Spacerless artificial disc replacements

a technology of artificial discs and spacers, applied in the field of artificial disc replacements, can solve problems such as design complexity, and achieve the effect of facilitating more normal spinal flexion, extension, and lateral bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

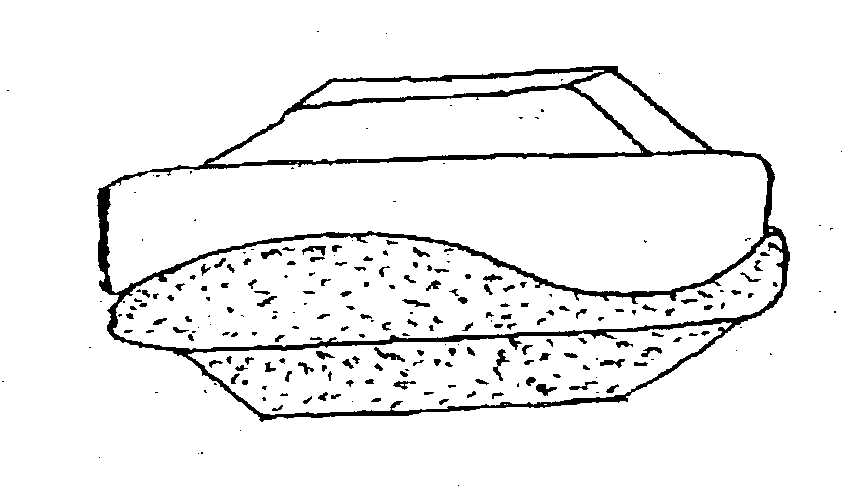

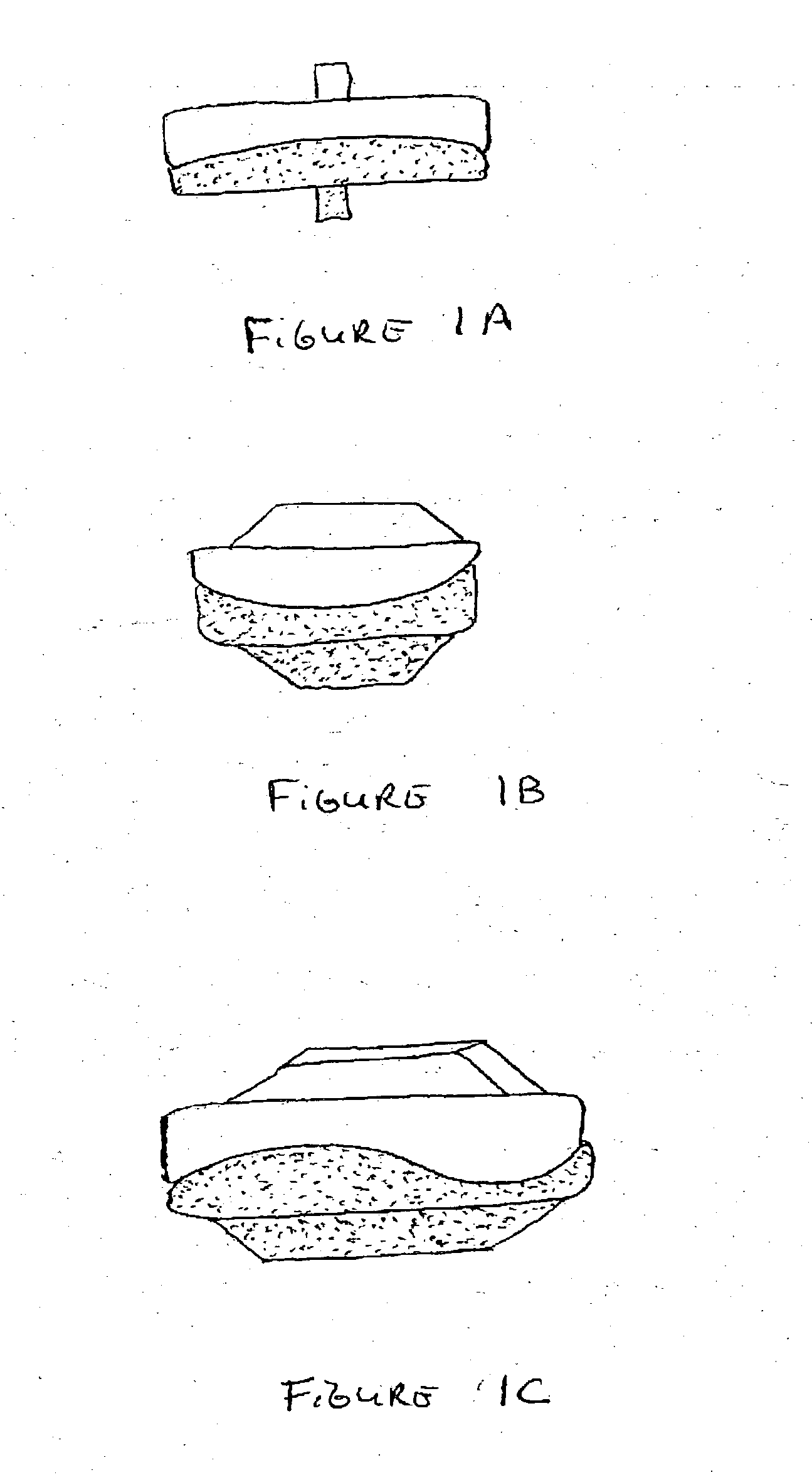

[0022]FIG. 1A is an anterior view of an ADR according to the invention. FIG. 1B is a lateral view of the ADR of FIG. 1. FIG. 1C is an oblique view of the ADR of FIG. 1.

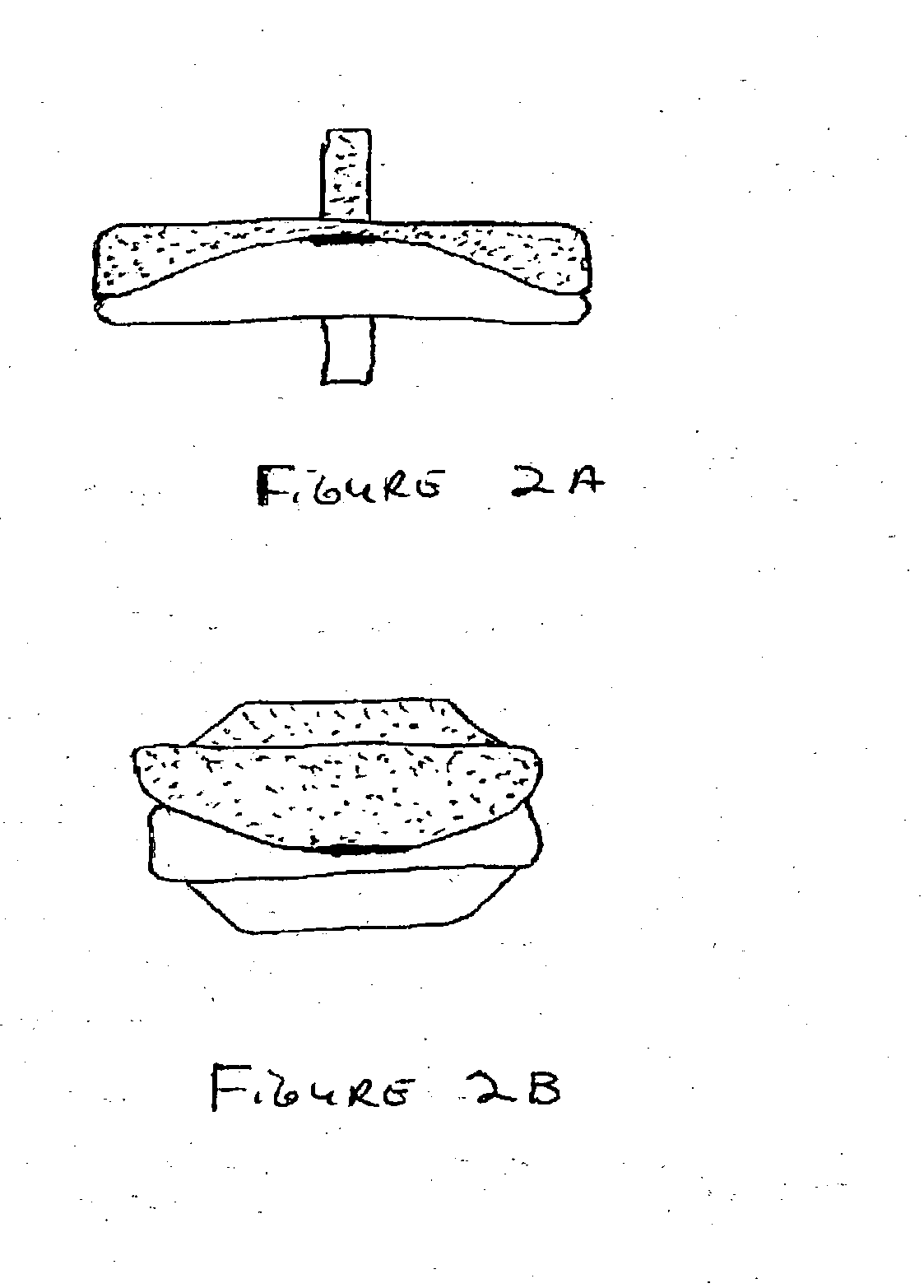

[0023]FIG. 2A is a view of the anterior aspect of an alternative embodiment of the ADR, wherein the articulating surfaces of both components have a flat area centrally from the front to the back of the ADR. FIG. 2B is a view of the lateral aspect of an alternative embodiment of the ADR drawn in FIG. 2B. The flat area of the articulating surfaces courses centrally from side of the ADR to the other side. The flat area allows one component to translate slightly on the other component. Alternatively, a curved area with a large radius could replace the flat area.

[0024]FIG. 3A is a view of the anterior aspect of an alternative, less constrained, embodiment of the saddle-shaped ADR drawn in a fully flexed position. The less constrained embodiment facilitates spinal flexion, extension, and lateral bending. FIG. 3B is a view...

PUM

| Property | Measurement | Unit |

|---|---|---|

| metallic | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

| shape-memory characteristics | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com