Diesel engine four-valve cylinder head gravity casting die and casting method thereof

A four-valve cylinder head and gravity casting technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of poor casting quality, complex shape, difficult demoulding, etc., and achieve good casting quality and easy mold opening , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

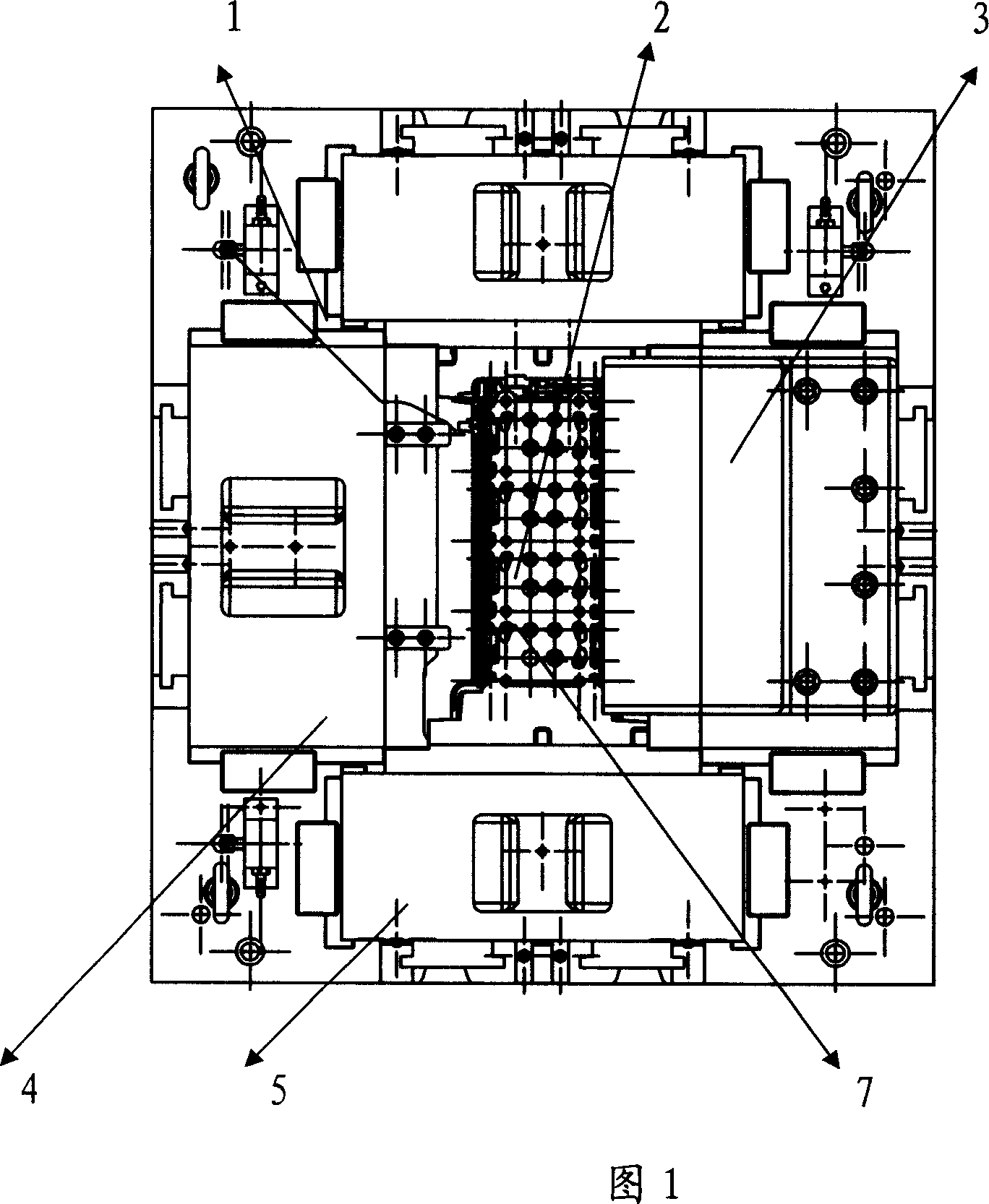

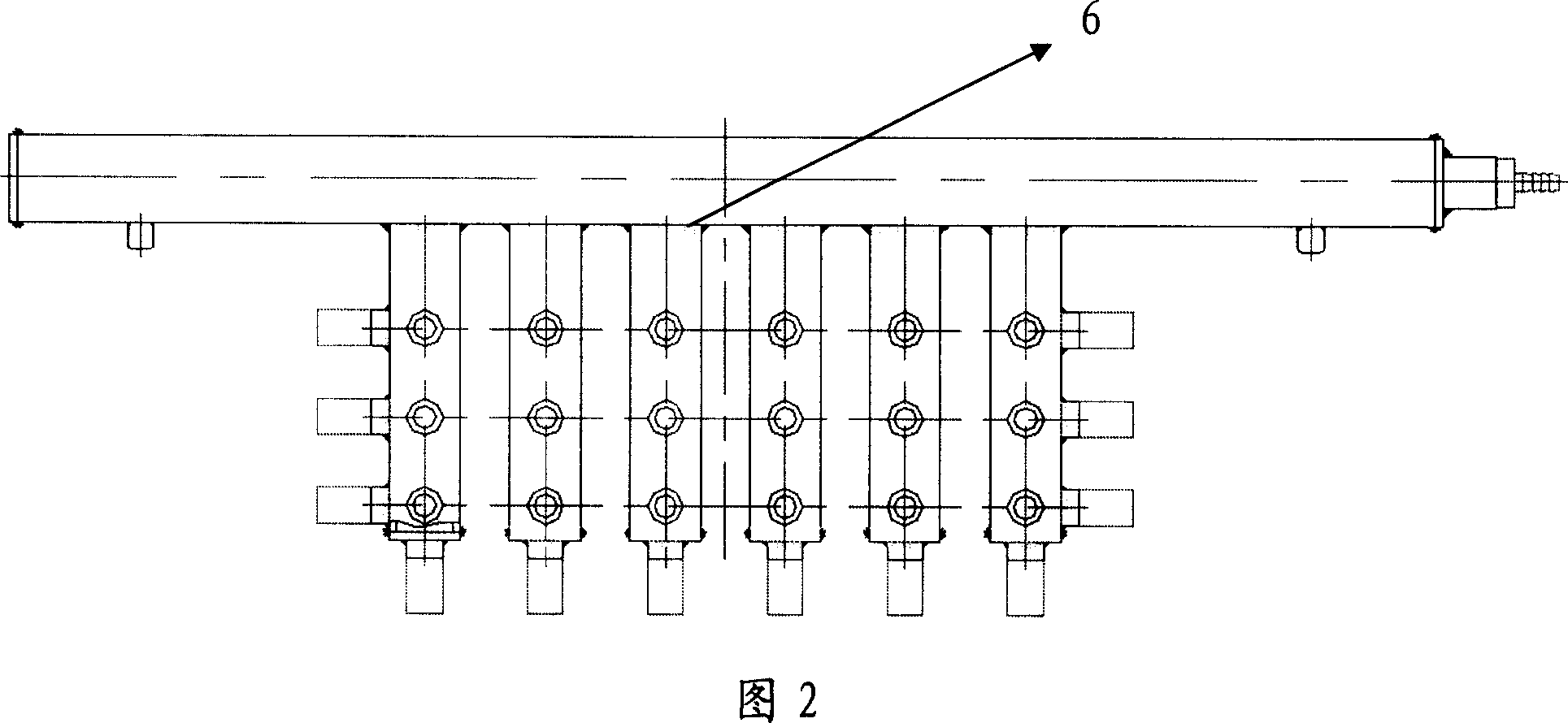

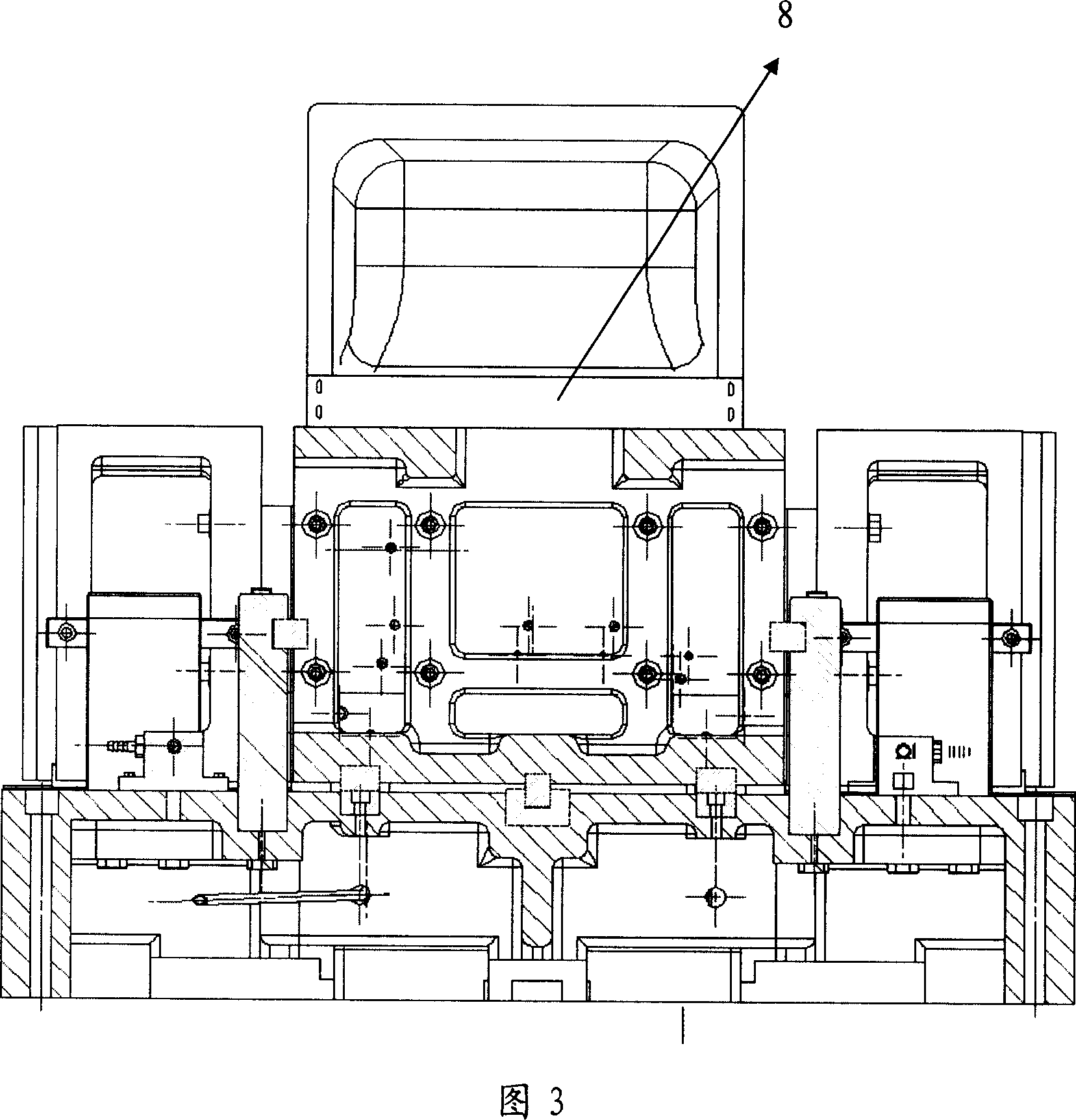

[0024] A specific structure of the gravity casting mold for the diesel engine four-valve cylinder head of the present invention will be further described below in conjunction with the accompanying drawings. The mold includes a front mold 1, a left mold 4, a right mold 5, a rear mold 3, a bottom mold 2, a central heater 6, a tilting sprue cup 8 with adjustable flow rate, casting and slag blocking at the same time, and cylinder head water Set sand core 7. Front mold 1, left mold 4, right mold 5, and rear mold 3 are respectively on the four sides of bottom mold 2. Guide rails for fixing and opening and closing molds. The central heater 6 is placed inside the cavity of the whole set of molds when the mold is heated. The central heater 6 is welded into a piping system by a square tube main pipe and a square branch pipe, and is composed of a burner (as shown in Figure 2). There is an adjustable baffle at the outlet of the sprue cup to adjust the flow. By adjusting the adjustable b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com