Dual L seamless high power electronic amperite housing

A kind of electronic ballast and fit technology, applied in the direction of electric light source, electrical components, lighting devices, etc., can solve the problems of high-power radio frequency interference, unreasonable process, circuit instability, etc., to improve electromagnetic compatibility, heat dissipation effect The effect is obvious and easy to install and debug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

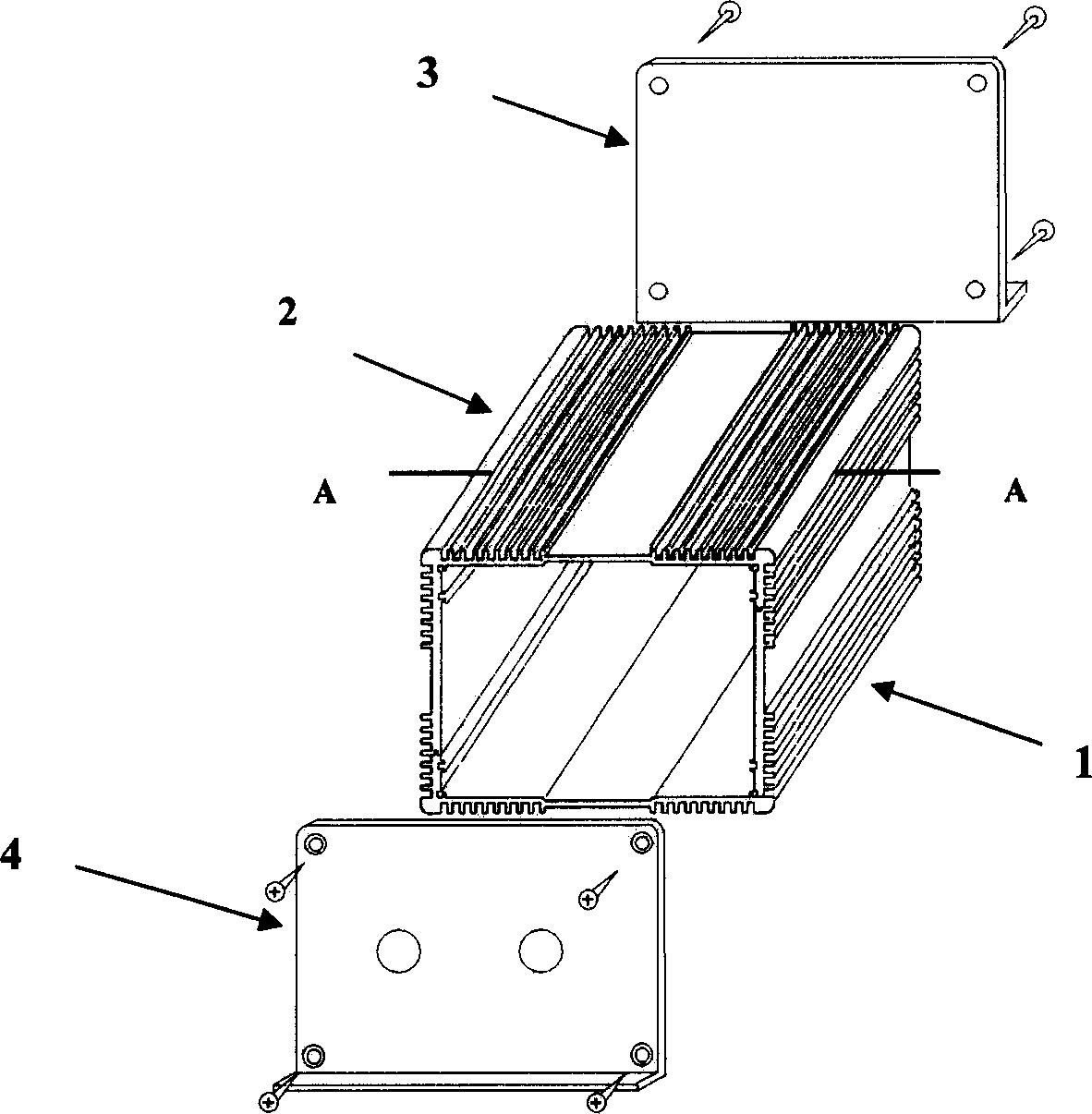

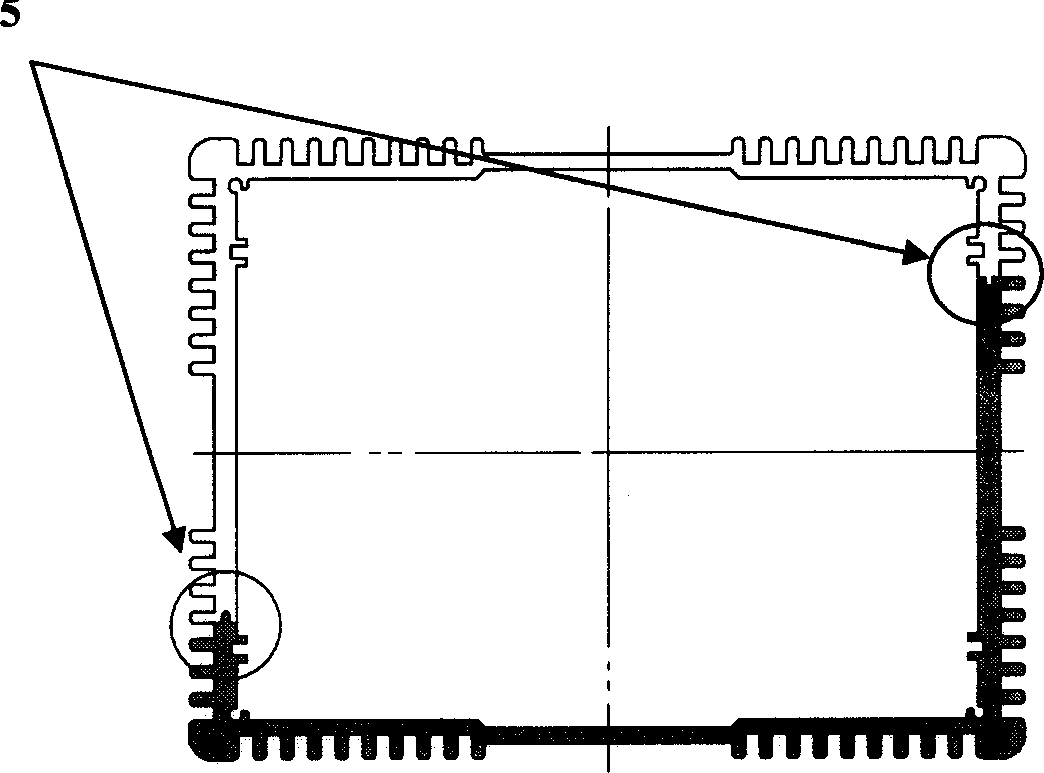

[0013] Such as figure 1 As shown, the present invention includes: a lower L-shaped shell 1, an upper L-shaped shell 2, a first side cover 3, a second side cover 4, two concave-convex joint points 5, and two lower L-shaped shells with the same shape and size. The L-shaped housing 1 and the upper L-shaped housing 2 form an L-shaped main housing through the relative fit of two concave-convex joint points 5. The two ends of the L-shaped main housing are square in section, and the first side cover 3 and the second side 4 is fixed on the two end sections of the L-shaped main shell by screws, and the two concavo-convex joint points 5 are concavo-convex shapes with the same nominal size.

[0014] For the two concave-convex meeting points 5, the positive tolerance is selected for the concave shape, and the negative tolerance is selected for the convex shape, so as to maintain a three-level interference fit during the fit.

[0015] The central dimensions of the two concavo-convex joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com