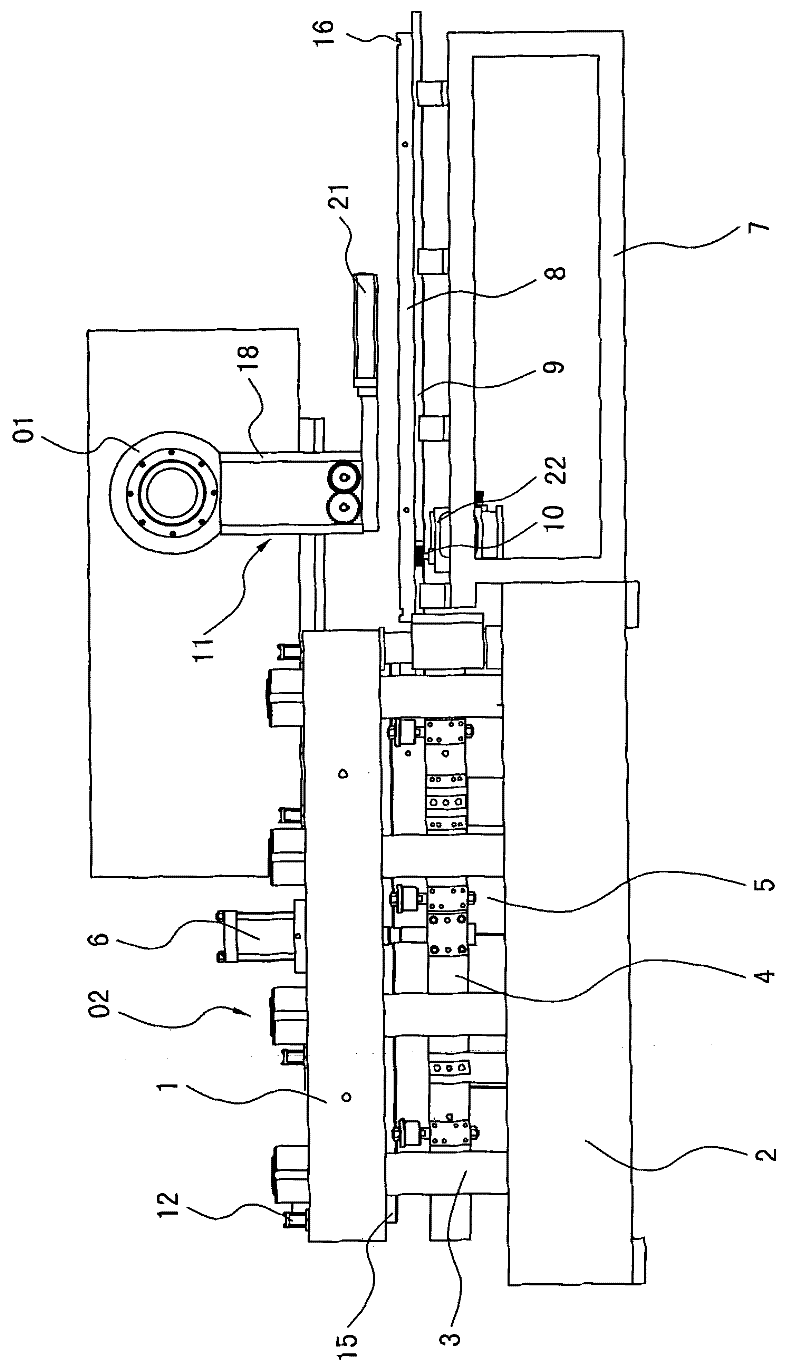

[0013] The present invention relates to a mobile distributed plastic mixture molding machine, such as Figure 1-Figure 6 As shown, it includes a mold clamping forming mechanism 02, and the mold clamping forming mechanism includes an upper fixed template 1 and a lower fixed template 2, the upper and lower fixed templates are connected by pull rods 3, and a movable template 4 is installed on the lower fixed template 2, and the movable template 4 has a closing The mold oil cylinder 5 and the mold opening cylinder 6, the mold plate 8 is set on the movable template, and it is characterized in that the mold plate 8 has a moving device, and the moving device drives the mold pressing plate 8 to move out of the clamping forming mechanism 02 and into the clamping forming mechanism Inside, a material distributor 11 is arranged above the molding plate 8 outside the mold clamping mechanism 02 , and the material distributor 11 is blanked against the mold plate 8 at the outlet of the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com