Compression molding butt-fusion forming method for large-sized plastic pipe joint

A technology of plastic pipe and molding method, which is applied in the direction of household components, household appliances, and other household appliances, etc., can solve the problems of low molding efficiency, low blending degree, and large power consumption, and achieve fast molding speed, simple equipment, and low power consumption. The effect of low battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

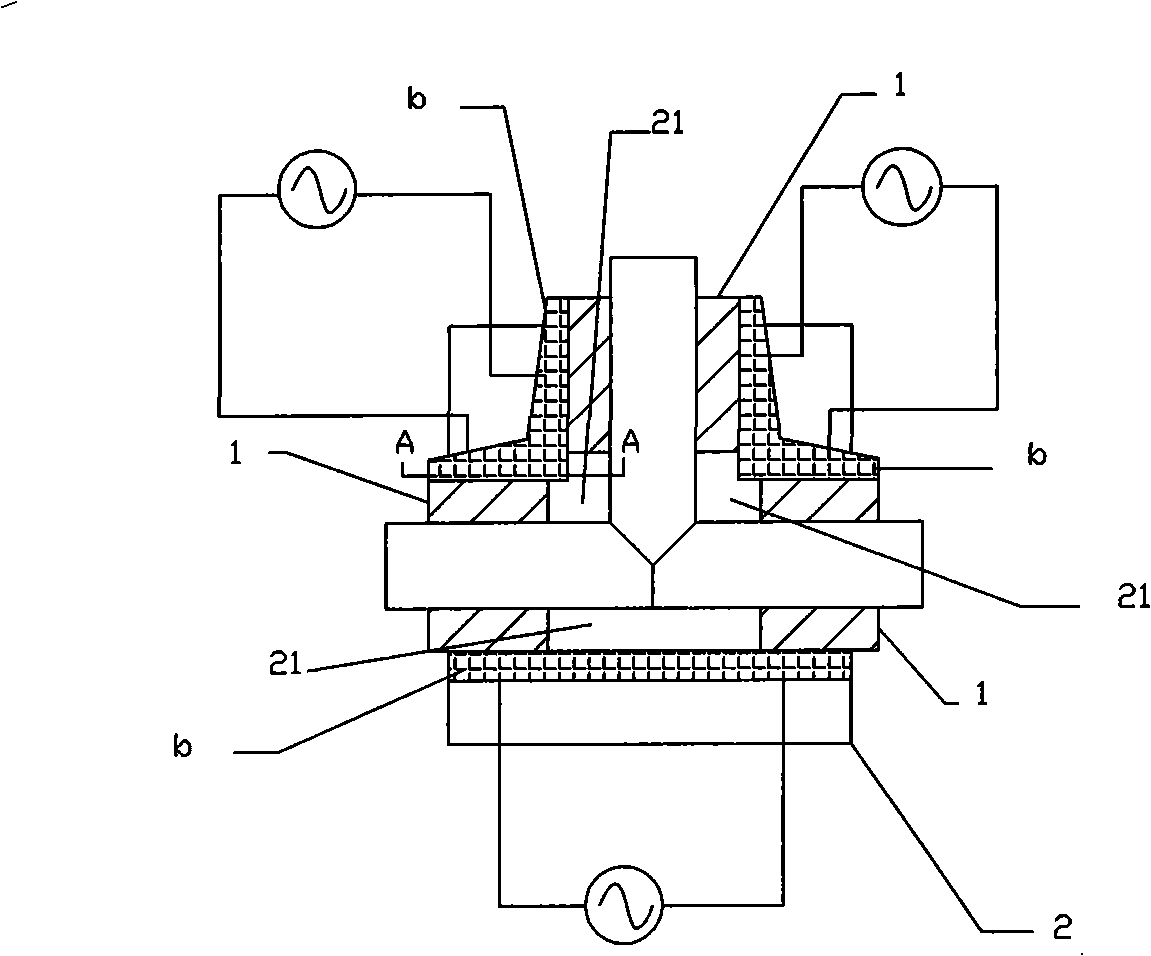

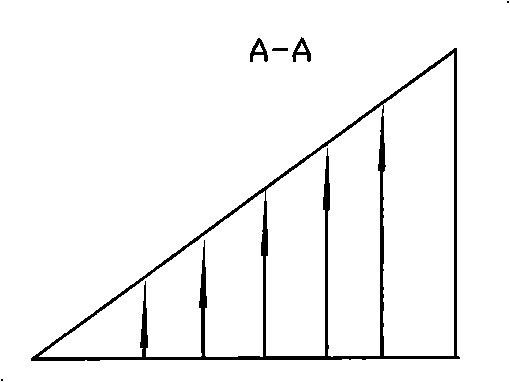

[0029] Refer to attached Figure 1-4 : where a is the pressure sensor; b is the heating wire; c is the cooling water.

[0030] This embodiment is an example in which the present invention is applied to the forming of T-shaped pipe joints.

[0031] The compression molding welding molding method of the large-scale plastic pipe joint of the present invention comprises the following steps:

[0032] (1) Get the straight pipe 1 that matches the pipe diameter of the pipeline that the pipe joint is used, as the fork pipe of the pipe joint, there are three in total;

[0033] (2) Prepare a variable temperature mold with a mold cavity 21 in the shape of a pipe joint, and the front ends of each fork pipe are connected to each other;

[0034] (3) Put the three straight pipes 1 taken into the variable temperature mold 2, and heat the mold cavity 21 corresponding to the part of the straight pipe 1 that needs to be deformed, so as to soften and melt the front end of the straight pipe 1;

...

Embodiment 2

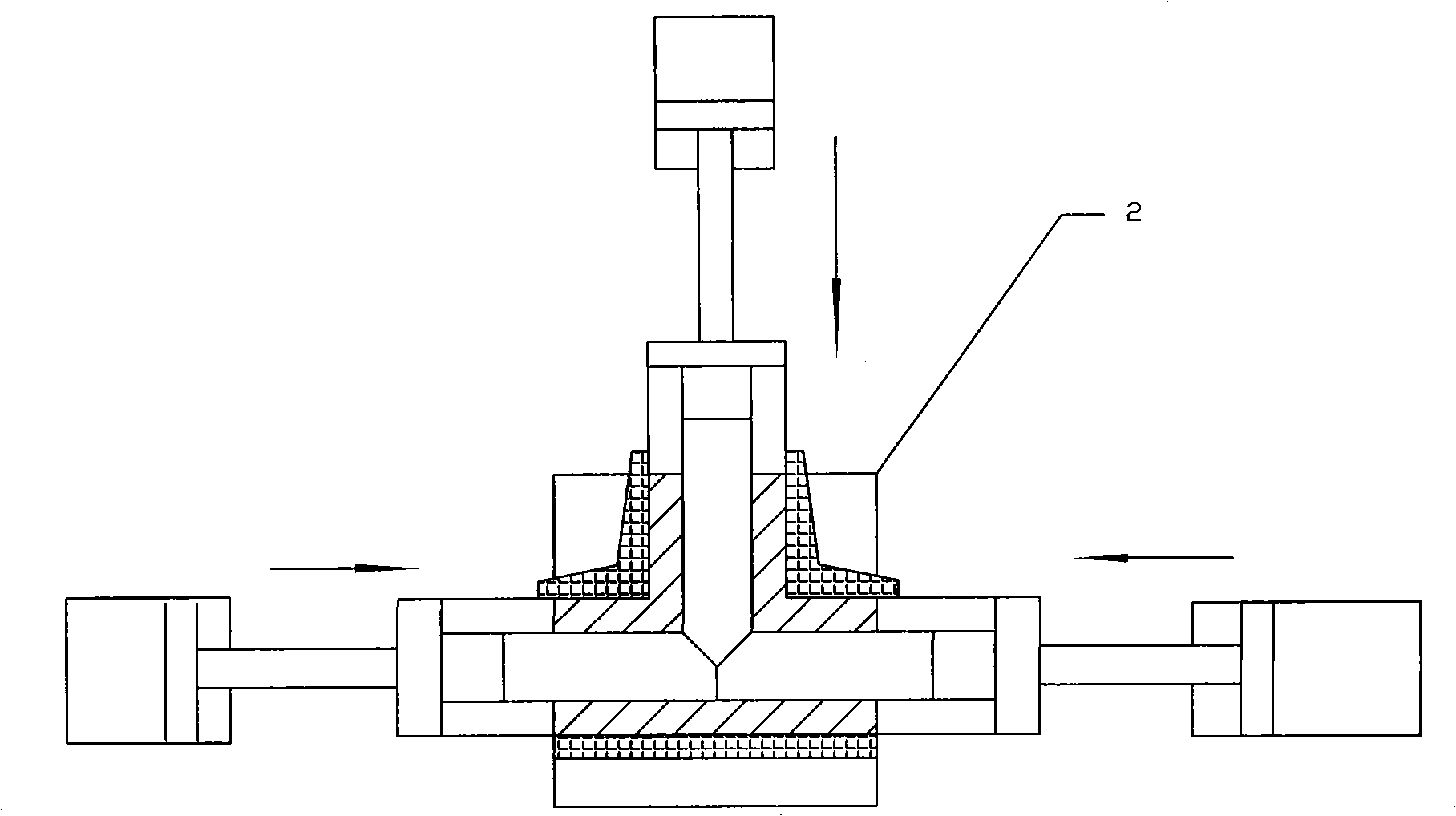

[0041] Refer to attached Figure 5-7 : where a is the pressure sensor; b is the heating wire; c is the cooling water.

[0042] This embodiment is an example in which the present invention is applied to the molding of four-way pipe joints.

[0043] (1) Get the straight pipe 1 that matches the pipe diameter of the pipeline that the pipe joint is used, as the fork pipe of the pipe joint, there are four in total;

[0044] (2) Prepare a variable temperature mold 3 with a mold cavity in the shape of a pipe joint, and the front ends of each fork pipe are connected to each other;

[0045] (3) Put the four straight pipes 1 taken into the variable temperature mold, and heat the mold cavity 31 corresponding to the part of the straight pipe 1 that needs to be deformed, so that the front end of the straight pipe 1 is softened and melted;

[0046] (4) Simultaneously pressurize the tails of the straight pipes 1 to deform the molten parts of the straight pipes 1 and fill the cavity 31 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com