Full-automatic super-long roller kiln for sintering positive electrode material

A positive electrode material and fully automatic technology, applied in the field of roller kiln, can solve problems such as roller breakage, obvious limitations, and collision with the side wall of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

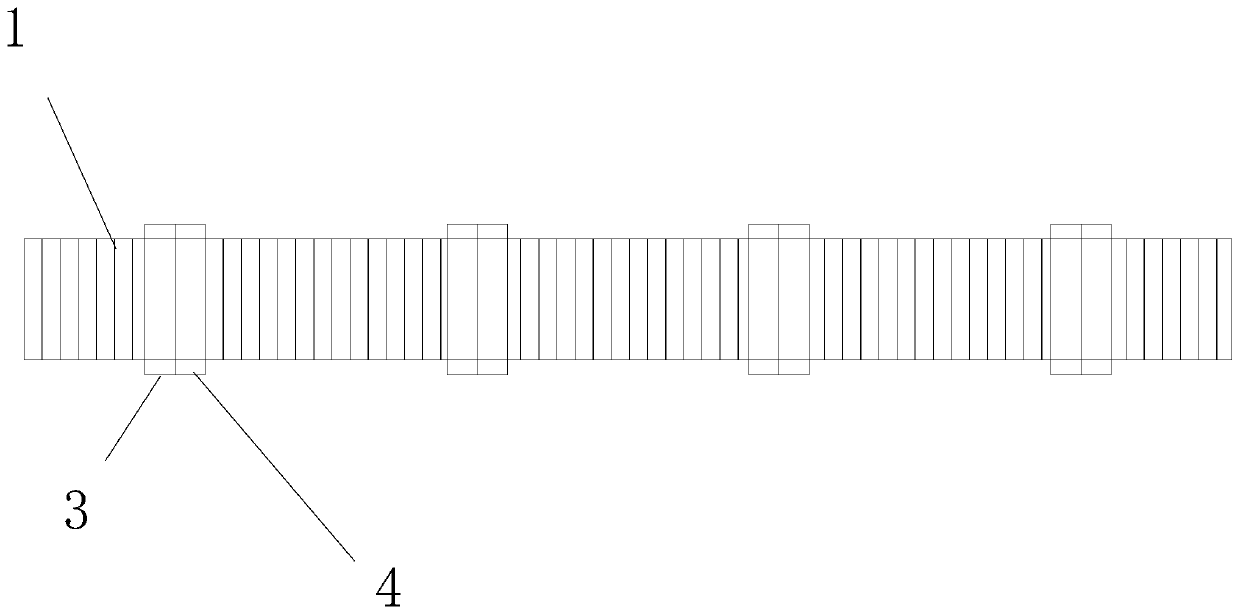

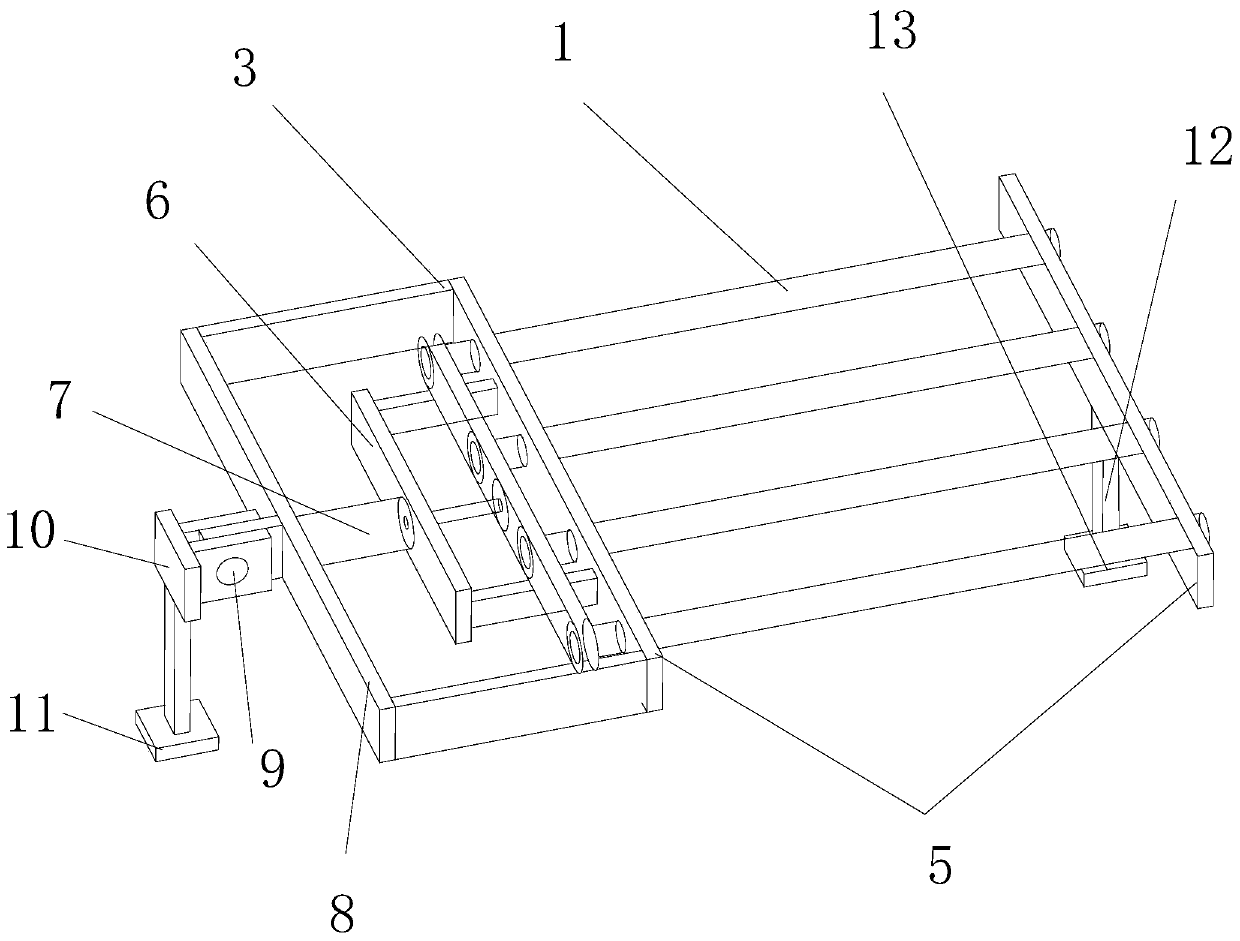

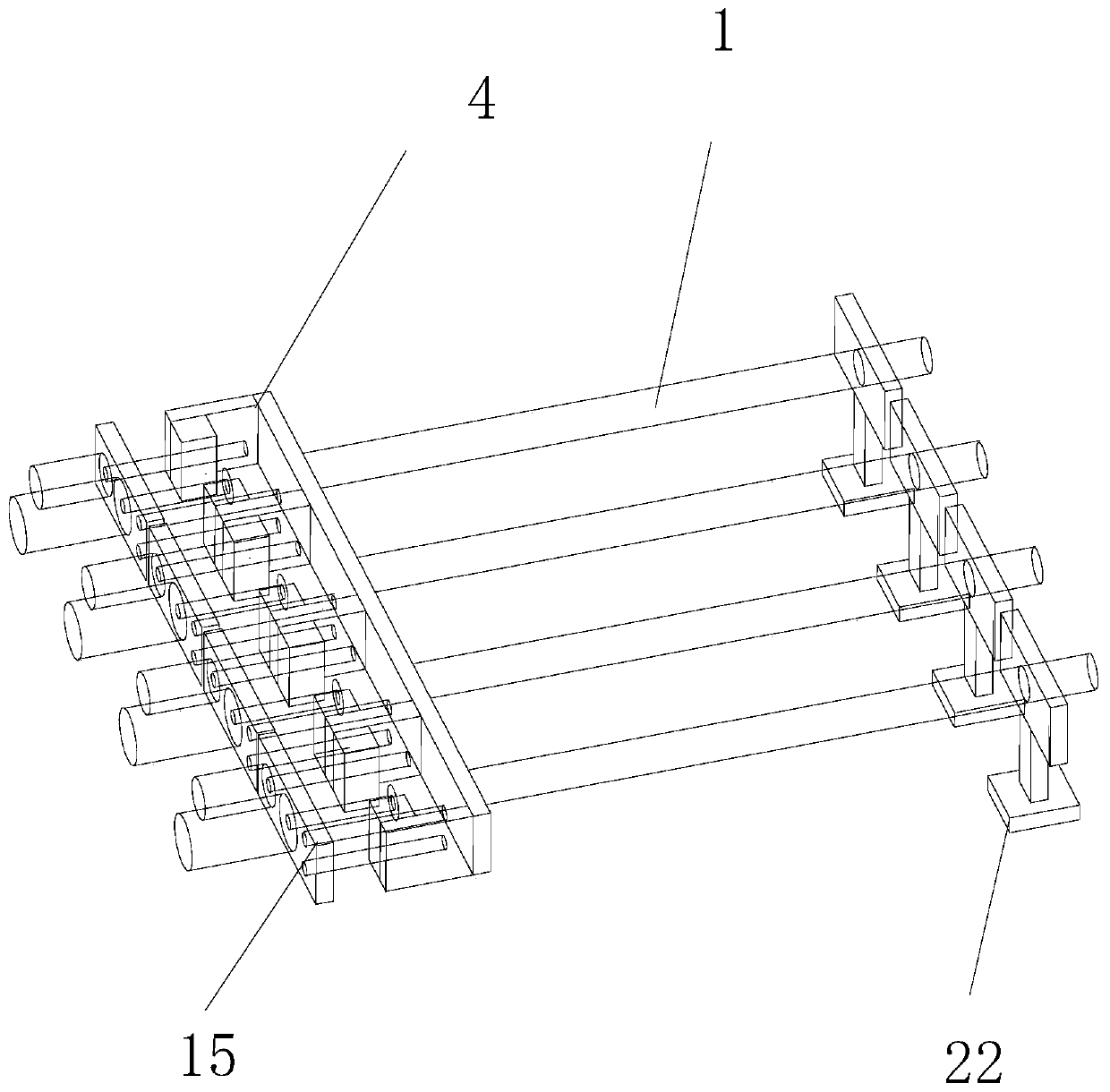

[0016] refer to figure 1 , figure 2 , a fully automatic ultra-long roller kiln for positive electrode material sintering, including a roller table composed of roller bars 1, a sagger on the roller table, positioning devices 3 for measuring the position of the sagger are distributed on the roller table, each positioning device 3 The end is provided with a correction device 4 for correcting the position of the sagger, and the positioning device 3 and the correction device 4 are installed at both ends of the roller bar 1. 5 can prevent the sagger from falling out of the roller bar 1, and one of the limiting plates 5 is provided with a fixed mount 6, and the fixed mount 6 is provided with a motor 7, and the motor 7 drives the roller bar 1 to rotate through a chain, and the fixed mount 6 is provided with Limiting plate 5 is provided with rotating frame 8, and rotating frame 8 is connected with pin plate 10 by rotating shaft 9, and rotating frame 8 and rotating shaft can form a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com