Core pulling structure for stripping composite sliding blocks from front mold and rear mold

A core-pulling structure and composite slider technology, which is applied in the field of plastic product molds, can solve problems such as increased processing and injection costs, longer molding cycles, and complex mold opening actions, and achieves simple mold opening actions, reduced working steps, and reduced thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

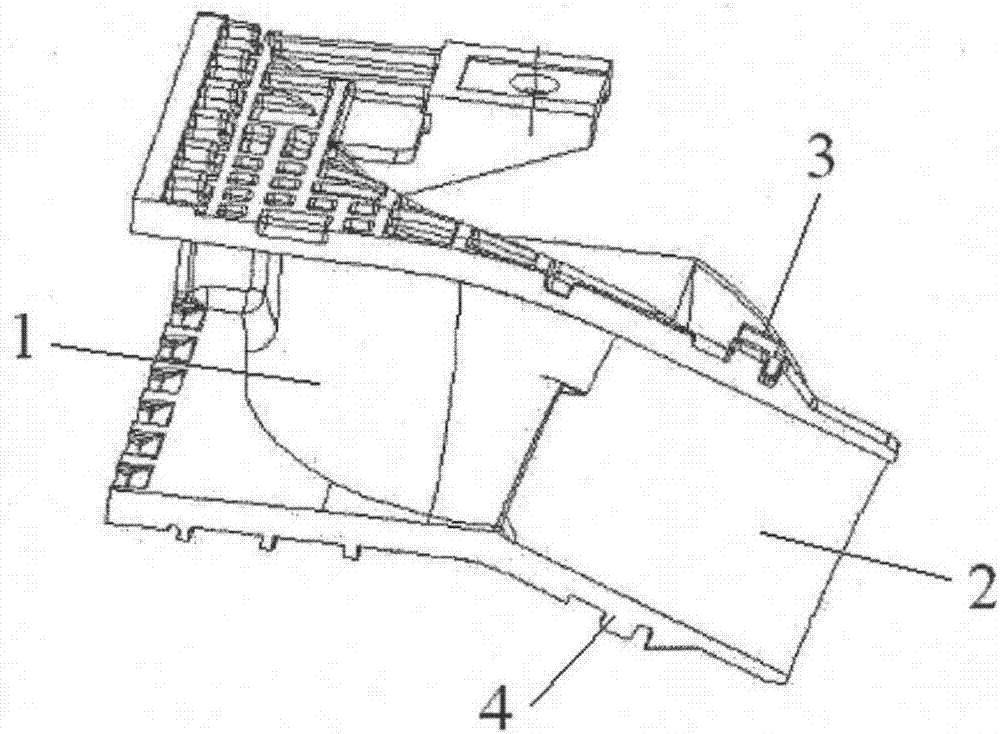

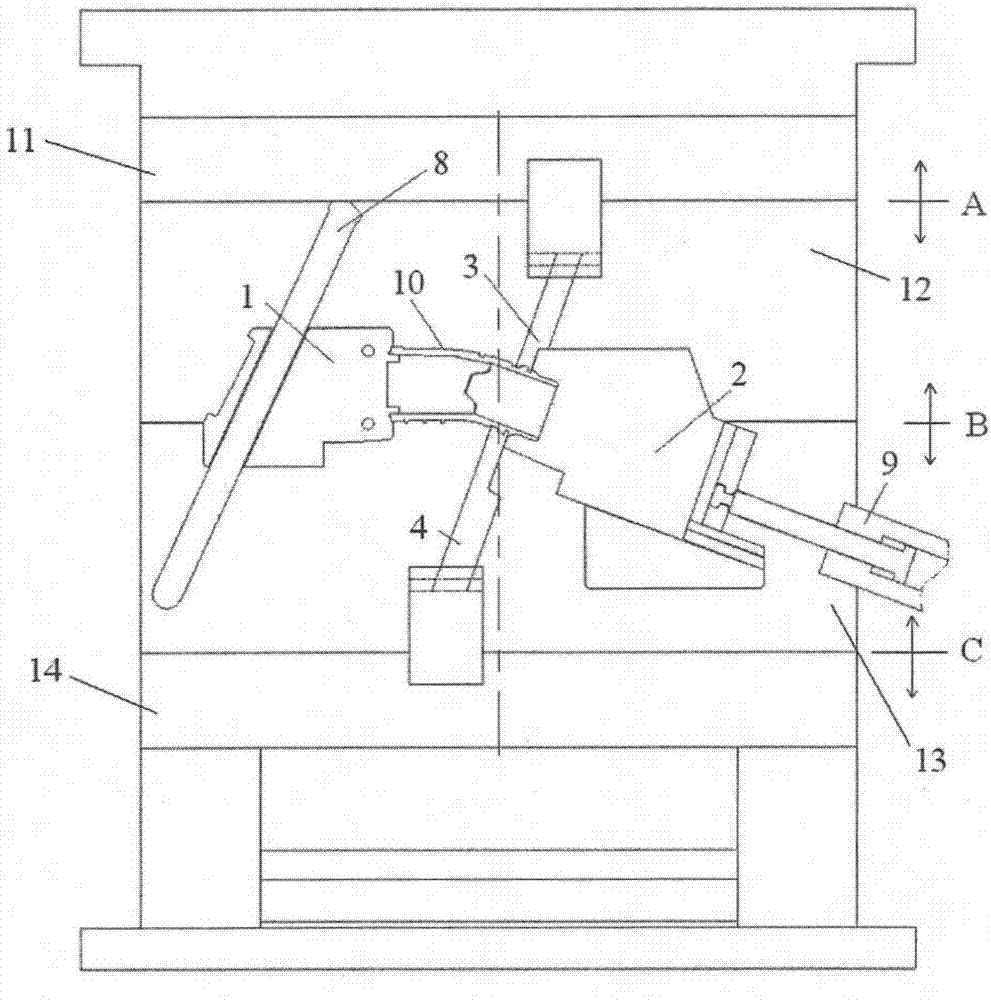

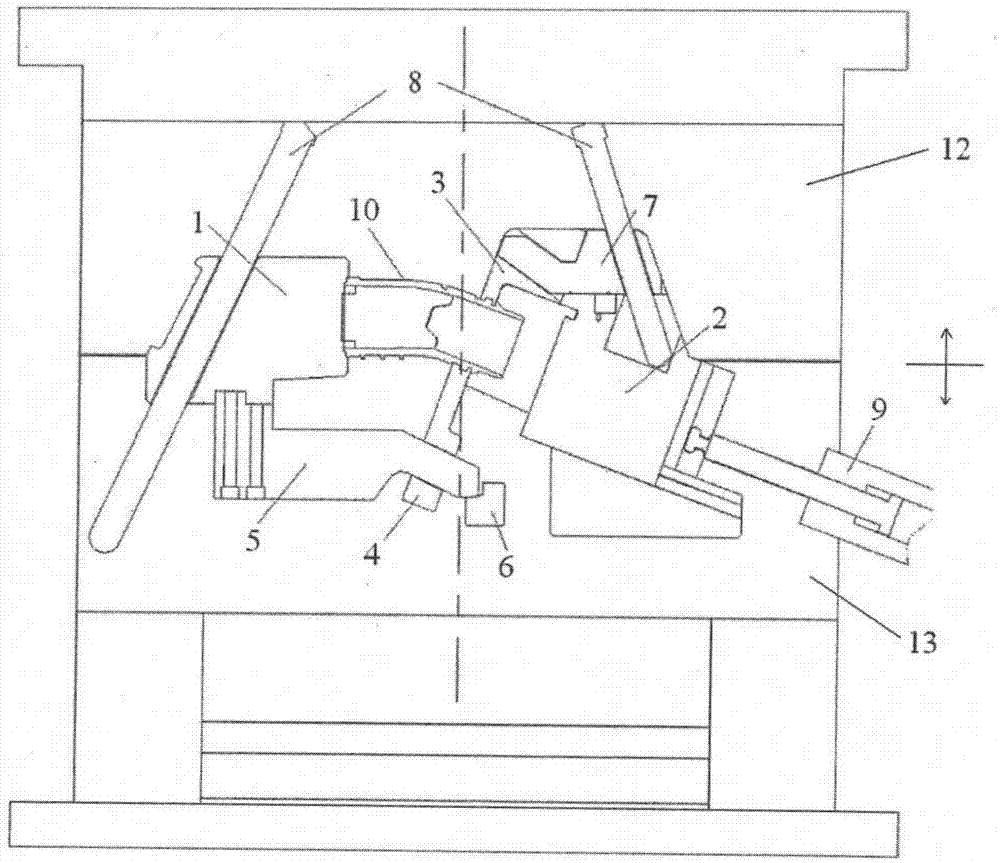

[0016] The present invention is a core-pulling structure of the front and rear molds of the composite slider, which adopts two-two combination, and can complete this series of complex movements with one parting. The conventional slider 1 is driven together with the rear mold core-pulling slider 4, and the oil cylinder drives the slider 2 and the front mold core-pulling slider 3 to form an integral slider to complete the ejection. The present invention includes a conventional slider 1 and an oil cylinder driven slider 2 arranged on both sides of the plastic product 10, the conventional slider 1 is fixedly connected to one end of the rear mold core-pulling block 5, and the rear mold core-pulling block 5 is provided with a rear mold The core-pulling slider 4 and the rear mold core-pulling block 5 collide with the stopper 6 when the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com