Oil gas pipeline rapid pressured plugging apparatus and plugging method

A technology for oil and gas pipelines and plugging devices, which is applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of non-hot welding, can not achieve rapid pressure sealing of leakage points, etc., and achieves less labor. , the effect of short time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

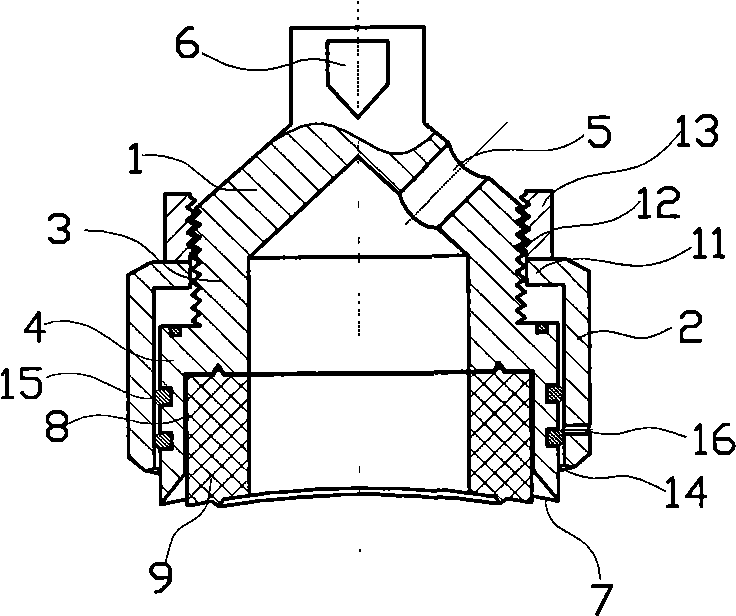

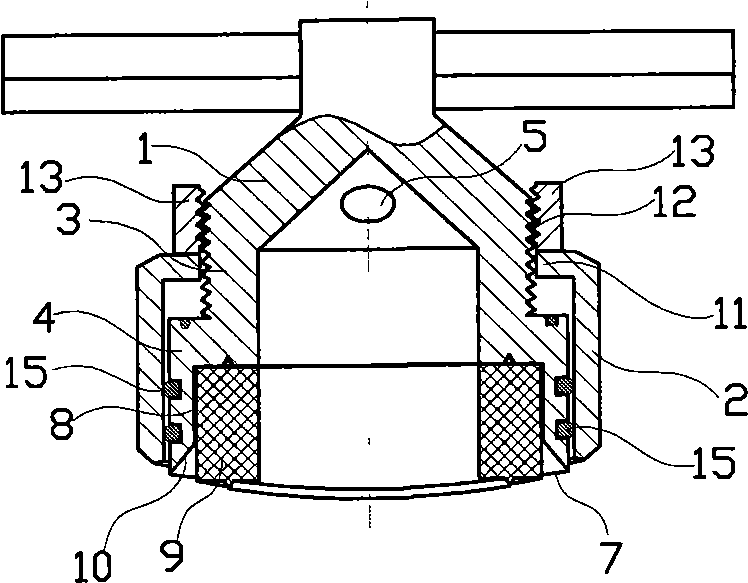

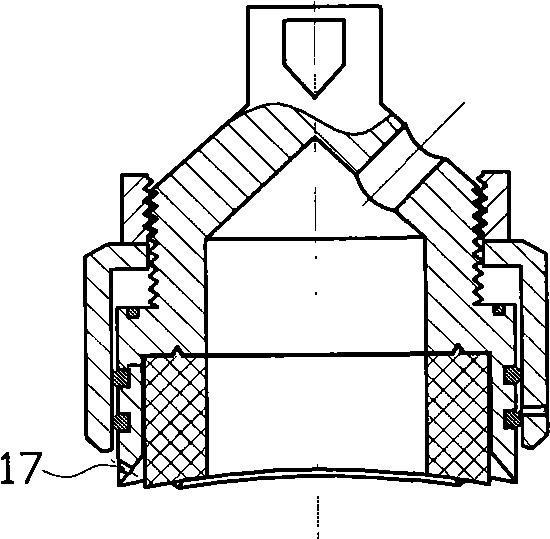

[0027] The quick pressurized plugging method of oil and gas pipelines has the following steps:

[0028] 1. Take the above-mentioned oil and gas pipeline rapid pressure sealing device, and sequentially connect the drainage valve and drainage pipe at the drainage port of the oil and gas pipeline rapid pressure sealing device;

[0029] 2. Fix the oil and gas pipeline rapid pressure sealing device on the bucket teeth of the excavator with bolts, and use the bucket of the excavator to tightly cover the saddle-shaped ring cover mouth of the inner steel cover towards the leakage point of the oil and gas pipeline At the leakage point of the oil and gas pipeline, keep the pressure of the inner steel cover being pressed by the bucket on the leakage point of the oil and gas pipeline, insert the pressure bar into the pressure bar hole, and use the chain to fasten the oil and gas pipeline with pressure sealing device tightly Tightly tie it on the oil and gas pipeline, inject sealant into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com