Fusiform grid and mounting method thereof

An installation method and shuttle-shaped technology, applied in the field of architectural decoration, can solve the problems of affecting the appearance of the full shuttle-shaped decorative part a, unavoidable positioning deviation, long production cycle, etc., achieving considerable economic benefits in production and easy construction and operation , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

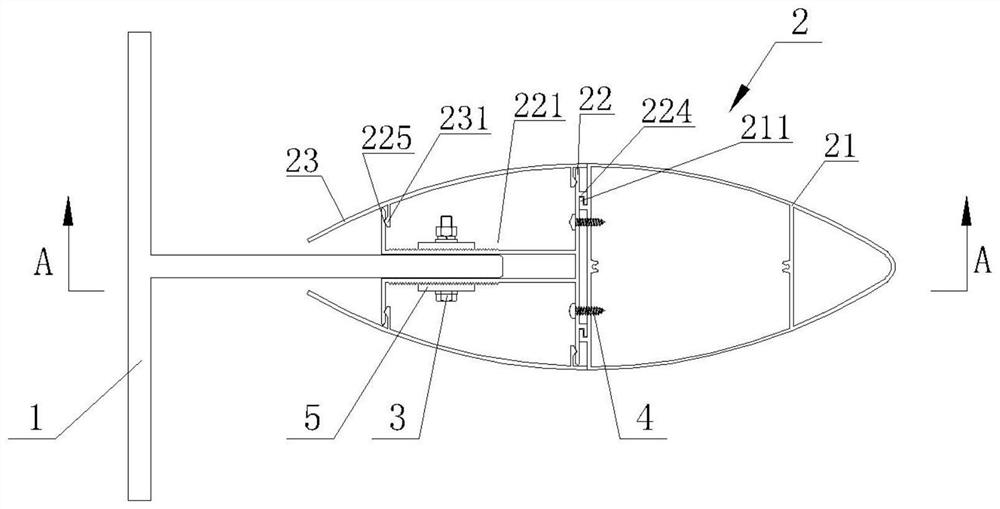

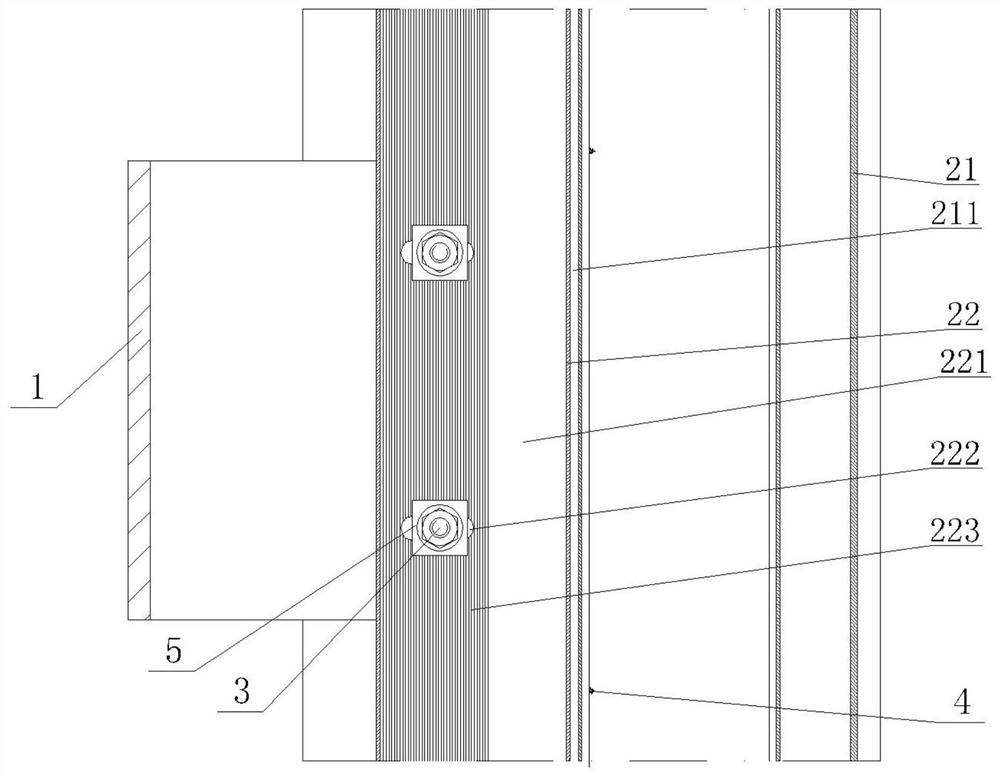

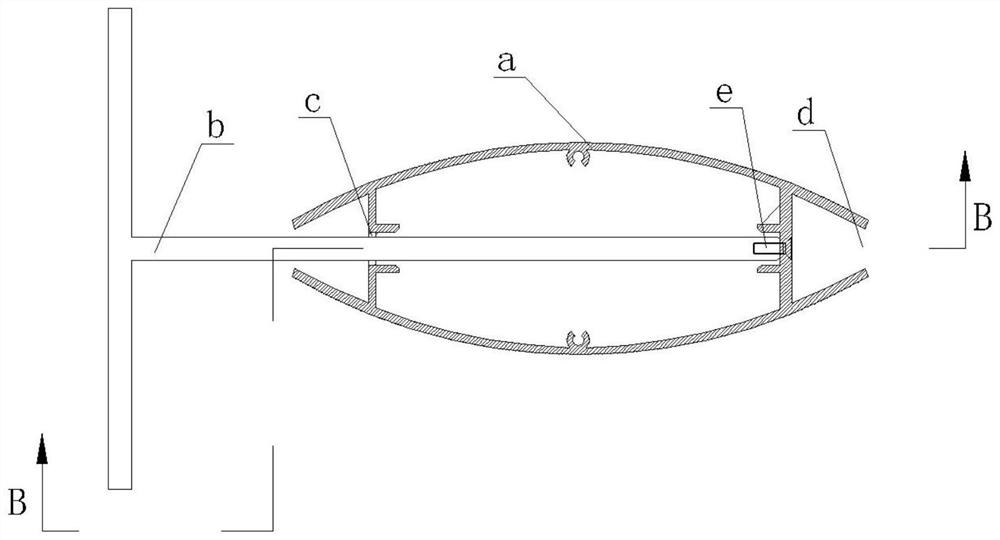

[0031] from figure 1 with figure 2 It can be seen that the shuttle grille of the present invention includes a T-shaped base 1, a shuttle-shaped decorative strip body 2, a bolt assembly 3, a screw 4 and a toothed gasket 5,

[0032] The T-shaped base 1 is fixed on the foundation interface through threaded fasteners, and a round hole is opened on the protruding end of the T-shaped base 1.

[0033] The body 2 of the shuttle-shaped decorative strip includes a half-shuttle housing 21, a connecting piece 22 and two arc-shaped gussets 23, and two symmetrically distributed and side-opened through grooves 221 are arranged at the rear of the connecting piece 22. On the opposite side, there are coaxially arranged elongated holes 222 arranged along the front and back direction of the connector 22,

[0034] The connector 22 is inserted on the protruding end of the T-shaped base 1 through the two-way slot 221, and the bolt assembly 3 passes through the elongated hole 222 and the round ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com