Easily produced and assembled disc type brake caliper assembly and assembling method

A disc brake and assembly technology, which is applied to the types of brakes, brake parts, engine components, etc., can solve the problems of inability to drive out the air from the dust cover of the shaft pin, abnormal sound of the shaft pin and the pin hole of the bracket, eccentric wear and The drag torque is too large and other problems, to achieve the effect of simple and convenient rework, simple mold opening, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

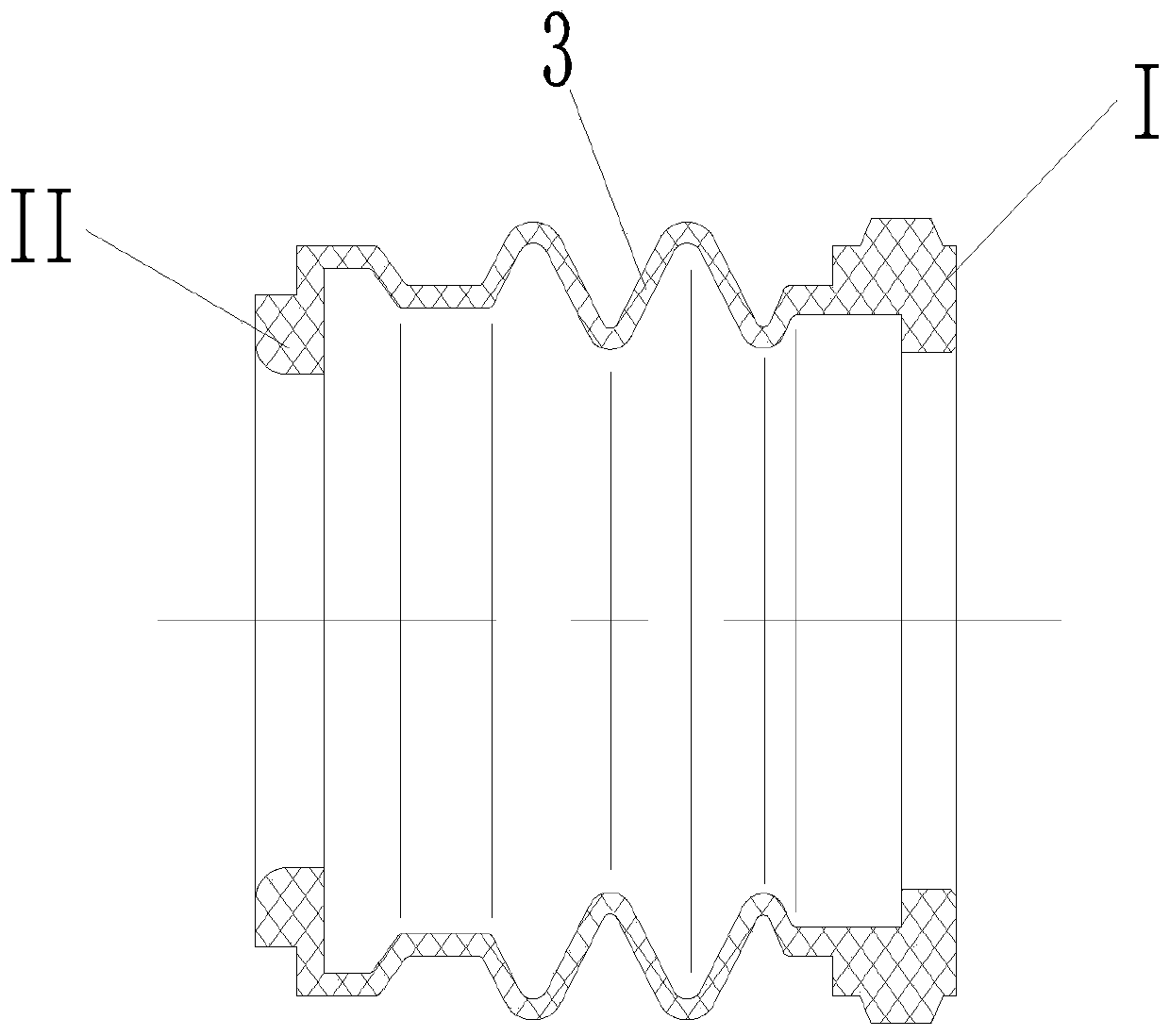

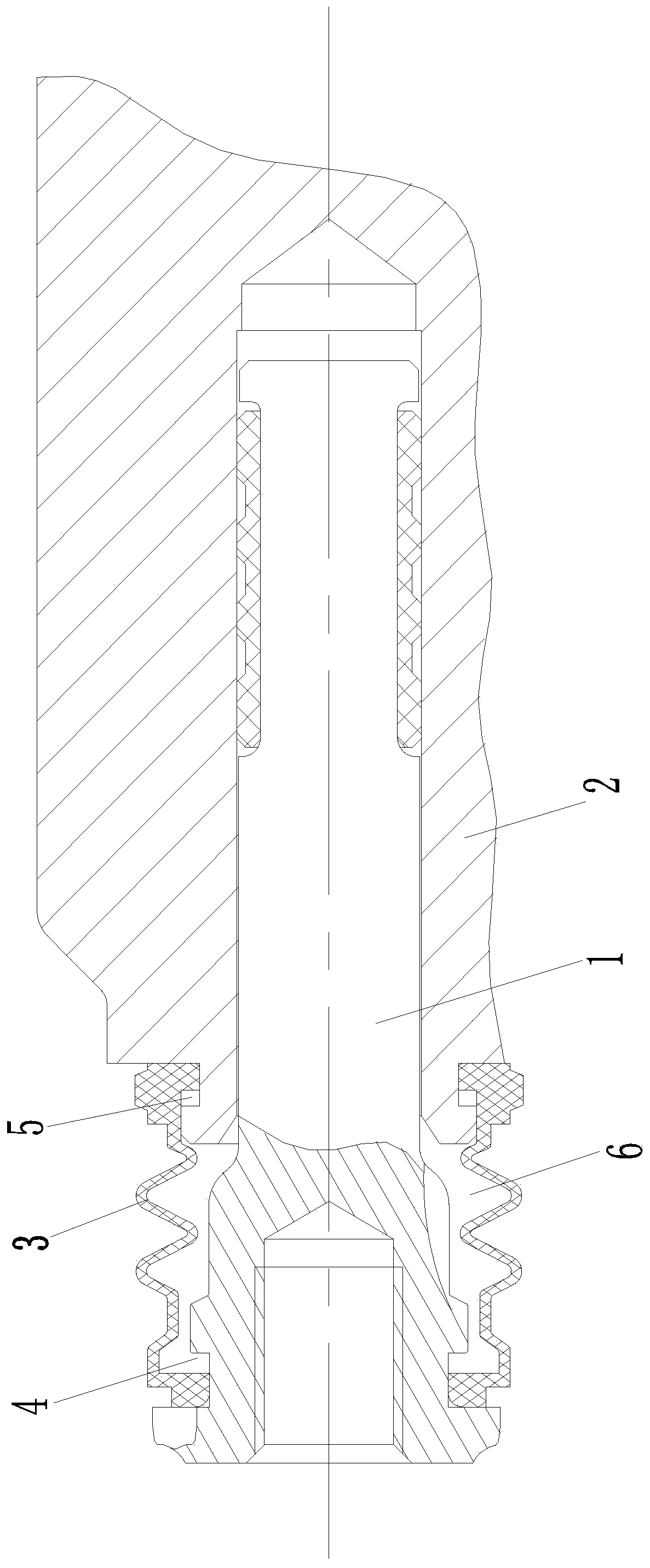

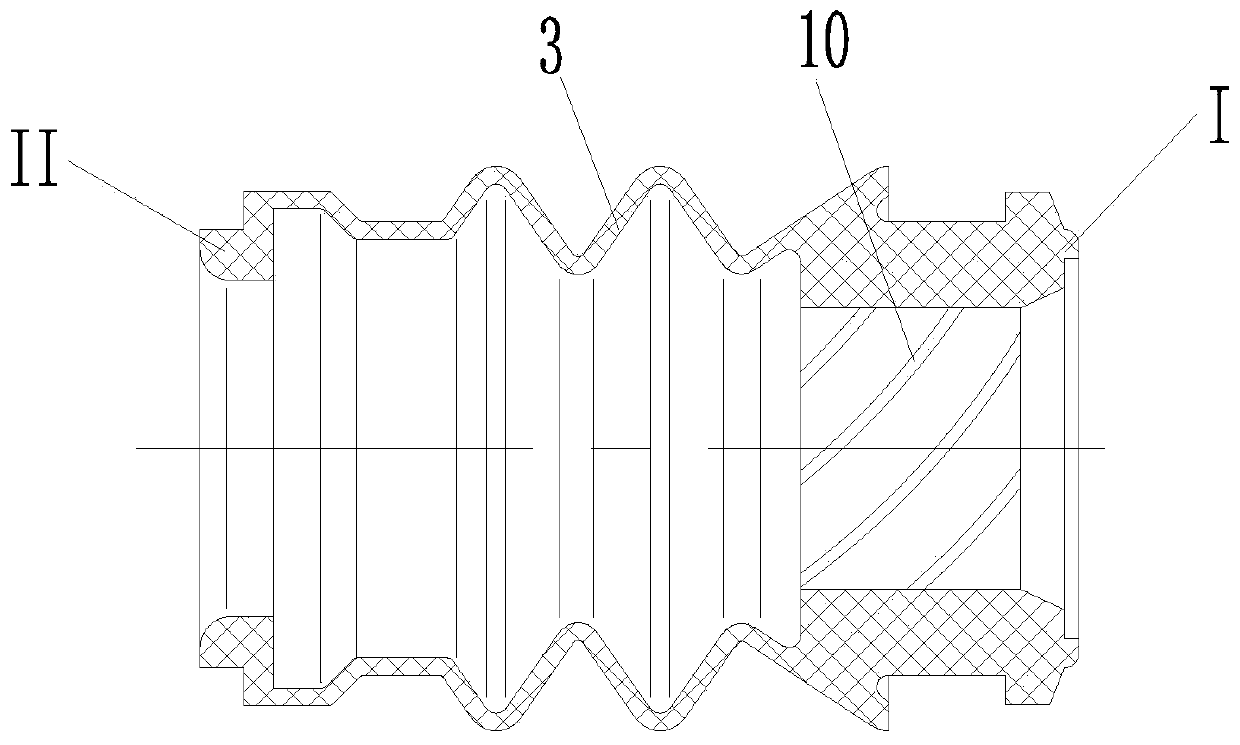

[0042] Such as Figure 7-11 As shown, this embodiment provides a disc brake caliper assembly that is easy to produce and assemble, including a shaft pin 1, a bracket 2, and a shaft pin dust cover 3 for sealing the connection between the shaft pin 1 and the bracket 2 , the shaft pin 1 includes an integrally formed pin body 11, a neck portion 12 and an end portion 13, the bracket 2 is provided with a bracket pin hole 21, the pin body 11 is inserted into the bracket pin hole 21, and is connected with the bracket pin hole 21 clearance fit, the outer periphery of the mouth of the bracket pin hole 21 is provided with a bracket pin dust cover groove 5, and a shaft pin dust cover groove 4 is provided between the neck 12 and the end 13 of the shaft pin 1, so The two ends of the shaft pin dust cover 3 are sealed and clamped with the bracket pin dust cover groove 5 and the shaft pin dust cover 4 groove respectively, and the neck 12 of the shaft pin 1 is provided with a shaft pin exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com