An instant beverage bottle with built-in solid beverage

A solid beverage and beverage bottle technology, applied in the field of beverage containers, can solve the problems of high production cost and complex structure, and achieve the effects of low production cost, long stroke, and easy mold opening and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

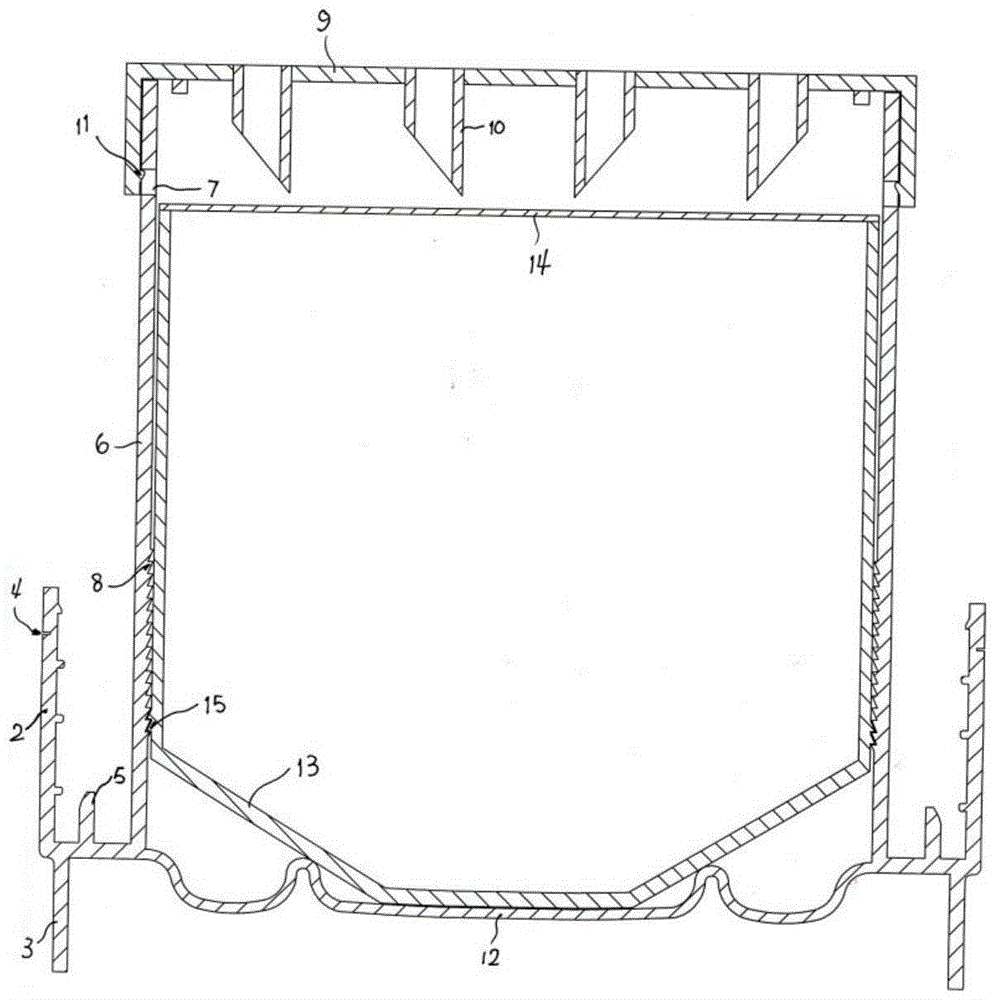

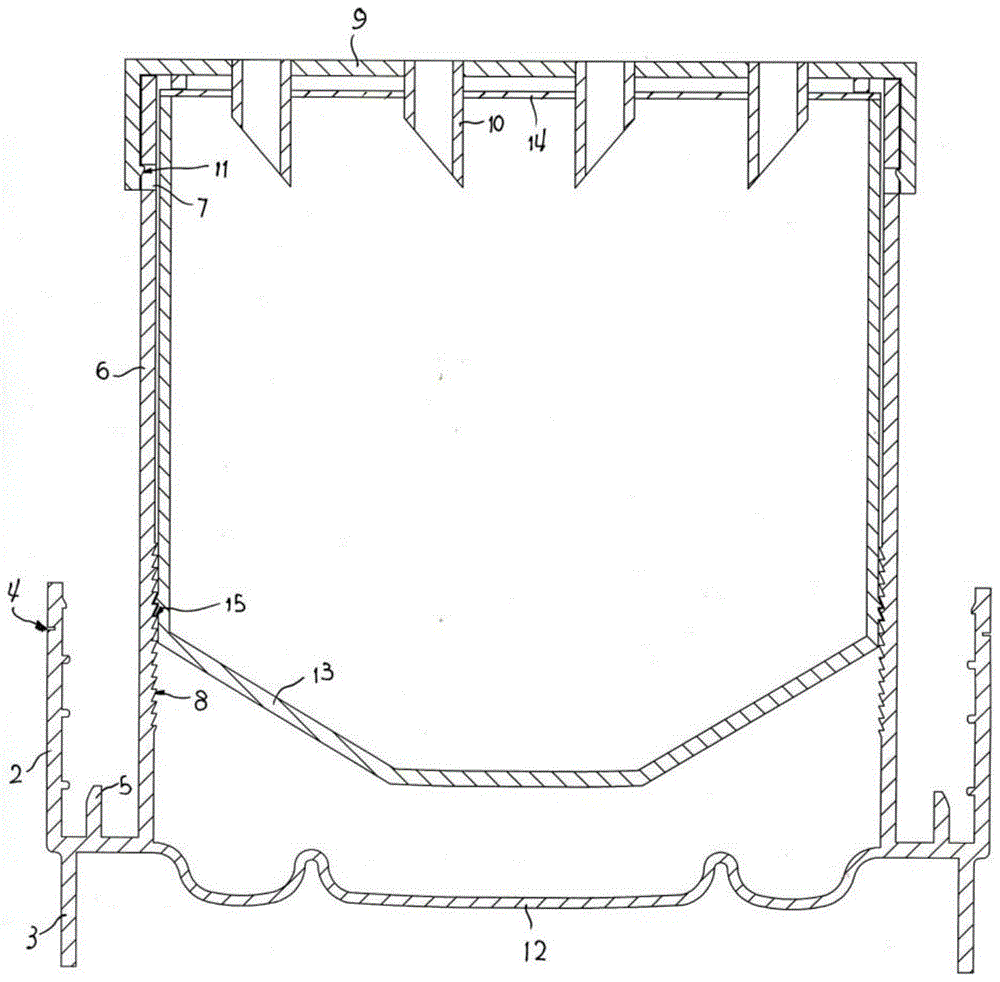

[0033] Beverage bottle is made up of bottle cap and bottle body, and bottle body (existing) is divided into upper bottle body 1 again (referring to figure 1 ) and the lower bottle body, the two are connected in a spiral manner. figure 2 , image 3 It shows the ready-to-drink beverage bottle with built-in solid beverage. The bottle body is composed of an upper bottle body 1 and a lower bottle body 2, which are spirally connected. A corrugated elastic film 12 or an outer convex circle is arranged at the middle position of the bottom of the lower bottle body 2. Arc elastic film or planar elastic film, two chutes 6 are symmetrically fixed on the outside of the middle position of the bottom of the lower bottle body 2, and the chute 6 is composed of two side plates fixed on both sides of a vertical plate. The plate is an outwardly convex arc-shaped plate or a flat plate, and the material box 13 is clamped between two chutes 6 to form a sliding fit relationship with each other. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com