Installation structure of cylindrical battery pack

A technology for installing structures and battery packs, which is applied to battery pack parts, structural parts, circuits, etc., and can solve problems such as troublesome disassembly and poor use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

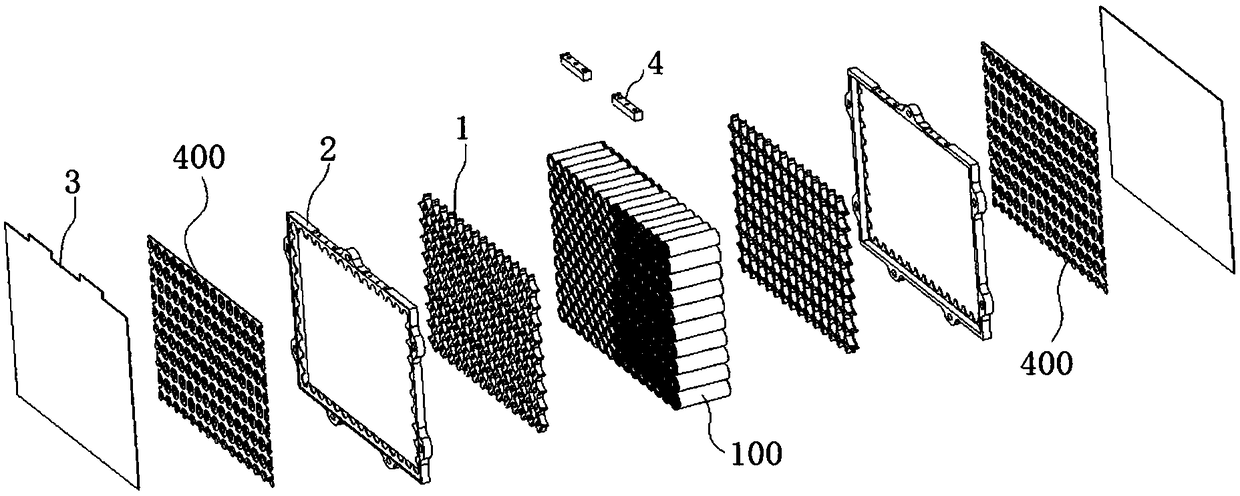

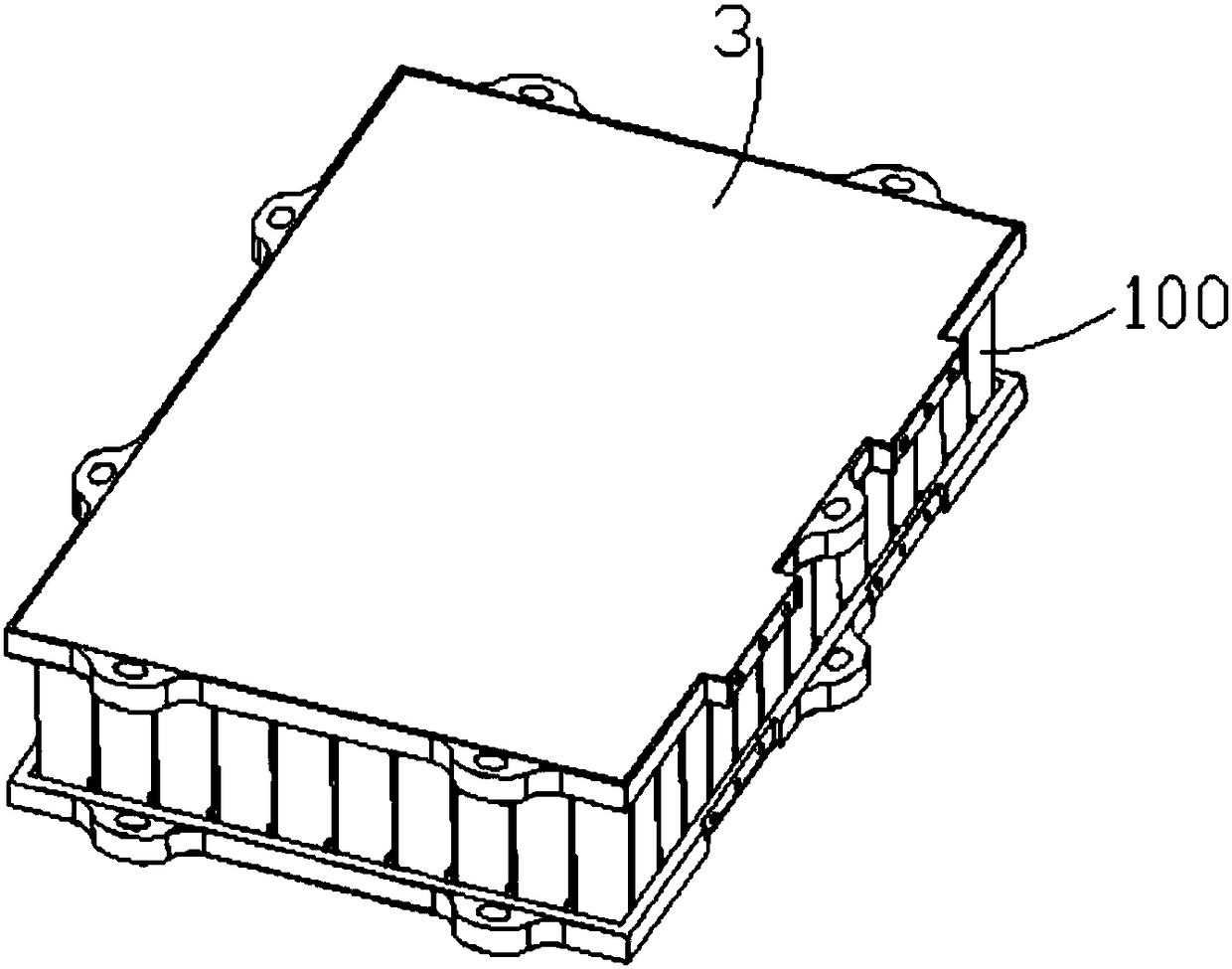

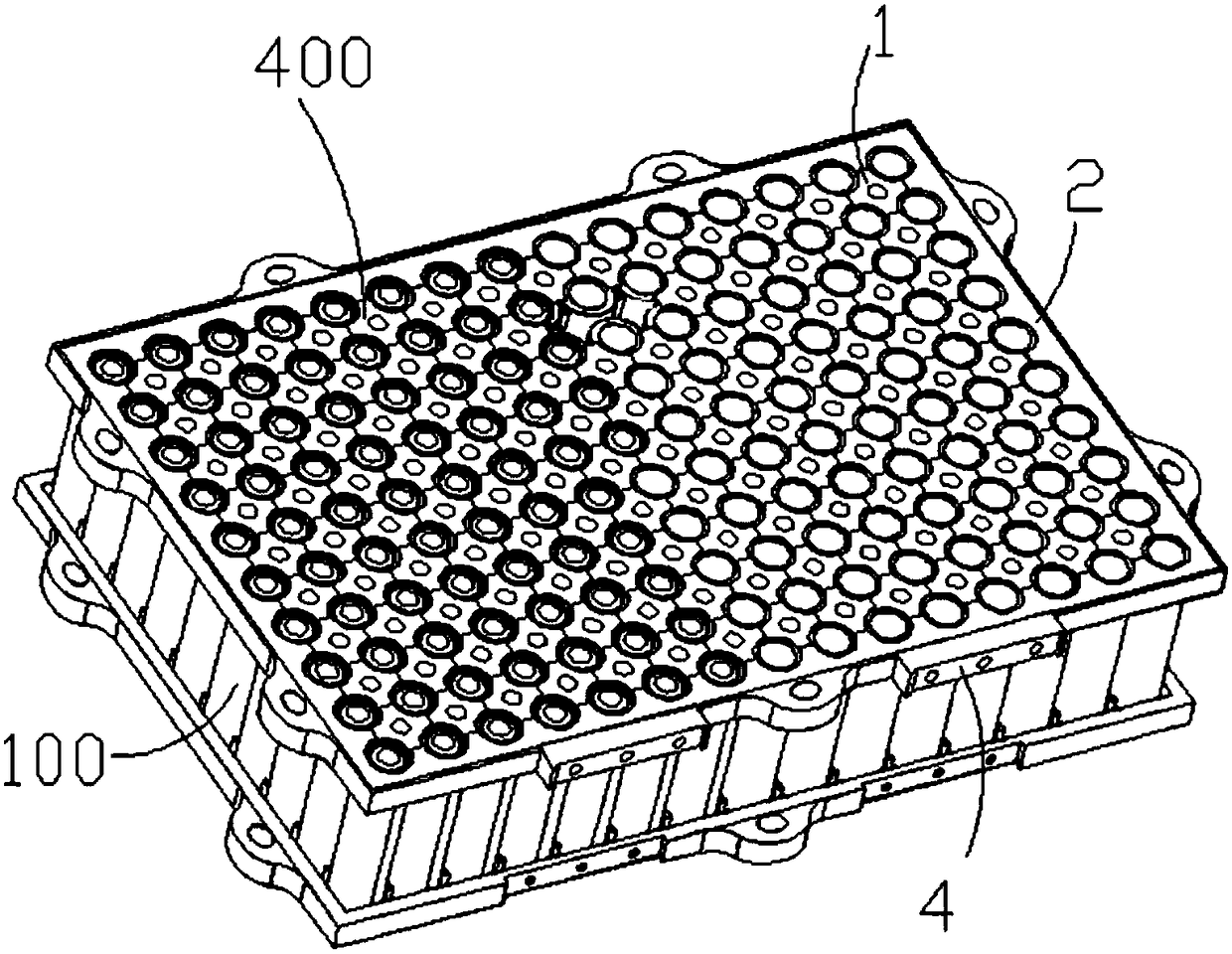

[0031] Such as Figure 1 to Figure 9 , the present invention discloses an installation structure of a cylindrical battery pack, which includes a cylindrical battery cell 100 and an electrical connection frame 400 welded by nickel sheets 200 and copper sheets 300. Several cylindrical battery cells 100 are combined to form a battery pack. Two The electrical connection frame 400 is arranged on both sides of the battery pack, and each side of the electrical connection frame 400 is correspondingly connected to the positive and negative electrodes of each cylindrical battery cell 100 in the battery pack.

[0032] The installation structure for assembling the cylindrical cells 100 into a battery pack includes a battery module bracket 1, an outer frame bracket 2, an insulating plate 3 and an adapter bracket 4. The two outer frame brackets 2 are respectively placed on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com